1. Introduction

The growing demand for high-performance, lightweight, and customizable components has intensified research into advanced polymeric and composite materials, particularly within the context of additive manufacturing (AM) technologies [

1,

2,

3]. Among these, fused deposition modeling (FDM)—also known as fused filament fabrication (FFF)—has emerged as one of the most widely adopted processes due to its cost efficiency, material versatility, and ability to produce geometrically complex structures [

2]. The continued improvement of polymer feed stocks and printing systems has expanded the industrial relevance of FDM from rapid prototyping to the fabrication of functional components with tailored mechanical and structural properties.

In additive manufacturing, material selection requires a deep understanding of the interplay between functionality, process parameters, and design constraints, as these factors jointly determine the mechanical response and microstructural integrity of printed parts. The mechanical performance of FDM products depends not only on the intrinsic properties of the polymer or composite but also on process-induced features such as interlayer adhesion, porosity, and residual stresses [

4]. Therefore, correlating microstructural evolution with mechanical behavior is essential for optimizing printing parameters and ensuring consistent performance in engineering applications.

Additive manufacturing provides clear advantages over conventional subtractive and formative methods such as casting, forging, and milling [

5,

6]. Its layer-by-layer deposition mechanism enables the fabrication of complex geometries with minimal waste, shorter production cycles, and high design flexibility [

7,

8]. Despite these advantages, FDM parts often exhibit inherent limitations such as anisotropic mechanical behavior, interlayer adhesion defects, and porosity, which can compromise their structural reliability and long-term performance. According to ASTM Committee F42, AM is defined as the process of constructing three-dimensional objects by sequential material addition [

9]. ISO/ASTM 52900:2021 [

10] categorizes AM technologies into several main groups, among which material extrusion—realized through FDM—remains the most accessible and industrially relevant method [

11,

12].

In the FDM process, a thermoplastic filament is heated to a molten state and extruded through a nozzle, forming successive layers that solidify to create the final part [

13,

14,

15,

16,

17]. This simple yet effective principle enables accurate and repeatable fabrication of customized components at low cost. Due to its versatility and open accessibility, FDM is now widely used for both rapid prototyping and the production of functional end-use parts. Its ability to modify digital models and adjust material or process parameters without hardware changes makes it a key enabler of innovation in engineering design and product development [

18,

19,

20,

21].

Typical thermoplastic materials used in FDM include polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), and polyethylene terephthalate glycol (PETG), valued for their processability, mechanical strength, and affordability [

22,

23,

24]. More recently, composite filaments reinforced with short carbon fibers (CF), glass fibers (GF), or metallic fillers have been developed to improve stiffness, strength, and thermal stability [

25,

26,

27,

28]. The appropriate material choice and parameter tuning directly affect key mechanical properties—such as tensile strength, modulus, impact resistance, and ductility—relevant to the functional requirements of printed parts [

29,

30,

31,

32].

One of the distinctive features of FDM lies in its ability to create internal infill structures with adjustable geometry, density, and orientation, allowing mechanical performance to be tailored for specific loading scenarios. Common infill patterns—such as rectilinear, triangular, and hexagonal configurations—provide different trade-offs between stiffness, strength, and production efficiency [

33,

34,

35,

36]. Properly optimized infill structures can reduce material consumption and printing time while maintaining sufficient strength for engineering applications. However, both the infill design and process-induced microstructural features—such as voids, imperfect fusion, or misalignment between layers—play a decisive role in determining overall mechanical performance [

37,

38,

39,

40,

41,

42].

Numerous studies have examined how process parameters, infill design, and environmental conditions influence the mechanical and structural integrity of FDM-printed materials, demonstrating that layer thickness, printing speed, raster angle, and temperature strongly affect tensile performance and ductility, while external factors such as humidity, thermal cycling, or exposure to lubricants can promote microstructural degradation and delamination [

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

54,

55,

56,

57].

Recent tribological investigations have further confirmed that contact with lubricating fluids accelerates surface degradation and interfacial weakening in PLA- and PETG-based materials, particularly under repeated mechanical loading [

54,

58,

59,

60].

In real service conditions, the combined effect of mechanical loading and environmental exposure—such as contact with lubricants, moisture, or temperature fluctuations—can accelerate material degradation and significantly alter the microstructural and mechanical stability of FDM-printed components. This interrelationship has been increasingly recognized as a key factor affecting the long-term reliability of additively manufactured materials.

