Submitted:

12 June 2025

Posted:

12 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

2.1. Industrial Digitalization and Industrial Transformation

2.2. Influence Mechanism of Digital Technology on Carbon Emission in Manufacturing Industry

2.2. Comparison of Digitalization Research Methods

3. Model Building

3.1. Digitalization Degree Calculation

3.2. Carbon Emission Accounting

3.3. Data Sources

3.4. SDA Model

| TechEffect | Struct Effect | ScaleEffect | |

| Food and Tobacco Processing | -1523954.663 | -40273.39793 | 1554247.136 |

| Textile Industry | -6334503.097 | 2743807.047 | 4009767.908 |

| Textile Clothing Shoes and Hats Leather Down and its products | -1265568.841 | -211542.9817 | 940001.822 |

| Woodwork and Furniture | -474611.8052 | 189779.7323 | 290159.3434 |

| Paper, printing and stationery | -3456984.744 | 2259874.772 | 2784573.23 |

| Petroleum, coking products and processed nuclear fuel | 4350120.727 | -3572788.784 | 1543157.142 |

| Chemical products | -414517.3999 | 733783.2996 | 2764731.79 |

| Nonmetal Mineral Products | -38760022.87 | 87124698.11 | 70779646.35 |

| Smelting and Pressing of Metals | 7675511.848 | 76891809.72 | 126129635.2 |

| Metal Products | -1622959.736 | 335345.0404 | 1148140.695 |

| Ordinary Machinery | -120892.5008 | 140086.1948 | 1218281.694 |

| Equipment for Special Purposes | -622493.426 | -232772.5191 | 593749.7327 |

| Transportation Equipment | -768201.821 | -166827.9607 | 595702.0655 |

| Electric Equipment and Machinery | -1302721.86 | -234572.8099 | 809394.5448 |

| Telecommunications Equipment, Computers and Other Electronic equipment | -3414791.295 | -1749447.061 | 2310817.422 |

| Instrumentation Machinery | -415960.8536 | 129899.6814 | 210468.0162 |

| Other manufacturing products and scrap waste | -58676734.6 | 47202190.78 | 8200623.011 |

