Submitted:

19 November 2025

Posted:

20 November 2025

Read the latest preprint version here

Abstract

Keywords:

1. Introduction: Insects as Canonical Edge-AI Systems

Glossary table

- Reflex Tier — fastest safety-critical control with hard deadlines (Control).

- Reflex Island — isolated near-sensor partition executing the Reflex Tier (Platform).

- Reflex substrate (spintronic/CMOS) — technology implementing the Reflex Tier (Platform).

- Policy Tier — slower mapping/planning; publishes goals to Reflex (Control)

- FFI (freedom-from-interference) — faults/jitter in Policy can’t affect Reflex (Safety).

- ASIL allocation — ISO 26262 safety level assignment per function (Safety).

- DGC (Discontinuous Gas Exchange) — Closed–Flutter–Open; analogy for idle I/O gating (Biology↔Firmware).

- Thermal debt — required cool-down after a burst (Thermal).

- Set-point temperature — maintained flight-muscle band during work (Thermal/Biology).

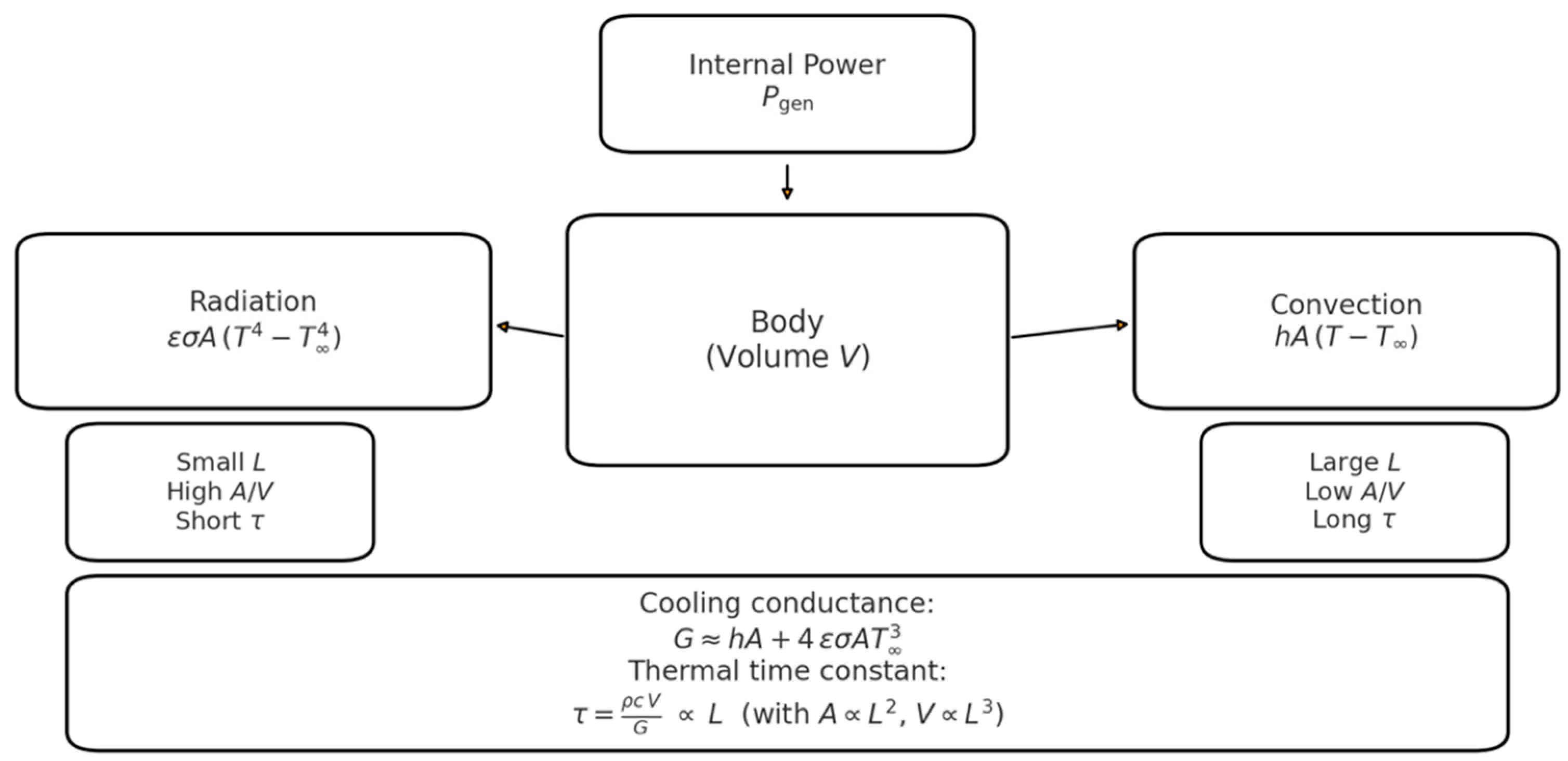

- — linearized convection + radiation loss (Physics).

- — response time; scales roughly with size (Physics).

- Prime mover — fuel engine/turbine kept at efficiency island (Propulsion).

- Cold-to-idle latency — light-off to usable idle time (Propulsion).

- BSFC map — brake-specific fuel consumption vs rpm/load (Efficiency).

- Injection event (micro-injection) — one pulse in a split injection (Engines).

- Thoracic shivering — pre-flight warm-up of flight muscles (Biology/Thermal).

- Optic flow — wide-field visual motion cue (Sensing).

- Halteres — gyroscopic sensory organs in Diptera (Sensing).

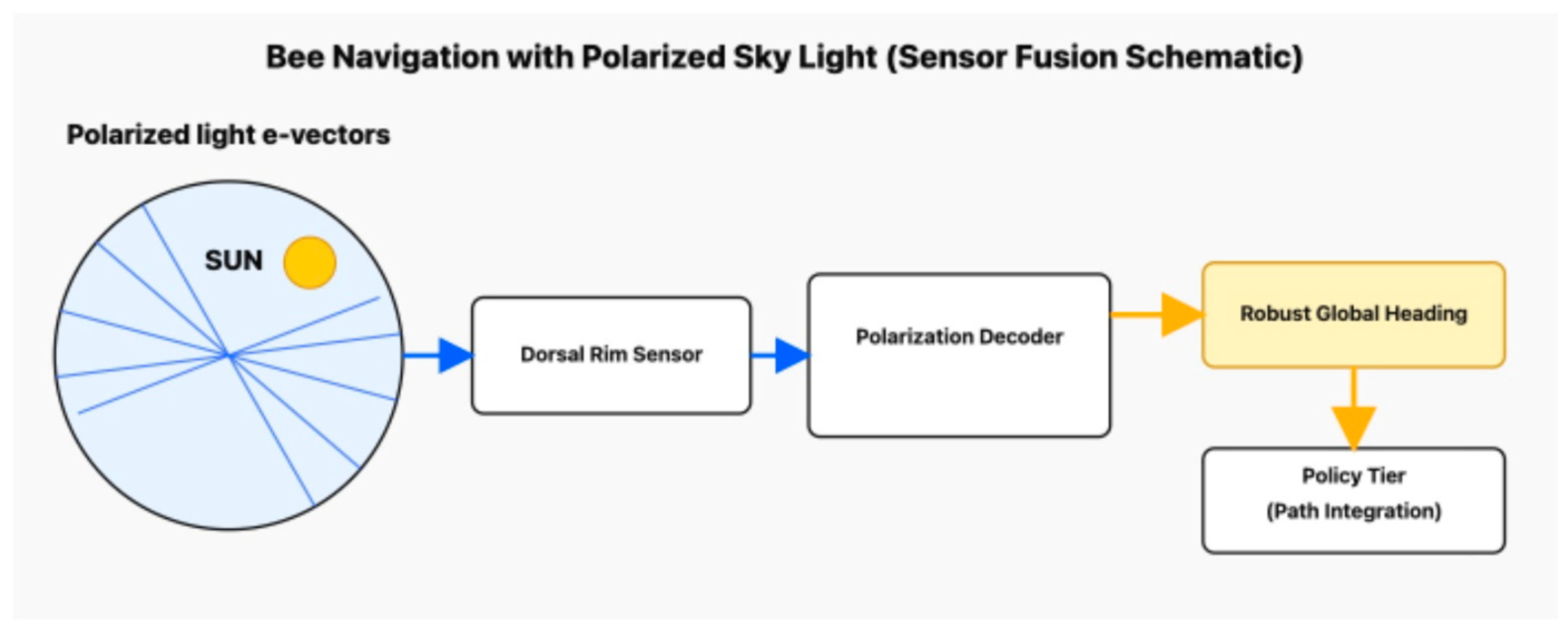

- Dorsal Rim Area (DRA) — polarization-sensitive zone for celestial compass (Sensing).