Recent investigations have provided valuable insights into these relationships. Pascual-González et al. [

61] demonstrated that heat treatment and improved interlayer adhesion enhance the microstructural integrity of carbon-fiber-reinforced composites. Guessasma et al. [

62] reported that microstructural morphology significantly influences the tensile behavior of FDM biopolymers. Özen et al. [

63] and Shanmugam et al. [

64] observed that optimized processing conditions and homogeneous layer bonding improve both tensile and fatigue performance. Pandžić et al. [

65] identified printing speed, temperature, and layer thickness as key determinants of strength in PLA and PLA reinforced with carbon fiber (PLA+CF) materials. Li et al. [

66] and Zhen et al. [

67] confirmed that controlled thermal treatment enhances the crystallinity and mechanical stability of PEEK. Patanwala et al. [

68] and Naveed [

69] found that nanoparticle reinforcement in PLA improves stiffness and tensile strength, while Kumar et al. [

70] emphasized the role of fiber orientation and distribution in optimizing composite behavior.

Collectively, these studies demonstrate a strong interdependence between process parameters, material composition, and microstructural development in FDM-fabricated components. Yet, few studies have systematically explored how combined mechanical loading and environmental exposure—particularly contact with lubricants and moisture—alter the microstructural features and mechanical performance of FDM parts. This gap limits our understanding of structure–property relationships and the long-term durability of FDM materials in practical applications.

The present study aims to bridge this gap by examining the correlation between microstructural characteristics and mechanical response in FDM-printed polymers and composites. Two materials—PLA and PLA reinforced with carbon fiber (PLA+CF)—were selected to represent both pure and fiber-reinforced polymers. To test this hypothesis, tensile testing (ISO 527-2) was combined with optical microscopy to analyze layer cohesion, porosity, and fracture morphology before and after loading. It is hypothesized that optimized infill geometry and carbon fiber reinforcement improve layer cohesion and reduce microvoid formation, thereby enhancing tensile performance and resistance to environmental degradation.

This dual focus enables a deeper understanding of both fundamental material behavior and practical durability under real-world operating conditions.

From an industrial perspective, understanding the interplay between internal architecture, microstructure, and mechanical performance is essential for advancing the use of FDM materials in functional components operating under exposure to lubricants, oils, or variable temperatures. The findings of this study will contribute to a better understanding of the reliability of FDM-manufactured components frequently exposed to such environmental factors—such as housings, brackets, and load-bearing elements in machinery.

Overall, the introduction of this research framework provides both scientific and practical insights for optimizing FDM-printed polymer and composite components used in demanding industrial environments.

This study hypothesizes that both the internal infill architecture and exposure to lubricating oils synergistically influence the tensile and microstructural performance of FDM-printed PLA and PLA+CF materials. The objectives are to quantify these effects through standardized tensile testing, microstructural image analysis, and correlation of porosity metrics with mechanical response.

2. Materials and Methods

2.1. Material Specification for 3D Printing

Two polymeric filaments—polylactic acid (PLA) and PLA reinforced with short carbon fibers (PLA+CF)—were used to fabricate the tensile test specimens. Both materials were commercial 1.75 mm filaments supplied by Zhejiang FlashForge 3D Technology Co., Ltd. [Zhejiang, China] [

71].

The addition of short carbon fibers (average length ≈ 100 µm) enhances stiffness, heat resistance, and interlayer bonding while reducing shrinkage and residual stresses during solidification. The selection of both pure and composite filaments enabled a comparative analysis of the effect of carbon-fiber reinforcement on the mechanical and microstructural response of FDM-printed components under identical process conditions.

Table 1 and

Table 2 present the key physical and mechanical properties of the materials, as reported by the manufacturer and verified by the tensile tests conducted in this study. Including this table provides a clear baseline for the comparative analysis of PLA and its CF-reinforced counterparts, highlighting expected differences in stiffness and ductility prior to experimental evaluation.

2.2. Preparation and Printing of Tensile Test Specimens

The tensile specimens were designed in accordance with the ISO 527-2:2012 standard [

72]. The 3D models were created using

SolidWorks 2023 (Dassault Systèmes, France) and subsequently sliced in

FlashPrint5 software (

http://www.flashforge.com/ accessed on 18 August 2023). Fabrication was performed on an

Adventurer 4 Series 3D printer, manufactured by Zhejiang FlashForge 3D Technology Co., Ltd. [Zhejiang, China], with a 0.4 mm hardened steel nozzle and an automatic filament calibration system.