3.5. Scenario Simulation

3.6. Data Sources

3.7. Result

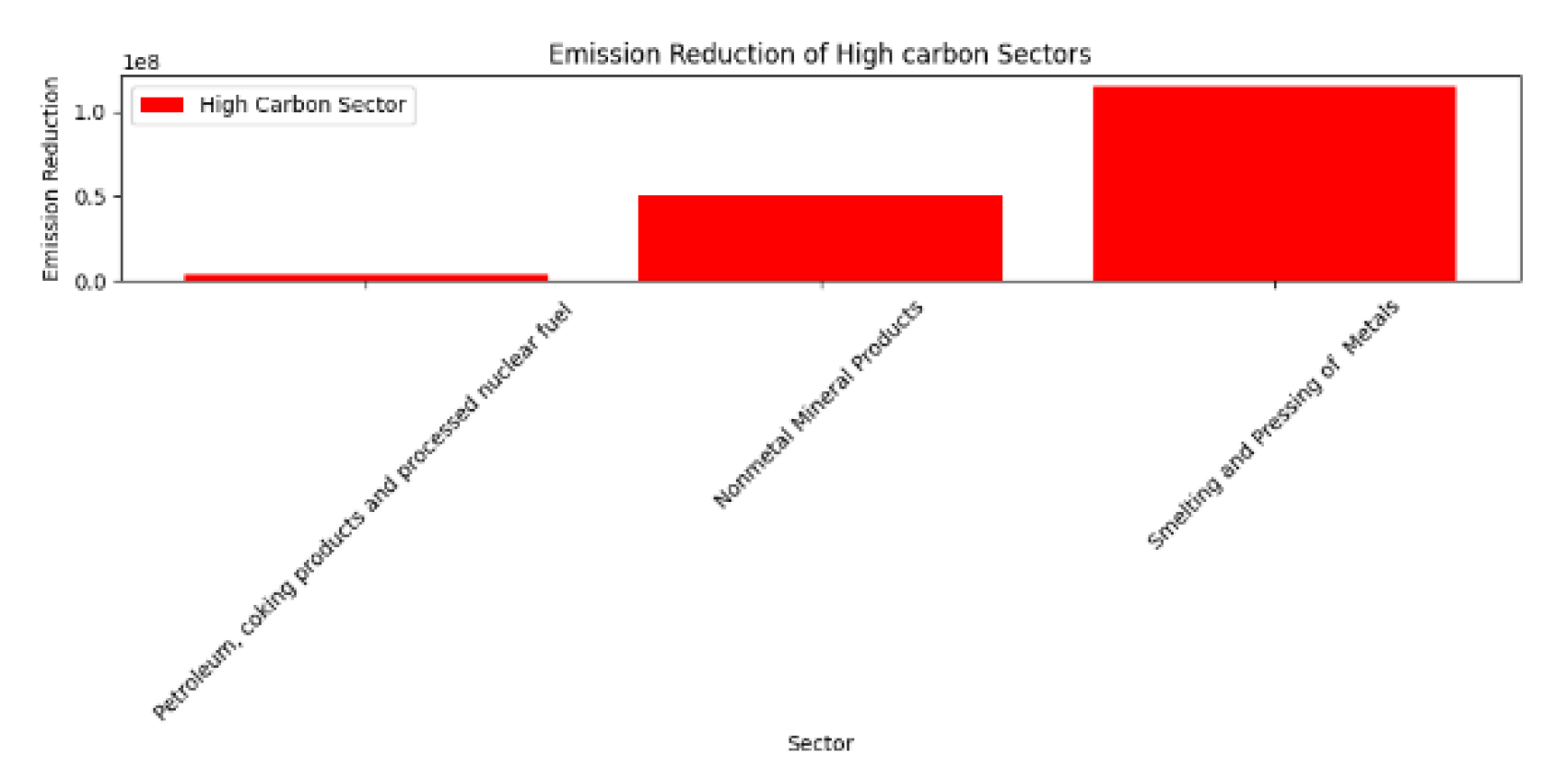

| High Carbon Sector | |||

| Sectors | Carbon Emission Factor (tons/ten thousand yuan) | Emission Reduction(tons) | Contribution Rate |

| Petroleum, coking products and processed nuclear fuel | 0.1835 | 4004624 | 1.11% |

| Nonmetal Mineral Products | 0.9804 | 50613240 | 14.05% |

| Smelting and Pressing of Metals | 0.7129 | 114984400 | 31.91% |

| Non-high Carbon Sector | |||

| Sectors | Carbon Emission Factor (tons/ten thousand yuan) | Emission Reduction(tons) | Contribution Rate |

| Food and Tobacco Processing | 0.0141 | 445695 | 0.12% |

| Textile Industry | 0.0548 | 1440923 | 0.40% |

| Textile Clothing Shoes and Hats Leather Down and its products | 0.0090 | 180762 | 0.05% |

| Woodwork and Furniture | 0.0063 | 100477 | 0.03% |

| Paper, printing and stationery | 0.0513 | 1965939 | 0.55% |

| Chemical products | 0.0144 | 1885076 | 0.52% |

| Metal Products | 0.0153 | 456614 | 0.13% |

| Ordinary Machinery | 0.0304 | 723410 | 0.20% |

| Equipment for Special Purposes | 0.0062 | 90056 | 0.03% |

| Transportation Equipment | 0.0065 | 164325 | 0.05% |

| Electric Equipment and Machinery | 0.0086 | 338039 | 0.09% |

| Telecommunications Equipment, Computers and Other Electronic equipment | 0.0035 | 648109 | 0.18% |

| Instrumentation Machinery | 0.0133 | 101559 | 0.03% |

| Other manufacturing products | 0.0272 | 582708 | 0.16% |

4. Conclusion and Policies

4.1. Research Conclusions and Policy Recommendations

4.2. Research Limitations and Future Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GHG | Green House Gas |

| IEA | International Energy Agency |

| CEAD | China Emission Accounts and Datasets |

| SDA | Structural Decomposition Analysis |

| EEIO | Environmentally-Extended Input-Output |

Appendix A

Appendix A.1

| Other Sectors | Food and Tobacco Processing | Textile Industry | Textile Clothing Shoes and Hats Leather Down and its products | Woodwork and Furniture | Paper, printing and stationery | Petroleum, coking products and processed nuclear fuel | Chemical products | Nonmetal Mineral Products |

| 10803122 | 18012718 | 160725 | 1766808 | 1638052 | 8600214 | 20456886 | 18243129 | 16869512.29 |

| 18012718 | 19043203 | 27310 | 578836 | 87707 | 357365 | 682 | 1021115 | 13467.83646 |

| 160725 | 20953 | 10331840 | 10627747 | 263206 | 739157 | 9326 | 442654 | 67565.12628 |

| 1766808 | 39917 | 140111 | 18050970 | 778543 | 499295 | 8644 | 213069 | 82736.45562 |

| 1638052 | 37487 | 11335 | 4226 | 6587696 | 393768 | 2550 | 25586 | 259973.9377 |

| 8600214 | 1220447 | 106319 | 690825 | 458024 | 15905058 | 14367 | 1453168 | 707554.5118 |

| 20456886 | 80183 | 61209 | 109154 | 387220 | 449664 | 8886934 | 4171999 | 1261996.291 |