- Central Complex (ring attractor) — neural compass with an activity bump (Control/Biology).

- CPG (central pattern generator) — rhythmic actuation circuit (Control/Biology).

- STNO reservoir — spin-torque oscillator network for temporal processing (Hardware).

- MRAM synapse — non-volatile weight (MTJ) for instant-on reflex (Hardware).

- DVFS — dynamic voltage/frequency scaling under thermal control (Platform).

- WCET envelope — worst-case execution-time budget from sensor exposure to actuator update, including safety margin, defined per Reflex loop (Timing/Safety).

1.1. The Fly (Stabilization Specialist)

| Component | Description and Function | Edge-AI Analogy |

| Sensors (Fast & Complementary) | "Compound eyes (wide FOV, very high temporal resolution); Ocelli (simple light sensors for attitude); Halteres (gyroscopes sensing body rotation via Coriolis forces); Antennae/hairs (airflow and vibration)." | IMU/Gyroscopes + Global-shutter/Event Cameras + Airflow Sensors. |

| On-board Computation | "Optic lobe motion detectors (parallel ""flow"" filters); Reflex pathways (e.g., ""giant fiber"" escape route) prioritizing latency; Central complex (orientation); Mushroom bodies (learning)." | Fixed-function accelerators (for optic flow); Low-latency neuromorphic circuits (Reflex Tier). |

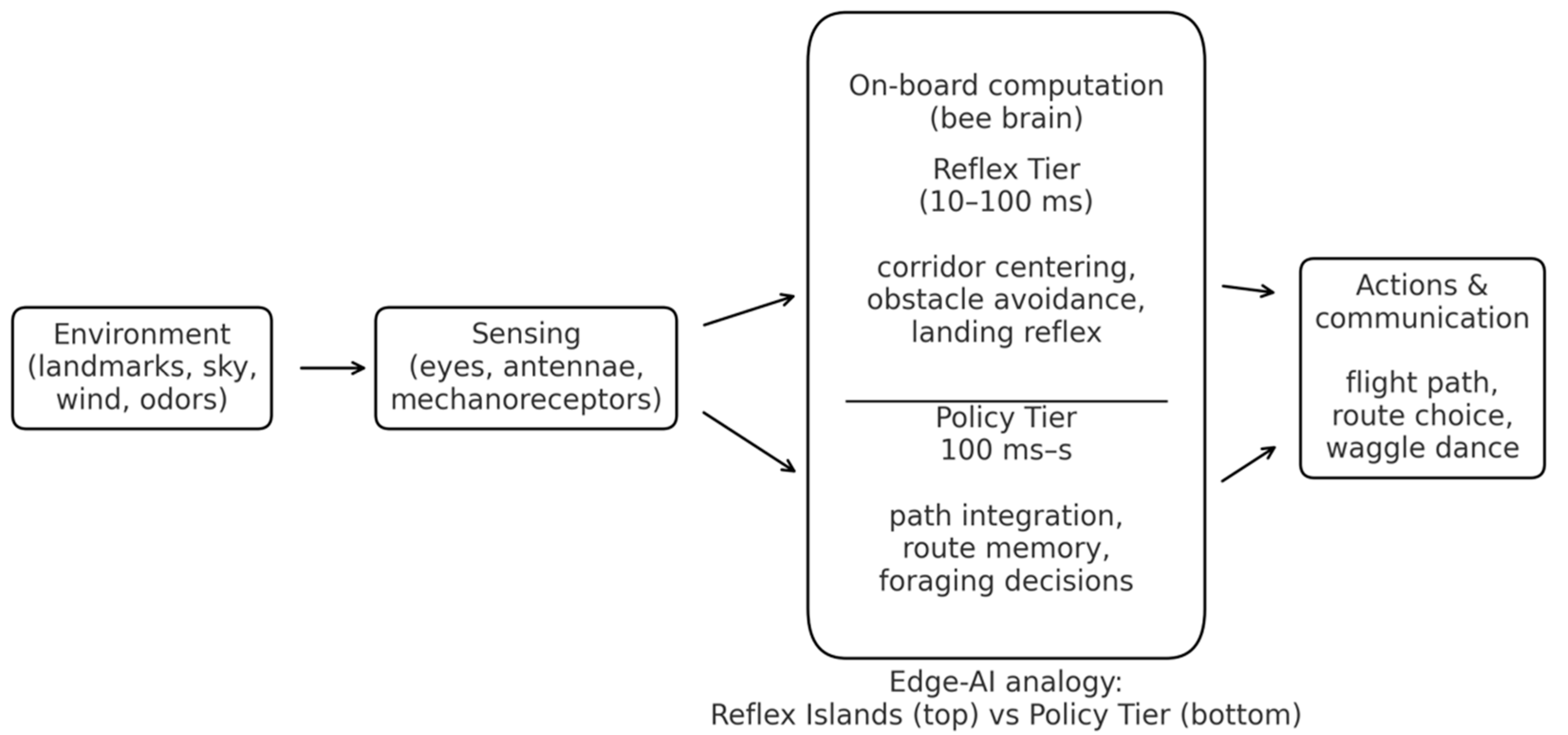

| Control Loops | Inner Loop (Stabilization): halteres + ocelli + wide-field motion → wing adjustments in a few–tens of ms. Outer Loop (Goal): visual flow + odor/airflow → course/target selection over longer windows. | Two-tier control: Reflex Tier (µs-ms) for stabilization; Policy Tier (ms-s) for planning. |

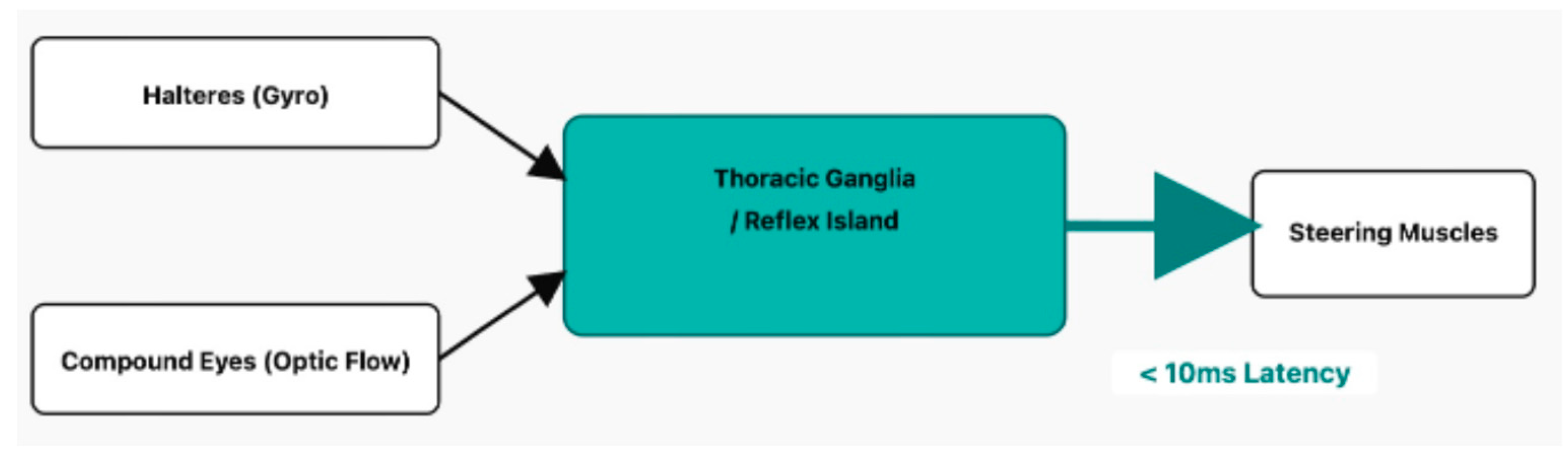

- Sensing: The halteres detect angular velocity via Coriolis forces, while the compound eyes detect wide-field optic flow.

- Compute (Fusion): These two streams are fused in thoracic reflex loops, creating a complementary filter where halteres handle fast perturbations and vision handles slow drift.

- Actuation: The resulting error signal directly modulates the phase and amplitude of tiny steering muscles, making micro-adjustments at each wingbeat to stabilize attitude.

