Submitted:

02 September 2025

Posted:

03 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing and Reprocessing of PLA

2.2.1. PLA Filament Production

2.2.2. PLA Film Production

2.3. Characterization of the Materials

2.3.1. Pellets characterization

- Melt Flow Index

- Viscosity average molecular weight

- Volatile, semi-volatile and non-volatile compounds

- Specific Migration of Metals

2.3.2. Films Characterization

- Viscosity average molecular weight

- Attenuated total reflectance Fourier transforms infrared (ATR-FTIR) spectroscopy

- Scanning electron microscopy

- Thermogravimetric analysis

- Differential Scanning Calorimetry

- Mechanical properties

- Static Water Contact Angle Measurements (WCA)

- Water Vapor Transmission Rate (WVTR)

- Oxygen Transmission Rate (OTR)

- Global migration

- Disintegration Tests Under Composting Conditions

2.3.3. Statistical Analysis

3. Results and Discussion

3.1. PLA and PLA-RP Pellets Characterization

3.1.1. Melt Flow Index

3.1.2. Viscosity Average Molecular Weight

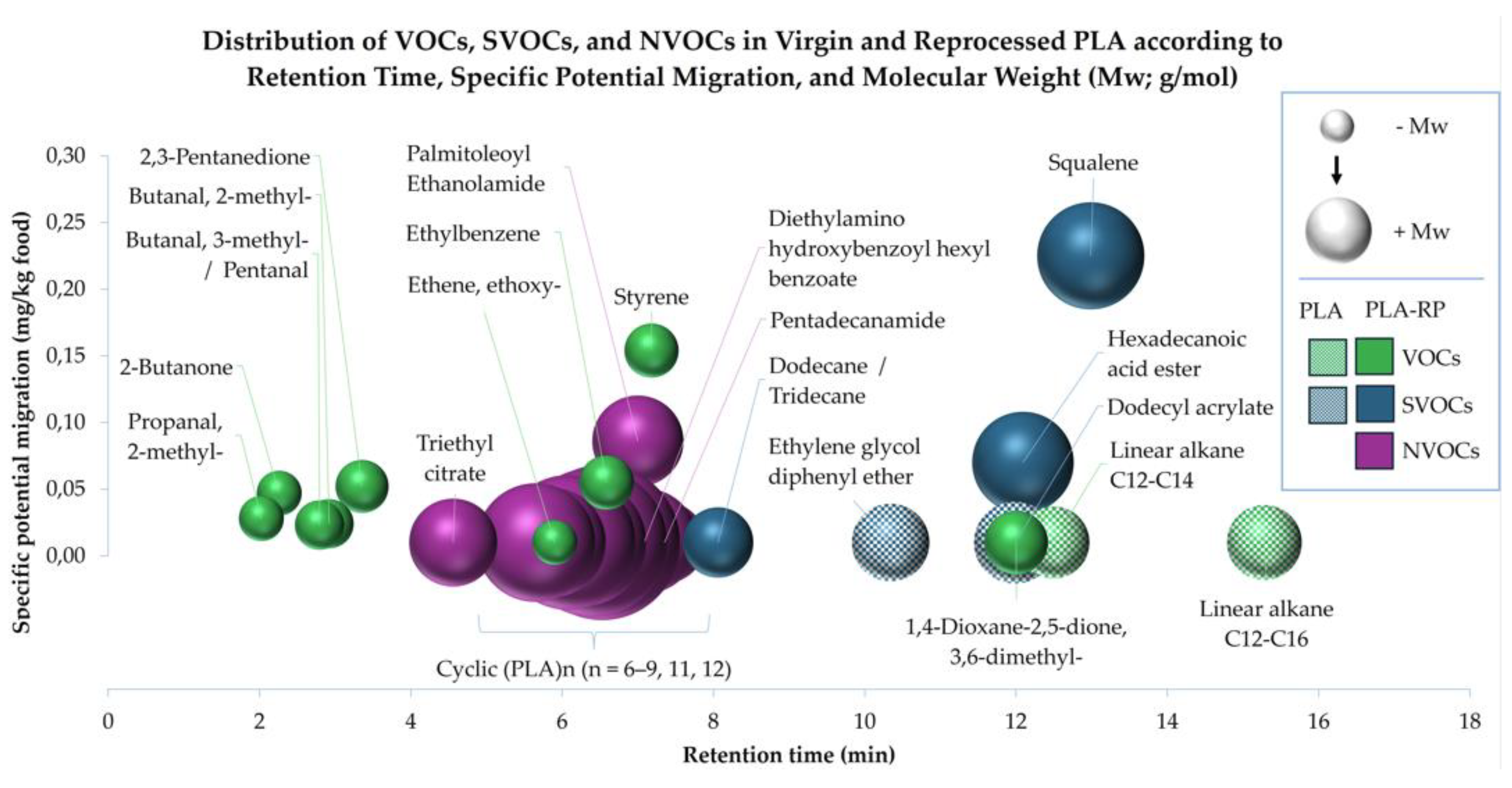

3.1.3. Volatile, Semi-Volatile and Non-Volatil Compounds

- (a)

- Analysis of volatile organic compounds (VOCs)

- (b)

- Analysis of semi volatile organic compounds (SVOCs)

- (c)

- Analysis of non-volatile organic compounds (NVOCs)

