Submitted:

15 December 2025

Posted:

17 December 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

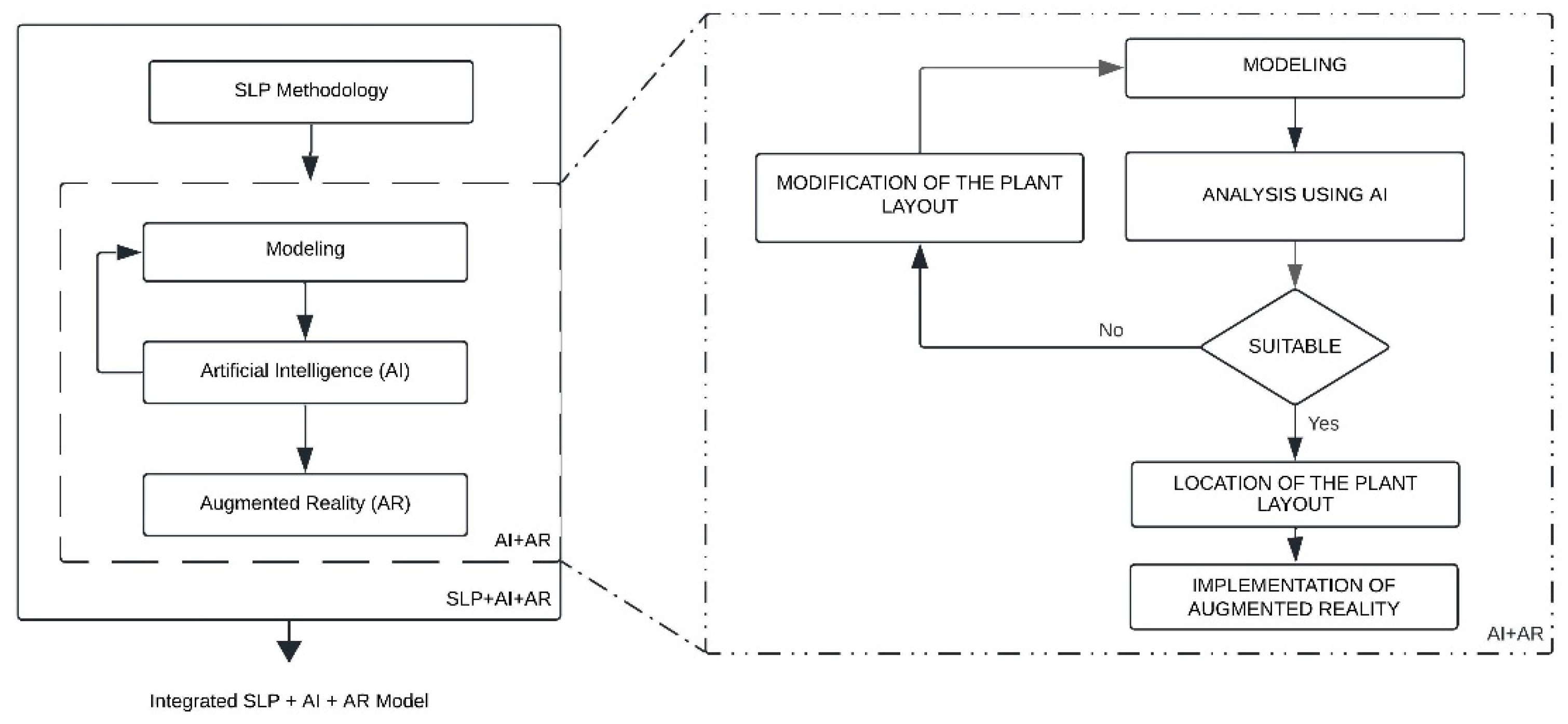

2. Materials and Methods

2.1. Procedure for Plant Design (Plant Layout)

- 1)

- Upload the top view of the plant layout, taken from [27].

- 2)

- Implement prompt and formulate questions to AI (Chat GPT 4.5).

- 1)

- Identification of a space with the appropriate dimensions, where the model was examined and evaluated through the implementation of AR.