1.2. The Bee (Navigation And Task Specialist)

| Component | Description and Function | Edge-AI Analogy |

| Sensors | Compound eyes (incl. UV) + polarization sensitivity (sun compass); Ocelli (attitude); Antennae (olfaction + mechanosensation); Body hairs (micro-climate). | Polarization/UV Sensors; Odorimeters; Temperature/Contact Sensors. |

| On-board Computation | Optic flow odometry (distance estimation); Central complex (heading/compass and path integration); Mushroom bodies (associative learning); Task switching with minimal memory. | Visual Odometry (2D V-SLAM); Rule-based Policies (Heuristics); Local Learning (small neural networks). |

| Control Loops | Landing/Altitude: Maintain constant optic-flow expansion → smooth landings without absolute altitude. Navigation: Polarization compass + optic-flow odometer + odor cues → waypoint-style guidance. | "Non-linear control based on heuristics (e.g., adaptive Proportional-Integral-Derivative); Low-cost sensor fusion." |

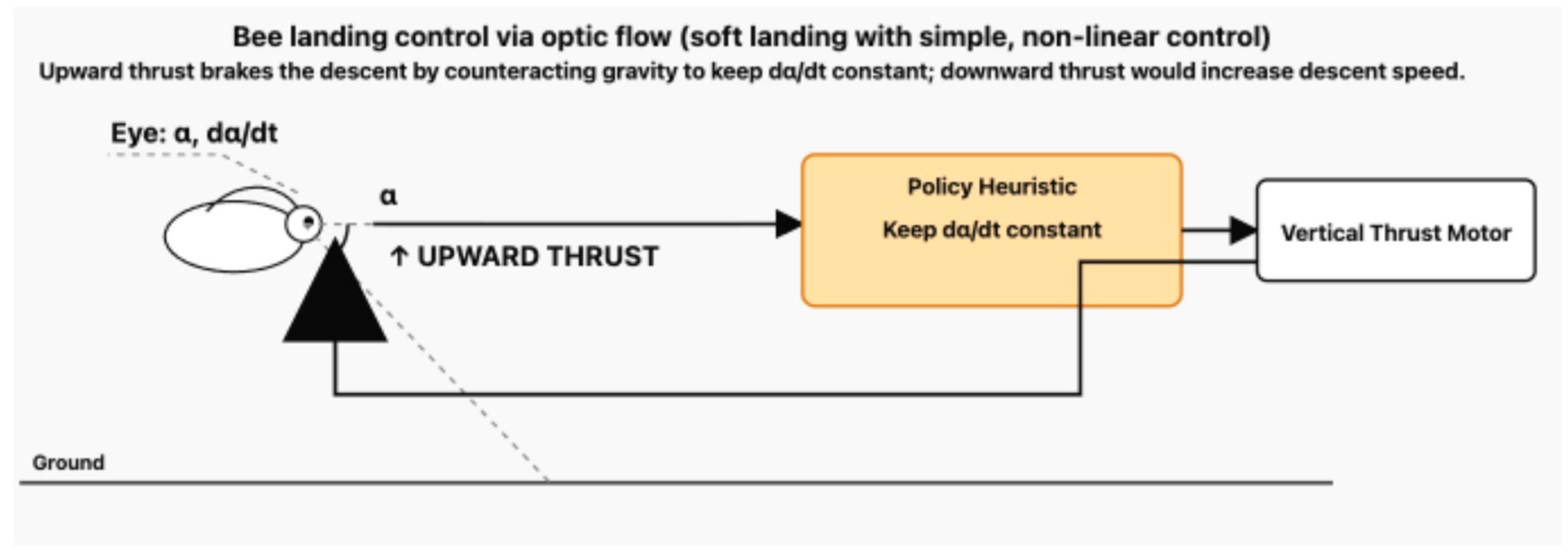

- Sensing: As the bee approaches a surface, the visual image of the ground expands on its retina. The rate of this expansion (dalpha/dt) is computed.

- Policy: The bee's control policy is a simple heuristic: "Modulate thrust to keep the optic expansion rate constant."

- Actuation: If expansion is too fast, the bee increases thrust; if too slow, it decreases thrust.

- Compute (Integration): Specialized neural circuits integrate the e-vector orientation to maintain a stable global heading, even when the sun is obscured.

- Policy: This stable heading signal feeds into the Policy Tier (Central Complex) to bias the path integration and course selection, providing a low-cost, long-range compass.

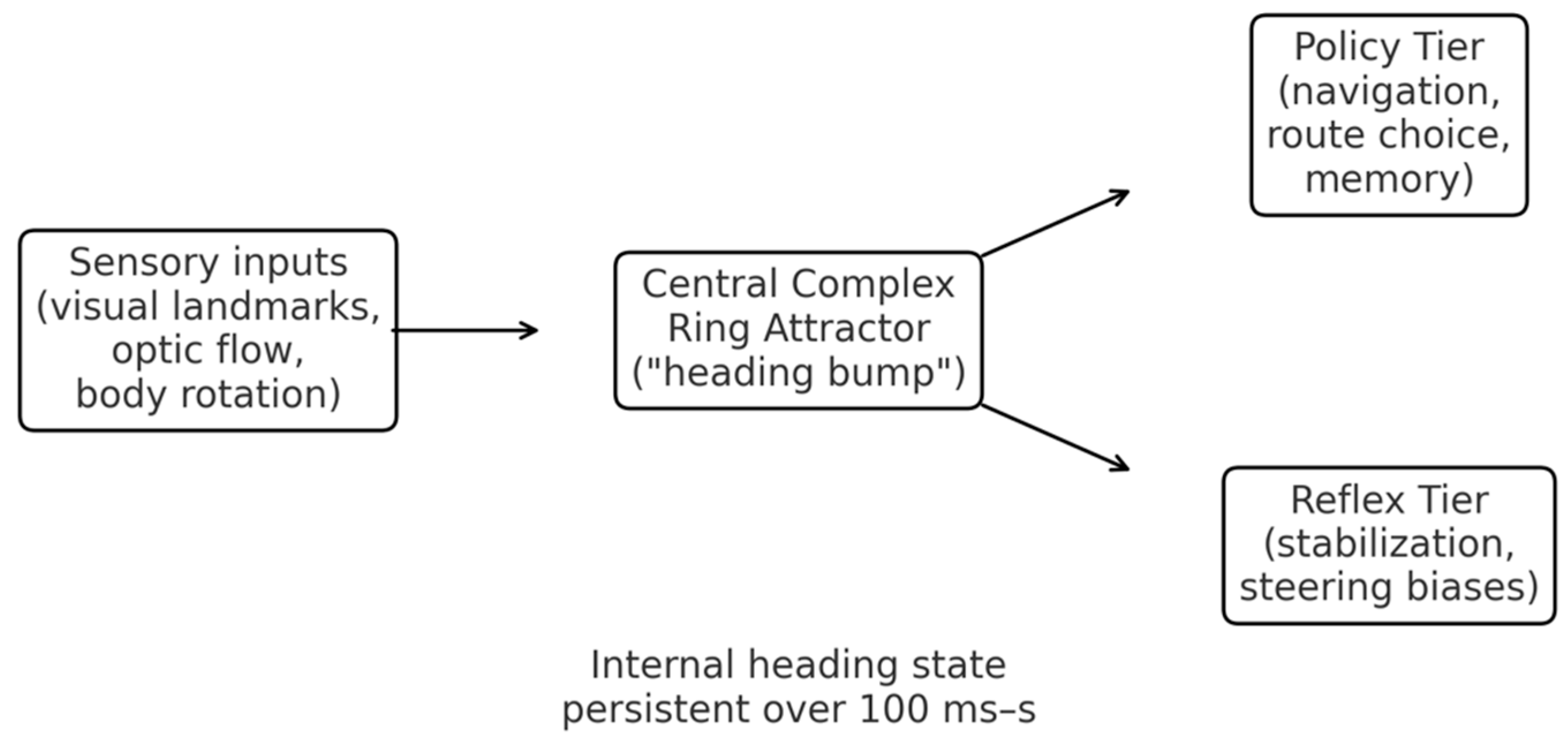

- Sensing/Input: Visual and proprioceptive inputs (e.g., optic flow, haltere signals) provide cues about angular velocity and landmarks.

- Compute (Ring Attractor): The Central Complex (specifically the Protocerebral Bridge) implements a recurrent neural network known as a ring attractor.

- This circuit maintains a persistent "bump" of activity that represents the animal's current heading.

