Submitted:

21 June 2025

Posted:

23 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

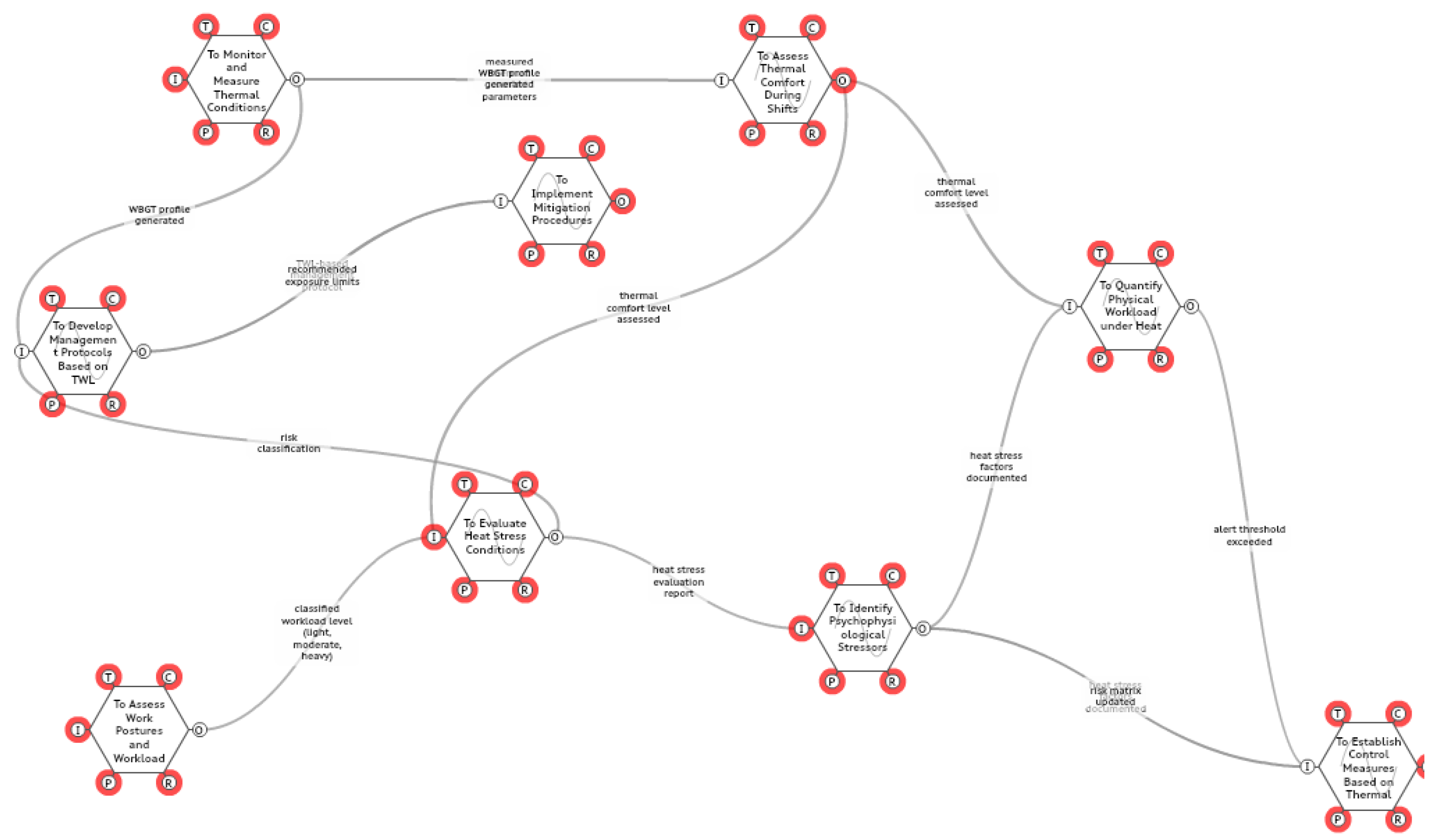

2.1. Functional Modeling Using FRAM

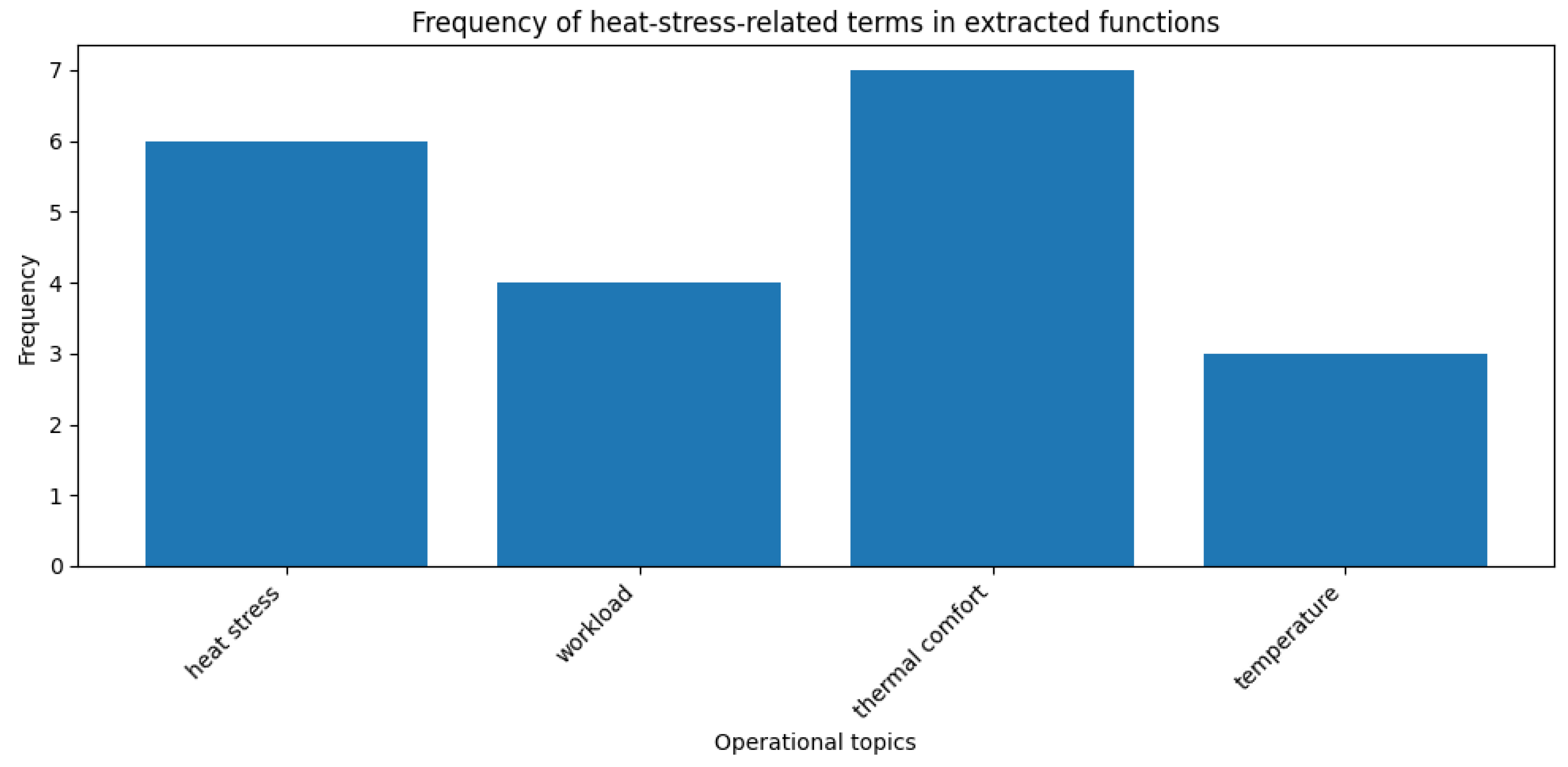

| # Install required libraries (run once in Colab or Jupyter) !pip install PyPDF2 matplotlib pandas # Import libraries from PyPDF2 import PdfReader import re import pandas as pd from collections import Counter import matplotlib.pyplot as plt # Define PDF file paths (uploaded to /content/ in Google Colab) pdf_paths = [ "/content/0002889748507014.pdf", "/content/mem035.pdf", "/content/s40033-022-00389-z.pdf", "/content/Vol.67,+No.11,+NOVEMBER+2019-15-19.pdf" ] # Function to extract full text from all PDFs def extract_text_from_pdfs(paths): full_text = "" for path in paths: reader = PdfReader(path) for page in reader.pages: text = page.extract_text() if text: full_text += text + "\n" return full_text # Extract text from selected papers full_text = extract_text_from_pdfs(pdf_paths) # Define action-related verbs (used as indicators of functional behavior) verbs = [ "monitor", "evaluate", "assess", "estimate", "measure", "record", "analyze", "control", "regulate", "adjust", "implement", "detect", "observe", "apply", "interrupt", "determine", "manage", "reduce", "prevent" ] |

# Define technical contexts associated with thermal stress contexts = [ "heat stress", "thermal comfort", "WBGT", "hydration", "acclimatization", "workload", "temperature", "body heat", "fatigue", "performance", "core temperature", "dehydration", "cooling", "rest breaks", "TWL", "exhaustion" ] # Regular expression to identify function-like sentences (verb + context) pattern = rf"((?:{'|'.join(verbs)}).*?(?:{'|'.join(contexts)}).*?\.)" # Extract sentences that match the pattern raw_phrases = re.findall(pattern, full_text, flags=re.IGNORECASE) # Create DataFrame with extracted functional sentences df_functions = pd.DataFrame(raw_phrases, columns=["Function (textual description)"]) # Count frequency of key context terms used_terms = [ctx.lower() for phrase in raw_phrases for ctx in contexts if ctx in phrase.lower()] term_freq = Counter(used_terms) # Generate frequency graph of terms plt.figure(figsize=(10, 5)) plt.bar(term_freq.keys(), term_freq.values()) plt.xticks(rotation=45, ha='right') plt.title("Frequency of heat-stress-related terms in extracted functions") plt.xlabel("Operational topics") plt.ylabel("Frequency") plt.tight_layout() plt.savefig("function_term_frequency.png") plt.show() # Display top 10 extracted functions df_functions.head(10) |