- 2)

- Implementation of visualization systems using AR:

- ∙

- The three-dimensional model was converted to the .glb (Graphics Language Binary) extension. This transformation was performed by installing the ARexporter plugin in the SketchUp Web 2025 software (Trimble 2025). The resulting .glb file was transferred to Google Drive for later access and viewing. The mobile device used met the hardware requirements for AR viewing [28].

- ∙

- The model was viewed by opening the file in Google Drive, where the system offers the option of viewing through Google’s native viewer. This automatically generated a preview of the three-dimensional model in the browser. To activate the AR experience, the “view in your space” option was selected, allowing the virtual model to be projected and integrated into the desired physical environment, facilitating spatial evaluation and decision-making based on the immersive visualization of the proposed design.

2.2. Methodological Validation of AI and AR Integration in the Design of the Plant Layout

3. Results

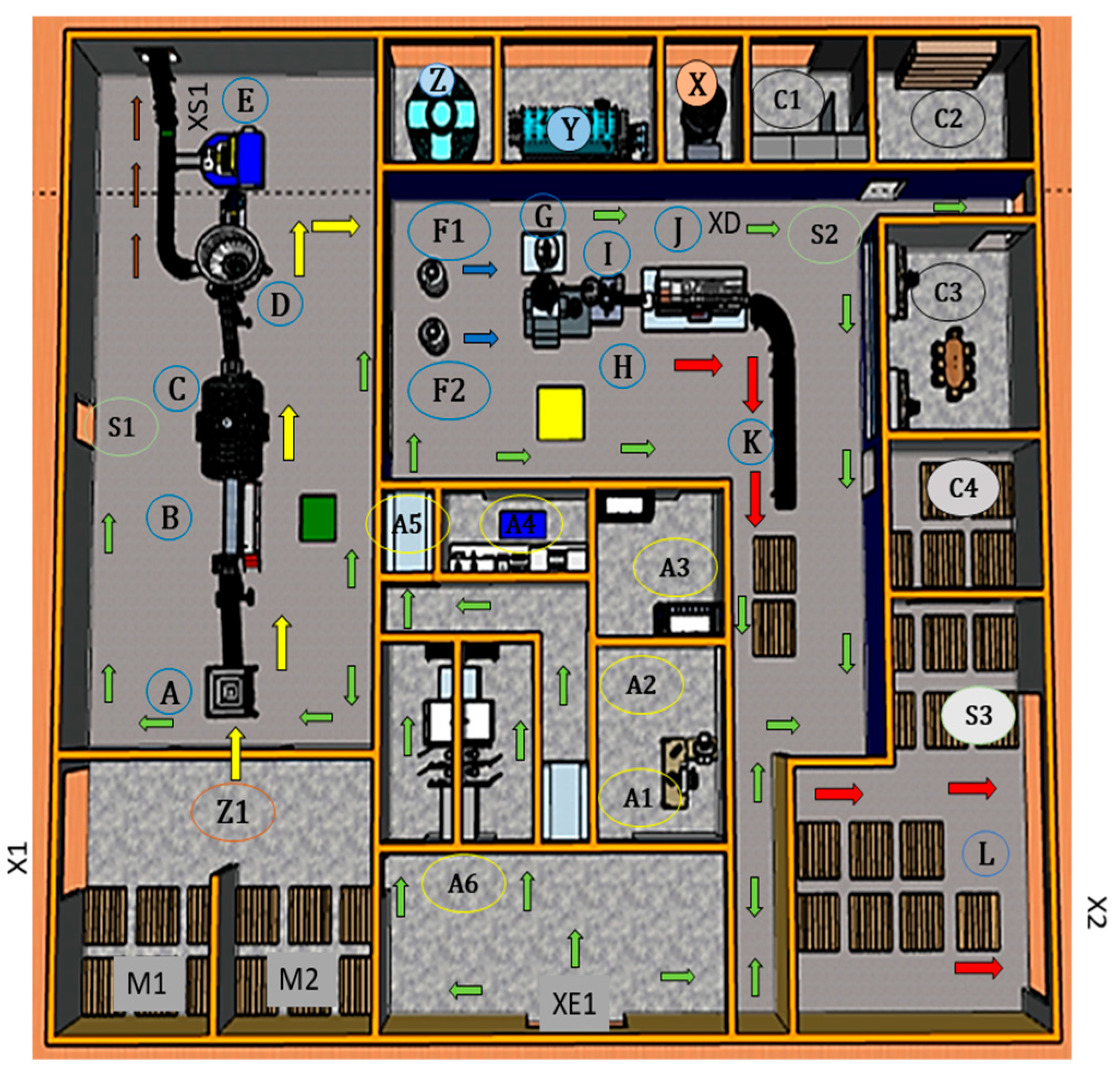