- Policy: The position of the bump acts as a stable, internal state variable, a heading set-point that biases downstream motor reflexes, separating the high-level goal (direction) from low-level execution (torque).

2. Latency-First Architecture (Biology → Engineering)

| Biological Tier | Engineering Tier | Typical Latency | Function |

| Reflex | Reflex Tier (Neuromorphic Island) | Microseconds–Milliseconds (µs–ms) | "Stabilization, immediate reactions, low-level control (e.g., halteres → steering muscles)." |

| Policy | Policy Tier (RT Core/NPU) | Tens–Hundreds of Milliseconds (ms–s) | "Navigation, path planning, associative learning, goal selection (e.g., central complex → reflexes)." |

3. Neuromorphic and Spintronic Hardware

3.1. Why Neuromorphic Matches the Insect Edge

3.2. Spintronic Primitives as "Physical Synapses and Neurons"

- MRAM synapses (MTJs). Non-volatile, instant-on “innate” reflex weights, perfect for a cold-start Reflex Island [10,15]. The "synapses," which store the network's knowledge, are implemented using Magnetic RAM (MRAM). These are physical analogs for synapses, built from Magnetic Tunnel Junctions (MTJs). Their most critical property is non-volatility: they store the synaptic weights (the "innate reflexes") permanently, without requiring any power. This provides two transformative advantages for an edge device:

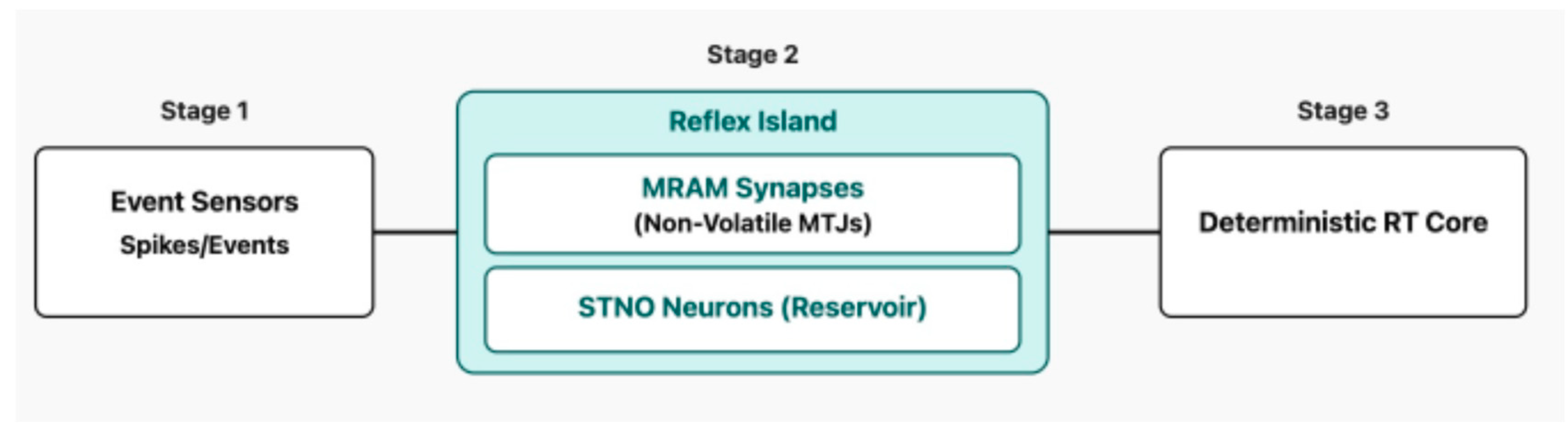

- Sensing: Event streams from sensors (e.g., event cameras, IMU) are converted into spikes (electrical pulses).

- Compute (MRAM Synapses): Magnetic Tunnel Junctions (MTJs) in MRAM act as non-volatile synapses, storing neural network weights directly where they are used. This enables instant-on capability and near-zero standby power, emulating innate memory and reflexes.

- Compute (STNO Neurons): Spin-Torque Nano-Oscillators (STNOs) act as compact, high-frequency (GHz) spiking neurons. They can form reservoirs for processing temporal tasks and sensorimotor transformation, such as optic flow analysis.

- Actuation (RT Core): The output (set-points) of the spintronic SNN feeds a deterministic Real-Time Core (RT Core) that performs final control (PID/LQR) and drives the actuators.

4. Thermoregulation, Frequency Control, and “Natural Engine” Analogies

4.1. Discontinuous Gas Exchange (DGC) and Idle I/O Gating

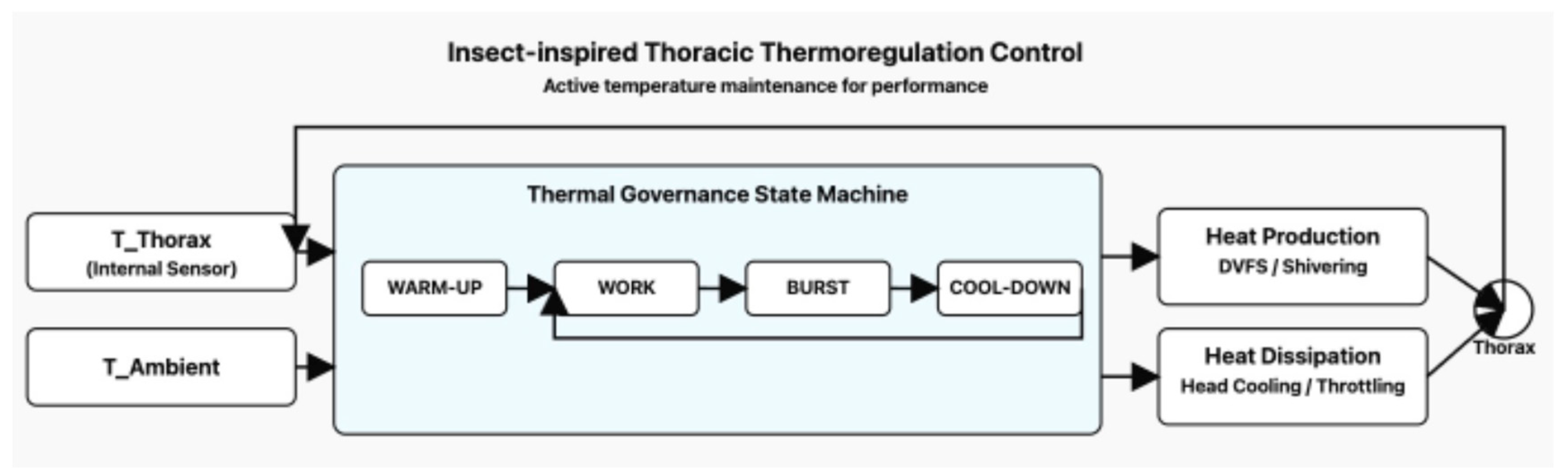

4.2. Thermal Governance as a State Machine

4.3. Why Thermoregulation Tightens at Small Scale (Black-Body + Convection)

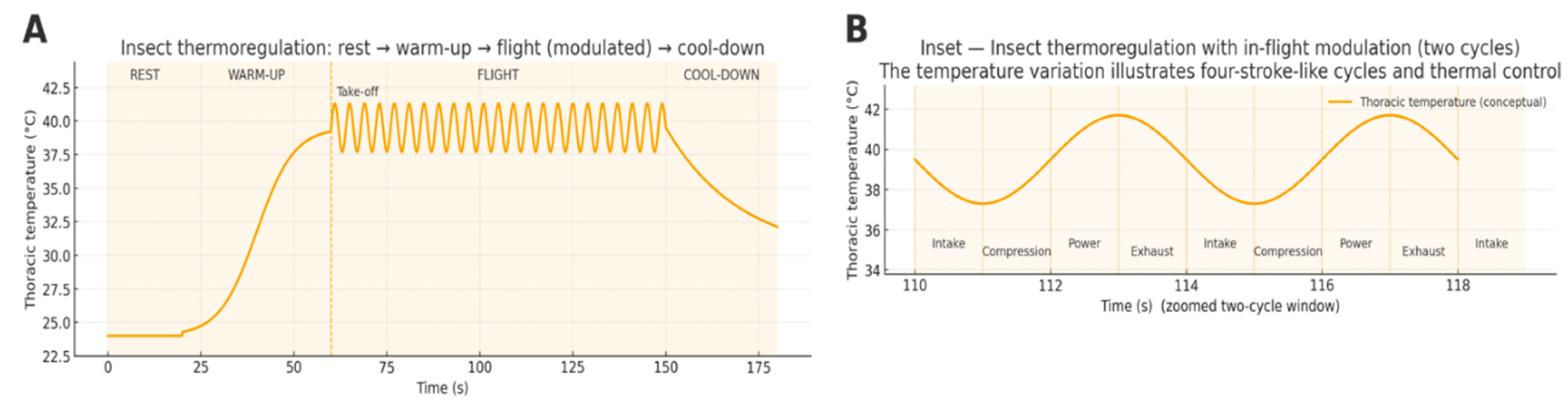

4.4. A Four-Stroke “Natural Engine” for Insect Thermoregulation

- 2.

