Submitted:

07 February 2025

Posted:

08 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction and Context

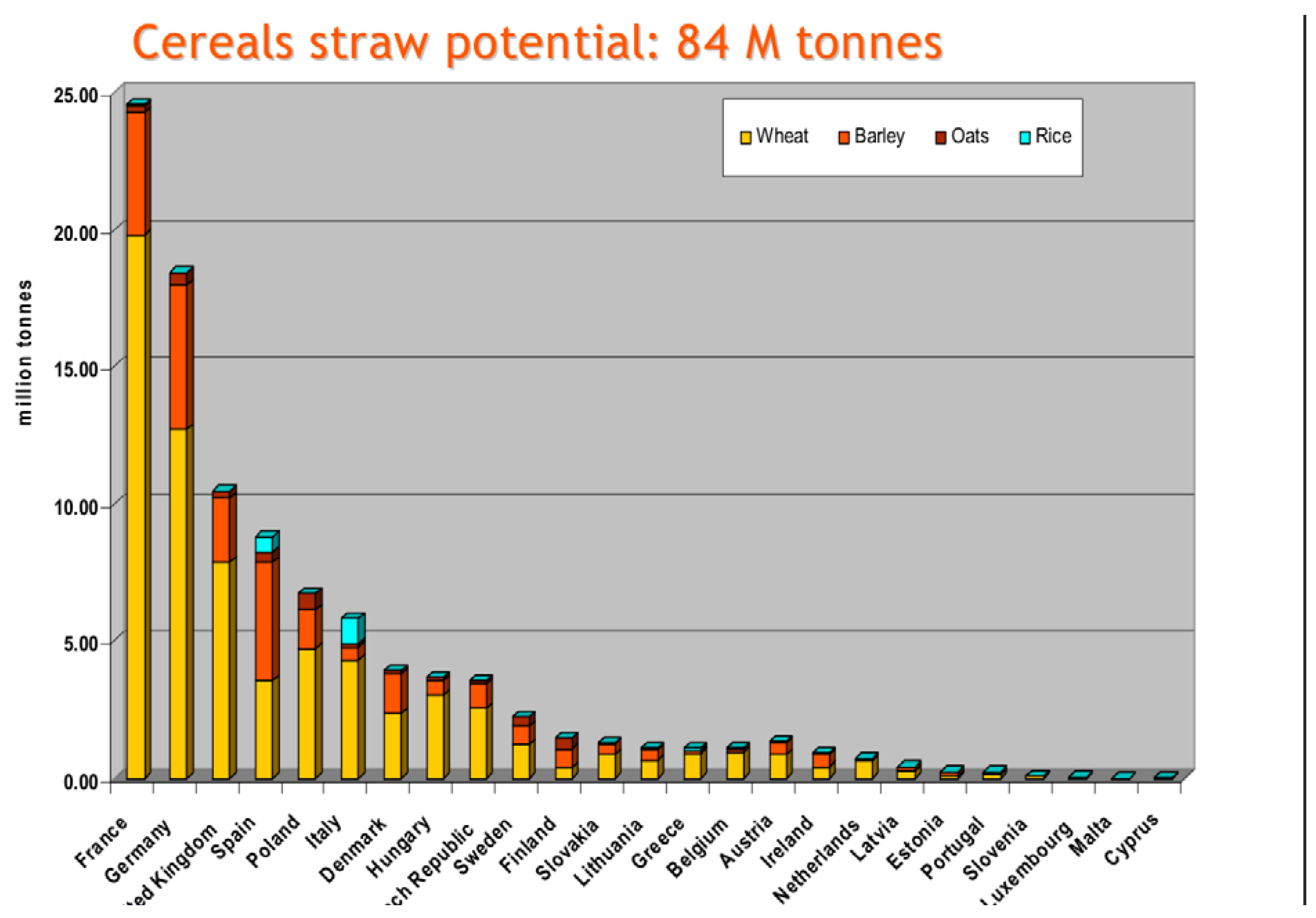

2. Material Substrate and Binders