3.1. Obtaining the Ideal Model Through AI-Assisted Analysis

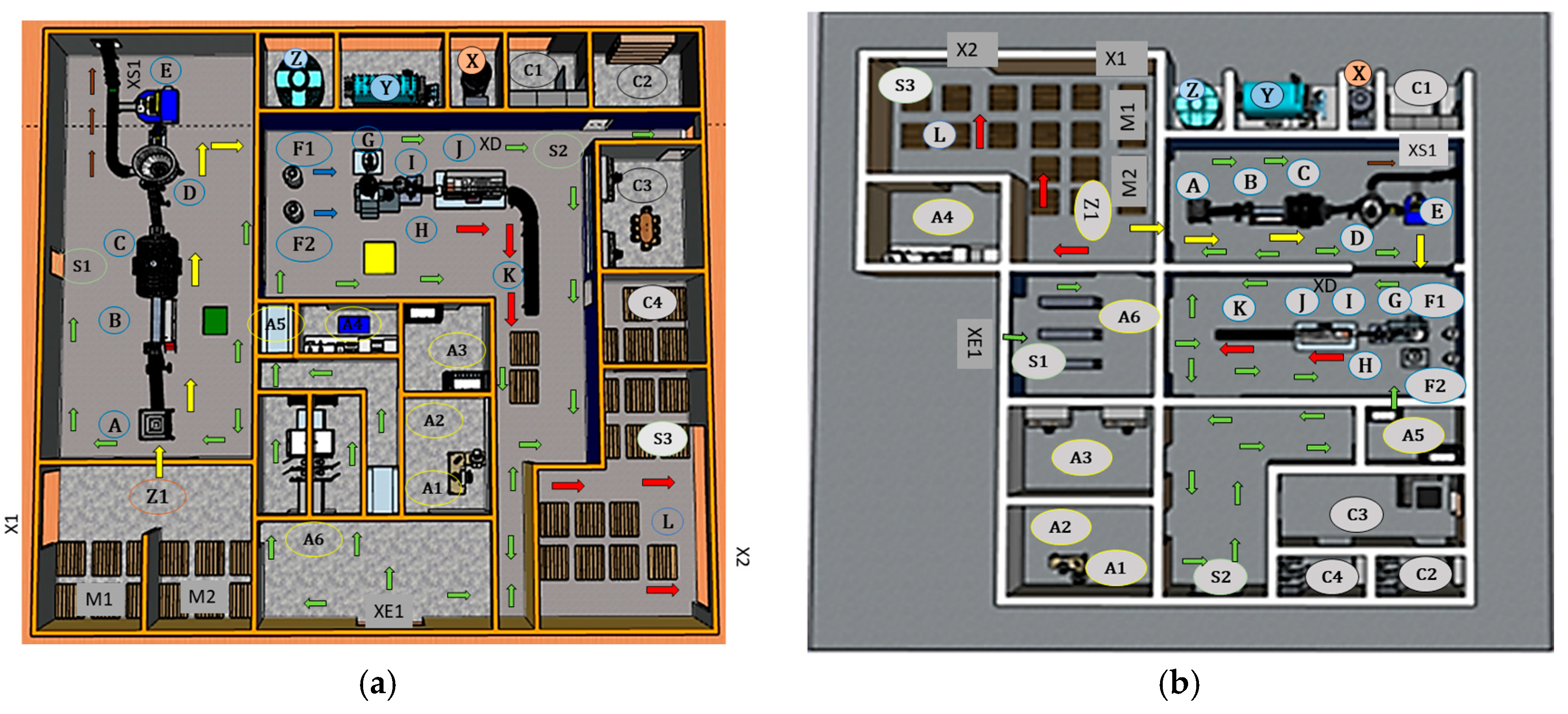

3.2. Final Plant Design After AI-Assisted Analysis

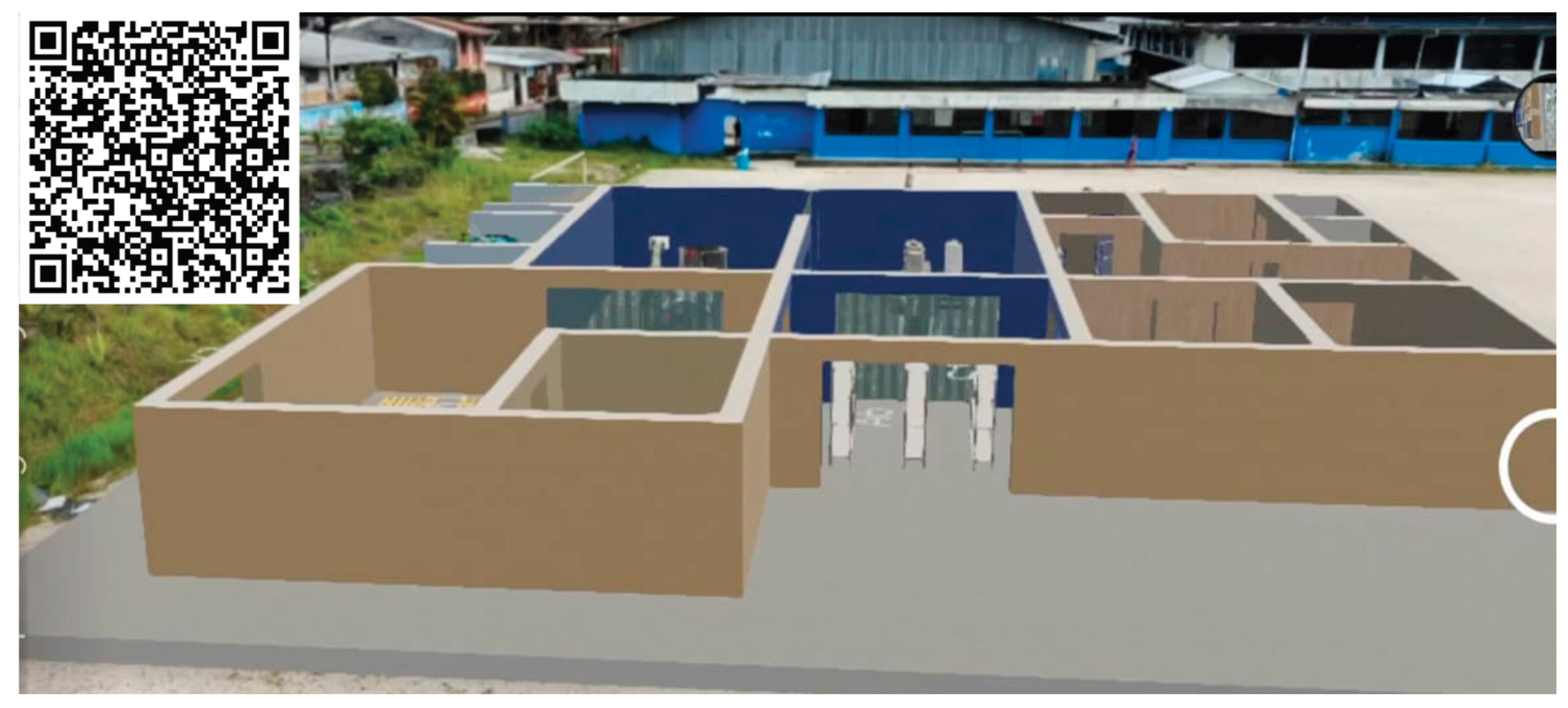

3.3. Spatial Evaluation of the Design: Static Verification and Immersive Validation in Augmented Reality

3.3.1. Plant Location

3.3.2. AR-Assisted Three-Dimensional Validation

4. Discussion

Integrated SLP + AI + AR

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chasipanta Baraja, A. J.; Corrales Bonilla, J. I. Perspectivas y desafíos en la industria 4.0 para el sector agroindustrial de La Maná. Revista Científica Multidisciplinar G-nerando 2023, 4. [Google Scholar] [CrossRef]

- Peñalver-Higuera, M. J.; Rodríguez-Alegre, L. R.; López-Padilla, R. D. P.; Isea-Argüelles, J. J. Ingeniería de prompts en la industria 4.0: Optimización y automatización inteligente de procesos industriales. Ingenium et Potentia 2025, 7, 35–49. [Google Scholar] [CrossRef]

- Gonzales-Zurita, O.; Rosero, R.; Llumiquinga, C.; Rosero, M. Diseño e implementación de una aplicación de realidad aumentada enfocada a mejorar la educación tecnológica. I+D Tecnológico 2023, 19. [Google Scholar] [CrossRef]