- 3.

- 4.

- Sensing: Thoracic temperature (for power output) and ambient temperature are monitored.

- Compute (Control): A central control mechanism (analogous to a firmware state machine) actively regulates heat production (e.g., shivering) and heat dissipation (e.g., head cooling/evaporative cooling) to maintain a performance-optimal thoracic temperature set-point.

- Engineering Analogy: This is mirrored by an Edge AI system's thermal governance, which uses a state machine to dynamically adjust power/clock frequency (DVFS) and sensor duty cycles based on thermal sensors and predicted load, allowing for short, high-performance bursts while preventing thermal runaway.

4.5. Propulsion Analogy: Injection/Wingbeat Frequency and Efficiency

4.5.1. Injection Event Frequency in ICEs

4.5.2. Wingbeat Frequency in Insects

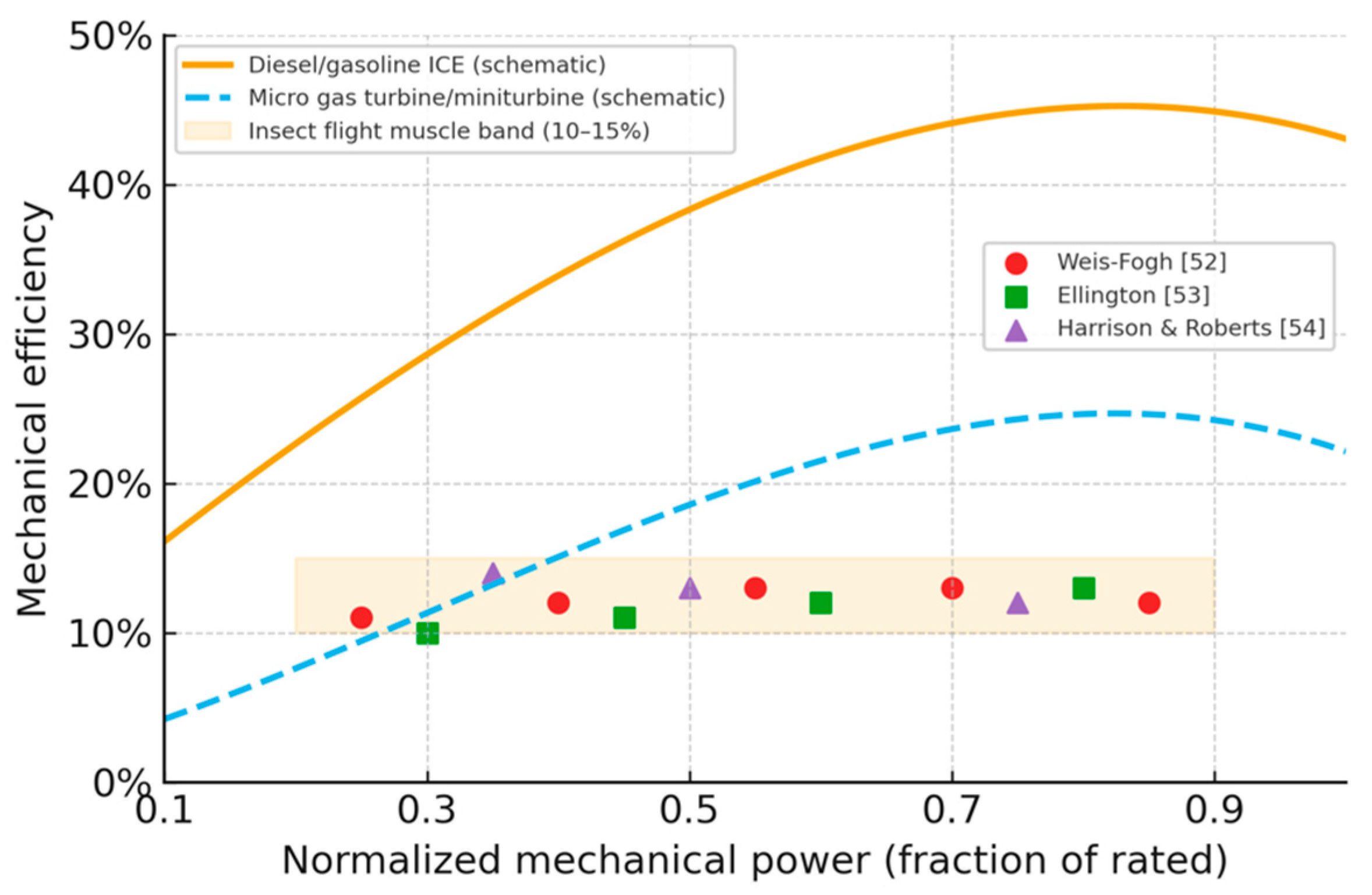

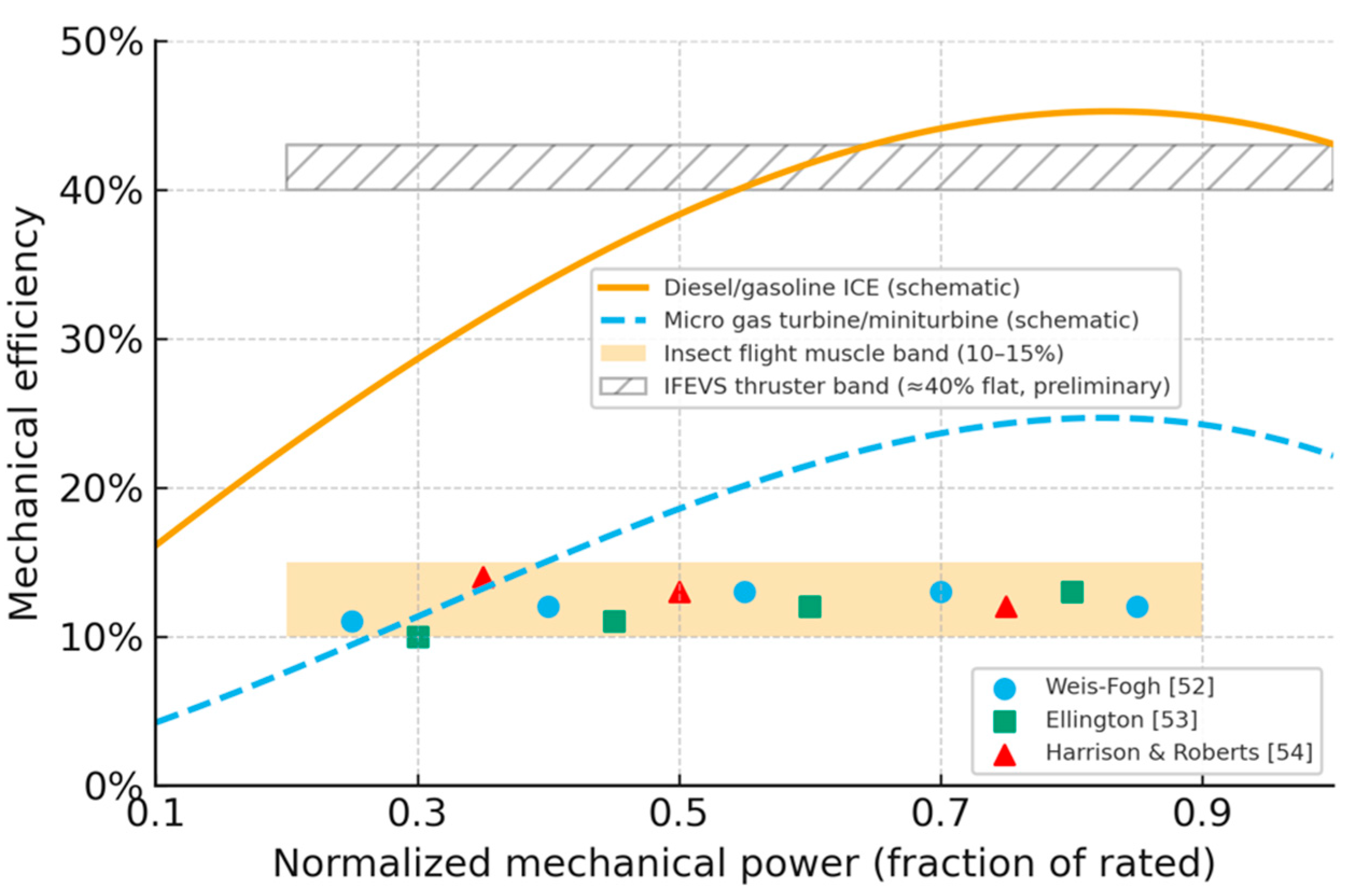

4.5.3. Efficiency Maps: Narrow Islands vs. Near-Flat Bands

- Optimal Temperature: The enzymes and contractile filaments within the muscle are designed to operate at a specific, elevated temperature (often 35oC to 40oC). At this thermal set-point, the muscle fibers achieve their maximum power output and mechanical efficiency (10%-15%).