| 18243129 | 1806391 | 3001232 | 5000307 | 1314942 | 7776336 | 1974371 | 55634866 | 3185942.552 |

| 16869512 | 272896 | 217 | 19544 | 620168 | 125176 | 4165 | 286628 | 9915032.929 |

| 8699518 | 10824 | 15355 | 76947 | 739963 | 13360826 | 0 | 687319 | 579556.0654 |

| 8003489 | 619058 | 116454 | 153327 | 1368905 | 548764 | 5803 | 1245068 | 295300.3958 |

| 1173533 | 34541 | 45809 | 117922 | 63430 | 147947 | 796 | 760041 | 118157.8579 |

| 3346361 | 285026 | 65846 | 530360 | 40207 | 297965 | 22466 | 2110491 | 158300.747 |

| 1755843 | 2910 | 2227 | 6201 | 1780 | 5008 | 421 | 5554 | 7675.104688 |

| 5435455 | 5594 | 1645 | 19150 | 24592 | 772354 | 240 | 202421 | 34932.76037 |

| 20359795 | 6397 | 5978 | 8788 | 46341 | 4430097 | 880 | 202954 | 35226.08003 |

| 3695275 | 1795 | 141 | 148 | 1129 | 16270 | 401 | 6839 | 44127.78412 |

| 665073.0294 | 9150.861 | 6017.922 | 26891.98 | 421.1396 | 44896.08 | 4.3191 | 4866.764 | 4298.034431 |

| Nonmetal Mineral Products | Smelting and Pressing of Metals | Metal Products | Ordinary Machinery | Equipment for Special Purposes | Transportation Equipment | Electric Equipment and Machinery | Telecommunications Equipment, | Instrumentation Machinery |

| 16869512.29 | 8699518 | 8003489 | 1173533 | 3346361 | 1755843 | 5435455 | 20359795 | 3695275 |

| 13467.83646 | 7481.968 | 23296.52 | 8780.34 | 8050.552 | 6058.593 | 27384.83 | 33155.64 | 1774.914 |

| 67565.12628 | 15639.41 | 31904.42 | 19638.51 | 5922.402 | 115082.6 | 10917.5 | 28530.14 | 1503.439 |

| 82736.45562 | 65391.51 | 160097.2 | 38331.02 | 103488.8 | 142914 | 77939.83 | 49866.2 | 17747.82 |

| 259973.9377 | 18107.97 | 253948.2 | 41898.98 | 20639.17 | 52255.25 | 83468.02 | 161478.3 | 3691.901 |

| 707554.5118 | 83730.83 | 565247.3 | 323890.3 | 62914.86 | 228018.5 | 1845824 | 538909.1 | 50901.28 |

| 1261996.291 | 983370.3 | 515997.2 | 153708.8 | 31829.55 | 102921.9 | 158789.4 | 195668.5 | 8386.591 |

| 3185942.552 | 1349378 | 2773798 | 1315258 | 1395942 | 2048274 | 6096270 | 2933351 | 141673.6 |

| 9915032.929 | 287258.4 | 181457.9 | 285560 | 41350.8 | 126221.3 | 1331555 | 2829368 | 144901.2 |

| 579556.0654 | 26809814 | 18937751 | 3956352 | 2064960 | 4048100 | 20743179 | 4055704 | 645034.8 |

| 295300.3958 | 54483.46 | 11017134 | 1539455 | 684332.2 | 261097.3 | 2843489 | 1312469 | 132774.7 |

| 118157.8579 | 215920.6 | 291790 | 8427733 | 999006.1 | 1511473 | 4935654 | 1557527 | 153509 |

| 158300.747 | 26449 | 226599.1 | 391294.6 | 4374516 | 258538.1 | 1704138 | 1830711 | 70226.54 |

| 7675.104688 | 2071.779 | 21643.84 | 3669.804 | 268989.7 | 27916297 | 7332.644 | 1711.752 | 764.4908 |

| 34932.76037 | 153899.8 | 193199.3 | 2097231 | 1046769 | 1152965 | 19586183 | 7611000 | 696607.7 |

| 35226.08003 | 5054.854 | 116142.3 | 6789660 | 2037272 | 1761126 | 15727202 | 1.65E+08 | 2343635 |

| 44127.78412 | 591.7538 | 9951.925 | 135573.3 | 172722.7 | 34520.32 | 168553.3 | 226515.1 | 867952.5 |

| 4298.034431 | 10.48424 | 36238.16 | 1167.404 | 28.1403 | 32622.88 | 22939.39 | 27411.01 | 1223.708 |

| Other manufacturing products and scrap waste | Final Demand | Total Output | f | |||||