- Furlan, S. Industria 4.0 y cosmética: hacia una revolución en la gestión de competencias. MERCATEAM. 2024. Available online: https://merca.team/es/industrie-4-0-cosmetique-gestion-de-competencias/.

- Montalván-Vélez, C. L.; Mogrovejo-Zambrano, J. N.; Romero-Vitte, I. J.; Pinargote-Carrera, M. L. D. C. Introducción a la Inteligencia Artificial: Conceptos Básicos y Aplicaciones Cotidianas. Journal of Economic and Social Science Research 2024, 4, 173–183. [Google Scholar] [CrossRef]

- Pérez Fernández, C.; Espinosa Escudero; del M., M. La realidad aumentada como apoyo al diseño. Técnica Industrial 2022, 332, 40–48. [Google Scholar]

- Cuevas Magaña, J. J.; Najar Macías, D. G.; Cárdenas Magaña, J. A. Análisis Descriptivo de Aplicaciones de Realidad Aumentada en la Industria y Educación Técnica. Investigación y Ciencia Aplicada a la Ingeniería 2025, 8, 26–35. [Google Scholar]

- Medina Fonseca, D. F.; Lozano González, J. S.; Barbosa Rodríguez, R. A. Implementación de la Realidad Aumentada en la Logística de Bodegas Automatizadas. Revista Innovación y Desarrollo Sostenible 2023, 3, 21–28. [Google Scholar] [CrossRef]