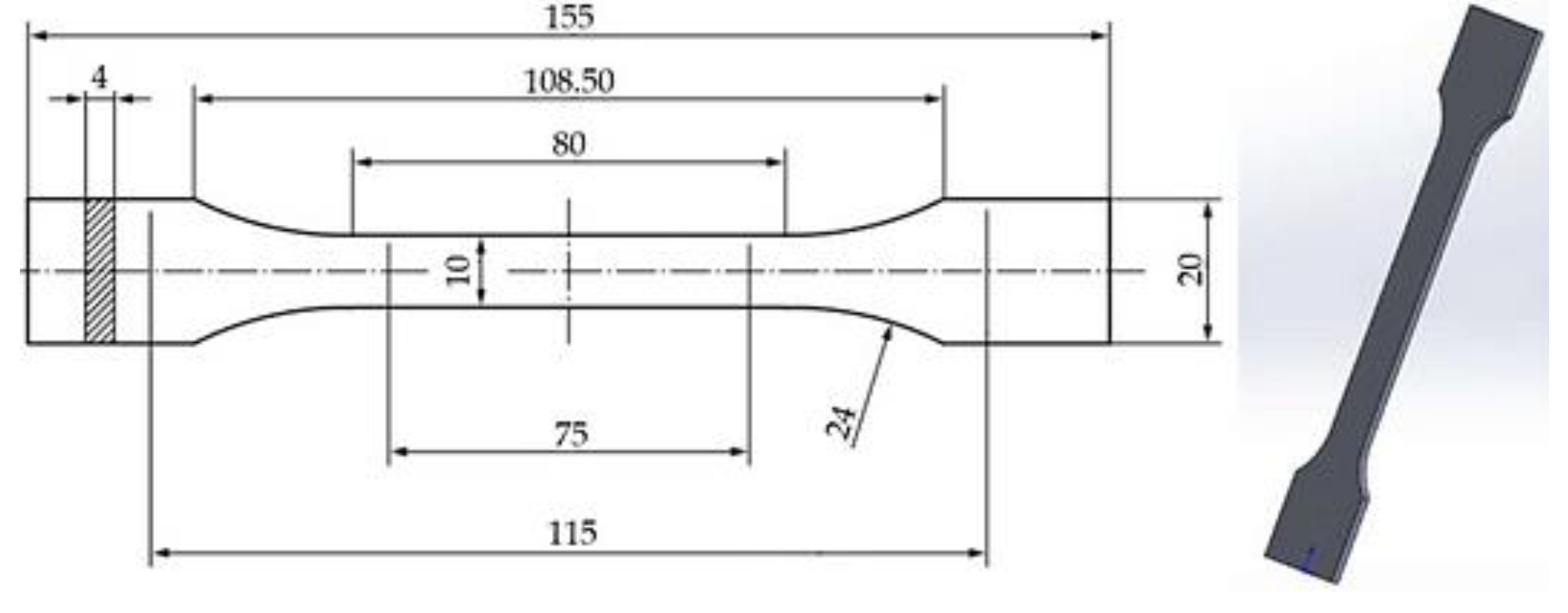

Figure 1 illustrates the CAD model of the standardized tensile specimen designed in

SolidWorks, with dimensions defined by ISO 527-2 geometry [

72]. The inclusion of this figure ensures replicability and provides a visual reference for the specimen configuration used across all tested materials.

To systematically isolate the effect of internal architecture, three experimental series were fabricated under identical printer settings (nozzle Ø 0.40 mm, layer height 0.20 mm; first layer 0.30 mm; four top and three bottom layers; print/travel speeds 60/100 mm·s

−1; bed 50 °C; extrusion 210 °C for PLA and 225 °C for PLA+CF). (i) Geometry series (30 % infill): PLA specimens with three infill patterns—linear/rectilinear (raster 0° parallel to the tensile axis), triangular (slicer default equiangular toolpaths, nominal 0°/±60°), and hexagonal (slicer-generated honeycomb with equiangular deposition). (ii) Density series (linear infill): PLA specimens with 30 %, 60 % and 100 % infill, raster 0° to the tensile axis. (iii) Oil-exposure series: PLA specimens with hexagonal, 30 % infill printed as in the geometry series; one group remained unexposed, the other was immersed 7 days in SAE 15W-40 (API SF/CD) prior to testing. For each condition we prepared tensile coupons (suffix A) and companion, unfractured coupons for microscopy (suffix B), using specimen codes consistent with

Section 3. After exposure, specimens were gently wiped and conditioned for 24 h prior to testing.

To achieve dimensional stability and eliminate residual moisture effects, all printed specimens were conditioned for 48 h in a controlled environment (23 ± 2 °C, 50 ± 5% RH) before testing.

Before mechanical testing, all specimens were visually inspected and measured using a digital caliper to verify dimensional conformity with the ISO 527-2:2012 standard [

72]. This step ensured that deviations in mechanical results were not caused by geometric inaccuracies or printing defects.

This controlled and repeatable fabrication process ensured that any variations in measured mechanical performance could be attributed primarily to material composition and environmental exposure rather than inconsistencies in printing parameters.