| 665073.0294 | 456151960.9 | 6.84E+08 | 0.574927 | |||||

| 441.1856918 | 31536557.12 | 61543528.11 | 0.027075 | |||||

| 31006.59189 | 9581156.728 | 25438350.13 | 0.136994 | |||||

| 2716.082201 | 44061213.67 | 62016113.22 | 0.022447 | |||||

| 628.0850725 | 17326181.34 | 23358394.78 | 0.015434 | |||||

| 23851.76764 | 50607783.67 | 73150707.43 | 0.076928 | |||||

| 44762.41906 | 31911744.67 | 37910257.4 | 0.136139 | |||||

| 407096.08 | 53051392.37 | 119158413.9 | 0.015494 | |||||

| 2055.536838 | 13649353.09 | 39625898.36 | 1.26907 | |||||

| 277813.3173 | 19453405.62 | 54742578.09 | 0.694522 | |||||

| 418374.9577 | 28975871.39 | 54904166.08 | 0.030532 | |||||

| 6620.149463 | 35237188.28 | 38150809.13 | 0.031665 | |||||

| 1201.095382 | 16941474.39 | 21995769.23 | 0.016134 | |||||

| 102.498793 | 49319477.64 | 59469797.15 | 0.01284 | |||||

| 20265.6197 | 93466951.55 | 109239365.9 | 0.015522 | |||||

| 785942.6968 | 173076390.7 | 250432581.4 | 0.007809 | |||||

| 237.6688498 | 12438687.68 | 8262611.774 | 0.027727 | |||||

| 165208.4433 | 2508628.703 | 3250298.839 | 1.429921 | |||||

| Other Sectors | Food and Tobacco Processing | Textile Industry | Textile Clothing Shoes and Hats Leather Down and its products | Woodwork and Furniture | Paper, printing and stationery | Petroleum, coking products and processed nuclear fuel | Chemical products | Nonmetal Mineral Products | |

| 403850902 | 32881164 | 6182629 | 13367711 | 9604617 | 14418026 | 10203591 | 26099463 | 18626789.14 | |

| 21166471 | 18908530 | 68009 | 1076044 | 104889 | 74807 | 61773 | 492539 | 236314.1759 | |

| 414644 | 43624 | 14328827 | 22291025 | 871632 | 1753946 | 2587 | 511610 | 234403.9337 | |

| 2330402 | 45779 | 585540 | 13553300 | 368823 | 716691 | 21840 | 518664 | 126473.7718 | |

| 2208440 | 185635 | 160240 | 77978 | 9612795 | 1260307 | 169 | 533144 | 805449.1197 | |

| 11154357 | 1207992 | 480297 | 1595982 | 1364631 | 25996301 | 20414 | 3005962 | 1397380.122 | |

| 13946671 | 52403 | 60599 | 101475 | 135636 | 135310 | 5564807 | 4397845 | 875324.0842 | |

| 23860532 | 1753251 | 2765344 | 10343186 | 3224009 | 8050132 | 208878 | 69036210 | 6043620.967 | |

| 47306877 | 250711 | 55821 | 108176 | 325654 | 525196 | 680 | 1265490 | 13768527.63 | |

| 820860 | 6191 | 13598 | 113777 | 993932 | 6310342 | 1911 | 2899753 | 1452761.837 | |

| 10331336 | 1080390 | 220933 | 896113 | 1470489 | 1167312 | 4334 | 983823 | 843028.5798 | |

| 1374191 | 27827 | 84484 | 21520 | 319439 | 190835 | 9551 | 126551 | 995418.3862 | |

| 1099417 | 14437 | 25535 | 592969 | 190737 | 610378 | 23409 | 414208 | 93354.8344 | |

| 1326550 | 1452 | 2864 | 3299 | 2172 | 4206 | 2814 | 4237 | 6138.5632 | |

| 7504159 | 6388 | 11592 | 23436 | 61703 | 404051 | 1125 | 81821 | 60632.6828 | |

| 7002694 | 5908 | 4714 | 17536 | 8174 | 3646468 | 1693 | 889349 | 256708.1426 | |

| 3946537 | 1537 | 1157 | 59 | 64 | 35783 | 4076 | 8269 | 193674.9267 | |

| 7201298.578 | 14772.25 | 4067.437 | 209323 | 4992.34 | 5570702 | 23.9232 | 2863200 | 318935.8704 | |

| Smelting and Pressing of Metals | Metal Products | Ordinary Machinery | Equipment for Special Purposes | Transportation Equipment | Electric Equipment and Machinery | Telecommunications Equipment, Computers and Other Electronic equipment | Instrumentation Machinery | ||

| 8743253 | 10034218 | 5514641 | 5153966 | 11547822 | 17124506 | 28137998 | 1285732 | ||