3.1.4. Specific Migration of Metals

3.2. Neat PLA and PLA-RP Films Characterization

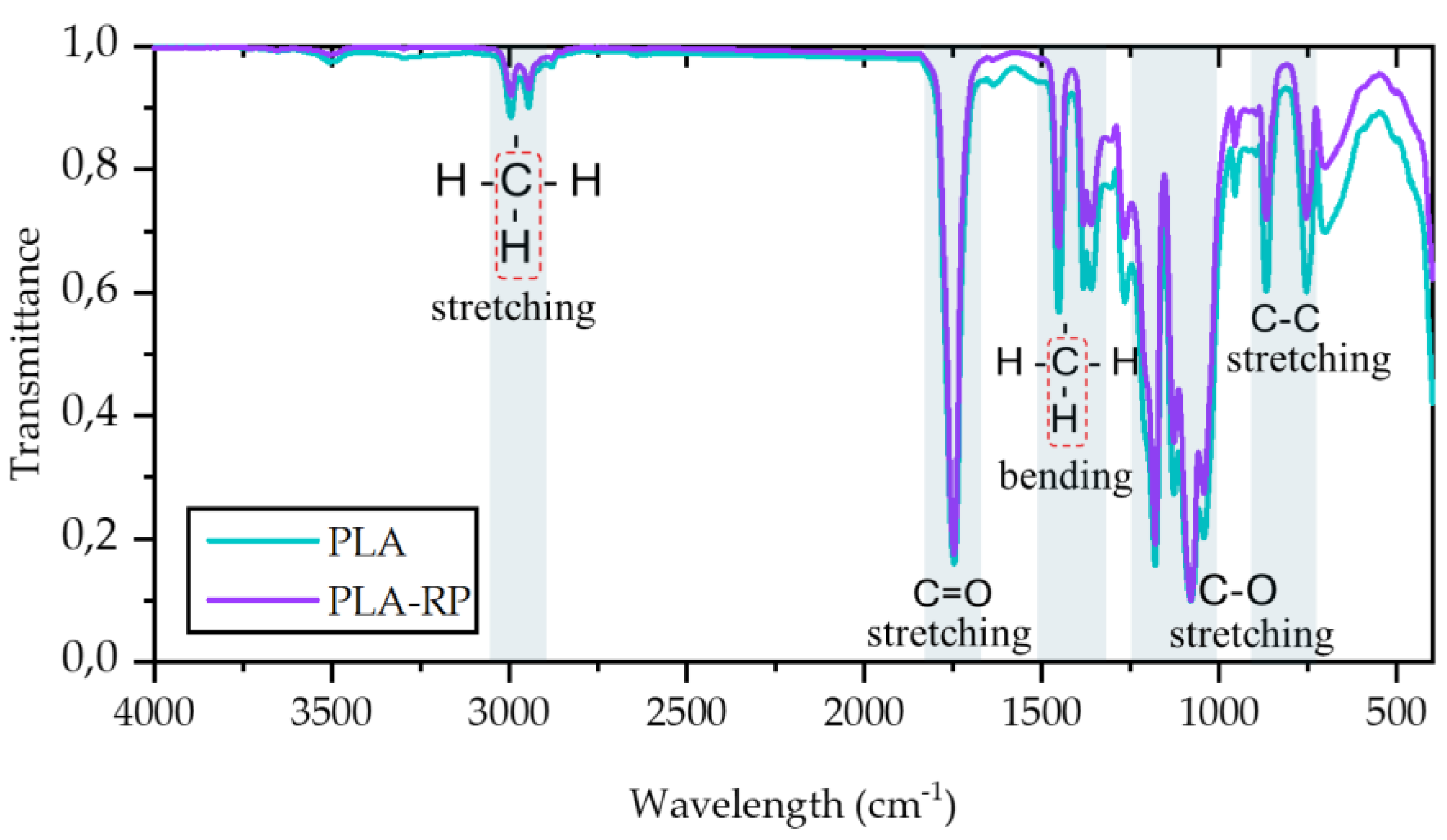

3.2.1. Attenuated Total Reflectance Fourier Transforms Infrared Spectroscopy

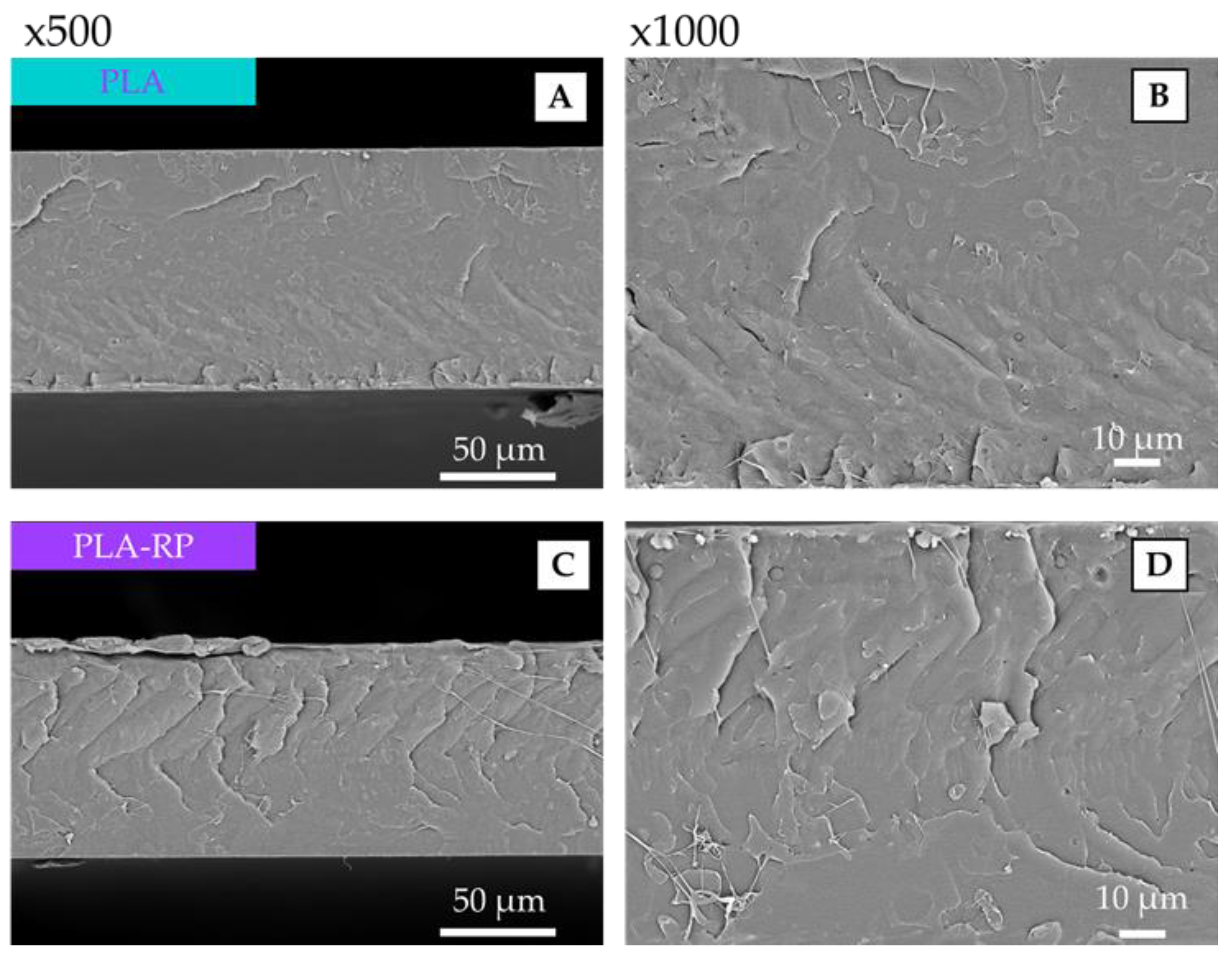

3.2.2. Scanning Electron Microscopy

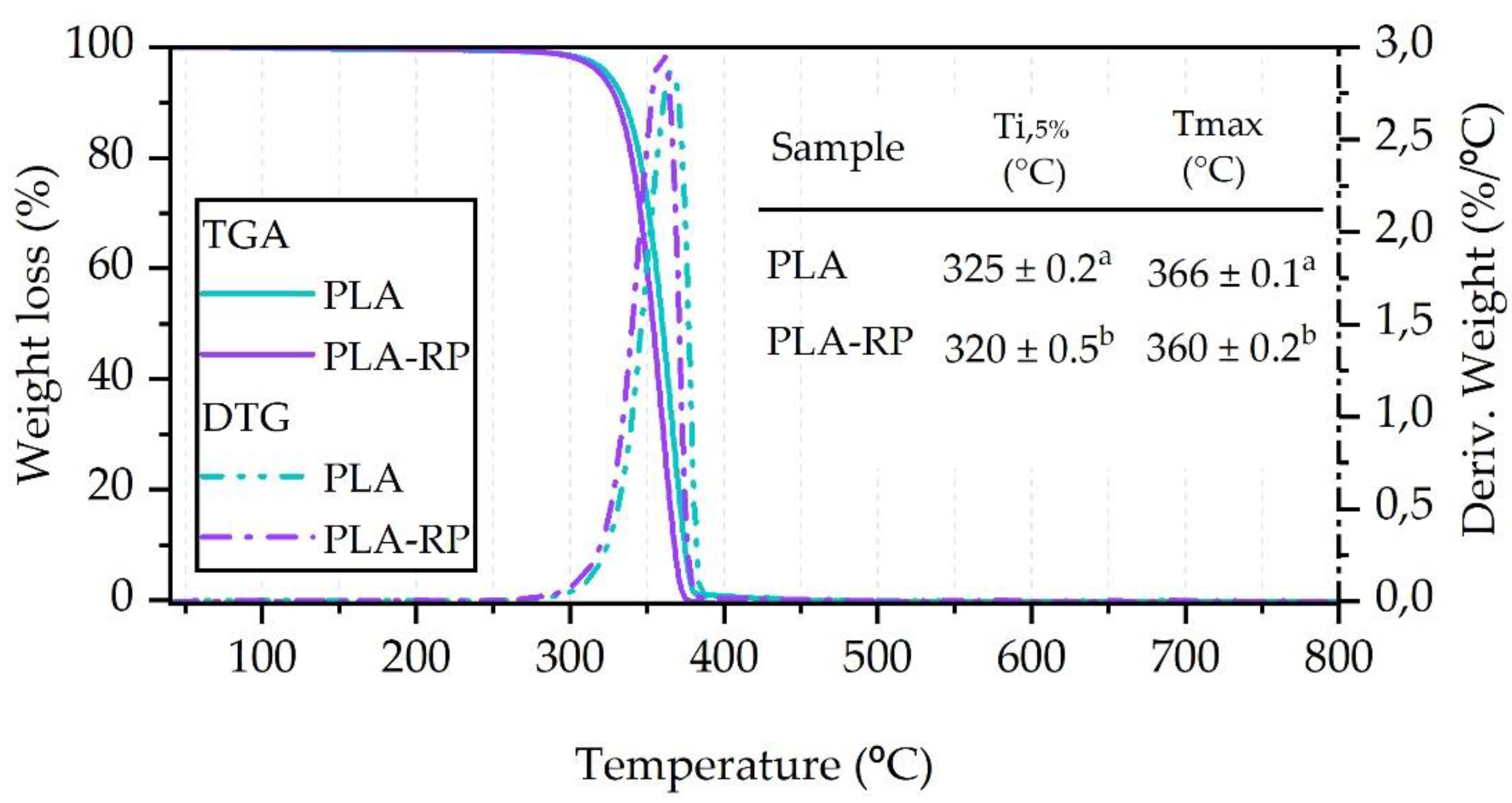

3.2.3. Thermogravimetric Analysis