- Active Regulation: The insect actively regulates its thoracic temperature to stay near this set-point. This means:

- If cold, the insect shivers (pre-flight warm-up) to generate waste heat and reach the set-point.

- During flight, if the power demand is low (generating less waste heat), the insect may actively reduce heat dissipation.

- Decoupling Power from Efficiency:By ensuring the muscle is always at its biomechanical "sweet spot," the insect can then adjust its mechanical power output simply by changing its wingbeat frequency (within limits) or adjusting its wing amplitude, without sacrificing its intrinsic mechanical

4.6. Miniturbines: Scaling Limits, High RPM, and Cold-Start Latency

4.7. Computational Governance: Engine ECUs vs. Insect Nervous Systems

4.8. Firmware Hooks: Operationalizing Natural Strategies for Timing, Thermal, and Safety Engineering

5. Use Cases and Actionable Guidance for Adoption

5.1. Design of Novel Fuel-Based Propulsion Systems with High Thrust

5.1.1. Objective and Rationale

5.1.2. Architecture Blueprint (“Frequency Governor” Hybrid)

- Prime mover (constant-efficiency island): a small ICE or miniturbine run near its best-efficiency point (narrow island; Section 4.5.3, Section 4.6).

- Electric buffer: battery + supercaps sized to absorb burst gaps between average and instantaneous power (Section 4.3 ODE + burst budgets).

- Propulsor (frequency-controlled): high-response electric motor + prop/fan/pump-jet; thrust tracks motor electrical frequency, keeping mechanical efficiency high across output range (insect analogue).

- Power electronics: bi-directional DC/DC + inverter; reflex-class PWM at kHz.

- Reflex Tier: MRAM-resident, instant-on controller executing stabilization and thrust commands at kHz (mirrors thoracic reflex loop).

- Policy Tier: slow planner (routing, mission, optimization), exporting only goal states.

- Thermal governance: the state machine from Section 4.2 enforces WARM-UP → WORK → BURST → COOL-DOWN with thermal-debt accounting from Section 4.3.

5.1.3. Control Strategy (Reflex/Policy Split)

5.1.4. Hardware Patterns by Domain

- 20–60 kW ICE or microturbine @ island → 400–800 V DC link; 200–400 kWh battery+cap bank sized for bursts.

- Propulsor: axle motors with field-oriented control (FOC); thrust = torque request = frequency (electrical).

- Outcome: city stop-go handled by the buffer + frequency control (insect-like), engine sits at steady island → flat real-world efficiency.

- 30–150 kW miniturbine-generator at island (cf. Section 4.6); high-rpm and start latency hidden by buffer.

- Multiple small props per wing; per-motor frequency sets local thrust, enabling gust rejection with Reflex kHz loops.

- Outcome: safe, responsive thrust modulation without throttling the turbine off-design.

- Diesel-gen at island; pump-jet thrust from impeller frequency; cavitation avoided via Reflex watchdogs (pressure/accel).

- Outcome: smooth low-speed thrust with prime mover steady; excellent station-keeping.

5.1.5. Sizing & Math Hooks (Quick Rules)

5.1.6. Safety & Certification Hooks

- Freedom-from-interference (FFI). The Reflex Tier runs on a pinned core (or dedicated neuromorphic die) with fixed priorities, no dynamic memory, and one-way single-producer/single-consumer (SPSC) queues from Policy. All plant-stabilizing loops (thrust, torque, braking) close entirely inside this island. Policy cannot pre-empt or delay Reflex work; its influence is limited to low-rate goal states (e.g., speed corridors, thrust limits).

5.1.7. Validation Plan (Step-by-Step)

- HIL loop at kHz with plant models (prop, drivetrain, buffer, engine/turbine).

- vs. predicted Section 4.3 curve; verify deadlines and miss counters = 0.

- Thermal cycles: alternate BURST/COOL-DOWN to validate thermal-debt controller.

- Off-design trials: hold prime mover at island while sweeping thrust frequency; confirm flat system efficiency compared to stock throttle maps.

- Fault injection: sensor dropout, clock drift, memory CRC fault; verify Reflex containment.

5.1.8. Quick “Principle → Requirement → Action” Table5.1.9. Insect Inspired Fuel Based IFEVS Thruster

| Principle | Propulsion Requirement | Actionable Guidance |

| Frequency-controlled thrust (insect) | Wide-range thrust with minimal efficiency drift | Decouple: prime mover at island; thrust via motor frequency; buffer covers transients (Section 4.5–Section 4.6) |

| Thermal governance | Bounded temps during bursts | Apply Section 4.3 ODE to compute burst time; enforce COOL-DOWN; shed Policy first |

| Instant-on Reflex | kHz stabilization independent of prime-mover state | MRAM Reflex Island near drivers/sensors; deadline monitors; DMA windows |

| Cold-start latency (miniturbine) | Usable thrust before light-off | Pre-warm plan; buffer-only takeoff/launch; soft-hand-over to turbine (Section 4.6) |

| Safety case | WCET & FFI | Fixed priorities; single-core pinning; one-way SPSC queues; watchdogs & logs |

- microturbine thrust and fuel flow,

- IFEVS thrust and fuel flow, and

- the resulting fuel-flow ratio IFEVS/microturbine.

- The uncertainties quoted above are engineering confidence intervals derived from:

- model sensitivity to assumed pressure losses and mixing efficiency (±3–4 percentage points on thermal efficiency),

- expected calibration accuracy of mass-flow and temperature sensors (±2–3%),

- variability in augmenter entrainment ratio and back-pressure (±0.05 on thrust multiplication), and

- variability in ambient conditions around the ISA reference (±5% in density over a 10–15 °C swing).

- Even with these conservative uncertainties, the picture that emerges is robust:

- an insect-style prime mover whose efficiency degrades gently with load instead of collapsing away from a narrow island;

- instantaneous response (valve/ignition limited) rather than seconds-scale spool dynamics;

- cool, slow exhaust (~150 °C at the augmenter exit) enabling safe operation near people and structures; and

- a mechanically simple, non-rotating architecture naturally compatible with the Reflex/Policy split and WCET reasoning of Section 2 and Section 5.1.6.

| Metric | IFEVS thruster | State-of-the-art microturbine (similar thrust) |

| Thermal efficiency (core) | > 40% before augmenter (fuel→jet power) | ~20–30% peak; sharp drop off-design |

| Thrust–load behaviour | Flat efficiency from ~30 N → 600+ N after augmenter | Narrow island; poor partial-load BSFC |

| Fuel use @ ~400 N | ≈ ½ the fuel of miniturbine | Baseline |

| Fuel use @ ~50 N | ≈ ⅓ the fuel vs turbine at low-load operation | Strong efficiency loss at low throttle |

| Exhaust temperature | ~150 °C at augmenter exit | ~500–1000 °C EGT; hot jet |

| Acoustic signature | ≤100 dB @ 3 m, subsonic ejector exit | Hot, often supersonic microjets; much louder |

| Response time | Near-instant; no spool-up | Spool-up / light-off delays (seconds) |

| Architecture / maintenance | No rotating parts; ~½ weight; low maintenance | High-speed rotor/bearings; higher maintenance load |

5.2. Autonomous Vehicles & Micro-Robotics (A One-To-One Mapping of the Insect Edge)

| Principle | Vehicle Requirement | Actionable Guidance |

| Reflex Tier (Fly) | Deterministic safety: stabilization, obstacle avoidance, traction/braking | Co-locate IMU/event camera + Reflex Island; run stabilization at 1–2 kHz; keep E-stop <1 ms path; MRAM for instant-on |

| Policy Tier (Bee) | Robust navigation: VO, mapping, intent | Separate RT core/NPU at low priority; publish only goal states (speed corridors, waypoints) to Reflex |

| Thermal governance | Predictive performance: short high-power bursts | Implement Section 4.2 state machine; compute burst budgets via Section 4.3; log thermal debt and deadline misses |

| Spintronics | Low-power, event-driven perception | Use STNO reservoirs for vibration/flow/event-camera streams; MRAM synapses for reflex weights |

| Certification | Freedom-from-interference | Partition clocks/cores/memory; lock-free SPSC; WCET tables; watchdog + safety log |

- a fast Reflex Tier (camera/IMU → neuromorphic looming SNN → haptic/LED) with a quantified sub-20 ms WCET envelope and clear separation from the slower route-planning Policy Tier;

- a solar-governed duty cycle where the bike operates much like an insect balancing energy intake and expenditure over the day; and

- a largely self-charging cargo platform analogous to existing IFEVS-type systems, but with an explicit safety-critical perception shell inspired by insect vision.