Prior to printing, both PLA and PLA+CF filaments were dried in a ventilated oven at 50 °C for 8 h to minimize the effect of absorbed moisture on extrusion stability and interlayer adhesion. This step was necessary because PLA is known to be hygroscopic, and residual humidity can lead to hydrolytic degradation and bubble formation during melting. The controlled pre-drying ensured consistent filament feeding, uniform layer deposition, and reliable mechanical performance of the printed specimens.

2.3. Tensile Testing for 3D-Printed Specimens

Tensile testing was performed in accordance with ISO 527-2:2012 standard [

72]. Mechanical characterization was conducted using a

Shimadzu AGS-X universal testing machine (Kyoto, Japan) equipped with a 10 kN load cell and an integrated

TrapeziumX control and data acquisition system.

The specimens were clamped using precision wedge grips to ensure uniform load distribution and minimize slippage. The tests were carried out under quasi-static loading at a constant crosshead speed of 5 mm/min and standard laboratory conditions (23 ± 2 °C, 50 ± 5% RH). Force and elongation were continuously measured by an extensometer with an accuracy of ±0.5 %, allowing for precise determination of strain behavior throughout the test. The testing order of samples was randomized to minimize potential systematic bias.

The mineral oil used for immersion testing was a commercially available multigrade engine lubricant (SAE 15W-40, API SN/CF classification). The oil temperature during the seven-day exposure was maintained at 25 ± 2 °C in sealed glass containers to prevent evaporation and contamination. The specimens were fully submerged and subsequently dried at room temperature for 24 h before testing to ensure stable mass and surface conditions.

Specimens were tested for both material type (PLA and PLA+CF) and condition (unexposed and lubricant-exposed), providing a statistically relevant dataset. From the recorded load–displacement data, the following mechanical parameters were derived: tensile strength (), calculated as the maximum load divided by the initial cross-sectional area; Young’s modulus (), obtained from the initial linear region of the stress–strain curve; nominal strain at break (), representing the percentage elongation at fracture; and maximum displacement (), defined as the total elongation of the specimen at the point of failure.

For specimens with infill < 100 %, tensile metrics are reported as apparent values referenced to the gross cross-section (σ_app = F_max / A_gross; E_app from the initial slope of the apparent stress–strain curve). This convention preserves geometric comparability within the present framework but yields values that are lower than catalogue properties obtained on fully dense, isotropic plastics. Where appropriate, we discuss how raster alignment, void topology and interlayer cohesion modulate these apparent properties.

For each experimental condition, three specimens (n = 3) were tested. The results are expressed as mean ± standard deviation (SD) and 95 % confidence interval (CI). The normality of data distribution was verified using the Shapiro–Wilk test, while the homogeneity of variances was assessed with Levene’s test. Statistical comparisons between groups within each series (geometry, infill density, and oil exposure) were performed using one-way analysis of variance (ANOVA) followed by Tukey’s HSD post-hoc test at a significance level of α = 0.05, or by the non-parametric Kruskal–Wallis test with Dunn’s multiple comparison correction where normality assumptions were not met. Effect sizes (η2) were calculated to evaluate the magnitude of differences, and potential outliers were screened using the robust median absolute deviation (MAD ± 3.5) criterion.

Given the small sample size (n = 3 per condition), normality and homoscedasticity tests have limited power, and effect-size estimates (η2) should be interpreted with caution. Accordingly, we report 95 % confidence intervals and treat marginal differences as indicative trends rather than definitive effects.