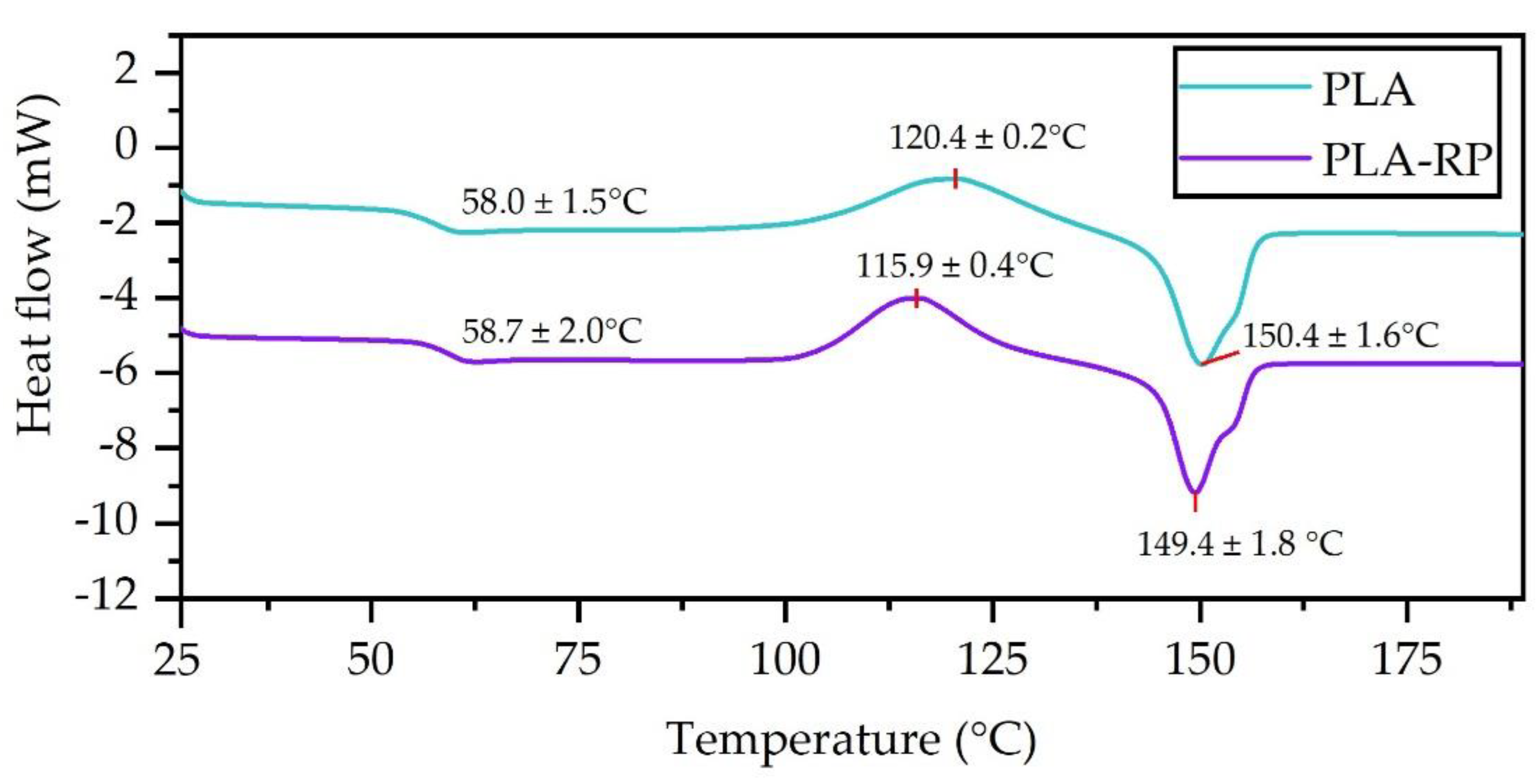

3.2.4. Differential Scanning Calorimetry

| Sample | Tg (°C) | Tcc (°C) | Tm (°C) | ΔHcc (J/g) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PLA | 58.5 ± 1.5 a | 120.4 ± 0.2 a | 150.4 ± 1.6 a | 29.6 ± 0.3 a | 29.7 ± 0.2 a | 0.11 ± 0.04 a |

| PLA-RP | 58.7 ± 2.0 a | 115.9 ± 0.4 b | 149.4 ± 1.8 a | 26.5 ± 0.5 b | 27.1 ± 1.4 a | 0.64 ± 0.06 b |