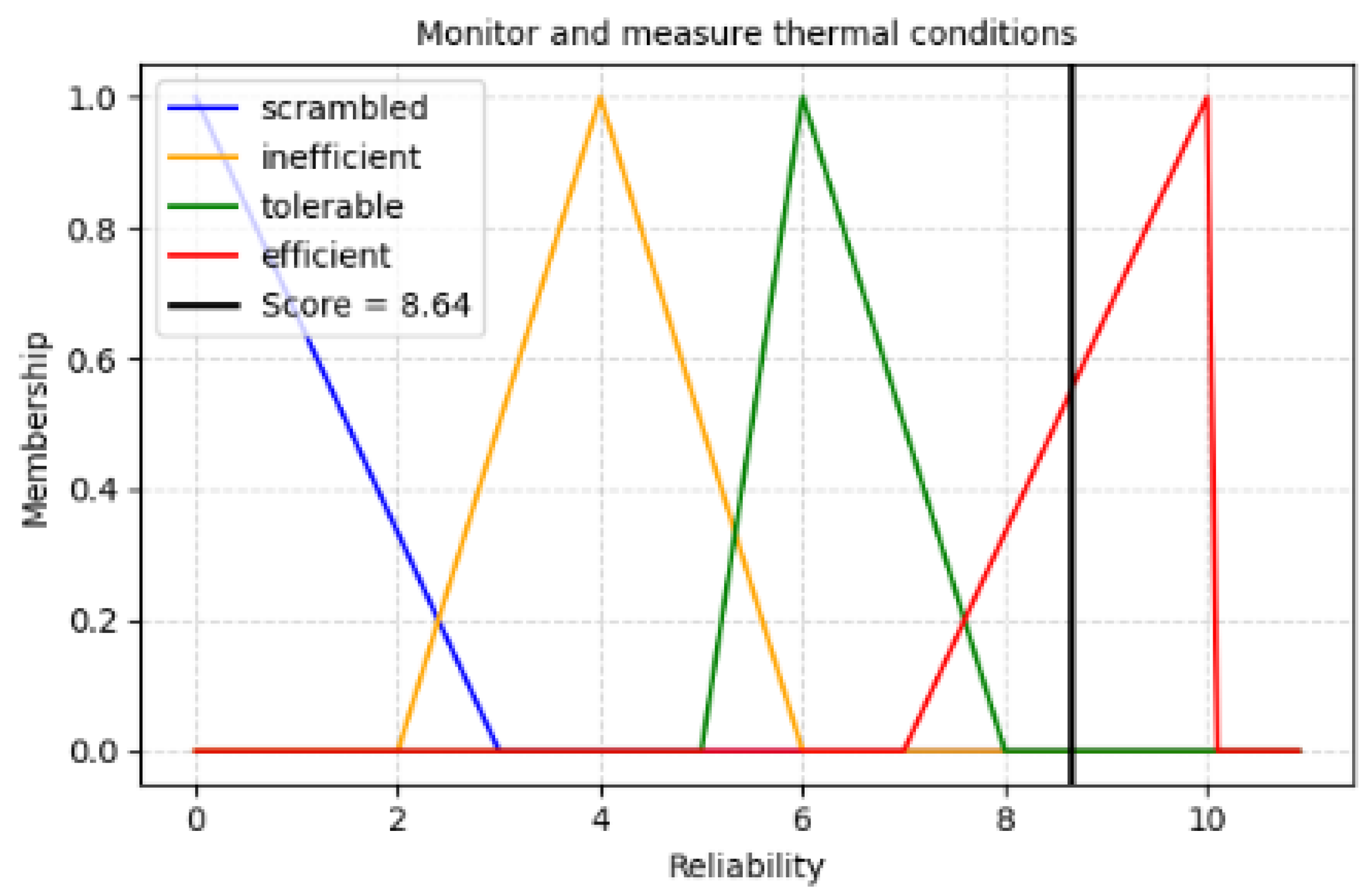

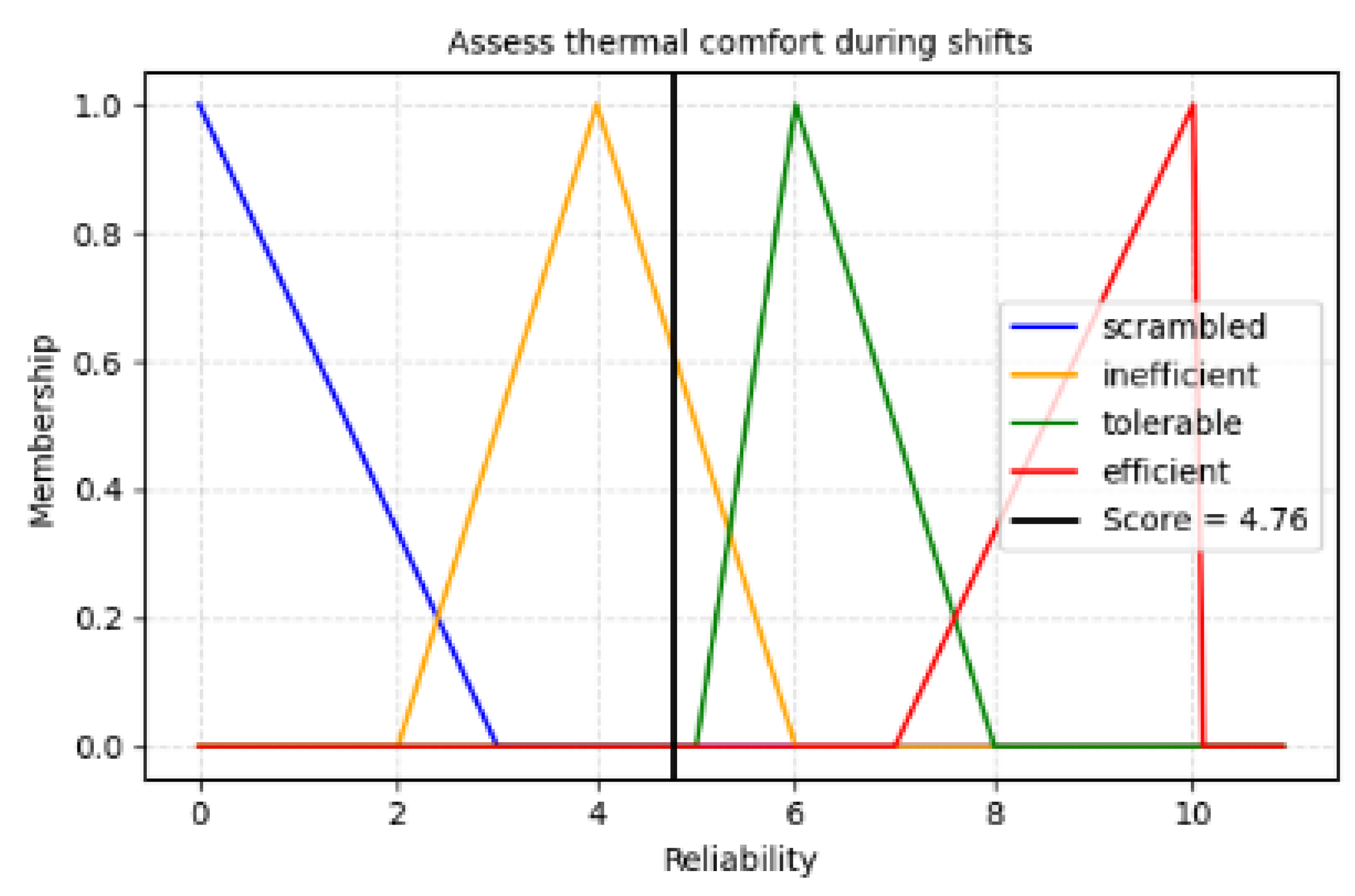

2.2. Human Reliability Assessment Using Fuzzy CREAM

- CPC₁: Adequacy of organization

- CPC₂: Working conditions

- CPC₃: Time available

- IF CPC₁ is “Adequate” AND CPC₂ is “Adequate” AND CPC₃ is “Adequate” → THEN Control Mode = “Efficient”

- IF CPC₁ is “Poor” OR CPC₂ is “Poor” → THEN Control Mode = “Scrambled”

2.3. Prioritization Using Gaussian AHP

- C1: Thermal Impact: the extent to which each function is affected by heat stress and contributes to risk propagation under thermal exposure.

- C2: Human Reliability: fuzzy control scores derived from the CREAM model, reflecting the likelihood of safe performance,

- C3: FRAM Connectivity: the level of interdependence a function has within the functional network, indicating its systemic influence.