2.4. Macroscopic and Microstructural Examination

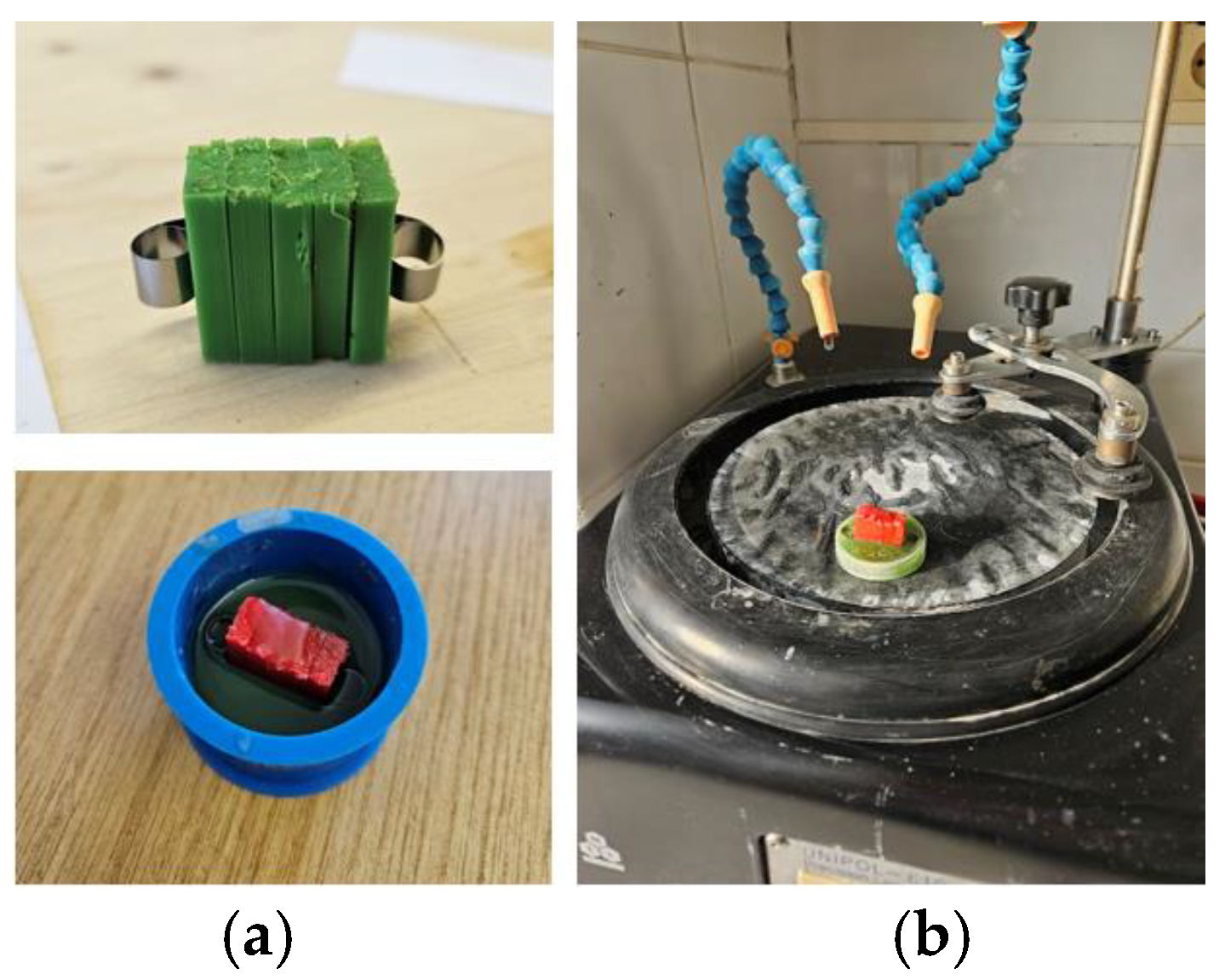

Following 3D printing, environmental exposure (including the 7-day immersion in mineral engine oil), and tensile testing, all specimens underwent systematic preparation for macroscopic and microscopic examination. Each specimen was first labeled with an identification code, and its midsection was precisely marked to ensure consistency across all analyzed samples. The central portions were then sectioned into approximately 15 mm long segments using a precision band saw. These subsections represented characteristic regions of the specimens, preserving both fracture zones and undamaged areas necessary for comparative microstructural assessment.

The extracted segments were subsequently embedded in epoxy resin molds to provide a stable base for surface preparation and analysis (

Figure 2a). After complete resin curing, the mounted samples were subjected to progressive mechanical grinding on an MTI Corporation

Unipol 810 grinding and polishing unit. The process began with coarse abrasive paper (P240) to remove excess resin and surface irregularities, followed by sequentially finer grades (P800, P1200, and P2500) to achieve a uniform and scratch-free surface finish (

Figure 2b). Upon completion of grinding, all specimens were carefully rinsed, cleaned, and then polished using alumina particles with an average size of 0.05 µm to produce a mirror-like surface suitable for high-resolution microscopy.

Macroscopic inspection of the prepared samples was first carried out using a VEVOR digital microscope (

VEVOR, EU [

74]), which provided a general overview of the surface morphology, identifying larger-scale defects such as delamination, void clusters, or surface tearing. This was followed by detailed optical microscopy performed with a Zeiss Axio Imager A1m (

Carl Zeiss Microscopy GmbH, Germany [

75]). Image acquisition and documentation were conducted using the

AxioVision software suite, ensuring precise calibration, focus uniformity, and reproducible imaging parameters across all specimens.

Subsequent quantitative image analysis was performed using

Fiji [

76], an open-source platform based on

ImageJ, which enabled accurate assessment of microstructural characteristics including pore size, shape distribution, and local heterogeneities in layer bonding. This digital image processing framework provided robust statistical data linking structural morphology with mechanical performance, particularly in identifying the initiation and propagation sites of cracks, the distribution of porosity, and the extent of interlayer cohesion.