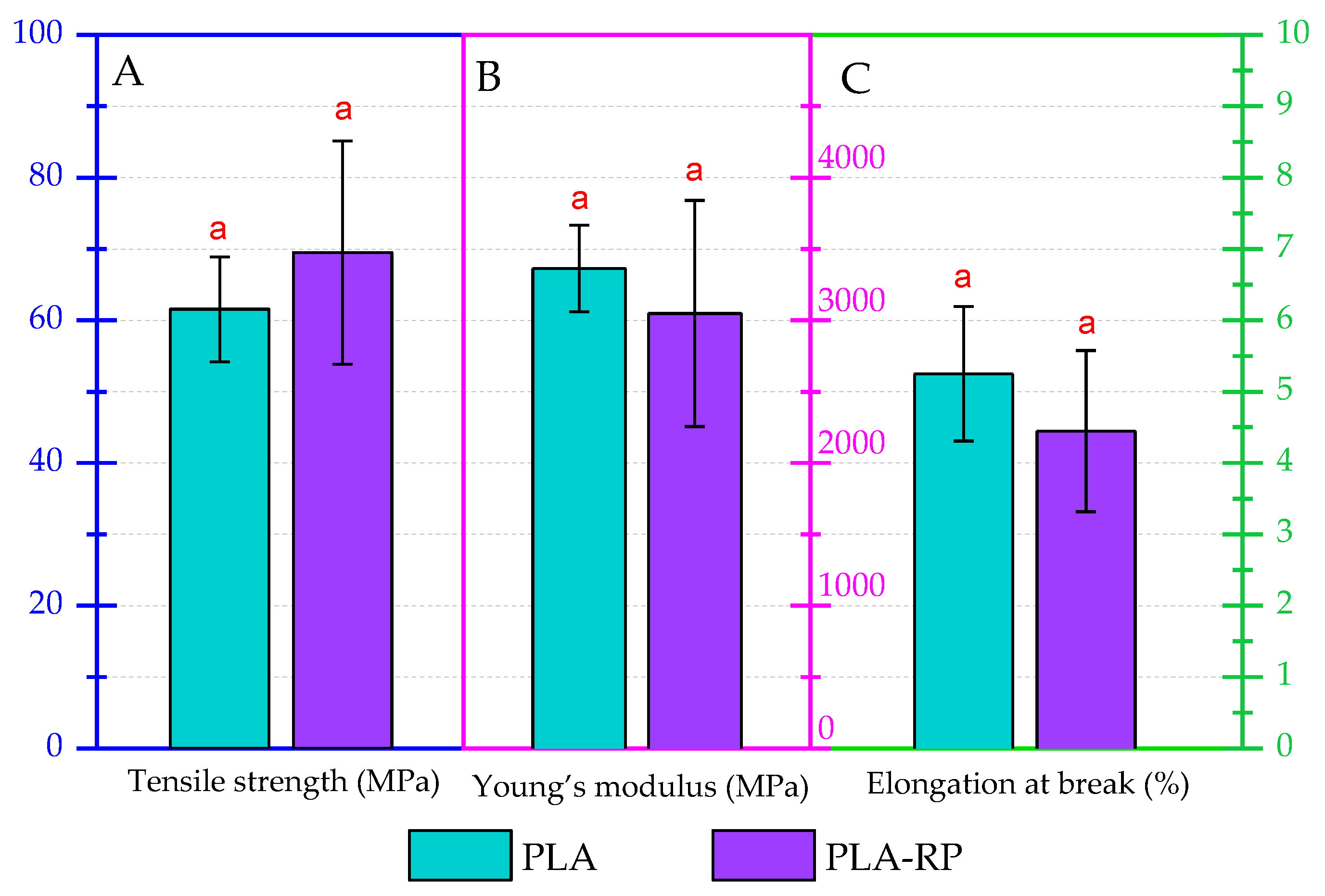

3.2.5. Mechanical Properties

3.2.6. Static Water Contact Angle Measurements (WCA)

3.2.7. Water Vapor Transmission Rate (WVTR)

3.2.8. Oxygen Transmission Rate (OTR)

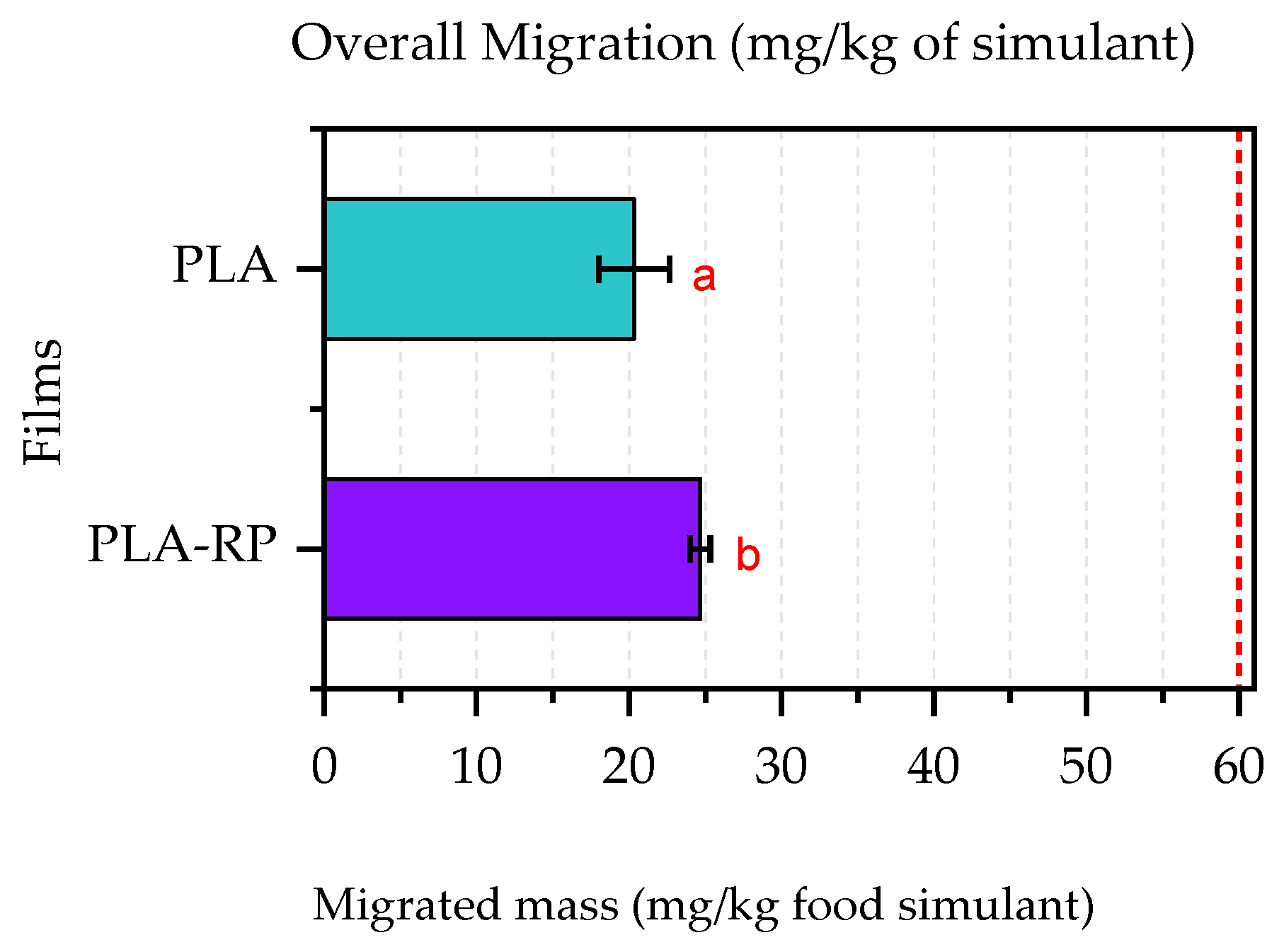

3.2.9. Global Migration Test

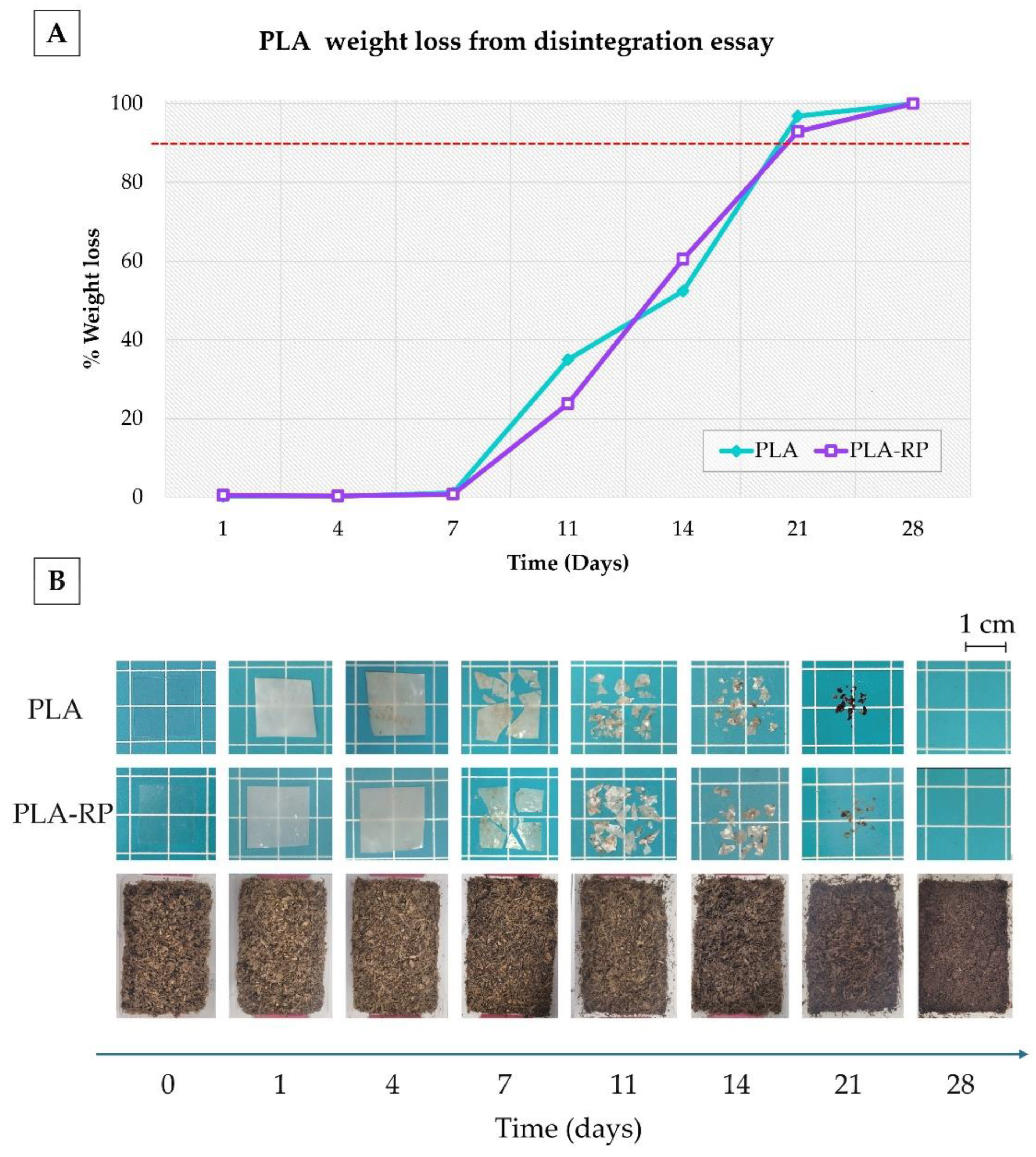

3.2.10. Disintegration Under Composting Conditions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Auras, R.A.; Singh, S.P.; Singh, J.J. Evaluation of Oriented Poly (Lactide) Polymers vs. Existing PET and Oriented PS for Fresh Food Service Containers. Packaging Technology and Science: An International Journal 2005, 18, 207–216. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol Biosci 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Burgos, N.; Martino, V.P.; Jiménez, A. Characterization and Ageing Study of Poly (Lactic Acid) Films Plasticized with Oligomeric Lactic Acid. Polym Degrad Stab 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; López, J.; Jiménez, A. Combined Effect of Poly(Hydroxybutyrate) and Plasticizers on Polylactic Acid Properties for Film Intended for Food Packaging. J Polym Environ 2014, 22. [Google Scholar] [CrossRef]

- Hidalgo-Carvajal, D.; Muñoz, Á.H.; Garrido-González, J.J.; Carrasco-Gallego, R.; Alcázar Montero, V. Recycled PLA for 3D Printing: A Comparison of Recycled PLA Filaments from Waste of Different Origins after Repeated Cycles of Extrusion. Polymers (Basel) 2023, 15, 3651. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M. del C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers (Basel) 2019, 11. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material Valorisation of Amorphous Polylactide. Influence of Thermo-Mechanical Degradation on the Morphology, Segmental Dynamics, Thermal and Mechanical Performance. Polym Degrad Stab 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Agüero, Á.; Corral Perianes, E.; de las Muelas, S.S.; Lascano, D.; de la Fuente García-Soto, M. del M.; Peltzer, M.A.; Balart, R.; Arrieta, M.P. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers (Basel) 2023, 15. [Google Scholar] [CrossRef]

- Badia, J.D.; Ribes-Greus, A. Mechanical Recycling of Polylactide, Upgrading Trends and Combination of Valorization Techniques. Eur Polym J 2016, 84, 22–39. [Google Scholar] [CrossRef]