3. Results

3.1. Functional Modeling Using FRAM

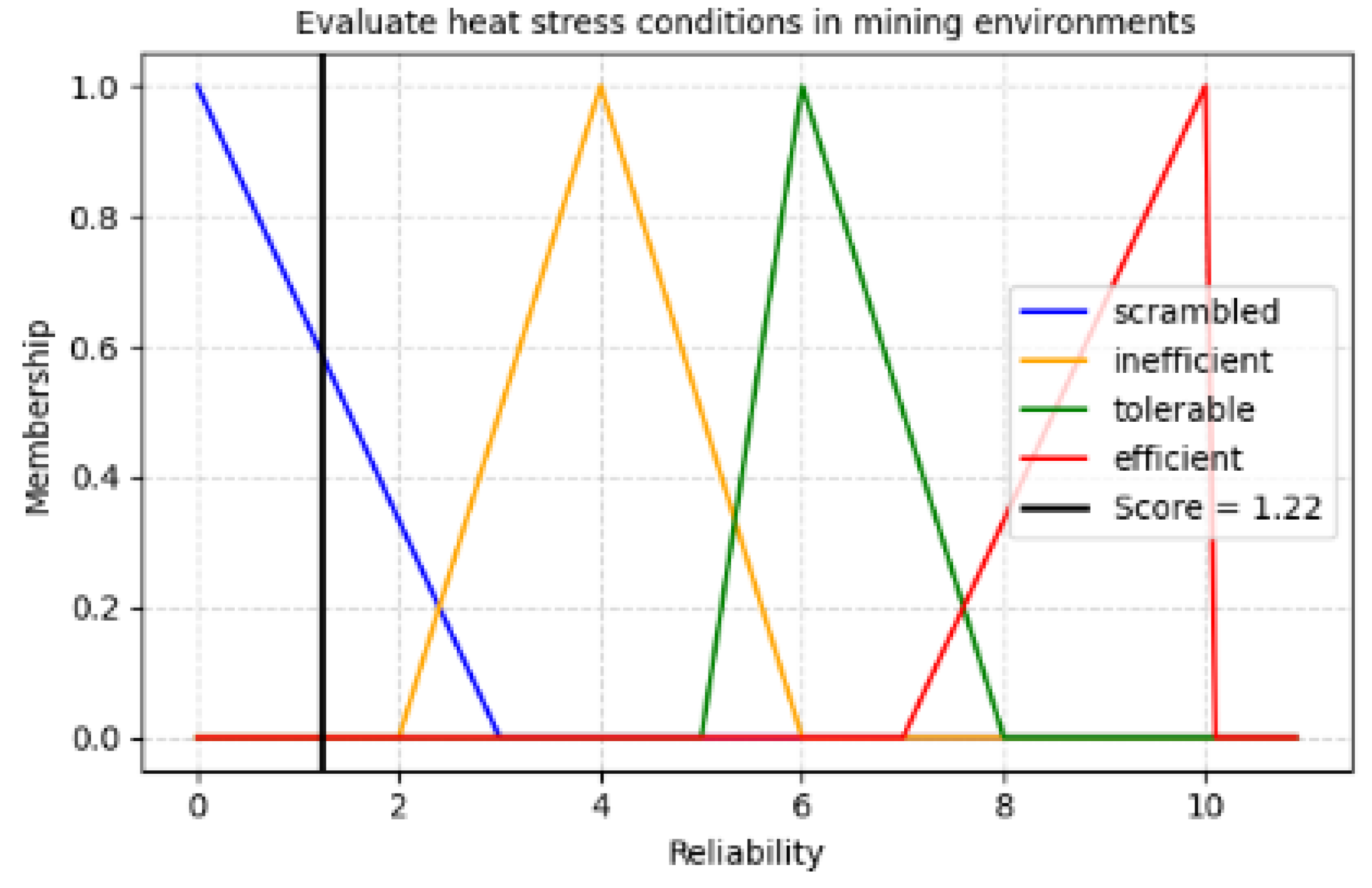

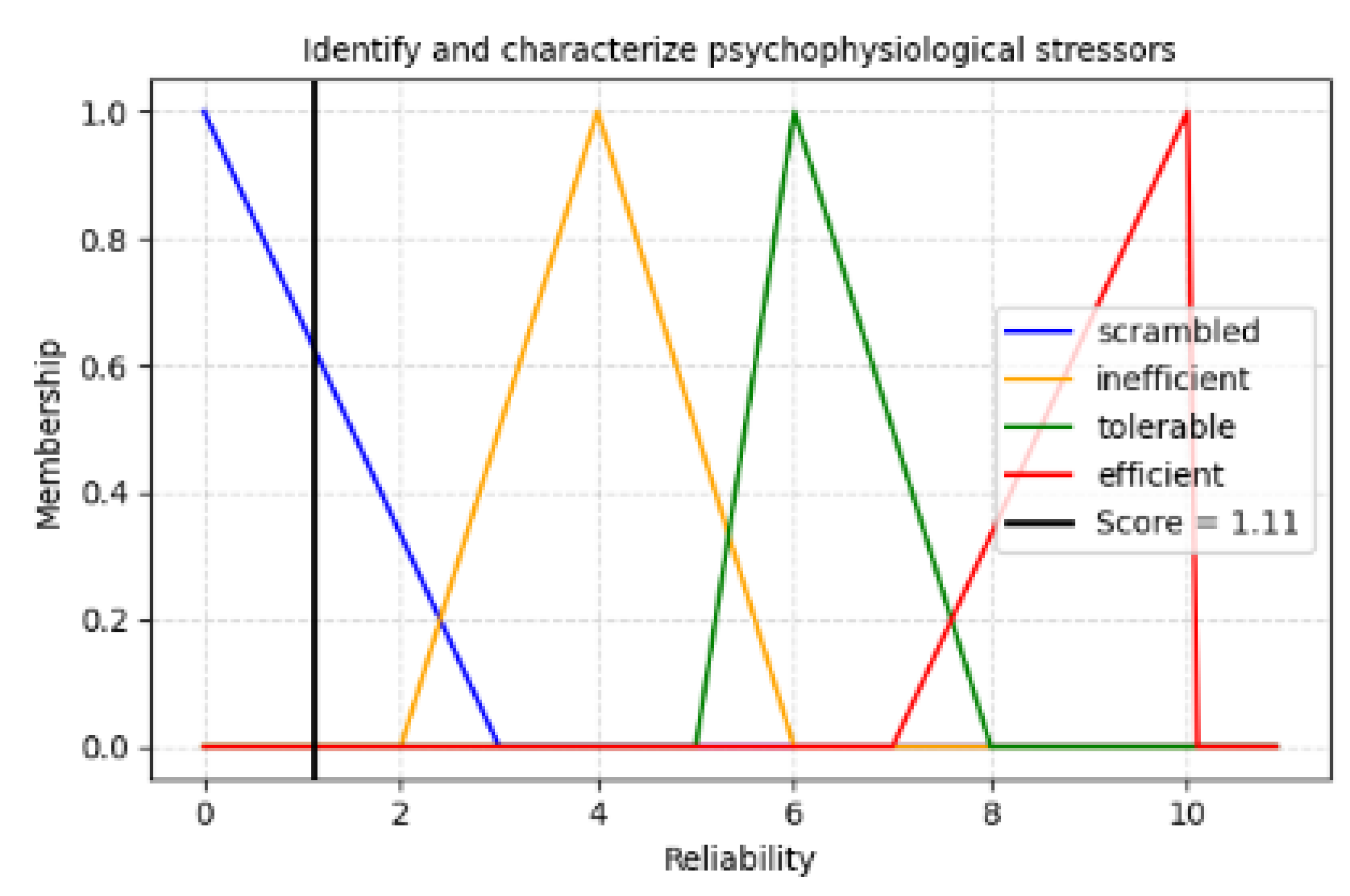

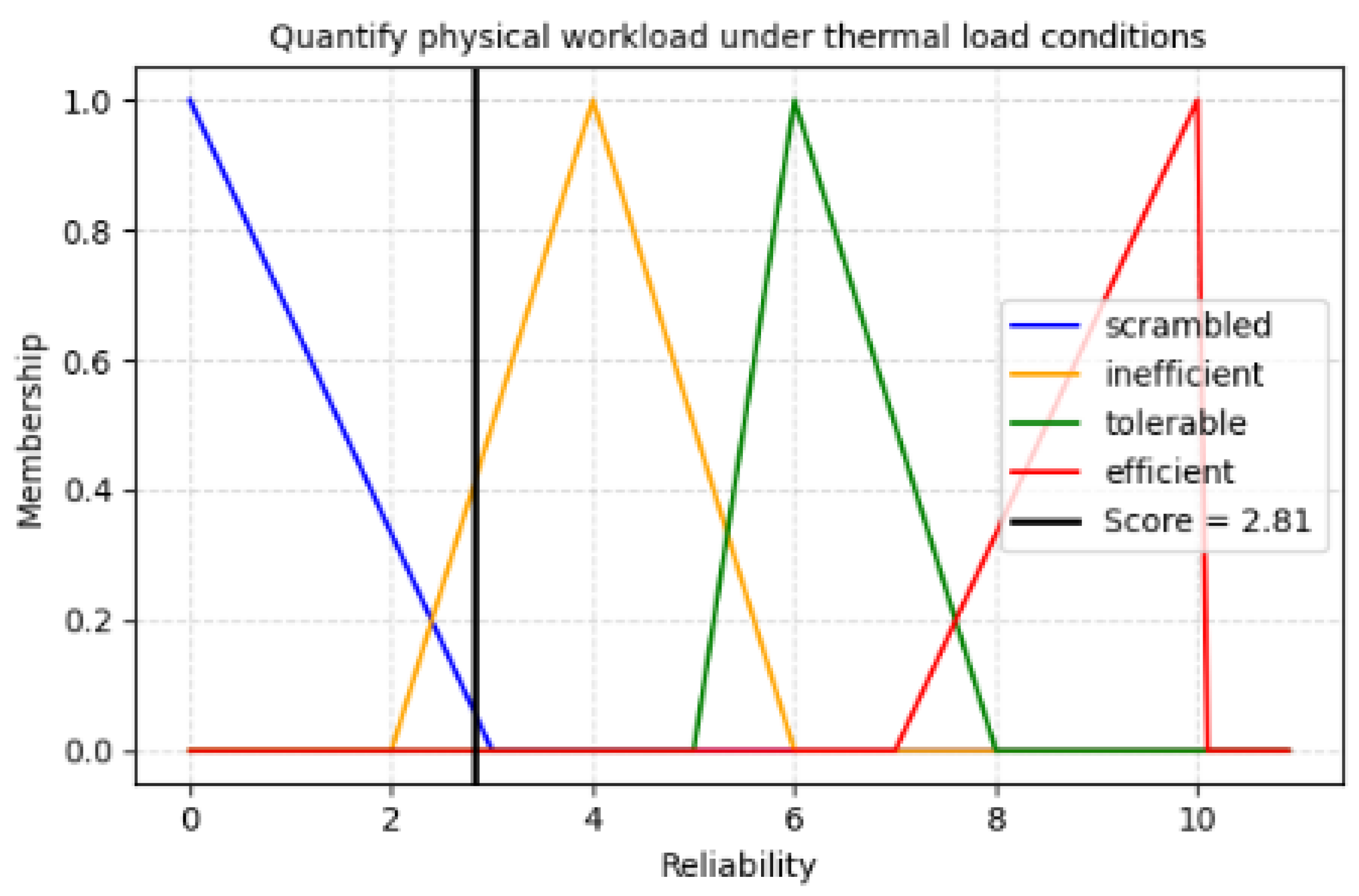

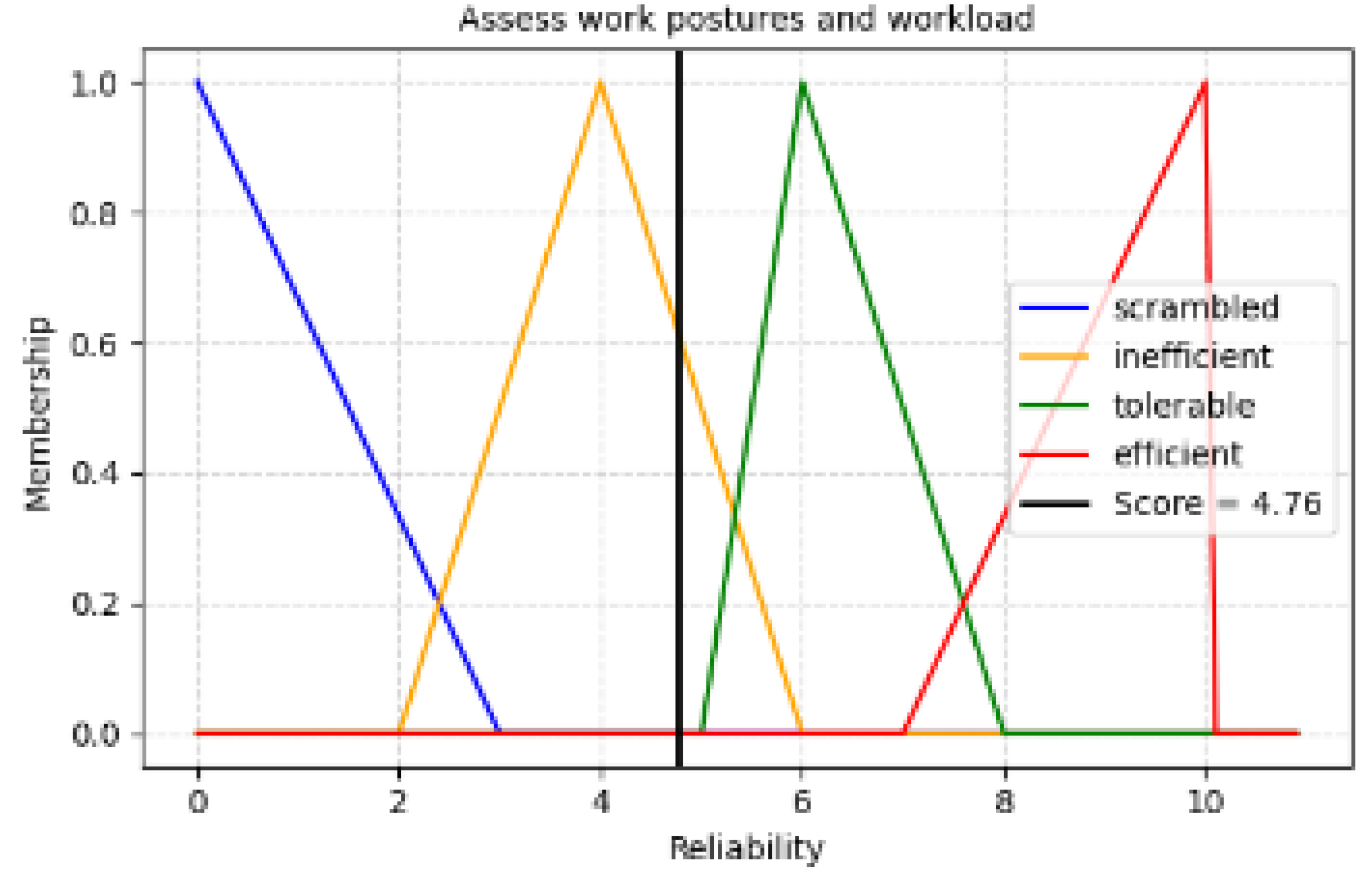

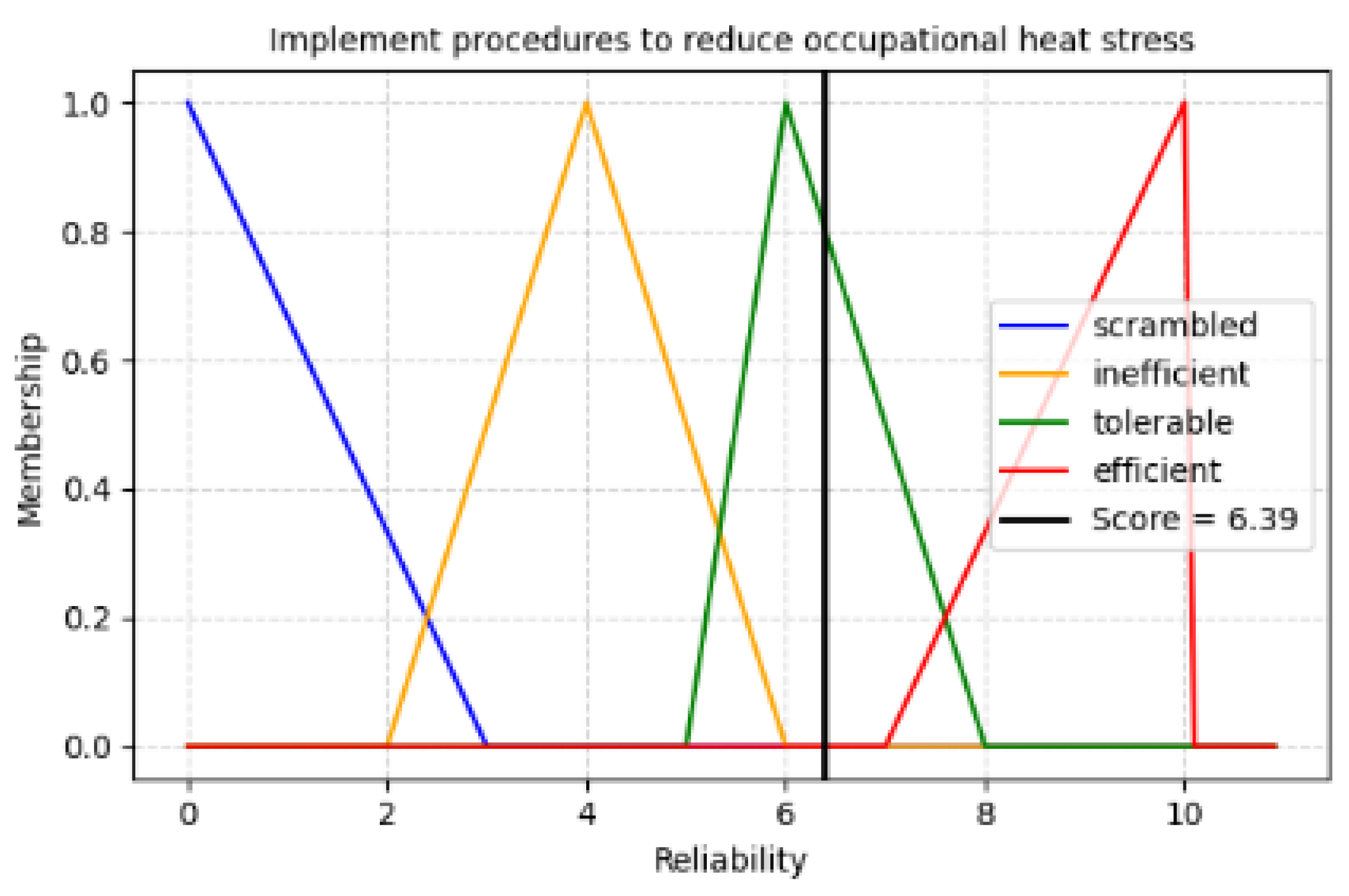

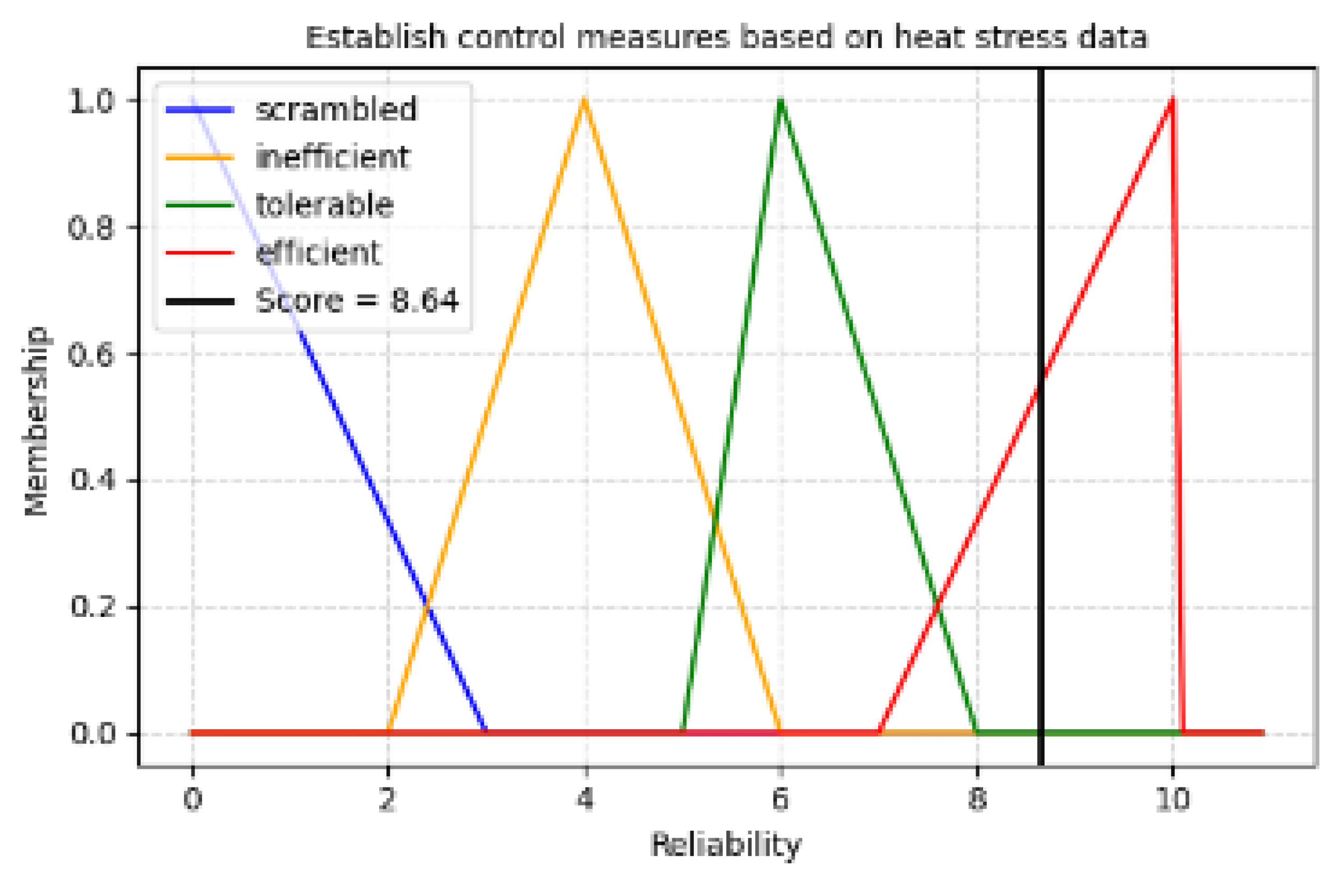

3.2. Human Reliability Assessment Using Fuzzy CREAM

3.3. Prioritization Using Gaussian AHP

- C1 – Thermal impact: the degree to which each function is sensitive to heat exposure and contributes to thermal risk propagation.

- C2 – Human reliability: the fuzzy score derived from the CREAM assessment, indicating the cognitive robustness of each function.

- C3 – FRAM connectivity: the level of interdependence and influence each function exerts in the functional network.

3.4. Practical Implications for the Mining Industry