| 16802.13 | 127132.3 | 94000.96 | 53675.43 | 81144.97 | 175647.9 | 699731.7 | 33560.36 | ||

| 7392.89 | 116434.4 | 61192.54 | 87548.48 | 59236.44 | 160289.1 | 287112.7 | 20534.07 | ||

| 73438.58 | 106289.2 | 50047.75 | 95100.35 | 273346.1 | 96327.15 | 199132.6 | 19928.8 | ||

| 666773.3 | 745352.1 | 163076.9 | 193029.9 | 298832.2 | 409444 | 372886.4 | 7762.236 | ||

| 74528.38 | 1329107 | 447348.9 | 428409.6 | 243500.4 | 1732980 | 2713651 | 103827.6 | ||

| 234606 | 454396.3 | 107177.8 | 75051.64 | 157488.8 | 171692.1 | 129245 | 8213.921 | ||

| 686881.2 | 4162191 | 1585620 | 1978111 | 3431477 | 9789363 | 9969751 | 173094.2 | ||

| 115175.2 | 1037865 | 953070.6 | 292118.7 | 46670.22 | 1265257 | 11618395 | 420878.8 | ||

| 35176008 | 33206339 | 8782648 | 7096128 | 10985506 | 26112504 | 7911635 | 396227.7 | ||

| 112875 | 12781977 | 3816035 | 1734535 | 1591709 | 8912062 | 2507639 | 165380.8 | ||

| 45614.37 | 3539878 | 12579541 | 3083253 | 3617492 | 3940170 | 2501799 | 360517 | ||

| 13223.82 | 52358.78 | 534028 | 4056368 | 147706.8 | 945081.7 | 4934084 | 190492.6 | ||

| 4259.311 | 61765.82 | 19732.8 | 13243.07 | 35474360 | 728288.8 | 327829.9 | 1017.049 | ||

| 124063.7 | 199962 | 3122934 | 1776934 | 1402260 | 24315263 | 8082311 | 300583.1 | ||

| 11730.04 | 222410.2 | 3167150 | 1733787 | 779849.9 | 10136994 | 2.25E+08 | 3165307 | ||

| 5744.282 | 815.1082 | 499080.9 | 801303.6 | 63783.77 | 280041.2 | 1430413 | 1624292 | ||

| 2267158 | 244364.6 | 19387.07 | 9735.512 | 634694.2 | 47758.05 | 24288.34 | 911.2901 | ||

| Other manufacturing products and scrap waste | Final Demand | Total Output | f | ||||||