5.3. Medical implants and wearable devices (Years of standby; milliseconds to act)

| Principle | Medical Requirement | Actionable Guidance |

| DGC / I/O gating (Section 4.1) | Extreme energy conservation | Closed/Flutter duty-cycling of sensing; Open on anomaly; RTC-only heartbeat during Closed |

| Spintronics (MRAM) | Instant event capture & integrity | Reflex Tier always resident in MRAM; no DRAM warm-up; log ring-buffers with ECC/CRC |

| Policy learning | Personalized thresholds | On-device adaptation (simple STDP/EMA) in Policy; export only gains/thresholds to Reflex |

| Thermal governance | Skin comfort & safety | Treat surface and battery with Section 4.2 state machine; guarantee Reflex availability while throttling analytics |

| Safety & privacy | Determinism & local data | WCET envelopes for detection; encrypted logs; on-device inference; no cloud dependency for immediate actions |

5.4. Industrial robotics & control (Uptime and determinism above all)

| Principle | Industrial Requirement | Actionable Guidance |

| Reflex isolation | Immediate safety (E-stop, limits, interlocks) | Put all safety loops on Reflex Island; pin core, fixed priorities; zero dynamic memory; deadline monitors |

| Two-tier split | Flexible tasks w/o jitter | Reflex: 1–2 kHz PID/LQR, commutators; Policy: vision, optimization, job scheduling; one-way queues |

| STNO reservoirs | High-bandwidth sensing | Inline temporal processing for accelerometers/vibration; predictive maintenance at the edge |

| Thermal governance | Shift-resilience | Use Section 4.3 budgets; enforce COOL-DOWN; rate-limit bursts; log thermals for maintenance |

| Certification | SIL 2–3 / ISO 13849 | Prove freedom-from-interference; margin ≥30% on Reflex deadlines at hot corner; watchdog and safe states documented |

6. Conclusions

Acknowledgments

References

- Chan, W.-P.; Prete, F.; Dickinson, M. H. Visual input to the efferent control of wing steering in Drosophila. Nature 396 (1998) 460–464.

- Dickinson, M. H. Halteres in Diptera: the gyroscope of the insect world. Phil. Trans. R. Soc. B 354 (1999) 903–911.

- Egelhaaf, M.; Kern, R.; Juusola, M. Optic-flow based spatial vision in insects. J. Comp. Physiol. A 209 (2023) 487–502.

- Palka, J.; et al. The giant fiber pathway of Drosophila. J. Neurogen. 3 (1986) 1–14.

- Dickerson, B. H.; et al. A fly’s view of the world. Curr. Opin. Neurobiol. 54 (2019) 112–119.

- Baird, E.; Srinivasan, M.V.; Zhang, S.; Cowling, A. Visual control of flight speed in honeybees. J. Exp. Biol. 2005, 208, 3895–3905. [Google Scholar] [CrossRef] [PubMed]

- De Marco, R. J.; Menzel, R. Encoding spatial information in the waggle dance. J. Exp. Biol. 208 (2005) 3885–3894. [CrossRef] [PubMed]

- Kim, S.S.; Rouault, H.; Druckmann, S.; Jayaraman, V. Ring attractor dynamics in the Drosophila central brain. Science 2017, 356, 849–853. [Google Scholar] [CrossRef] [PubMed]

- Hulse, B. K.; et al. A neural circuit for an internal compass in Drosophila. eLife 10 (2021) e66039.

- Grollier, J.; Querlioz, D.; Camsari, K.Y.; Everschor-Sitte, K.; Fukami, S.; Stiles, M.D. Neuromorphic spintronics. Nat. Electron. 2020, 3, 360–370. [Google Scholar] [CrossRef]

- Infineon Technologies. AURIX™ TC39x Product Brief (2019): up to ~2700 DMIPS; ASIL-D.

- Schuman, C. D.; et al. A survey of neuromorphic computing and applications. Appl. Phys. Rev. 9 (2022) 011307.

- Davies, M.; Srinivasa, N.; Lin, T.-H.; Chinya, G.; Cao, Y.; Choday, S.H.; Dimou, G.; Joshi, P.; Imam, N.; Jain, S.; et al. Loihi: A Neuromorphic Manycore Processor with On-Chip Learning. IEEE Micro 2018, 38, 82–99. [Google Scholar] [CrossRef]

- Indiveri, G.; et al. Neuromorphic vision sensors and processors. Proc. IEEE 99 (2011) 1524–1548.

- Chen, B.-J.; et al. Spintronic devices for in-memory and neuromorphic computing—A review. Materials Today 70 (2023) 193–217.

- Marrows, C. H.; et al. Neuromorphic computing with spintronics. Nat. Rev. Phys. 6 (2024) 1–15.

- Lighton, J. R. B. Discontinuous gas exchange in insects. Annu. Rev. Entomol. 41 (1996) 309–324.

- Chown, S. L.; et al. Discontinuous gas exchange: consensus view. J. Exp. Biol. 209 (2006) 3719–3725.

- Hetz, S.K.; Bradley, T.J. Insects breathe discontinuously to avoid oxygen toxicity. Nature 2005, 433, 516–519. [Google Scholar] [CrossRef]

- Chown, S.L. Discontinuous gas exchange: new perspectives on evolutionary origins and ecological implications. Funct. Ecol. 2011, 25, 1163–1168. [Google Scholar] [CrossRef]

- Heinrich, B. Keeping a Cool Head: Honeybee Thermoregulation. Science 1979, 205, 1269–1271. [Google Scholar] [CrossRef] [PubMed]

- Heinrich, B. The Hot-Blooded Insects. Springer, 1993.

- Stabentheiner, A.; Kovac, H.; Brodschneider, R. Honeybee Colony Thermoregulation – Regulatory Mechanisms and Contribution of Individuals in Dependence on Age, Location and Thermal Stress. PLOS ONE 2010, 5, e8967–e8967. [Google Scholar] [CrossRef]

- May, M. L. Thermoregulation in insects. Annu. Rev. Entomol. 36 (1991) 155–184.

- Incropera, F. P.; et al. Fundamentals of Heat and Mass Transfer (8th ed.). Wiley, 2017.

- NIST CODATA. Stefan–Boltzmann constant 5.670374419×10^(-8)W·m⁻²·K⁻⁴.

- Bosch Mobility. Modular common-rail systems: up to 8 injections per cycle. Tech note (accessed 2025).

- Postrioti, L.; et al. Zeuch method-based injection rate analysis of a CR system. Fuel 130 (2014) 38–49.

- Costa, M.; et al. Split injection in homogeneous-stratified GDI. Energy 109 (2016) 608–620.

- Ferrari, A.; et al. Response of injector typologies to dwell-time variation. Appl. Energy 169 (2016) 899–911.

- Ferrari, A.; et al. Impact of common-rail systems on diesel engines. Energies 18 (2025) 5259.

- Altshuler, D. L.; et al. High-frequency wing strokes in honeybee flight. PNAS 102 (2005) 18213–18218.

- Hedrick, T. L.; Miller, L.; Combes, S. A. Recent developments in insect flight. Can. J. Zool. 93 (2015) 925–943.

- Pringle, J. W. S. Insect Flight. Cambridge Univ. Press.