Prior to quantitative evaluation, all microscopic images were calibrated in Fiji using a micrometric reference scale, where one division corresponded to 10 µm. This calibration step established the initial pixel-to-length conversion and ensured accurate spatial measurements across all magnifications. The scale bar displayed on the final figures (500 µm) reflects the actual magnification of the composite (stitched) images, which represent entire specimens with dimensions of approximately 40 × 100 mm. Each full-view image was composed of several overlapping microscopic subfields (individual FOV ≈ 2.5 × 1.9 mm), stitched together to achieve complete coverage of the gauge section while preserving micrometric accuracy.

Image preprocessing included background normalization and Gaussian smoothing (σ = 1.0) to minimize illumination gradients and improve segmentation contrast. These operations did not alter the specimen morphology but ensured consistent image quality and thresholding conditions across all analyzed regions. Segmentation of pores was performed using Otsu’s global thresholding (applied per image after background normalization). Post-threshold refinement used morphological opening and closing (disk kernel, radius = 2 px) to suppress isolated noise and merge fragmented pore boundaries.

Porosity (%) was computed as the ratio of pore pixels to analyzable pixels, multiplied by 100 %. For each specimen, five randomly selected fields of view within the gauge section were analyzed; inter-field variability is reported as the coefficient of variation (CV, %). To mitigate edge bias, a 20-px guard band was applied along the image perimeter; pores intersecting this band were excluded, and the analyzable area was updated accordingly. After morphological cleaning, only pores with an equivalent area between 10 and 100,000 µm2 were retained for quantification.

This comprehensive preparation and analysis procedure ensured the reliability of both qualitative and quantitative observations, allowing a detailed correlation between mechanical performance, fracture morphology, and the internal structural features of FDM-printed PLA and PLA+CF specimens under varying geometric, density, and environmental conditions.

3. Results

This section presents a comprehensive analysis of the microstructural changes observed in polymeric and composite materials fabricated using FDM technology, and their influence on the resulting mechanical properties. The study is based on tensile testing and microstructural characterization of specimens printed from two different materials: PLA, and PLA reinforced with short carbon fibers (PLA+CF). Each subsection of this chapter is structured into three integral parts that together provide a holistic understanding of how the selected process parameters affect the mechanical and structural performance of the tested materials.

Section 3.1 reports PLA results; the PLA+CF composite is analyzed in

Section 3.2 under identical protocols.

The first part of each subsection presents the results of tensile testing as a function of the infill structure geometry. Three distinct infill patterns—linear, triangular, and hexagonal—were analyzed, while maintaining a constant infill density of 30 %. The obtained results include both mechanical parameters and microstructural features, elucidating the influence of the infill geometry on tensile strength, ductility, and internal structural integrity. Comparative analysis reveals how the geometric arrangement of the printed layers affects load distribution, crack propagation, and interlayer bonding, thereby determining the overall material performance under uniaxial stress.

The second part of each subsection focuses on the influence of infill density in specimens with a linear structure. Samples were printed at three infill densities—30 %, 60 %, and 100 %—to evaluate the correlation between internal porosity and mechanical response. This section provides insight into how increasing the material content within the specimen influences stiffness, ultimate tensile strength, and failure mechanisms, as well as the corresponding microstructural features observed under optical microscopy. The results also serve as an experimental validation of the well-established relationship between the effective load-bearing cross-section and the apparent modulus of elasticity in FDM-printed polymers and composites.

The third part addresses the environmental effects on mechanical and microstructural behavior, with particular emphasis on exposure to mineral motor oil. In this stage of the experiment, samples with hexagonal infill geometry and 30 % density were subjected to controlled oil exposure. The results demonstrate how environmental degradation—manifested through increased porosity, microcrack formation, and interlayer delamination—affects the mechanical performance of the materials, particularly their tensile strength. The findings highlight the susceptibility of polymeric and composite structures to chemical interactions with lubricants, providing critical information for potential applications in tribologically demanding environments.

Throughout this section, the results are presented using a combination of tables, graphs, and microscopic images, ensuring a clear visualization of the correlations between process parameters, microstructural morphology, and mechanical behavior. The primary objective of this chapter is to deliver a comprehensive and systematic presentation of the findings, forming a foundation for the optimization of FDM process parameters and the future development of polymeric and composite materials with enhanced structural integrity and environmental resistance.

3.1. Mechanical Parameters and Microstructural Response of 3D-Printed PLA Specimens

The mechanical behavior and microstructural response of FDM 3D-printed PLA specimens were systematically evaluated by examining the influence of infill structure geometry (

Section 3.1.1), the infill density of the linear pattern (

Section 3.1.2), and the exposure duration to mineral motor oil in specimens with hexagonal infill structures (

Section 3.1.3).