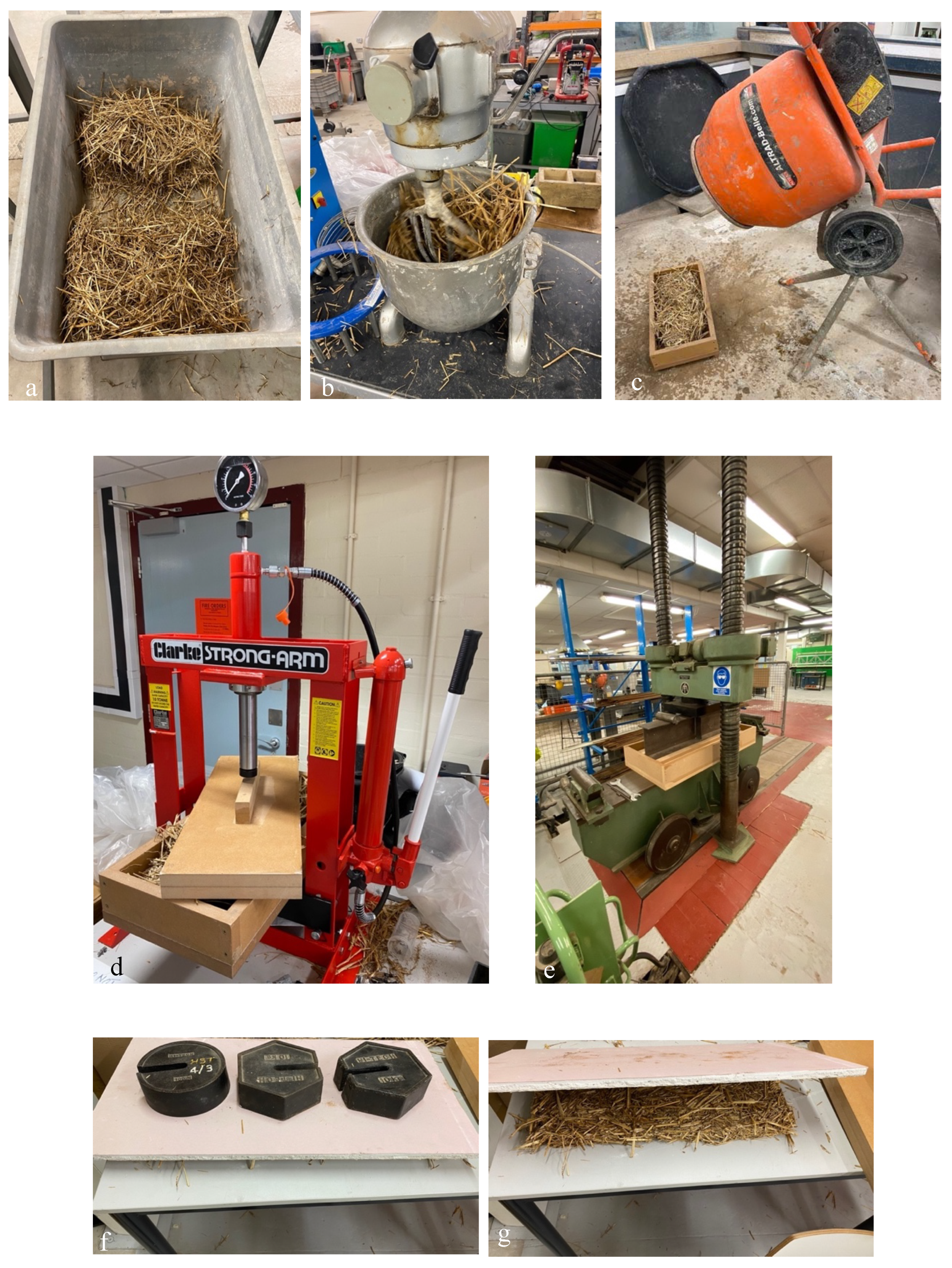

3. Manufacturing and Evaluation of Panel Assemblies

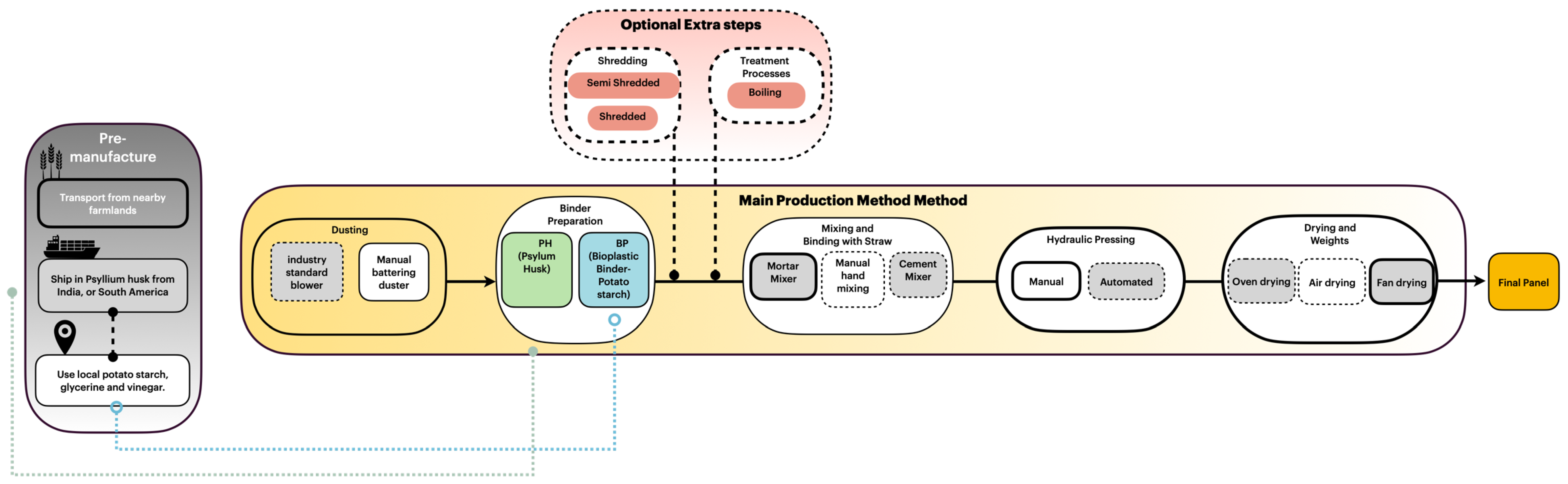

Hybrid Production Process

4. Results and Discussion

Heat-Flow Metres (Used Method)