- Silva, T.; Rodríguez-Mercado, F.; Bruna, J.E.; Torres, A.; Arrieta, M.P.; Faba, S.; Galotto, M.J.; Guarda, A.; Romero, J. Characterization of Simulated Postconsumer Recycled Poly (Lactic Acid)(PLA): Evaluation of Reprocessing Cycles on Its Physicochemical Properties. Journal of Polymer Science 2025, 63, 2043–2054. [Google Scholar] [CrossRef]

- European Parliament and Council of the European Union Regulation (EU) 2025/40 of the European Parliament and of the Council of on Packaging and Packaging Waste; Official Journal of the European Union: European Union, 2025; pp. 1–20; 19 December.

- Sepúlveda-Carter, J.; Moreno De Castro, J.L.; Marín, L.; Baños, P.; Rodríguez, M.S.; Arrieta, M.P. Regulatory Frameworks and State-of-the-Art Decontamination Technologies for Recycled Polystyrene for Food Contact Applications. Polymers (Basel) 2025, 17, 658. [Google Scholar] [CrossRef]

- Samper Madrigal, M.D.; Arrieta, M.P.; Ferrándiz Bou, S.; López Martínez, J. Influence of Biodegradable Materials in the Recycled Polystyrene. J Appl Polym Sci 2014, 131, 41161–41168. [Google Scholar]

- Aldas, M.; Pavon, C.; De La Rosa-Ramírez, H.; Ferri, J.M.; Bertomeu, D.; Samper, M.D.; López-Martínez, J. The Impact of Biodegradable Plastics in the Properties of Recycled Polyethylene Terephthalate. J Polym Environ 2021, 29, 2686–2700. [Google Scholar] [CrossRef]

- European Commision Regulation (EU) 2025/40 of the European Parliament and of the Council of on Packaging and Packaging Waste, Pub. L. No. 2025/40, L 1 (2025). Https://Eur-Lex.Europa.Eu/Eli/Reg/2025/40/Oj. 2025. 19 December.

- Commission, E. Commission Regulation (EU) 2022/1616 of 15 September 2022 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods. L 243 2022, 3. [Google Scholar]

- European Food Safety Authority (EFSA) Guidelines on Submission of a Dossier for Safety Evaluation by the EFSA of a Recycling Process to Produce Recycled Plastics Intended to Be Used for Manufacture of Materials and Articles in Contact with Food-Opinion of the Scientific Panel on Food Additives, Flavourings, Processing Aids and Materials in Contact with Food (AFC). EFSA Journal 2008, 6, 717.

- NatureWorks LLC PLA 2003D Safety Data Sheets, NatureWorks LLC Https://Www.Natureworksllc.Com/~/Media/Files/Natureworks/Technical-Documents/Safety-Data-Sheets/Sds-Polymers-Na-Eng/2003d%20us%20sds_pdf.Pdf?La=en.