4. Limitations

5. Conclusions

Funding

Conceptualization

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lazaro P, Momayez M. Heat Stress in Hot Underground Mines: a Brief Literature Review. Min Metall Explor 2021. [CrossRef]

- Maurya T, Karena K, Vardhan H, Aruna M, Raj MG. Effect of Heat on Underground Mine Workers. Procedia Earth and Planetary Science 2015;11:491–8. [CrossRef]

- Yoon YS, Ham DH, Yoon WC. A new approach to analysing human-related accidents by combined use of HFACS and activity theory-based method. COGNITION TECHNOLOGY & WORK 2017;19:759–83. [CrossRef]

- Fadeev G, Goryaev D V., Zaitseva N V., Shur PZ, Red’ko S V., Fokin V. HEALTH DISORDERS IN WORKERS ASSOCIATED WITH HEALTH RISKS AT WORKPLACES IN MINING INDUSTRY IN THE ARCTIC (ANALYTICAL REVIEW). Health Risk Analysis 2023;2023:173–82. [CrossRef]

- Härmä M. Workhours in relation to work stress, recovery and health. Scand J Work Environ Health 2006;32:502–14. [CrossRef]

- Molek-Winiarska D, Kawka T. Reducing Work-Related Stress Through Soft-Skills Training Intervention in the Mining Industry. Hum Factors 2024;66:1633–49. [CrossRef]

- Guoshan W, Heqing L, Zhirong W, You B, Jufeng Z, Yiming H. A heat stress control method for miners based on internal heat storage. Sci Technol Built Environ 2024. [CrossRef]

- Lazaro P, Momayez M. Validation of the Predicted Heat Strain Model in Hot Underground Mines. Min Metall Explor 2019;36:1213–9. [CrossRef]

- Hollnagel E. FRAM: The Functional Resonance Analysis Method. London: CRC Press; 2012.

- Patriarca R, Di Gravio G, Woltjer R, Costantino F, Praetorius G, Ferreira P, et al. Framing the FRAM: A literature review on the functional resonance analysis method. Saf Sci 2020;129. [CrossRef]

- Konstandinidou M, Nivolianitou Z, Kiranoudis C, Markatos N. A fuzzy modeling application of CREAM methodology for human reliability analysis. Reliab Eng Syst Saf 2006;91:706–16. [CrossRef]

- Marseguerra M, Zio E, Librizzi M. Human reliability analysis by fuzzy “CREAM.” Risk Analysis 2007;27:137–54. [CrossRef]

- Shi H, Wang JH, Zhang L, Liu HC. New improved CREAM model for human reliability analysis using a linguistic D number-based hybrid decision making approach. Eng Appl Artif Intell 2023;120. [CrossRef]

- Marins CS, Souza D de O, Barros M da S. O USO DO MÉTODO DE ANÁLISE HIERÁRQUICA (AHP) NA TOMADA DE DECISÕES GERENCIAIS – UM ESTUDO DE CASO. XLI SBPO, 2009.