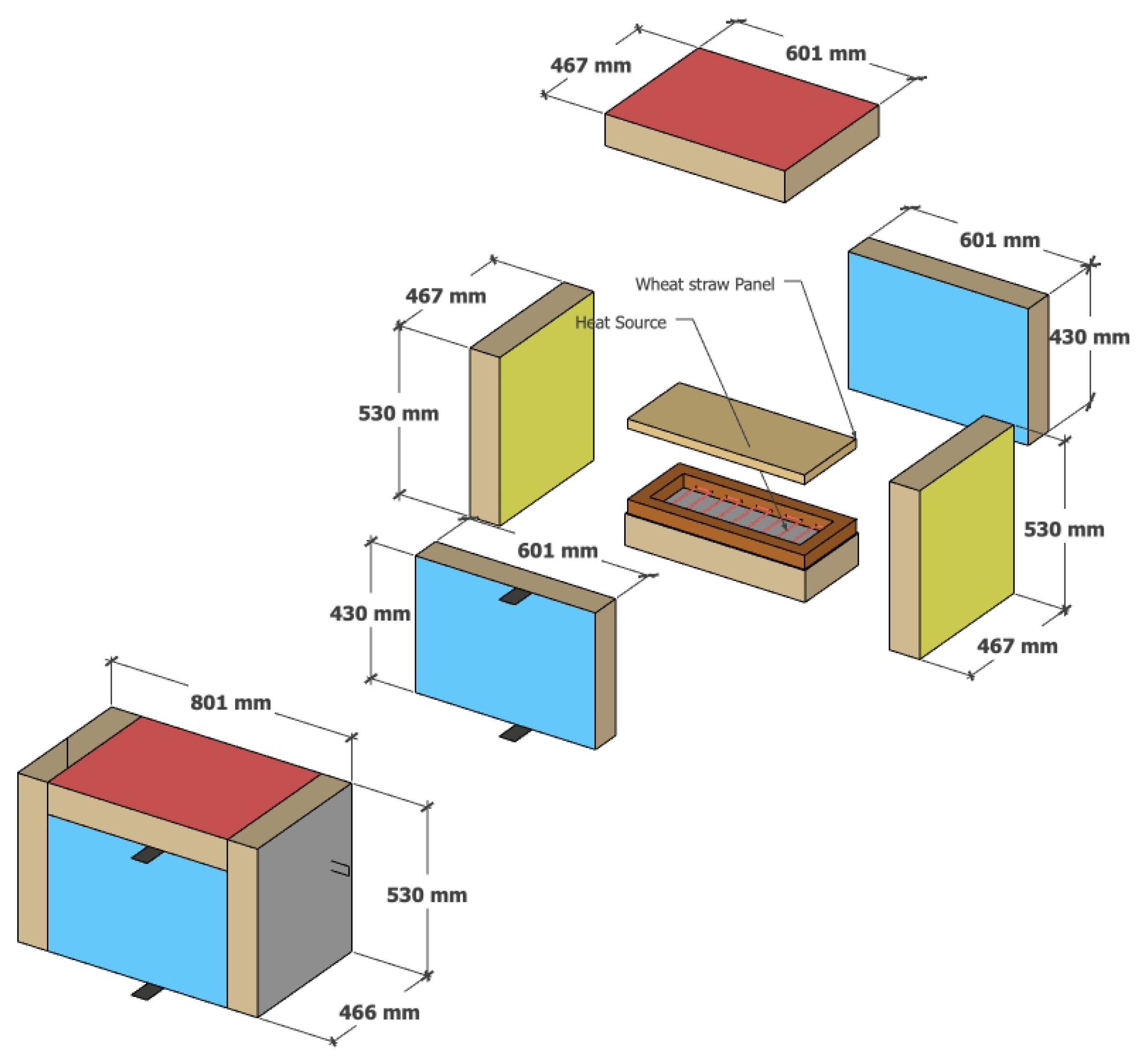

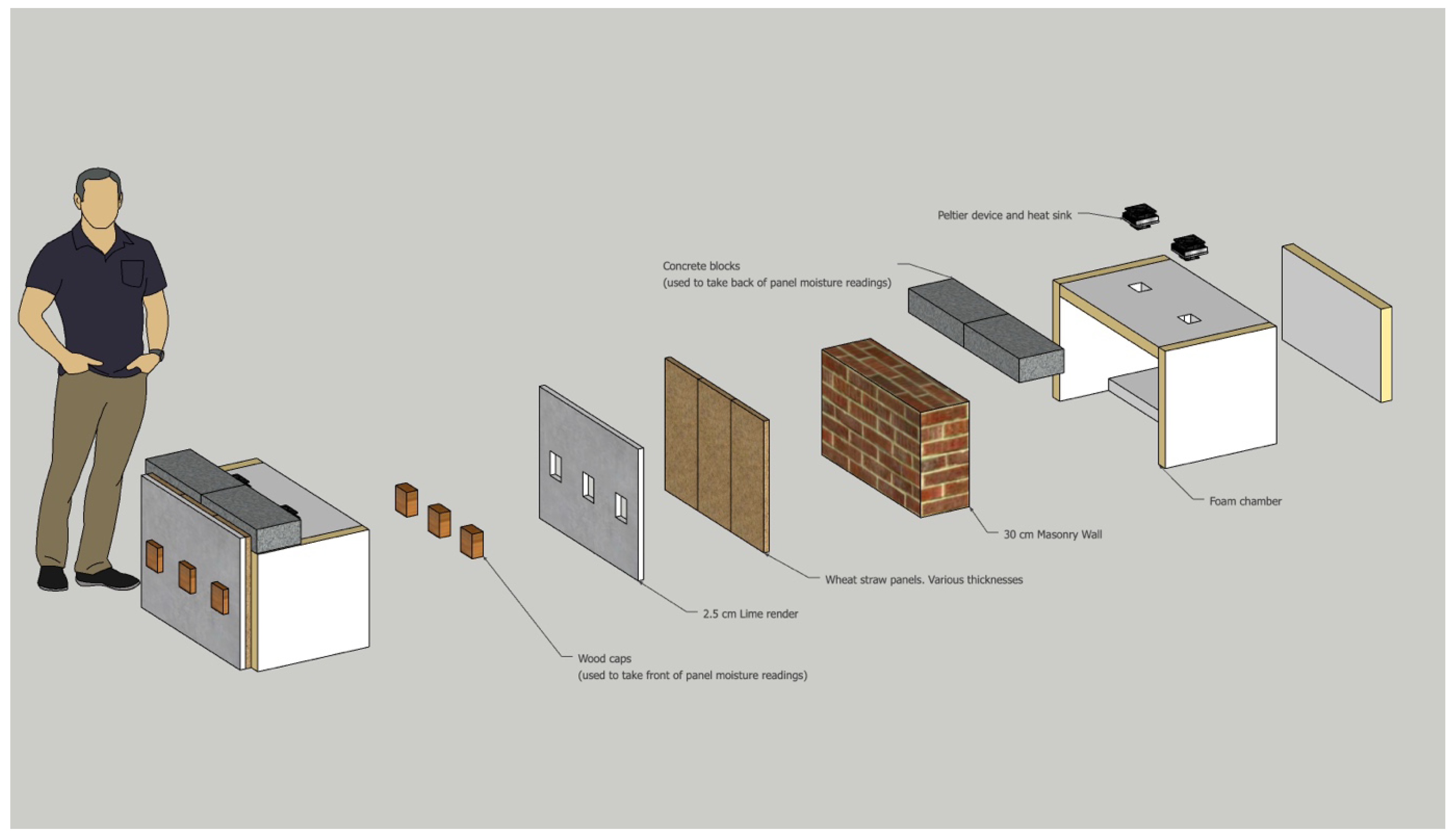

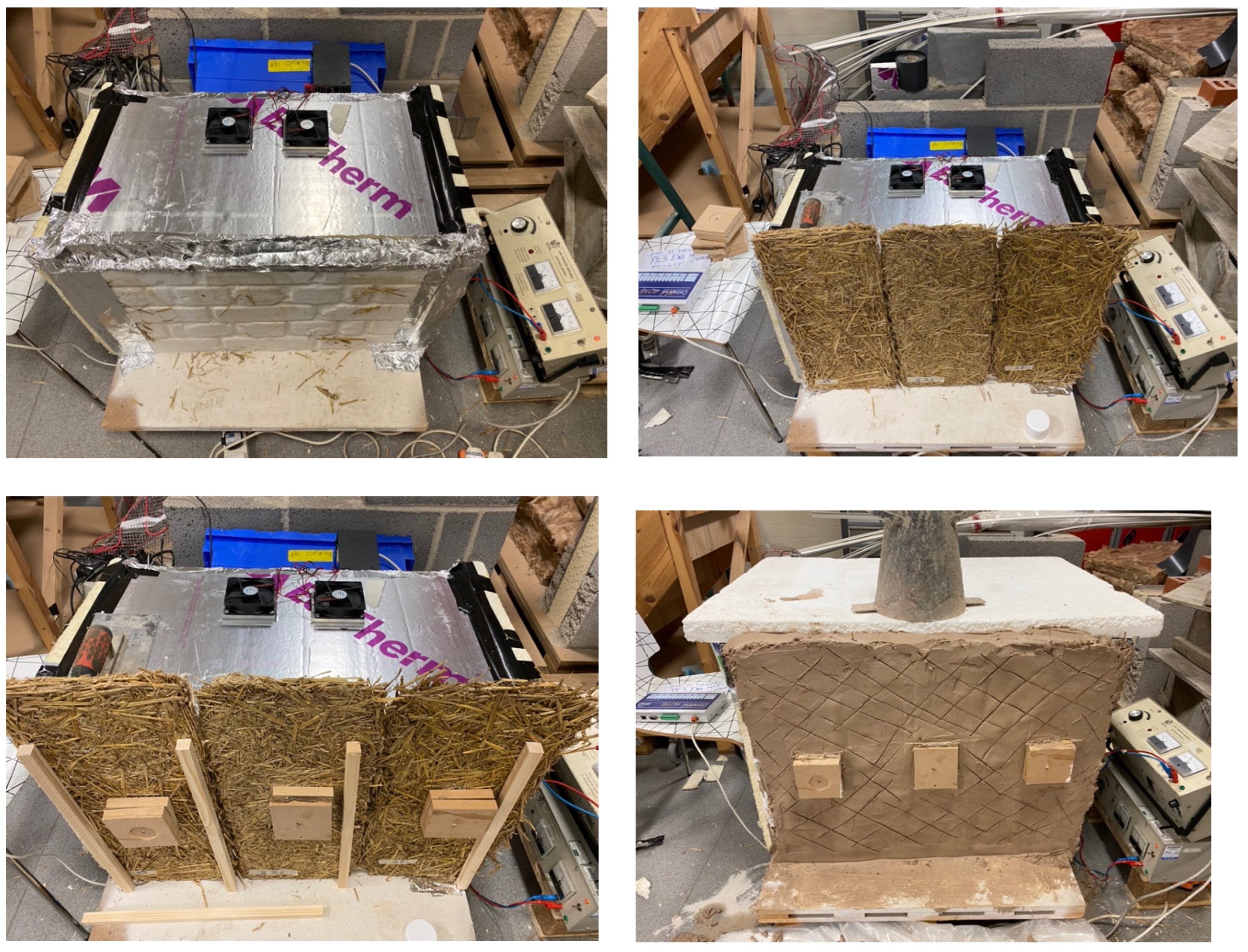

Calibrated Hotbox Design

Results of Pilot Test: Hotbox

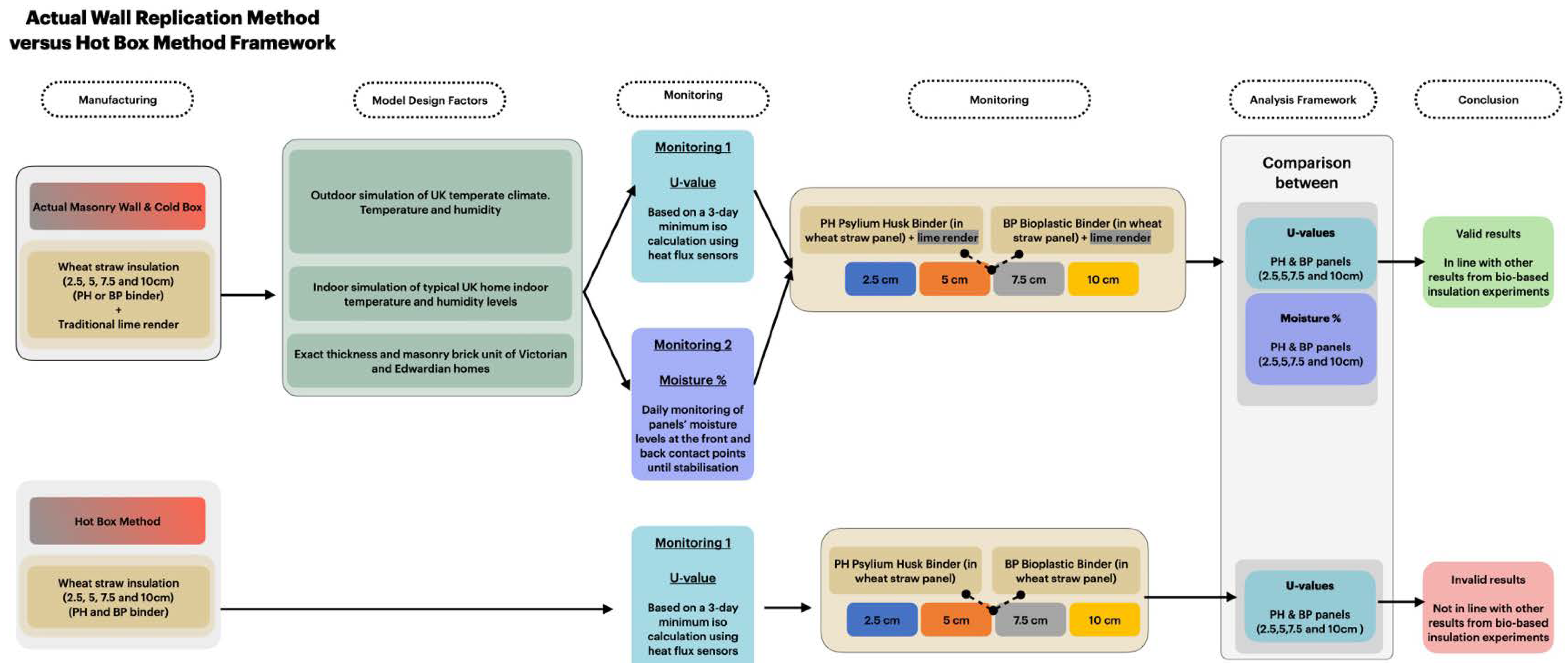

- Actual Wall Replication Method: Accurate thermal conductivity

- Design and build of the AWRM method

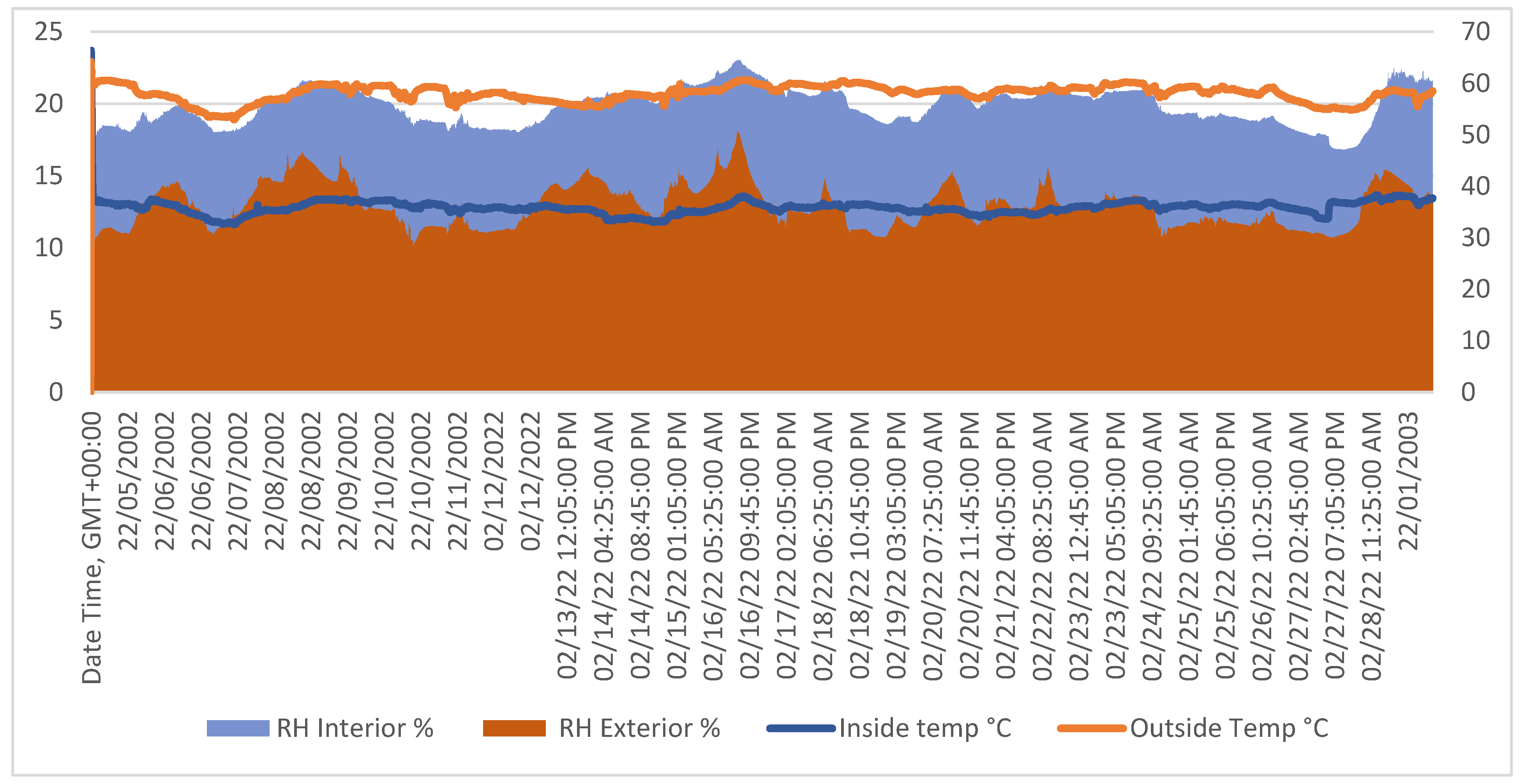

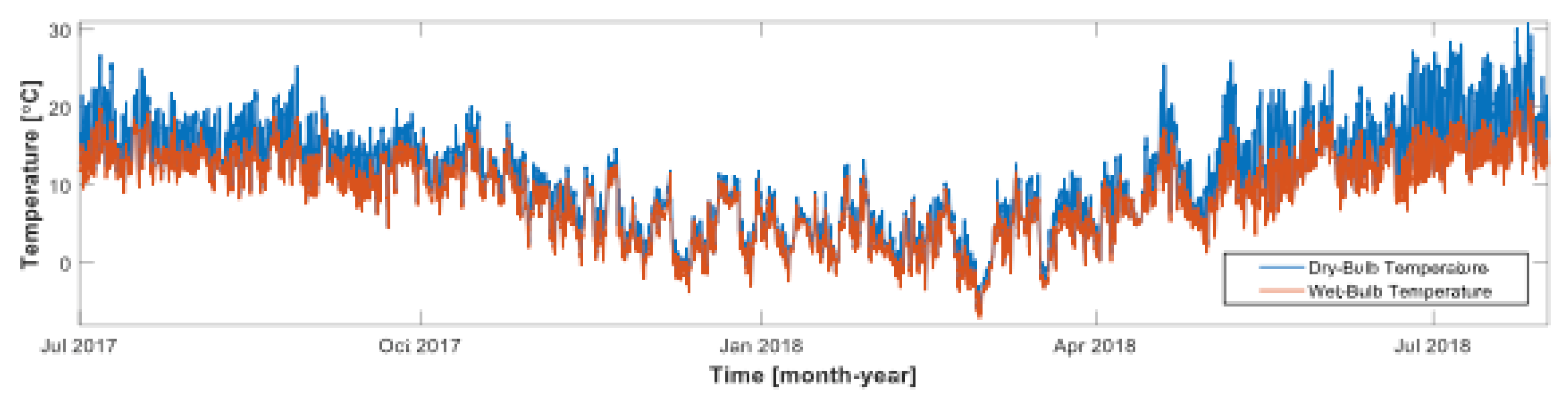

Replication of Site Conditions

| Temperature Cold chamber (Outdoor Conditions) °C | Temperature (Indoor Conditions) % | RH Cold chamber (Outdoor Conditions) % | RH Lab (Indoor Conditions) % | |

| Standard deviations | 0.5 | 0.6 | 3.7 | 4.2 |

| Maximum | 23.7 | 22.9 | 64.6 | 50.6 |