- Fernández, F. Inteligencia Artificial En Acción: Transformando Nuestra Vida y Trabajo; Independently Published; 2024; vol. 1. [Google Scholar]

- Chen Cheng, C.; Chung, E.; Correa, N. La inteligencia Artificial y su Impacto en la Industria de la Ingeniería. REICIT 2023, 3, 26–40. [Google Scholar]

- Singh, M.; et al. Digital Twin: Origin to Future. Applied System Innovation 2021, 4, 36. [Google Scholar] [CrossRef]

- Bustamante-Limones, A.; Rodriguez-Borges, C.; Pérez-Rodriguez, J. A. Evaluación del uso de gemelos digitales en los sistemas de producción. AiBi Revista de Investigación, Administración e Ingeniería 2024, 12, 195–204. [Google Scholar] [CrossRef]

- Bacca-Acosta, J.; Beltrán-Sánchez, K. Co-diseño y co-creación de experiencias de realidad aumentada: una revisión sistemática de la literatura. Revista científica 2024, 49, 99–124. [Google Scholar]

- Aguilar Larrarte, E. M.; Vivas Alban, O. A.; Sabater Navarro, J. M. Una aproximación a la realidad aumentada y sus aplicaciones quirúrgicas. Entre Ciencia e Ingeniería 2018, 12, 15–24. [Google Scholar] [CrossRef]