- Russo AC, Russo E. Application of the AHP-Gaussian method to support the prioritization of workers’ health actions in Brazil, based on data from DATASUS. Gestao e Producao 2024;31. [CrossRef]

- Mahdi Rezaie F, Fakoor Saghih AM, Motahari Farimani N. A novel hybrid approach based on CREAM and fuzzy ANP to evaluate human resource reliability in the urban railway. Journal of Transportation Safety and Security 2021;13:1326–64. [CrossRef]

- Patriarca R, Di Gravio G, Costantino F. A Monte Carlo evolution of the Functional Resonance Analysis Method (FRAM) to assess performance variability in complex systems. Saf Sci 2017;91:49–60. [CrossRef]

- Maia França JE, Hollnagel E. Human Factors Approach to Assess Risks and Reliability in Offshore Operations with FRAM (Functional Resonance Analysis Method). Offshore Technology Conference Brasil, OTCB 2023, Offshore Technology Conference; 2023. [CrossRef]

- Huang Y, Liu Y, Zhao D, Song X. Fuzzy comprehensive performance evaluation method for radar control. CICTP 2012: Multimodal Transportation Systems - Convenient, Safe, Cost-Effective, Efficient - Proceedings of the 12th COTA International Conference of Transportation Professionals, Department of Air Navigation, Air Traffic Management College, Civil Aviation University of China, Tianjin, P.O. Box 68, China: 2012, p. 1845–56. [CrossRef]

- Mamdani EH. Application of Fuzzy Algorithms for Control of Simple Dynamic Plant. Proceedings of the Institution of Electrical Engineers 1974;121:1585–8. [CrossRef]

- Santos M dos, Costa IP de A, Gomes CFS. Multicriteria Decision-Making In The Selection Of Warships: A New Approach To The Ahp Method. International Journal of the Analytic Hierarchy Process 2021;13:147–69. [CrossRef]

- Wyndham CH. Research in the human sciences in the gold mining industry. Am Ind Hyg Assoc J 1974;35:113–36. [CrossRef]

- Miller VS, Bates GP. The thermal work limit is a simple reliable heat index for the protection of workers in thermally stressful environments. Annals of Occupational Hygiene 2007;51:553–61. [CrossRef]

- Sakinala V, Paul PS, Chandrakar S. Assessment of Work Postures and Physical Workload of Machine Operators in Underground Coal Mines. Journal of The Institution of Engineers (India): Series D 2023;104:87–98. [CrossRef]

- Dey S, Dey NC. Determining factors affecting thermal comfort in underground coal mine. JOURNAL OF MINES, METALS & FUELS 2019.

- França JEM, Hollnagel E. Analyzing human factors and complexities of mining and O&G process accidents using FRAM: Copiapó (Chile) and FPSO CSM (Brazil) cases. Process Safety Progress 2023;42:S9–18. [CrossRef]

- Hirose T, Sawaragi T. Development of FRAM Model Based on Structure of Complex Adaptive Systems to Visualize Safety of Socio-Technical Systems. IFAC-PapersOnLine, vol. 52, Elsevier B.V.; 2019, p. 13–8. [CrossRef]

- Vieira LC, Saurin TA. Environmental disaster analysis: Case study using the functional resonance analysis method. Engenharia Sanitaria e Ambiental 2018;23:373–83. [CrossRef]

- Dekker S, Hollnagel E. Computers in the cockpit: Practical problems cloaked as progress. Coping with Computers in the Cockpit, Linköping University, Sweden: Taylor and Francis; 2018, p. 1–6. [CrossRef]

- Molek-Winiarska D, Kawka T. Reducing Work-Related Stress Through Soft-Skills Training Intervention in the Mining Industry. Hum Factors 2022. [CrossRef]

- Härmä M. Workhours in relation to work stress, recovery and health. Scand J Work Environ Health 2006;32:502–14. [CrossRef]

- Brake DJ, Bates GP. Limiting metabolic rate (Thermal Work Limit) as an index of thermal stress. Appl Occup Environ Hyg 2002;17:176–86. [CrossRef]

- Yeoman K, Weakley A, DuBose W, Honn K, McMurry T, Eiter B, et al. Effects of heat strain on cognitive function among a sample of miners. Appl Ergon 2022;102. [CrossRef]

- Schmit C, Hausswirth C, Le Meur Y, Duffield R. Cognitive Functioning and Heat Strain: Performance Responses and Protective Strategies. Sports Medicine 2017;47:1289–302. [CrossRef]

- Rastegar Z, Ghotbi Ravandi MR, Zare S, Khanjani N, Esmaeili R. Evaluating the effect of heat stress on cognitive performance of petrochemical workers: A field study. Heliyon 2022;8. [CrossRef]

| Core aspects | Description |

|---|---|

| Input (I) | The trigger or starting point for the function |

| Output (O) | The result or outcome produced by the function |

| Preconditions (P) | The conditions that must be satisfied before the function can be executed |

| Resources (R) | The materials, tools, or information required to perform the function |

| Control (C) | The mechanisms or guidelines regulating the function’s execution |

| Time (T) | The temporal aspect that defines when the function must be completed |

| Range | Control Mode | Operational Interpretation |

|---|---|---|

| 0≤ y* ≤2.5 | Scrambled | Highly unpredictable; prone to errors |

| 2.6≤ y* ≤5.0 | Inefficient | Weak control, unstable contextual behavior |

| 0≤ y* ≤2.5 | Tolerable | Sufficient control with variability risks |

| 0≤ y* ≤2.5 | Efficient | Stable and reliable task execution |

| CPC | Linguistic Value | a (min) | b (peak) | c (max) |

|---|---|---|---|---|

| Adequacy of organization | Poor | 0.0 | 0.10 | 0.30 |

| Average | 0.20 | 0.50 | 0.80 | |

| Adequate | 0.70 | 0.90 | 1.00 | |

| Working conditions | Poor | 0.00 | 0.15 | 0.35 |

| Average | 0.25 | 0.50 | 0.75 | |

| Adequate | 0.65 | 0.90 | 1.00 | |

| Time available | Poor | 0.00 | 0.20 | 0.40 |

| Average | 0.30 | 0.50 | 0.70 | |

| Adequate | 0.60 | 0.85 | 1.00 |

| Rule | CPC₁ (Organization) | CPC₂ (Conditions) | CPC₃ (Time) | Output Control Mode |

|---|---|---|---|---|

| R1 | Adequate | Adequate | Adequate | Efficient |

| R2 | Poor | Any | Any | Scrambled |

| R3 | Any | Poor | Any | Scrambled |

| R4 | Average | Average | Average | Tolerable |

| R5 | Adequate | Average | Poor | Inefficient |

| R6 | Average | Poor | Poor | Scrambled |

| Author | Research Location and Context | Objective | Methodology | Key Results | Relevance |

|---|---|---|---|---|---|

| (Wyndham, 1974) | This study was conducted in the South African gold mining sector, specifically within the deep-level mines of the Witwatersrand region. | The primary aim was to evaluate how interdisciplinary research in human sciences—particularly physiology, psychology, and sociology—could be applied to improve health, safety, and productivity in underground mining, with an emphasis on heat acclimatization and worker resilience in hot environments. | The study utilized a combination of field experiments, physiological monitoring (including rectal temperature, oxygen consumption, and heart rate), and controlled environmental exposure in climatic rooms. From 1965 onwards, new recruits underwent an 8-day acclimatization program in chambers maintained at 32°C wet-bulb temperature. Exercises were calibrated to simulate moderate mining workloads, gradually increasing metabolic demand over the acclimatization period. | The controlled acclimatization protocol proved highly effective. By 1970, over 280,000 workers had participated across 28 acclimatization facilities. The program led to a significant reduction in heat stroke cases and fatalities, particularly due to improvements in early detection (via oral temperature checks) and immediate on-site cooling of affected individuals. Mortality rates dropped drastically compared to earlier years, when unrecognized or untreated heat stroke had resulted in up to 50% fatality among affected miners. | The study demonstrated that large-scale, structured acclimatization significantly enhances thermal safety in mining. It also allowed for partial work shift reallocation to include safety and productivity training, while reducing the supervisory burden. Wyndham’s findings contributed to the foundational practices in occupational heat stress management and laid the groundwork for modern protocols in thermal risk mitigation in mining environments. |