| Minimum | 11.6 | 18.9 | 29.8 | 28.4 |

| Averages | 12.8 | 20.7 | 55.6 | 36.2 |

AWRM Preliminary Results

Final AWRM Thermal Conductivity

| Hotbox Method | Actual Wall replication | |||||||

| PH binder panels (Psyllium husk) | BP binder panels (Bioplastic) | |||||||

| Wheat straw panel Thickness (cm) | Manually calculated total wall Thermal conductivity from Hotbox obtained Hotbox values(W/mK) | Panel Thermal conductivity, Hotbox (W/mK) | Manually calculated total wall Thermal conductivity from actual wall replication method (W/mK) | Panel Thermal conductivity from actual wall replication method (W/mK) | Density (Kg/m3) |

Potato wall Thermal conductivity (W/mK) |

Assumed potato panel Thermal conductivity (W/mK) |

Density (Kg/m3) |

| 2.5 | 1.036 | 0.6 | 0.57 | 0.025 | 133 | 0.66 | 0.033 | 146 |

| 5 | 0.986 | 0.55 | 0.27 | 0.017 | 186 | 0.31 | 0.0215 | 218 |

| 7.5 | 0.937 | 0.52 | 0.24 | 0.023 | 270 | 0.225 | 0.021 | 324 |

| 10 | 0.89 | 0.5 | 0.22 | 0.028 | 385 | 0.23 | 0.026 | 470 |

| PH binder panels (Psyllium husk) | BP binder panels (Bioplastic) | |||||

| Wheat straw panel Thickness (cm) |

Assumed wall Hotbox panel Thermal conductivity (W/mK) |

Wall Thermal conductivity, actual wall replication method (W/mK) | Ratio of Hotbox to AWRM experiment | Assumed wall Hotbox panel Thermal conductivity (W/mK) |