- Arrieta, M.P.; López, J.; Rayón, E.; Jiménez, A. Disintegrability under Composting Conditions of Plasticized PLA–PHB Blends. Polym Degrad Stab 2014, 108, 307–318. [Google Scholar] [CrossRef]

- Aznar, M.; Ubeda, S.; Dreolin, N.; Nerín, C. Determination of Non-Volatile Components of a Biodegradable Food Packaging Material Based on Polyester and Polylactic Acid (PLA) and Its Migration to Food Simulants. J Chromatogr A 2019, 1583, 1–8. [Google Scholar] [CrossRef]

- Tejada-Oliveros, R.; Balart, R.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Montanes, N.; Quiles-Carrillo, L. Improvement of Impact Strength of Polylactide Blends with a Thermoplastic Elastomer Compatibilized with Biobased Maleinized Linseed Oil for Applications in Rigid Packaging. Molecules 2021, 26. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material Valorisation of Amorphous Polylactide. Influence of Thermo-Mechanical Degradation on the Morphology, Segmental Dynamics, Thermal and Mechanical Performance. Polym Degrad Stab 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Commission, E. Consolidated Text: Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food. L 12 2011, 1. [Google Scholar]

- Roosen, M.; Van Laere, T.; Decottignies, V.; Morel, L.; Schnitzler, J.-L.; Schneider, J.; Schlummer, M.; Lase, I.S.; Dumoulin, A.; De Meester, S. Tracing the Origin of VOCs in Post-Consumer Plastic Film Bales. Chemosphere 2023, 324, 138281. [Google Scholar] [CrossRef] [PubMed]

- Palkopoulou, S.; Joly, C.; Feigenbaum, A.; Papaspyrides, C.D.; Dole, P. Critical Review on Challenge Tests to Demonstrate Decontamination of Polyolefins Intended for Food Contact Applications. Trends Food Sci Technol 2016, 49, 110–120. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food Packaging in the Circular Economy: Overview of Chemical Safety Aspects for Commonly Used Materials. J Clean Prod 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Plasteurope Styrenics Circular Solutions: Application to EFSA for RPS as Food Contact Material / Successful Trials 2021.

- Kosior, E. 2013.

- Dvorak, R.; Kosior, E.; Moody, L. Development of a Food-Grade Recycling Process for Post-Consumer Polypropylene. WRAP, Sep.

- Nextek NEXTLOOPP: Closing the Loop on Food Grade, PP. NEXTLOOPP 2020.

- EFSA CEF Panel Scientific Opinion on the Safety Assessment of the Processes ‘Biffa Polymers’ and ‘CLRrHDPE’ Used to Recycle High-density Polyethylene Bottles for Use as Food Contact Material. EFSA Journal 2015, 13. [CrossRef]

- Welle, F. Develop a Food Grade HDPE Recycling Process; WRAP Research Report; The Waste & Resources Action Programme: Fraunhofer Institute for Process Engineering and Packaging (IVV), 2005; ISBN 1-84405-225-7. [Google Scholar]

- Singh, S.; Pereira, J.; Brandão, T.; Oliveira, A.L.; Poças, F. Recycling of Polypropylene by Supercritical Carbon Dioxide for Extraction of Contaminants from Beverage Cups. A Comparison with Polyethylene Terephthalate and Polylactic Acid. J Sci Food Agric 2023, 103, 1127–1138. [Google Scholar] [CrossRef]

- Welle, F. Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 2: Co-Extruded Functional Barriers. Recycling 2023, 8, 39. [Google Scholar] [CrossRef]

- Welle, F. Twenty Years of PET Bottle to Bottle Recycling—An Overview. Resour Conserv Recycl 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Dutra, C.; Pezo, D.; Freire, M.T.D.A.; Nerín, C.; Reyes, F.G.R. Determination of Volatile Organic Compounds in Recycled Polyethylene Terephthalate and High-Density Polyethylene by Headspace Solid Phase Microextraction Gas Chromatography Mass Spectrometry to Evaluate the Efficiency of Recycling Processes. J Chromatogr A 2011, 1218, 1319–1330. [Google Scholar] [CrossRef]

- Vilaplana, F.; Ribes-Greus, A.; Karlsson, S. Chromatographic Pattern in Recycled High-Impact Polystyrene (HIPS) – Occurrence of Low Molecular Weight Compounds during the Life Cycle. Polym Degrad Stab 2010, 95, 172–186. [Google Scholar] [CrossRef]

- Cabanes, A.; Valdés, F.J.; Fullana, A. A Review on VOCs from Recycled Plastics. Sustainable materials and technologies 2020, 25, e00179. [Google Scholar] [CrossRef]

- Fabris, S.; Freire, M.T.D.A.; Wagner, R.; Reyes, F.G. A Method to Determine Volatile Contaminants in Polyethylene Terephthalate (PET) Packages by HDC-GC-FID and Its Application to Post-Consumer Materials. Ciência e Tecnologia de Alimentos 2010, 30, 1046–1055. [Google Scholar] [CrossRef]

- NatureWorks Https://Www.Natureworksllc.Com/~/Media/Files/Natureworks/Technical-Documents/Properties-Documents/Ingeo-Grades-Made-to-Stock-Specifications_2-Series_pdf.Pdf?La=e.

- National Center for Biotechnology Information PubChem Compound Summary for CID 8023, Ethyl Vinyl Ether. . National Library of Medicine 2025.

- Snow, N.H.; Rana, H. Does High Polarity Mean High Retention on Stationary Phases in Gas Chromatography? LCGC North America 2023, 18–22. [Google Scholar] [CrossRef]

- Salazar, R.; Domenek, S.; Plessis, C.; Ducruet, V. Quantitative Determination of Volatile Organic Compounds Formed during Polylactide Processing by MHS-SPME. Polym Degrad Stab 2017, 136, 80–88. [Google Scholar] [CrossRef]

- EFSA FEEDAP Panel Scientific Opinion on the Safety and Efficacy of Branched-chain Primary Aliphatic Alcohols/Aldehydes/Acids, Acetals and Esters with Esters Containing Branched-chain Alcohols and Acetals Containing Branched-chain Aldehydes (Chemical Group 2) When Used as Flavourings for All Animal Species. EFSA Journal 2012, 10. [CrossRef]

- Bradley, E.L. Distribution: 1. E L J Potter (FSA) (X1 +.Pdf Version) 2. 2010. [Google Scholar]

- 2025.

- Gao, Y.; Xue, Y.; Sun, C.; She, L.; Peng, Y. Emission Characteristics of Volatile Organic Compounds from Material Extrusion Printers Using Acrylonitrile–Butadiene–Styrene and Polylactic Acid Filaments in Printing Environments and Their Toxicological Concerns. Toxics 2025, 13. [Google Scholar] [CrossRef] [PubMed]

- EFSA CEP Panel Re-assessment of the Risks to Public Health Related to the Genotoxicity of Styrene Present in Plastic Food Contact Materials. EFSA Journal 2025, 23. [CrossRef]

- Lestido-Cardama, A.; Vázquez-Loureiro, P.; Sendón, R.; Bustos, J.; Santillana, M.I.; Paseiro Losada, P.; Rodriguez Bernaldo de Quiros, A. Characterization of Polyester Coatings Intended for Food Contact by Different Analytical Techniques and Migration Testing by LC-MSn. Polymers (Basel) 2022, 14, 487. [Google Scholar] [CrossRef] [PubMed]

- Demets, R.; Roosen, M.; Vandermeersch, L.; Ragaert, K.; Walgraeve, C.; De Meester, S. Development and Application of an Analytical Method to Quantify Odour Removal in Plastic Waste Recycling Processes. Resour Conserv Recycl 2020, 161, 104907. [Google Scholar] [CrossRef]

- Wojnowski, W.; Kalinowska, K.; Majchrzak, T.; Zabiegała, B. Real-Time Monitoring of the Emission of Volatile Organic Compounds from Polylactide 3D Printing Filaments. Science of the Total Environment 2022, 805, 150181. [Google Scholar] [CrossRef]

- Lestido-Cardama, A.; Vázquez-Loureiro, P.; Sendón, R.; Bustos, J.; Santillana, M.I.; Losada, P.P.; de Quirós, A.R.B. Characterization of Polyester Coatings Intended for Food Contact by Different Analytical Techniques and Migration Testing by LC-MSn. Polymers (Basel) 2022, 14. [Google Scholar] [CrossRef]

- Cooper, T.A. Developments in Plastic Materials and Recycling Systems for Packaging Food, Beverages and Other Fast-Moving Consumer Goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG); Elsevier Inc., 2013; pp. 58–107 ISBN 9780857095039.