| (Miller and Bates, 2007) | The study included both controlled laboratory trials and field observations at mining and construction sites in northwest Australia, where summer conditions regularly exceed conventional heat stress thresholds. | The main objective was to evaluate the Thermal Work Limit (TWL) index as a practical, accurate, and robust tool for managing occupational heat stress in both controlled environments and real-world outdoor work settings. The TWL was compared to the widely used but often overly conservative Wet Bulb Globe Temperature (WBGT) index. | Twelve physically active male participants underwent trials in a climate chamber simulating hot environments (38–40 °C dry bulb, ~28 °C wet bulb). They performed repeated 30-minute work intervals at increasing workloads (40–60 W) interspersed with rest, while heart rate, core temperature (via ingestible sensors), and hydration status were monitored. Field studies involved continuous environmental and physiological monitoring of mine and construction workers across three outdoor sites, using heart rate monitors, tympanic thermometers, and urine specific gravity measurements. Environmental conditions were assessed using both TWL and WBGT indices. | In the controlled trials, TWL accurately predicted the metabolic threshold at which physiological strain (elevated core temperature >38.2 °C or heart rate >115 bpm) would occur. Ten of the twelve subjects stayed within predicted limits; the two outliers were likely impacted by poor acclimatization or excess body fat. In the field, TWL provided realistic thresholds that permitted safe continuous labor even when WBGT values suggested mandatory work-rest cycles. Despite consistently high WBGTs (>30 °C), workers maintained stable heart rates, hydration, and core temperatures when TWL exceeded 140 W/m². Management protocols based on TWL were proposed, allowing unrestricted work when TWL >220 W/m² and recommending restrictions and monitoring when TWL <140 W/m². | This study validated TWL as a more reliable and applicable index for heat stress management in hot workplaces compared to WBGT. It demonstrated that TWL better reflects the cooling potential of environmental factors like air movement, thus avoiding unnecessary productivity losses. The authors recommend TWL-based protocols for industry-wide adoption, highlighting its benefits in protecting health while sustaining operational efficiency. |

| (Sakinala et al., 2023) | The study was carried out in a fully mechanized underground coal mine operated by Eastern Coalfields Limited (ECL), a subsidiary of Coal India Ltd. This mine, located in eastern India, produces 3.4 million tons annually and represents a key example of mechanized underground mining in the country. | The study aimed to evaluate the ergonomic conditions of underground machine operators by analyzing their working postures and physical workload. The goal was to identify risk factors for musculoskeletal disorders (MSDs) and fatigue, which are common in deep mining due to constrained workspaces and prolonged exposure to poor environmental conditions. | Work posture was assessed using the Ovako Working Posture Analysis System (OWAS), which classifies postural stress based on joint angles and time spent in each posture. Physical workload was evaluated using pulse rate measurements captured by a Polar M430 activity monitor, and energy expenditure was estimated via the Varghese formula. Four types of machinery operators were evaluated: continuous miner (CM), universal drilling machine (UDM), road header, and load haul dumper (LHD). | Postural analysis revealed that most operators regularly assumed slightly to distinctly harmful postures. For example, CM operators spent 70% of their time with the neck bent backward (distinctly harmful), while UDM, road header, and LHD operators exhibited prolonged bent or twisted trunk positions. In terms of workload, CM operators had a light workload (average pulse: 96 bpm; energy expenditure: 6.5 kJ/min), whereas the UDM, road header, and LHD operators showed moderately heavy workloads (pulse rates ~112–114 bpm; energy expenditure ~9.1–9.4 kJ/min). These findings suggest a substantial risk of fatigue and MSDs, particularly for UDM and road header operators. | This study emphasizes the urgent need for ergonomic interventions in Indian underground mines. The authors advocate for better postural training, workload management, and the adoption of ergonomic design principles (e.g., anthropometry and participatory ergonomics) to reduce occupational health risks. The methodology and findings may be extended to other mining contexts, including opencast and non-coal operations. |

| (Dey and Dey, 2019) | The study was conducted in two underground coal mines in India (referred to as Mine A and Mine B), both operated under subsidiaries of Coal India Limited. While the mines shared similar ventilation and geological conditions, they differed in depth—150 m for Mine A and 320 m for Mine B. | The objective of the study was twofold: (1) to assess the thermal comfort status of underground coal miners using standardized thermal stress indices, and (2) to examine the correlations between thermal comfort and physiological and environmental stress factors. | Twenty male participants (10 per mine) were selected based on strict inclusion criteria: healthy BMI and body surface area, no cardiovascular or physiological disorders, acclimatized to underground work, and with normal resting ECG. Thermal comfort was evaluated using the Predicted Mean Vote (PMV) and Predicted Percentage of Dissatisfied (PPD) indices derived from environmental data collected hourly during the work shift. Pearson correlation and Student’s t-tests were applied to determine the strength of association between PMV/PPD and various environmental and physiological variables such as heart rate, metabolic heat generation, air velocity, convection and evaporation heat exchange. | Both mines showed high thermal stress levels with PMV and PPD values exceeding comfort thresholds—Mine A had a PMV of 3.74 and PPD of 99.28%, while Mine B showed a PMV of 4.09 and PPD of 99.97%. WBGT (Wet Bulb Globe Temperature) values were also elevated compared to OSHA’s recommended limits. A strong positive correlation was found between PMV and metabolic heat production (r = 0.99), while strong negative correlations were found with evaporative heat loss (r = –0.99) and convective heat exchange in breathing (r = –0.88). Medium-strength correlations existed between PMV and PPD (r = 0.60 in Mine A and r = 0.53 in Mine B). These findings indicate that thermal comfort in Indian underground mines is governed by multiple interacting factors, and even relatively shallow mines can present substantial heat stress risks. | The study underscores the importance of systematically identifying and monitoring the various determinants of thermal comfort in underground environments. As Indian mining shifts toward deeper operations, understanding the interplay between physiological strain, environmental heat stress, and mine design becomes increasingly critical. The authors advocate for better air velocity management, targeted work-rest schedules, and enhanced environmental monitoring to reduce discomfort and maintain productivity in heat-stressed mines. |

| Function | Thermal Impact (C1) | Human Reliability (C2) | FRAM Connectivity (C3) | Final Score |

|---|---|---|---|---|

| Evaluate heat stress conditions | 0.92 | 0.91 | 0.90 | 0.91 |

| Quantify physical workload | 0.89 | 0.87 | 0.88 | 0.88 |

| Identify psychophysiological stressors | 0.85 | 0.86 | 0.84 | 0.85 |

| Monitor and measure thermal conditions | 0.80 | 0.82 | 0.83 | 0.82 |

| Assess thermal comfort | 0.78 | 0.79 | 0.81 | 0.79 |

| Assess postures and workload | 0.75 | 0.74 | 0.73 | 0.74 |

| Establish control measures | 0.70 | 0.72 | 0.71 | 0.71 |

| Implement heat stress procedures | 0.68 | 0.70 | 0.69 | 0.69 |

| Develop protocols based on TWL | 0.65 | 0.68 | 0.67 | 0.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).