Potato wall Thermal conductivity (W/mK) |

Ratio of Hotbox to AWRM experiment |

| 2.5 | 1.036 | 0.57 | 1.82 | 1.036 | 0.66 | 1.57 |

| 5 | 0.986 | 0.27 | 3.65 | 0.986 | 0.31 | 3.18 |

| 7.5 | 0.937 | 0.24 | 3.90 | 0.937 | 0.225 | 4.16 |

| 10 | 0.89 | 0.22 | 4.05 | 0.89 | 0.23 | 3.87 |

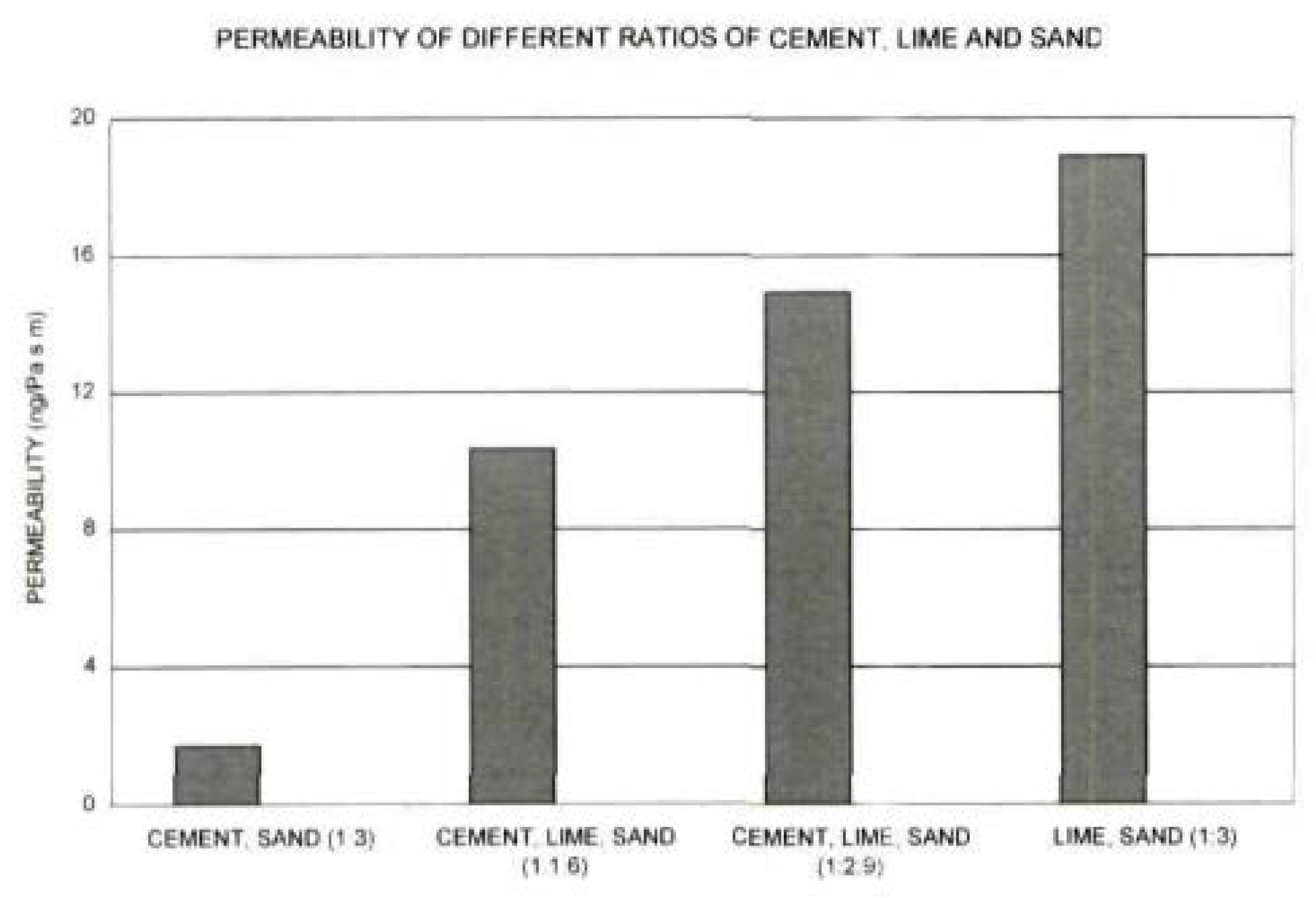

Resistance to Moisture

5. Discussion

- Significance of the Study

6. Conclusion

- Main Contributions and Impact

- 1.

- Innovative Materials: The research established wheat straw, an abundant agricultural waste product, as a viable substrate for insulation, offering an eco-friendly alternative to non-renewable materials.

- 2.

- Novel Methodologies: By developing the Actual Wall Replication Method (AWRM), this study set a precedent for more realistic performance evaluation of insulation panels, addressing the limitations of conventional testing techniques.

- 3.

- Heritage Compatibility: The proposed solution bridges the gap between environmental sustainability and the strict conservation requirements of heritage properties.

- Limitations and Future Directions

- Recommendations

- Enhancing Production Efficiency: Refining the hybrid production process for greater scalability and uniformity across manufacturing setups.

- Policy and Incentives: Engaging stakeholders to establish regulatory support, training, and subsidies for heritage retrofitting projects using sustainable materials.

- Material Optimisation: Exploring alternative binders with higher thermal and moisture performance while maintaining compostability and local availability.

References

- Abu-Bakar, H. , & Charnley, F. Developing a Strategic Methodology for Circular Economy Roadmapping: A Theoretical Framework. Sustainability 2024, 16, 6682. [Google Scholar] [CrossRef]

- Ahmad, A. , Maslehuddin, M., & Al-Hadhrami, L. M. In situ measurement of thermal transmittance and thermal resistance of hollow reinforced precast concrete walls. Energy and Buildings 2014, 84, 132–141. [Google Scholar]

- Alhawari, A. , Alhawari, A., & Mukhopadhyaya, P. Construction and Calibration of a Unique Hot Box Apparatus. Energies 2022, 15, 4677. [Google Scholar] [CrossRef]

- Ali, A. , Issa, A., & Elshaer, A. A Comprehensive Review and Recent Trends in Thermal Insulation Materials for Energy Conservation in Buildings. Sustainability 2024, 16, 8782. [Google Scholar] [CrossRef]

- Almusaed, A. , Almssad, A., Alasadi, A., Yitmen, I., & Al-Samaraee, S. Assessing the Role and Efficiency of Thermal Insulation by the “BIO-GREEN PANEL” in Enhancing Sustainability in a Built Environment. Sustainability (Switzerland) 2023, 15, 10418. [Google Scholar] [CrossRef]

- Alqadi, S., & Elnokaly, A. (2023). An Empirical Study of a Residential Building. In 20th International Conference on Sustainable Energy Technologies (p. 158).