- Salgado Reveles, M. A. The effects of virtual and augmented reality on attitudes towards science in Mexican primary school students. Paakat: Revista de Tecnología y Sociedad 2023, 13, 1–30. [Google Scholar]

- Martínez-Manso, H.; Delgado-Fernández, T. Arquitectura básica de diseño de gemelos digitales para la construcción. Revista de Investigación, Desarrollo e Innovación 2022, 12, 327–336. [Google Scholar]

- Stern, C. Tech Talk Q&A: Why virtual twins are the next big step for cosmetics and personal care manufacturers and suppliers. In CosmeticsDesign USA; 2025. [Google Scholar]

- ADÉX. Digital Twin – The Future of the Cosmetic Industry; 2023. [Google Scholar]

- Basetwo. Digital Twins for Optimized Cosmetic Emulsion Processes. 2025. Available online: https://www.basetwo.ai/blogs/digital-twins-for-optimized-cosmetic-emulsion-processes.

- Kilari, S. D. Use Artificial Intelligence into Facility Design and Layout Planning Work in Manufacturing Facility. European Journal of Artificial Intelligence and Machine Learning 2025, 4, 27–30. [Google Scholar] [CrossRef]

- Reed, Ruddell. Plant Layout: Factors, Principles, and Techniques; R. D. Irwin, USA: Homewood, Illinois, 1961. [Google Scholar]

- Muther, R. Planificación y Proyección de La Empresa Industrial: (Método S.P.L., Sistematic Layout Planning); Richard Muther & Associates, Inc.: Barcelona, España, 1968. [Google Scholar]

- Arango-Serna, M. D.; Zapata, J.; Cáceres-Gelvez, S. Sistemas Prácticos Para El Diseño Del Layout de Plantas Industriales Con Celdas de Manufactura; Universidad Nacional de Colombia: Facultad de Minas, Departamento de Ingeniería de la Organización, Medellín, Colombia, 2024. [Google Scholar] [CrossRef]

- García-Mujica, R.; Benavides-Cedeño, G. Diseño de una planta a escala industrial para la elaboración de ácido láctico mediante fermentación líquida. Revista Científica INGENIAR: Ingeniería, Tecnología e Investigación 2020, 3, 25–34. [Google Scholar]

- Ortiz-Campo, G.; Javier-Sánchez, H.; Ipatia-Moreno, G.; Fabian-Heredia, I.; Sebastián-Sánchez, C. Diseño de una planta de acabados textiles para la optimización de sus procesos químicos, mediante el uso de diagramas bpd, pfd y disposición layout. Polo del Conocimiento 2022, 7, 42–71. [Google Scholar]

- Hu, F.; Wang, C.; Wu, X. Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm. Applied Sciences 2025, 15, 5697. [Google Scholar] [CrossRef]

- Scalvenzi, L.; et al. The Design of an Intensified Process and Production Plant for Cosmetic Emulsions Using Amazonian Oils. Processes 2025, 13, 1923. [Google Scholar] [CrossRef]

- Augmented Reality for Enterprise Alliance. AR Hardware Requirements: Inputs / Outputs: Sensors – Augmented. 2025. Available online: https://thearea.org/ar_requirement/ar-hardware-requirements-inputs-outputs-sensors-augmented/.

- Zhuang, E. Process location decisions; 2016. [Google Scholar]

- Voinea, G.-D.; Gîrbacia, F.; Duguleană, M.; Boboc, R. G.; Gheorghe, C. Mapping the Emergent Trends in Industrial Augmented Reality. Electronics (Basel) 2023, 12, 1719. [Google Scholar]

- Tompkins, J. A.; White, J. A.; Bozer, Y. A.; Tanchoco, J. M. A. Facilities Planning; Wiley, 2010. [Google Scholar]

- Disselkamp, J.-P.; Schütte, B.; Dumitrescu, R. Challenges of the integrative product and production system development. Proceedings of the Design Society 2024, 4, 553–562. [Google Scholar] [CrossRef]