Across

Section 3.1.1–3.1.3, specimen codes are used as follows: geometry series (30 % infill): V1A/V1B = hexagonal, V2A/V2B = triangular, V3A/V3B = linear. Density series (linear infill): V3A–V5A (tensile) and V3B–V5B (microstructure) correspond to 30 %, 60 %, 100 %. Oil exposure (hexagonal, 30 %): V1A/V1B = unexposed; V6A/V6B = 7-day exposure. Suffix A = tensile specimens; B = unfractured for microscopy.

3.1.1. Influence of Infill Structure Geometry on the Mechanical and Microstructural Behavior of 3D-Printed PLA Specimens

The geometry of the internal infill structure plays a decisive role in determining the load-bearing capacity and microstructural integrity of FDM-printed polymer components. In particular, the arrangement of filament paths and the quality of interlayer bonding significantly influence the resulting mechanical performance.

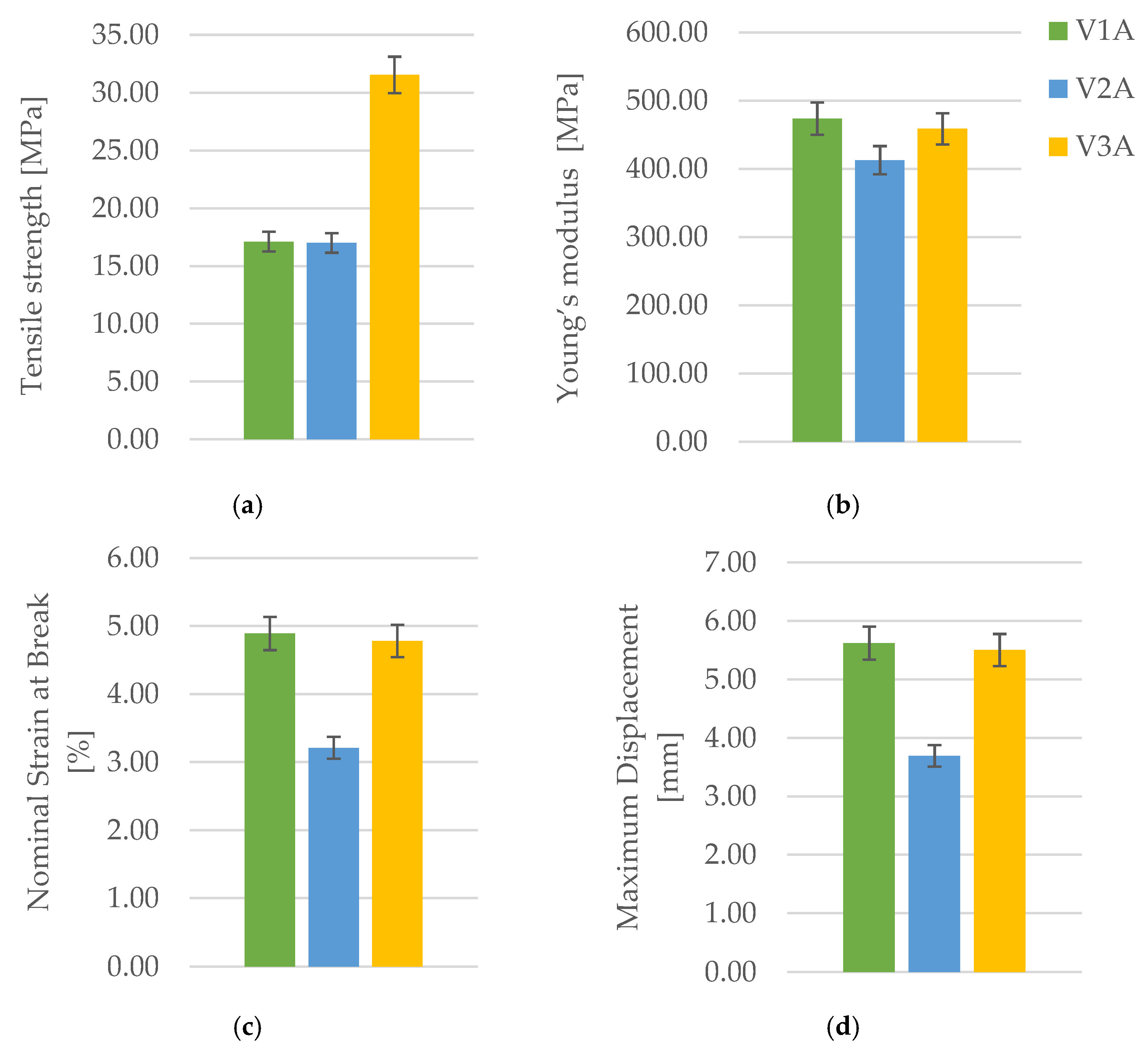

Figure 3 presents the PLA specimens after tensile testing, printed with three distinct infill geometries: hexagonal (V1A), triangular (V2A), and linear (V3A). All were printed with PLA and an infill density of 30 %. The corresponding results of the tensile tests for all PLA specimens fabricated via FDM are summarized in

Table 3. The comparative analysis of the principal mechanical parameters—tensile strength (

), Young’s modulus (

), maximum displacement (

), and nominal strain at break (

)—is shown in

Figure 4.