- Asdrubali, F. , & Baldinelli, G. Thermal transmittance measurements with the hot box method: Calibration, experimental procedures, and uncertainty analyses of three different approaches. Energy and Buildings 2011, 43, 1618–1626. [Google Scholar] [CrossRef]

- Asdrubali, F. , D’Alessandro, F., & Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Ashour, T. , Wieland, H., Georg, H., Bockisch, F. J., & Wu, W. The influence of natural reinforcement fibres on insulation values of earth plaster for straw bale buildings. Materials and Design 2010, 31, 4676–4685. [Google Scholar] [CrossRef]

- Aviram, D. P. , Fried, A. N., & Roberts, J. J. Thermal properties of a variable cavity wall. Building and Environment 2001, 36, 1057–1072. [Google Scholar]

- Binici, H. , Eken, M., Dolaz, M., Aksogan, O., & Kara, M. An environmentally friendly thermal insulation material from sunflower stalk, textile waste and stubble fibres. Construction and Building Materials 2014, 51, 24–33. [Google Scholar] [CrossRef]

- Bovo, M. , Giani, N., Barbaresi, A., Mazzocchetti, L., Barbaresi, L., Giorgini, L., … Tassinari, P. Contribution to thermal and acoustic characterization of corn cob for bio-based building insulation applications. Energy and Buildings 2022, 262, 111994. [Google Scholar] [CrossRef]

- Carfrae, J., Wilde, P., Goodhew, S., Walker, P., & Littlewood, J. (2009). Detailing the effective use of rain-screens to protect walls made from straw bales in combination with hygroscopic, breathable finishes.

- Cesaratto, P. G. , De Carli, M., & Marinetti, S. Effect of different parameters on the in situ thermal conductance evaluation. Energy and Buildings 2011, 43, 1792–1801. [Google Scholar]

- Chougan, M., Ghaffar, S. H., Al-Kheetan, M. J., & Gecevicius, M. Wheat straw pre-treatments using eco-friendly strategies for enhancing the tensile properties of bio-based polylactic acid composites. Industrial Crops and Products 2020, 155. [CrossRef]

- CIBSE. (2015). Guide A Environmental design (2015, updated 2021).

- Climate Data. (2022). Climate in Nottingham, UK.

- Costes, J.-P. , Evrard, A., Biot, B., Keutgen, G., Daras, A., Dubois, S., … Courard, L. Thermal conductivity of straw bales: Full size measurements considering the direction of the heat flow. Buildings 2017, 7, 11. [Google Scholar] [CrossRef]

- Council, O. C. (2022). Keeping Your Home Free From Damp.

- Czajkowski, Ł. , Kocewicz, R., Weres, J., & Olek, W. Estimation of Thermal Properties of Straw-Based Insulating Panels. Materials 2022, 15, 1073. [Google Scholar] [CrossRef]

- Dore, C., Murrells, T., Passant, N., Hobson, M., Thistlethwaite, G., Wagner, a, … Hann, M. (2008). UK emissions of air pollutants 1970 to 2006. AEA Energy & …, (October), 194. Available online: http://uk-air.defra.gov.uk/reports/cat07/0810141045_2006_Report_Final_Version_ready_to_print.pdf.

- Elnokaly, A. , & Elseragy, A. (2011). Sustainable urban regeneration of historic city centres: lessons learnt.

- European Commission. (2011). COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS.

- Goodhew, S. , & Griffiths, R. Sustainable earth walls to meet the building regulations. Energy and Buildings 2005, 37, 451–459. [Google Scholar]

- GreenTEG. (2020). Instruction Manual for gSKIN® U-Value Kit, 1–7.

- Grilo, J. , Faria, P., Veiga, R., Santos Silva, A., Silva, V., & Velosa, A. New natural hydraulic lime mortars - Physical and microstructural properties in different curing conditions. Construction and Building Materials 2014, 54, 378–384. [Google Scholar] [CrossRef]

- Historic England. Energy efficiency and historic buildings: Insulating Solid Walls. Historic England 2016, 29, 16–17. [Google Scholar]

- Historic England. (2021). “Greening” Historic Homes Could Save up to 84% in Carbon Emissions. Historic England, 1–6. Available online: https://historicengland.org.uk/whats-new/news/greening-historic-homes/.

- ISO. (1994). ISO 9869:1994(en) Thermal insulation — Building elements — In-situ measurement of thermal resistance and thermal transmittance.

- ISO. (2019). BS ISO 8990:1994 Thermal insulation — Determination of steady-state thermal transmission properties — Calibrated and guarded hot box.

- Ji, Y. , Fitton, R., Swan, W., & Webster, P. Assessing overheating of the UK existing dwellings - A case study of replica Victorian end terrace house. Building and Environment 2014, 77, 1–11. [Google Scholar] [CrossRef]

- Jones, M. , Mautner, A., Luenco, S., Bismarck, A., & John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Materials and Design 2020, 187, 108397. [Google Scholar] [CrossRef]

- Kumfu, S., & Jintakosol, T. (2012). Thermal insulation produced from pineapple leaf fiber and natural rubber latex. In Advanced Materials Research (Vol. 506, pp. 453–456).

- Kus, H. , Özkan, E., Göcer, Ö., & Edis, E. Hot box measurements of pumice aggregate concrete hollow block walls. Construction and Building Materials 2013, 38, 837–845. [Google Scholar]

- Lawrence, M. , Heath, A. , & Walker, P. THE IMPACT OF EXTERNAL FINISHES ON THE WEATHER RESISTANCE OF STRAW BALE WALLS 2008, 161, 87–98. [Google Scholar]

- Lechtenböhmer, S. , & Schüring, A. The potential for large-scale savings from insulating residential buildings in the EU. Energy Efficiency 2011, 4, 257–270. [Google Scholar]

- Lopez Hurtado, P. , Rouilly, A., Vandenbossche, V., & Raynaud, C. A review on the properties of cellulose fibre insulation. Building and Environment 2016, 96, 170–177. [Google Scholar] [CrossRef]

- Met Office. (2022). Climate in Nottingham 2017-2022. Available online: https://www.metoffice.gov.uk/weather/forecast/gcrjp3v96#?date=2023-04-05.