- Syme, D.A.; Josephson, R.K. How to Build Fast Muscles: Synchronous and Asynchronous Designs. Integr. Comp. Biol. 2002, 42, 762–770. [Google Scholar] [CrossRef]

- Heywood, J. B. Internal Combustion Engine Fundamentals (2nd ed.). McGraw-Hill, 2018.

- Stone, R. Introduction to Internal Combustion Engines (4th ed.). Palgrave, 2012.

- Tran, B. N.; et al. Tip-clearance vs turbine performance. Energies 13 (2020) 4055.

- Xiang, J.; et al. Tip-clearance flow in miniature compressors. Int. J. Therm. Sci. 140 (2019) 123–133.

- Yamada, K.; et al. Low-Re effects in small turbomachinery. J. Turbomach. 141 (2019) 111004.

- AIP Advances: Tip-clearance & pre-stall features. 13 (2023) 115108.

- Capstone Turbine Corp. C30 Microturbine Data Sheet (NG): ≈26% LHV.

- Pure World Energy. Capstone C30 (30 kW): heat rate ≈13.8 MJ/kWh (26% LHV).

- Barnard Microsystems (UAV Engines). Typical rotor ranges: 35k–120k rpm (accessed 2025).

- Garrett/Turbo technical notes. High-speed micro-turbocharger dynamics (accessed 2025).

- JetCat. P250-PRO-S Turbojet: 13–20 s start-to-idle (2019).

- NXP. MPC5777C engine-control MCU: dual 300 MHz + eTPU2 (96 ch), eMIOS (32 ch).

- Renesas. VC4 domain controller: A55 + RH850, tens of kDMIPS (accessed 2025).

- ISO 26262. Road vehicles, Functional safety. 2018.

- Goodman, D.; et al. Descending neurons in Drosophila control behavior. Curr. Biol. 30 (2020) R928–R934.

- Lin, A.; Yang, R.; Dorkenwald, S.; Matsliah, A.; Sterling, A.R.; Schlegel, P.; Yu, S.-C.; McKellar, C.E.; Costa, M.; Eichler, K.; et al. Network statistics of the whole-brain connectome of Drosophila. Nature 2024, 634, 153–165. [Google Scholar] [CrossRef]

- Weis-Fogh, T. Energetics of Hovering Flight in Hummingbirds and in Drosophila. J. Exp. Biol. 1972, 56, 79–104. [Google Scholar] [CrossRef]

- Ellington, C.P. Power and efficiency of insect flight muscle. J. Exp. Biol. 1985, 115, 293–304. [Google Scholar] [CrossRef]

- Harrison, J.F.; Roberts, S.P. Flight Respiration and Energetics. Annu. Rev. Physiol. 2000, 62, 179–205. [Google Scholar] [CrossRef] [PubMed]

- Davies, M.; Srinivasa, N.; Lin, T.-H.; Chinya, G.; Cao, Y.; Choday, S.H.; Dimou, G.; Joshi, P.; Imam, N.; Jain, S.; et al. Loihi: A Neuromorphic Manycore Processor with On-Chip Learning. IEEE Micro 2018, 38, 82–99. [Google Scholar] [CrossRef]

- Grollier, J.; Querlioz, D.; Camsari, K.Y.; Everschor-Sitte, K.; Fukami, S.; Stiles, M.D. Neuromorphic spintronics. Nat. Electron. 2020, 3, 360–370. [Google Scholar] [CrossRef]

- Leveson, N. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- MaBouDi, H.; Roper, M.; Guiraud, M.-G.; Juusola, M.; Chittka, L.; Marshall, J.A. A neuromorphic model of active vision shows how spatiotemporal encoding in lobula neurons can aid pattern recognition in bees. eLife 2025, 14. [Google Scholar] [CrossRef] [PubMed]

- Dalgaty, T.; Vianello, E.; De Salvo, B.; Casas, J. Insect-inspired neuromorphic computing. Curr. Opin. Insect Sci. 2018, 30, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Yanguas-Gil, A.; Madireddy, S. General policy mapping: online continual reinforcement learning inspired on the insect brain. NeurIPS 2022 Workshop on Offline Reinforcement Learning, OpenReview (2022). https://openreview.net/forum?

- Lin, Z.; Hao, Q.; Zhao, B.; Hu, M.; Pei, G. Performance analysis of solar electric bikes. Transp. Res. Part D: Transp. Environ. 2024, 132. [Google Scholar] [CrossRef]

- Furber, S.; Bogdan, P. (Eds.) . SpiNNaker: A Spiking Neural Network Architecture. Now Publishers, Hanover, MA, 2020. (Monograph describing the Manchester SpiNNaker neuromorphic platform and its large-scale deployments.

- Akopyan, F.; Sawada, J.; Cassidy, A.; Alvarez-Icaza, R.; Arthur, J.; Merolla, P.; Imam, N.; Nakamura, Y.; Datta, P.; Nam, G.-J.; et al. TrueNorth: Design and Tool Flow of a 65 mW 1 Million Neuron Programmable Neurosynaptic Chip. IEEE Trans. Comput. Des. Integr. Circuits Syst. 2015, 34, 1537–1557. [Google Scholar] [CrossRef]

- BrainChip Holdings Ltd. BrainChip Akida neuromorphic processor and MetaTF development environment. Company technical overview and product pages, accessed 2025. (Describes the AKD1000 neuromorphic SoC used in commercial edge-AI kits.

- Christensen, D.V.; Dittmann, R.; Linares-Barranco, B.; Sebastian, A.; Le Gallo, M.; Redaelli, A.; Slesazeck, S.; Mikolajick, T.; Spiga, S.; Menzel, S.; et al. 2022 roadmap on neuromorphic computing and engineering. Neuromorphic Comput. Eng. 2022, 2, 022501. [Google Scholar] [CrossRef]

- IEEE International Roadmap for Devices and Systems (IRDS). Emerging Research Devices / Beyond CMOS Chapter, IRDS 2020 Edition, IEEE, 2020. Available at irds.ieee.org.

- Semiconductor Research Corporation; Semiconductor Industry Association. Decadal Plan for Semiconductors. Full report, 2021. (Defines research priorities including spintronic memories and beyond-CMOS logic for energy-efficient computing.

- www.solbian.

- https://www.edgeai-trust.

- Josephson, R. K. (1985). The mechanical power output of insect flight muscle. Annual Review of Physiology, 47(1), 543-563. [CrossRef]

- Niewiarowski, P.H.; Balk, M.L.; Londraville, R.L. Phenotypic Effects of Leptin in an Ectotherm: A New Tool to Study the Evolution of Life Histories and Endothermy? J. Exp. Biol. 2000, 203, 295–300. [Google Scholar] [CrossRef] [PubMed]

| Stage | Function (example stack) | WCET (µs) | Cumulative (µs) |

| 1 | DVS/IMU exposure → interrupt assertion | 50 | 50 |

| 2 | DMA + time-stamp + spike encoding into Reflex Island | 150 | 200 |

| 3 | FF-SNN layer 1 (elementary motion detectors) | 800 | 1,000 |

| 4 | STNO reservoir / RSNN update + readout | 1,200 | 2,200 |

| 5 | Reflex decision logic + watchdog comparators | 400 | 2,600 |

| 6 | RT core arbitration, FOC current reference update | 400 | 3,000 |

| 7 | PWM/timer update + gate-driver propagation | 400 | 3,400 |

| Thrust (N) | IFEVS fuel (mL/min) | P400 fuel (mL/min) | Fuel ratio IFEVS / P400 |

| 80 | 143 | 391 | 0.37 |

| 120 | 215 | 507 | 0.42 |

| 160 | 287 | 623 | 0.46 |

| 200 | 358 | 739 | 0.48 |

| 240 | 430 | 855 | 0.50 |

| 280 | 502 | 971 | 0.52 |

| 320 | 573 | 1087 | 0.53 |

| 360 | 645 | 1203 | 0.54 |

| 400 | 717 | 1319 | 0.54 |

| 440 | 788 | — | — |

| 480 | 860 | — | — |

| 520 | 932 | — | — |

| 540 | 968 | — | — |

| Stage | Function | Latency (ms) | Cumulative (ms) |

| 1 | Camera exposure + readout / event aggregation | 5 | 5 |

| 2 | DMA + timestamp + spike/event encoding into Reflex Island | 2 | 7 |

| 3 | Looming-detection SNN inference (1–2 layers, few k neurons) | 4 | 11 |

| 4 | Reflex decision logic + hazard classification + queue write | 3 | 14 |

| 5 | Haptic/LED driver update + actuator rise time | 4 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).