| 948777.8926 | 814793447.5 | 1140800857.8622 | 0.3806171 | ||||||

| 5716.1697 | 67248633.1 | 74115326.75 | 0.014123 | ||||||

| 157415.7289 | 19454301.41 | 31625292.63 | 0.054789 | ||||||

| 183826.944 | 83975304.81 | 84192618.54 | 0.008951 | ||||||

| 23168.1139 | 32268566.2 | 37019037.26 | 0.006312 | ||||||

| 161849.3282 | 63441911.78 | 89990616.19 | 0.051325 | ||||||

| 68575.0155 | 15410153.83 | 23955106.64 | 0.183462 | ||||||

| 700132.5177 | 84802630.59 | 146100301.7 | 0.014438 | ||||||

| 10924.6678 | 25872441.34 | 59375197.87 | 0.980368 | ||||||

| 2035936.961 | 27966274.04 | 60012916.32 | 0.712886 | ||||||

| 63691.6807 | 47025205.4 | 86269872.22 | 0.015279 | ||||||

| 26881.2829 | 50777884.7 | 53066298.79 | 0.030402 | ||||||

| 12684.9635 | 49539268.61 | 39005228.58 | 0.006194 | ||||||

| 258.5803 | 81457080 | 89695566.21 | 0.00645 | ||||||

| 114156.6272 | 124722964.4 | 136206346.7 | 0.008589 | ||||||

| 562737.8609 | 279534496.5 | 382487753.7 | 0.003482 | ||||||

| 68655.8619 | 16639027.43 | 11126103.64 | 0.013292 | ||||||

| 1919490.334 | 12013111.99 | 16806188.55 | 0.027218 | ||||||

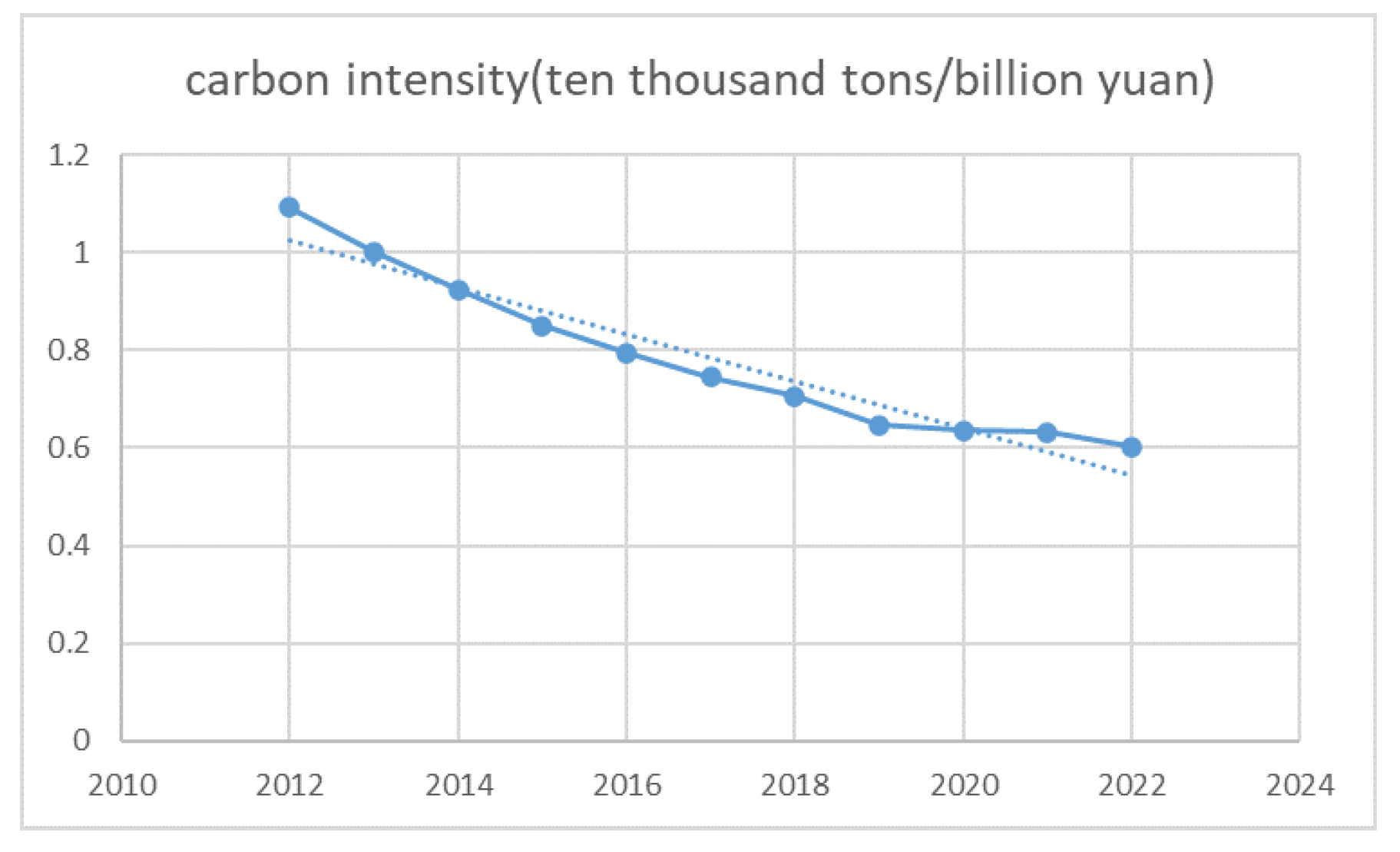

| year | Carbon emissions (million tons CO2e) | GDP(billion dollars) | Carbon emission intensity (tons/billion dollars) |

| 2012 | 62253.41 | 57007.7 | 1.092018 |

| 2013 | 62637.52 | 62503.4 | 1.002146 |

| 2014 | 63078.54 | 68173 | 0.925272 |

| 2015 | 63485.74 | 74732.4 | 0.849508 |

| 2016 | 65295.89 | 82163.2 | 0.79471 |

| 2017 | 68253.42 | 91648.7 | 0.744729 |

| 2018 | 70549.51 | 99945.2 | 0.705882 |

| 2019 | 69855.48 | 107987 | 0.646888 |

| 2020 | 70717.62 | 111152 | 0.636224 |

References

- Raymond Murphy, What is undermining climate change mitigation? How fossil-fuelled practices challenge low-carbon transitions, Energy Research & Social Science, Volume 108,2024,103390,ISSN 2214-6296,https://doi.org/10.1016/j.erss.2023.103390.

- IEA (2024), CO2 Emissions in 2023, IEA, Paris https://www.iea.org/reports/co2-emissions-in-2023,Licence: CC BY 4.0.