- Isuru, A.; Kelton, W.; Bayer, C. Digital twins in food processing: A conceptual approach to developing multi-layer digital models. Digital Chemical Engineering 2023, 7, 100087. [Google Scholar] [CrossRef]

- Tan, C. H.; et al. Augmented reality assisted facility layout digitization and planning. Journal of Mechanical Science and Technology 2021, 35, 4115–4123. [Google Scholar] [CrossRef]

- Fernández-Moyano, J. A.; Remolar, I.; Gómez-Cambronero, Á. Augmented Reality’s Impact in Industry—A Scoping Review. Applied Sciences 2025, 15, 2415. [Google Scholar] [CrossRef]

- Peladarinos, N.; et al. Enhancing Smart Agriculture by Implementing Digital Twins: A Comprehensive Review. Sensors 2023, 23, 7128. [Google Scholar] [CrossRef]

- Escribà-Gelonch, M.; et al. Digital Twins in Agriculture: Orchestration and Applications. J Agric Food Chem 2024, 72, 10737–10752. [Google Scholar] [CrossRef]

- Begout, P.; Kubicki, S.; Bricard, E.; Duval, T. Augmented Reality Authoring of Digital Twins: Design, Implementation and Evaluation in an Industry 4.0 Context. Front Virtual Real 3 2022. [Google Scholar] [CrossRef]

| SLP Analysis Criteria | Implemented Prompt |

|---|---|

| Product journey (PJ) | What are the main deficiencies that can arise throughout a product’s journey within an industrial plant? How does the absence of a traceability system influence the efficiency and control of the production process? What criteria should AI consider when suggesting the optimal location for receiving raw material? |

| Relationship between activities (RBA) | How can the layout of critical areas, such as formulation and packaging, affect operational continuity? What risks can arise from the inappropriate location of complementary areas, such as laboratories, staff access points, and common areas? What advantages does the implementation of digital communication systems offer for the internal operations of an industrial plant? |

| Relational diagram of journeys and activities | What types of deficiencies can be identified by using AI in relational diagrams of the production process? What are the most common errors in the graphical representation of activities and journeys within a plant’s design? What general recommendations does the AI analysis offer to improve the integration and fluidity of the production process? |

| Space requirements | What problems can arise from not properly scaling and sizing the spaces required in an industrial plant? What general guidelines can AI offer for optimizing space distribution in different types of production processes? |

| Iteration | SLP criteria used in the prompt | AI Analysis | |

|---|---|---|---|

| Opportunities for refinement identified | Adjustment suggestions | ||

| 1 | 1. Product journey (PJ) | Lack of a traceability system for cosmetic ingredients from raw material reception to mixing. Inefficient connection between the mixing (processing) and packaging (storage and distribution) areas, affecting continuous production. |

Relocate the raw material reception area in line with the first processing station. Reorganize the layout to bring the mixing and packaging areas closer together, optimizing product transfer. |

| 2. Relationship between activities (RBA) | Limited communication between formulation (processing) and packaging areas, causing errors in specifications. | Implement a digital communication system to coordinate formulation and packaging between processing and storage. | |

| 3. Relational diagram of journeys and activities | Incomplete graphical representation, omitting key interactions between emulsification (processing) and quality control (laboratory) processes. | Include all interactions, with emphasis on quality control points between processing and laboratory. | |

| 4. Space requirements | Determination of the size required for each area, according to its function and operational load. | Estimate of the area required per area, based on its function and frequency of use: - Raw Material Reception: 15% - Processing Area: 25% - Packaging: 15% - Storage: 20% - Laboratory: 5% - Offices (management and conf.): 10% - Services (cleaning, restrooms, and supplies): 10% |

|

| Decision-making/Ideal Model | AI response: No | AI response: Yes. If yes, changes are made. | |

| 2 | 1. | No deficiencies identified | No adjustments required |

| 2. | No deficiencies identified | No adjustments required | |

| 3. | No deficiencies identified | No adjustments required | |

| 4. | No deficiencies identified | No adjustments required | |

| Decision-making/Ideal Model | AI response: No | AI response: Yes | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).