- Eckardt, M.; Kubicova, M.; Simat, T.J. Universal Response Quantification Approach Using a Corona Charged Aerosol Detector (CAD) – Application on Linear and Cyclic Oligomers Extractable from Polycondensate Plastics Polyesters, Polyamides and Polyarylsulfones. J Chromatogr A 2018, 1572, 187–202. [Google Scholar] [CrossRef]

- Zhong, H.N.; Su, Q.Z.; Chen, S.; Li, D.; Sui, H.; Zhu, L.; Dong, B.; Wu, S.; Wang, X. Revealing Contaminants in China’s Recycled PET: Enabling Safe Food Contact Applications. Resour Conserv Recycl 2025, 212. [Google Scholar] [CrossRef]

- Bronczyk, K.; Dabrowska, A.; Bielicka-Daszkiewicz, K.; Milczewska, K. Safety of New Food Contact Materials: Migration and Sorption Studies Based on Tenax, Powdered Milk, Baby Cereal and Oat Flakes. Food Chem 2025, 483. [Google Scholar] [CrossRef]

- Ruellan, A.; Guinault, A.; Sollogoub, C.; Ducruet, V.; Domenek, S. Solubility Factors as Screening Tools of Biodegradable Toughening Agents of Polylactide. J Appl Polym Sci 2015, 132. [Google Scholar] [CrossRef]

- García Ibarra, V.; Rodríguez Bernaldo de Quirós, A.; Paseiro Losada, P.; Sendón, R. Non-Target Analysis of Intentionally and Non Intentionally Added Substances from Plastic Packaging Materials and Their Migration into Food Simulants. Food Packag Shelf Life 2019, 21. [Google Scholar] [CrossRef]

- Emery Oleochemicals 2-EH-Palmitate Technical-Data-Sheet Available online:. Available online: https://www.emeryoleo.com/sites/default/files/2020-09/EMERY-E-6216%282-EH-palmitate%29Technical-Data-Sheet.pdf (accessed on 3 July 2025).

- Roosen, M.; Van Laere, T.; Decottignies, V.; Morel, L.; Schnitzler, J.L.; Schneider, J.; Schlummer, M.; Lase, I.S.; Dumoulin, A.; De Meester, S. Tracing the Origin of VOCs in Post-Consumer Plastic Film Bales. Chemosphere 2023, 324. [Google Scholar] [CrossRef]

- Scientific Opinion of the Panel on Food Additives, F.P.A. and M. in C. with F. Flavouring Group Evaluation 25, (FGE.25) :Aliphatic and Aromatic Hydrocarbons from Chemical Group 31. EFSA Journal 2008, 6, 918. [Google Scholar] [CrossRef]

- European Food Safety Authority Chemical Hazards - Substances Browser Available online:. Available online: https://www.efsa.europa.eu/en/microstrategy/openfoodtox (accessed on 16 June 2025).

- Su, Q.Z.; Vera, P.; Salafranca, J.; Nerín, C. Decontamination Efficiencies of Post-Consumer High-Density Polyethylene Milk Bottles and Prioritization of High Concern Volatile Migrants. Resour Conserv Recycl 2021, 171. [Google Scholar] [CrossRef]

- European Commission Consolidated Text: Commission Regulation (EU) No 10/2011 of on Plastic Materials and Articles Intended to Come into Contact with Food; Official Journal of the European Union: European Union, 2011; p. 1; 14 January.

- Estremera, C.; Paiva, R.; Aznar, M.; Nerín, C.; Domeño, C. Identification of Volatile and Non-Volatile Migrants Released during Sous Vide Cooking by UPLC-IMS-QTOF and DI-SPME-GC-MS Using a Design of Experiments Approach. Food Packag Shelf Life 2024, 43, 101297. [Google Scholar] [CrossRef]

- Ye, F.; Chen, W.; Deng, Z.; Chen, S.-L.; Dong, Z.; Dang, L.; Li, M.-D. Ultrafast Excited-State Energy Dissipation Pathway of Diethylamino Hydroxybenzoyl Hexyl Benzoate (DHHB) via the Nanoparticles. Photochemical & Photobiological Sciences 2023, 22, 2133–2142. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Wang, M.; Li, Y.; Xiong, Y.; Wu, C. Recycling and Degradation of Polyamides. Molecules 2024, 29, 1742. [Google Scholar] [CrossRef] [PubMed]

- Dhaini, A.; Hardouin-Duparc, V.; Alaaeddine, A.; Carpentier, J.-F.; Guillaume, S.M. Recent Advances in Polyhydroxyalkanoates Degradation and Chemical Recycling. Prog Polym Sci 2024, 149, 101781. [Google Scholar] [CrossRef]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-Sourced Polymers as Alternatives to Conventional Food Packaging Materials: A Review. Trends Food Sci Technol 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Kameno, N.; Yamada, S.; Amimoto, T.; Amimoto, K.; Ikeda, H.; Koga, N. Thermal Degradation of Poly(Lactic Acid) Oligomer: Reaction Mechanism and Multistep Kinetic Behavior. Polym Degrad Stab 2016, 134, 284–295. [Google Scholar] [CrossRef]

- Rung, C.; Welle, F.; Gruner, A.; Springer, A.; Steinmetz, Z.; Munoz, K. Identification and Evaluation of (Non-)Intentionally Added Substances in Post-Consumer Recyclates and Their Toxicological Classification. Recycling 2023, 8, 24. [Google Scholar] [CrossRef]

- EFSA Scientific Committee Scientific Opinion on Exploring Options for Providing Advice about Possible Human Health Risks Based on the Concept of Threshold of Toxicological Concern (TTC). EFSA Journal 2012, 10. [CrossRef]

- European Food Safety Authority (EFSA) Chemical Hazards Database (OpenFoodTox).

- Chen, B.; Wang, X.; Zhang, Y.; Zhang, W.; Pang, X.; Zhang, S.; Lu, J.; Lv, J. Determination and Risk Assessment of Flavor Components in Flavored Milk. Foods 2023, 12. [Google Scholar] [CrossRef]

- Younes, M.; Aquilina, G.; Castle, L.; Degen, G.; Engel, K.-H.; Fowler, P.J.; Frutos Fernandez, M.J.; Fürst, P.; Gundert-Remy, U.; Gürtler, R.; et al. Scientific Opinion on the Renewal of the Authorisation of SmokEz C-10 (SF-005) as a Smoke Flavouring Primary Product. EFSA Panel name on Food Additives and Flavourings (FAF), EFSA Journal 2023, 21, e08367. [Google Scholar] [CrossRef]

- Claire Chambers; Gisela Degen; Ruta Dubakiene; Bozena Jazwiec-Kanyion; Vassilios Kapoulas; Jean Krutmann; Carola Lidén; Jean-Paul Marty; Thomas Platzek; Suresh Chandra Rastogi; et al. Scientific Committee on Consumer Products SCCP OPINION ON Diethylamino Hydroxybenzoyl Hexyl Benzoate COLIPA N° S83.