- 2024; 95, 3. Yuhong Tang, Qi Zhao, Yuheng Ren, Nexus among government digital development, resource dependence, and carbon emissions in China,Resources Policy, Volume 95, 2024, 105186, ISSN 0301-4207,https://doi.org/10.1016/j.resourpol.2024.105186. [CrossRef]

- Shanyong Wang, Rongwei Zhang, Yejun Yang, Jiusong Chen, Shu Yang, Has enterprise digital transformation facilitated the carbon performance in Industry 4.0 era? Evidence from Chinese industrial enterprises, Computers & Industrial Engineering, Volume 184, 2023, 109576, ISSN 0360-8352, https://doi.org/10.1016/j.cie.2023.109576.

- 2050; 5. Guangyue Xu, Haoyun Dong, Zhenci Xu, Nishan Bhattarai, China can reach carbon neutrality before 2050 by improving economic development quality, Energy, Volume 243,2022,123087,ISSN 0360-5442,https://doi.org/10.1016/j.energy.2021.123087. [CrossRef]

- The State Council of China, ACTION PLAN FOR CARBON DIOXIDE PEAKING BEFORE 2030[EB/OL](2021-10-24) [2025-3-28], https://en.ndrc.gov.cn/policies/202110/t20211027_1301020.html.

- Cui Huiming,Chen Lin. “Intelligent manufacturing in the strategy of ”Made in China 2025"[J]. Science and Technology Economy Market 2022,(04):7-9.

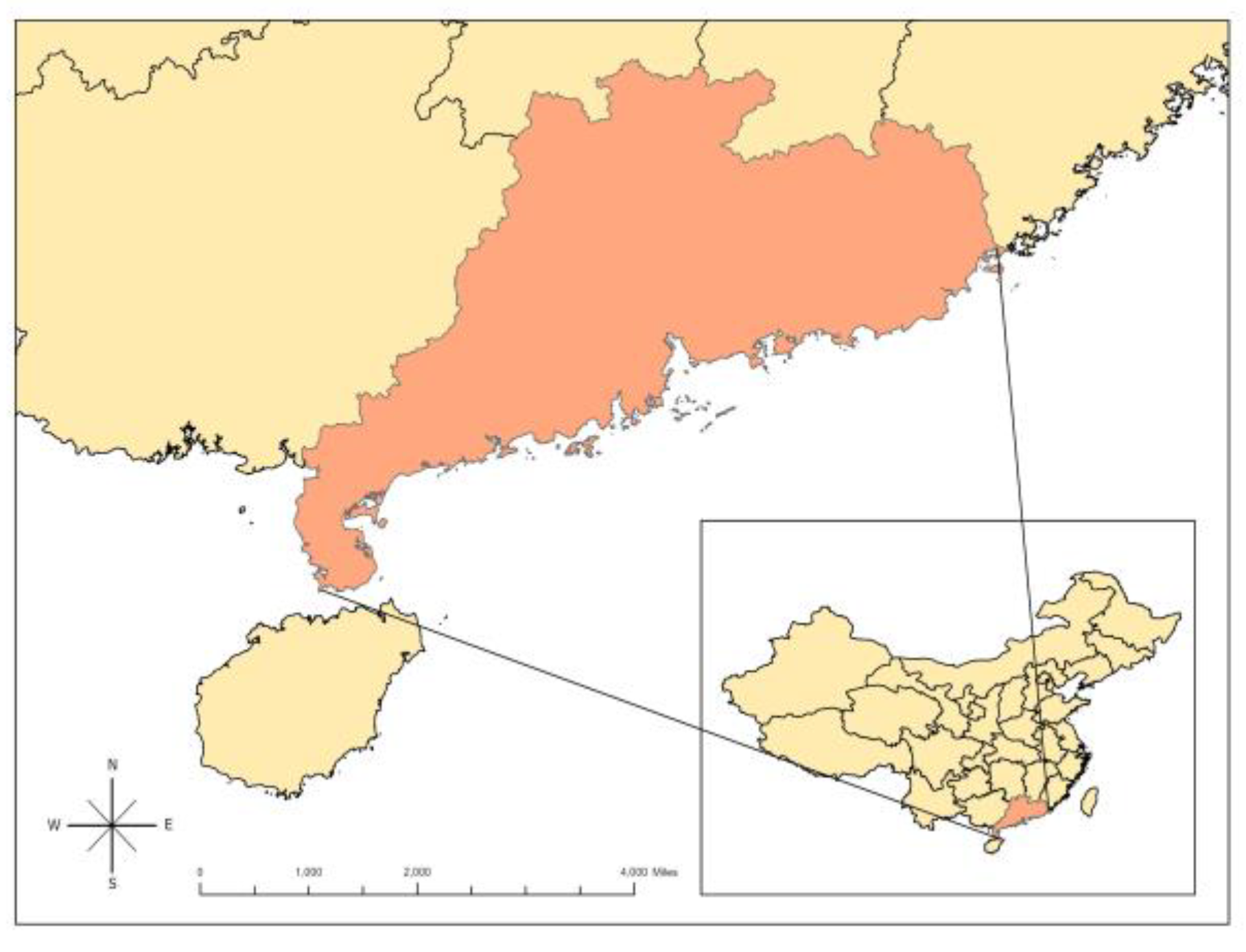

- Guangdong Provincial Bureau of Statistics Guangdong Province Fifth National Economic Census Leading Group Office. Bulletin of the Fifth National Economic Census of Guangdong Province (No. 1) [N]. Nanfang Daily, 2025-03-13(A07).