- Milutiene, E. , Staniškis, J. K., Kručius, A., Auguliene, V., & Ardickas, D. Increase in buildings sustainability by using renewable materials and energy. Clean Technologies and Environmental Policy 2012, 14, 1075–1084. [Google Scholar]

- Mohammed, A. M. , Elnokaly, A., & Aly, A. M. M. Empirical investigation to explore potential gains from the amalgamation of phase changing materials (PCMs) and wood shavings. Energy and Built Environment 2021, 2, 315–326. [Google Scholar]

- Moncada, L. G. G., Asdrubali, F., & Rotili, A. (2013). Influence of new fac tors on global energy prospects in the medium term: compar ison among the 2010, 2011 and 2012 editions of the IEA’s World Energy Outlook reports. Economics and Policy of Energy and the Environment 2013.

- Nardi, I., Paoletti, D., Ambrosini, D., De Rubeis, T., & Sfarra, S. Validation of quantitative IR thermography for estimating the U-value by a hot box apparatus. Journal of Physics: Conference Series, 2015; 655. [CrossRef]

- Pacheco-Torgal, F. Eco-efficient construction and building materials research under the EU Framework Programme Horizon 2020. Construction and Building Materials 2014, 51, 151–162. [Google Scholar] [CrossRef]

- Palladino, D. , Scrucca, F., Calabrese, N., Barberio, G., & Ingrao, C. (2021). Durum-Wheat Straw Bales for Thermal Insulation of Buildings : Findings from a Comparative Energy Analysis of a Set of Wall-Composition Samples on the Building Scale.

- Peng, C. , & Wu, Z. In situ measuring and evaluating the thermal resistance of building construction. Energy and Buildings 2008, 40, 2076–2082. [Google Scholar]

- Peters, B., Sharag-Eldin, A., & Callaghan, B. (2017). Development of a simple hot box to determine the thermal characteristics of three-dimensional printed bricks, 2017. Architecture of Complexity: Design, Systems, Society, and the Environment (2017 ARCC), (June), 457–466. Available online: https://www.brikbase.org/sites/default/files/ARCC2017_Session4B_Peters_Sharag-Eldin_Callaghan.pdf%0Ahttps://www.brikbase.org/sites/default/files/ARCC2017_Session4B_Peters_Sharag-Eldin_Callaghan.pdf%0Ahttps://www.brikbase.org/sites/default/files/ARCC2017_S.

- Potton, E., & Hinson, S. (2020). Housing and Net Zero, (8830), 3. Available online: https://researchbriefings.files.parliament.uk/documents/CBP-8830/CBP-8830.pdf.

- Pruteanu, M. Investigations regarding the thermal conductivity of straw. Buletinul Institutului Politehnic Din Lasi. Sectia Constructii, Arhitectura 2010, 56, 9. [Google Scholar]

- Robinson, J. A. 2014. Quantifying and evaluating the risk posed to straw bale constructions from moisture, (February), 35–44. Available online: http://irep.ntu.ac.uk:80/R/?func=dbin-jump-full&object_id=218939.

- Romero Quidel, G. , Soto Acuña, M. J., Rojas Herrera, C. J., Rodríguez Neira, K., & Cárdenas-Ramírez, J. P. Assessment of Modular Construction System Made with Low Environmental Impact Construction Materials for Achieving Sustainable Housing Projects. Sustainability 2023, 15, 8386. [Google Scholar] [CrossRef]

- Sala, J. M. , Urresti, A., Mart\’\in, K., Flores, I., & Apaolaza, A. Static and dynamic thermal characterisation of a hollow brick wall: Tests and numerical analysis. Energy and Buildings 2008, 40, 1513–1520. [Google Scholar]

- Salonen, T. , Fischer, H., & Korjenic, A. Chopped Straw as an Insulation Material: The Influence of Different Blow-In Technologies and Flame Retardants on Hygrothermal Properties. Buildings 2023, 13, 2555. [Google Scholar] [CrossRef]

- Sheweka, S. M. , & Elnokaly, A. (2016). Waste management and material recycle as a potential of sustainable building envelope for low income housing.

- Smith, S. 2016. Development of the Modified Hot Box: A Convective Heat Transfer Device for Measuring the Steady State and Transient Thermal Properties of Non-homogenous Building Materials, (December). Available online: https://tigerprints.clemson.edu/all_theses/2548/.

- Soto, M. , Rojas, C., & Cárdenas-Ramírez, J. P. Characterization of a Thermal Insulating Material Based on a Wheat Straw and Recycled Paper Cellulose to Be Applied in Buildings by Blowing Method. Sustainability (Switzerland) 2023, 15, 58. [Google Scholar] [CrossRef]

- Straube, J. Moisture Properties of Plaster and Stucco for Straw Bale Buildings. Research Highlight 2000, 4. [Google Scholar]

- Sun, R. C. , Salisbury, D., & Tomkinson, J. Chemical composition of lipophilic extractives released during the hot water treatment of wheat straw. Bioresource Technology 2003, 88, 95–101. [Google Scholar] [CrossRef]

- Tangjuank, S. Thermal insulation and physical properties of particleboards from pineapple leaves. International Journal of Physical Sciences 2011, 6, 4528–4532. [Google Scholar]

- Williamson, A. , & Finnegan, S. Sustainability in heritage buildings: Can we improve the sustainable development of existing buildings under approved document l? Sustainability (Switzerland) 2021, 13, 3620. [Google Scholar] [CrossRef]

| Hotbox Method | |||

| PH binder panels (psyllium husk) | |||

| Wheat straw panel thickness (cm) | Panel Thermal conductivity, hotbox (W/mK) | Manually calculated total wall Thermal conductivity from Hotbox obtained Hotbox values(W/mK) | Density (kg/m3) |

| 2.5 | 0.6 | 1.036 | 133 |

| 5 | 0.55 | 0.986 | 186 |

| 7.5 | 0.52 | 0.937 | 270 |

| 10 | 0.5 | 0.89 | 385 |

| Insulation Material Type | Product density (kg/m3) |

Thermal conductivity (W/ mK) | References |

|---|---|---|---|

| Cellulose fibre | 50 | 0.04 | (Lopez Hurtado et al., 2016) |

| Pineapple leaves | 178-232 | 0.035-0.045 | (Tangjuank, 2011} |

| Sunflower, sunflower stalks and cotton textile waste | 200 | 0.1642 | (Binici et al., 2014) |

| Sunflower, rape straw, sunflower bark, sunflower pith and a mix of sunflower pith and bark |

235-714 | 0.055-0.156 | (Jones et al., 2020) |

| Straw bales | 1 5 | 0.155 | (Palladino et al., 2021) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).