- Chibwe, L.; De Silva, A.O.; Spencer, C.; Teixera, C.F.; Williamson, M.; Wang, X.; Muir, D.C.G. Target and Nontarget Screening of Organic Chemicals and Metals in Recycled Plastic Materials. Environ Sci Technol 2023, 57, 3380–3390. [Google Scholar] [CrossRef]

- Klingenberg, P.; Schirmeister, C.G.; Kappeler, M.; Calean, A.; Biester, H.; Licht, E.; Rapp, B. Quantification of Regulated Metals in Recycled Post-Consumer Polypropylene through Comparative ICP-MS, AAS and LIBS Analyses. Polym Test 2024, 136. [Google Scholar] [CrossRef]

- Sepulveda, J.; Villegas, C.; Torres, A.; Vargas, E.; Rodriguez, F.; Baltazar, S.; Prada, A.; Rojas, A.; Romero, J.; Faba, S.; et al. Effect of Functionalized Silica Nanoparticles on the Mass Transfer Process in Active PLA Nanocomposite Films Obtained by Supercritical Impregnation for Sustainable Food Packaging. J Supercrit Fluids 2020, 161, 104844. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I.; Romani, S.; Tylewicz, U.; Rocculi, P.; Rosa, M.D. Poly(Lactic Acid)-modified Films for Food Packaging Application: Physical, Mechanical, and Barrier Behavior. J Appl Polym Sci 2012, 125. [Google Scholar] [CrossRef]

- Zhang, M.; Thomas, N.L. Blending Polylactic Acid with Polyhydroxybutyrate: The Effect on Thermal, Mechanical, and Biodegradation Properties. Advances in Polymer Technology 2011, 30, 67–79. [Google Scholar] [CrossRef]

- Hu, Y.; Sato, H.; Zhang, J.; Noda, I.; Ozaki, Y. Crystallization Behavior of Poly(l-Lactic Acid) Affected by the Addition of a Small Amount of Poly(3-Hydroxybutyrate). Polymer (Guildf) 2008, 49, 4204–4210. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; de la Orden, M.U.; Martínez Urreaga, J. Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex Paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(Lactic Acid). Polymers (Basel) 2020, 12. [Google Scholar] [CrossRef]

- Shabani Samghabady, M. Characterization of Mechanically Recycled Polylactic Acid (PLA) Filament for 3D-Printing by Evaluating Mechanical, Thermal, And Chemical Properties and Process Performance. All Theses, Clemson University, 2023.

- Agüero, A.; Lascano, D.; Ivorra-Martinez, J.; Gómez-Caturla, J.; Arrieta, M.P.; Balart, R. Use of Bacterial Cellulose Obtained from Kombucha Fermentation in Spent Coffee Grounds for Active Composites Based on PLA and Maleinized Linseed Oil. Ind Crops Prod 2023, 202. [Google Scholar] [CrossRef]

- Fortunati, E.; Armentano, I.; Iannoni, A.; Barbale, M.; Zaccheo, S.; Scavone, M.; Visai, L.; Kenny, J.M. New Multifunctional Poly(Lactide Acid) Composites: Mechanical, Antibacterial, and Degradation Properties. J Appl Polym Sci 2012, 124, 87–98. [Google Scholar] [CrossRef]

- Nomadolo, N.; Mtibe, A.; Ofosu, O.; Mekoa, C.; Letwaba, J.; Muniyasamy, S. The Effect of Mechanical Recycling on the Thermal, Mechanical, and Chemical Properties of Poly (Butylene Adipate-Co-Terephthalate) (PBAT), Poly (Butylene Succinate) (PBS), Poly (Lactic Acid) (PLA), PBAT-PBS Blend and PBAT-TPS Biocomposite. J Polym Environ 2024, 32, 2644–2659. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.O.; Maspoch, M.L. Processing of Poly(Lactic Acid): Characterization of Chemical Structure, Thermal Stability and Mechanical Properties. Polym Degrad Stab 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Müller, A.J.; Ávila, M.; Saenz, G.; Salazar, J. Crystallization of PLA-Based Materials. In Poly(lactic acid) Science and Technology: Processing, Properties, Additives and Applications; Chemistry, R.S. of, Jiménez, A., Peltzer, M., Ruseckaite, R., Eds.; The Royal Society of Chemistry, 2014; p. 0 ISBN 978-1-84973-879-8.

- Gálvez, J.; Correa Aguirre, J.P.; Hidalgo Salazar, M.A.; Vera Mondragón, B.; Wagner, E.; Caicedo, C. Effect of Extrusion Screw Speed and Plasticizer Proportions on the Rheological, Thermal, Mechanical, Morphological and Superficial Properties of PLA. Polymers (Basel) 2020, 12, 2111. [Google Scholar] [CrossRef] [PubMed]

- Hambleton, A.; Fabra, M.-J.; Debeaufort, F.; Dury-Brun, C.; Voilley, A. Interface and Aroma Barrier Properties of Iota-Carrageenan Emulsion–Based Films Used for Encapsulation of Active Food Compounds. J Food Eng 2009, 93, 80–88. [Google Scholar] [CrossRef]

- Sahoo, B.L.; Mohanty, S.; Nayak, S.K. Synergistic Effects of Nucleating Agent, Chain Extender and Nanocrystalline Cellulose on PLA and PHB Blend Films: Evaluation of Morphological, Mechanical and Functional Attributes. Ind Crops Prod 2024, 215, 118614. [Google Scholar] [CrossRef]

- Tee, Y.B.; Rosnita, At.; Khalina, A.; Chin, N.L.; Roseliza, K.B.; Khairul Faezah, M.Y. Reinforcing Mechanical, Water Absorption and Barrier Properties of Poly (Lactic Acid) Composites with Kenaf-Derived Cellulose of Thermally-Grafted Aminosilane. 2015.

- Jung, B.N.; Jung, H.W.; Kang, D.H.; Kim, G.H.; Lee, M.; Shim, J.K.; Hwang, S.W. The Fabrication of Flexible and Oxygen Barrier Cellulose Nanofiber/Polylactic Acid Nanocomposites Using Cosolvent System. J Appl Polym Sci 2020, 137, 49536. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Processing and Characterization of Plasticized PLA/PHB Blends for Biodegradable Multiphase Systems. Express Polym Lett 2015, 9, 583–596. [Google Scholar] [CrossRef]

- Fortunati, E.; Peltzer, M.; Armentano, I.; Torre, L.; Jiménez, A.; Kenny, J.M. Effects of Modified Cellulose Nanocrystals on the Barrier and Migration Properties of PLA Nano-Biocomposites. Carbohydr Polym 2012, 90, 948–956. [Google Scholar] [CrossRef]

- Afshar, S. V; Boldrin, A.; Christensen, T.H.; Corami, F.; Daugaard, A.E.; Rosso, B.; Hartmann, N.B. Disintegration of Commercial Biodegradable Plastic Products under Simulated Industrial Composting Conditions. Sci Rep 2025, 15, 8569. [Google Scholar] [CrossRef]

- Feijoo, P.; Marín, A.; Samaniego-Aguilar, K.; Sánchez-Safont, E.; Lagarón, J.M.; Gámez-Pérez, J.; Cabedo, L. Effect of the Presence of Lignin from Woodflour on the Compostability of PHA-Based Biocomposites: Disintegration, Biodegradation and Microbial Dynamics. Polymers (Basel) 2023, 15, 2481. [Google Scholar] [CrossRef]

| Sample |

Mv (g/mol) |

MFI (g/10 min) |

|---|---|---|

| PLA pellet | 113,200 ± 900 | 6.5 ± 0.1 |

| PLA-RP pellet | 107,000± 3,500 | 9.9 ± 0.4 |

| PLA film | 106,000 ± 4,000 | - |

| PLA-RP film | 99,800± 4,000 | - |

| Sample | WCA (°) | WVTR (g/m2·day) |

OTR.e (cm3·mm/m2·day) |

|---|---|---|---|

| PLA | 74.6 ± 1.4 a | 31.2 ± 1.1 a | 19.6 ± 1.3 a |

| PLA-RP | 74.7 ± 1.3 a | 32.7 ± 1.9 a | 22.3 ± 1.1 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).