- Li Tianren, Huang Sufeng, Does digital-industrial technology integration reduce corporate carbon emissions?, Environmental Research, Volume 257,2024,119313,ISSN 0013-9351,https://doi.org/10.1016/j.envres.2024.119313.

- A: Guo, Tao Li, Bowen Shi, Hongchao Zhang, Economic impacts and carbon emissions of electric vehicles roll-out towards 2025 goal of China, 2025; 31, 10. Zhiwei Guo, Tao Li, Bowen Shi, Hongchao Zhang, Economic impacts and carbon emissions of electric vehicles roll-out towards 2025 goal of China: An integrated input-output and computable general equilibrium study, Sustainable Production and Consumption, Volume 31, 2022,Pages 165-174,ISSN 2352-5509,https://doi.org/10.1016/j.spc.2022.02.009. [CrossRef]

- WU Fei, HU Huizhi, LIN Huiyan, et al. Corporate digital transformation and capital market performance - Empirical evidence from stock liquidity[J]. Management World 2021,37(7):130-144. DOI:10.3969/j.issn.1002-5502.2021.07.010.

- LI Yingmei, JIAO Wanru, YANG Zhonghai. Enterprise digital transformation and auditor risk decision making[J]. Finance and Accounting Monthly 2023,44(19):111-119. DOI:10.19641/j.cnki.42-1290/f.2023.19.015.

- ZHOU Jinghua, HE Wanhong, LIU Jiayu. The Construction Path of Modernized Industrial System in Guangdong[J]. Sichuan Province ,2025,(01):56-58.

- Huang Lichun. Research on the Path of Digital Transformation and Development of Guangdong Manufacturing Cluster[J]. Science, Technology and Finance.2024,(07):13-19.

- Jingke Hong, He Huang, Xianzhu Wang, Bertie Dockerill, Jiexu Ye, Shihan Zhang, Structural effects of provincial digital economy on carbon emissions within China: A multi-region input-output based structural decomposition analysis, Science of The Total Environment, Volume 934,2024,173140,ISSN 0048-9697,https://doi.org/10.1016/j.scitotenv.2024.173140.

- Zhiwei Guo, Tao Li, Bowen Shi, Hongchao Zhang, Economic impacts and carbon emissions of electric vehicles roll-out towards 2025 goal of China: An integrated input-output and computable general equilibrium study, Sustainable Production and Consumption, Volume 31, 2022, Pages 165-174, ISSN 2352-5509,https://doi.org/10.1016/j.spc.2022.02.009.

- Yuanjie Li, Na Li, Zibiao Li, Evolution of carbon emissions in China’s digital economy: An empirical analysis from an entire industry chain perspective, Journal of Cleaner Production, Volume 414,2023,137419,ISSN 0959-6526,https://doi.org/10.1016/j.jclepro.2023.137419.

- Bin Dou, SongLin Guo, XiaoChen Chang, Yong Wang, Corporate digital transformation and labor structure upgrading, International Review of Financial Analysis, Volume 90, 2023, 102904, ISSN 1057-5219, https://doi.org/10.1016/j.irfa.2023.102904.

- Tingting Bai, Yong Qi, Zihao Li, Dong Xu, Digital economy, industrial transformation and upgrading, and spatial transfer of carbon emissions: The paths for low-carbon transformation of Chinese cities, Journal of Environmental Management, Volume 344, 2023, 118528, ISSN 0301-4797, https://doi.org/10.1016/j.jenvman.2023.118528.

- Minglong Zhang, Yin Liu, Influence of digital finance and green technology innovation on China’s carbon emission efficiency: Empirical analysis based on spatial metrology, Science of The Total Environment, Volume 838, Part 3, 2022, 156463, ISSN 0048-9697, https://doi.org/10.1016/j.scitotenv.2022.156463.

- China Academy of Information and Communications Technology, CHINA DIGITAL ECONOMY DEVELOPMENT WHITE PAPER[EB/OL] (2017-07-13)[2025-3-28], https://www.cac.gov.cn/files/pdf/baipishu/shuzijingjifazhan.pdf.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).