The results summarized in

Table 3 and illustrated in

Figure 4 clearly demonstrate that infill geometry strongly influences the tensile behavior of FDM-printed PLA specimens. The linear infill pattern (V3A) exhibited the highest tensile strength (31.53 MPa) and moderate ductility (

= 4.78 %,

= 5.50 mm), indicating efficient stress transfer along the printing direction due to highly oriented filament paths. The hexagonal infill (V1A) showed lower tensile strength (17.10 MPa) but the highest elongation (

= 4.89 %,

= 5.62 mm), reflecting superior ductility and energy absorption capability. In contrast, the triangular infill (V2A) exhibited the lowest mechanical performance (

= 16.99 MPa,

= 412.69 MPa,

= 3.21 %), attributed to stress concentration at the sharp cell junctions and weaker interlayer bonding.

The linear infill was printed with raster lines aligned to the loading axis, enabling efficient axial load transfer and explaining the highest tensile strength in V3A. In contrast, hexagonal and especially triangular topologies introduce multi-directional paths and sharper junctions that elevate local stress concentration and reduce net load-bearing efficiency.

Overall, the linear pattern provided the highest tensile strength, while the hexagonal pattern displayed the most balanced performance, combining moderate stiffness with excellent ductility. The triangular pattern was mechanically the least favorable, reflecting more pronounced stress localization and limited deformation capacity prior to fracture.

The observed differences were further examined through a combined fractographic and microstructural approach to correlate macroscopic behavior with underlying structural features.

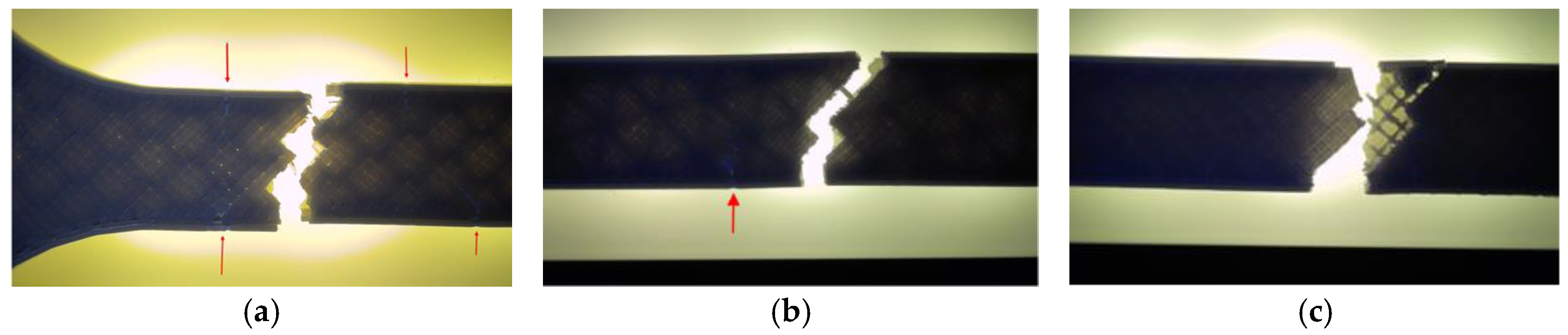

Fractographic analysis provided further insight into the distinct failure mechanisms observed among the specimens. The hexagonal specimen (V1A) (

Figure 5a) exhibited a clean and relatively brittle fracture at the narrowest cross-section, where stress concentration was highest. Subtle color changes along the internal walls, especially at the intersections of the hexagonal cells, indicated localized stress redistribution prior to fracture. The external layers remained well-bonded with no visible delamination, confirming strong interlayer adhesion.

The triangular specimen (V2A) (

Figure 5b) fractured along the cell junctions, following the principal stress paths inherent to its geometry. Sharp fracture edges and localized discoloration near cell vertices suggest stress accumulation leading to brittle failure. In contrast, the linear specimen (V3A) (

Figure 5c) fractured predominantly along the printed line direction. The relatively smooth fracture surface and absence of delamination indicate that failure was governed by localized stress accumulation at the filament junctions, resulting in abrupt rupture.

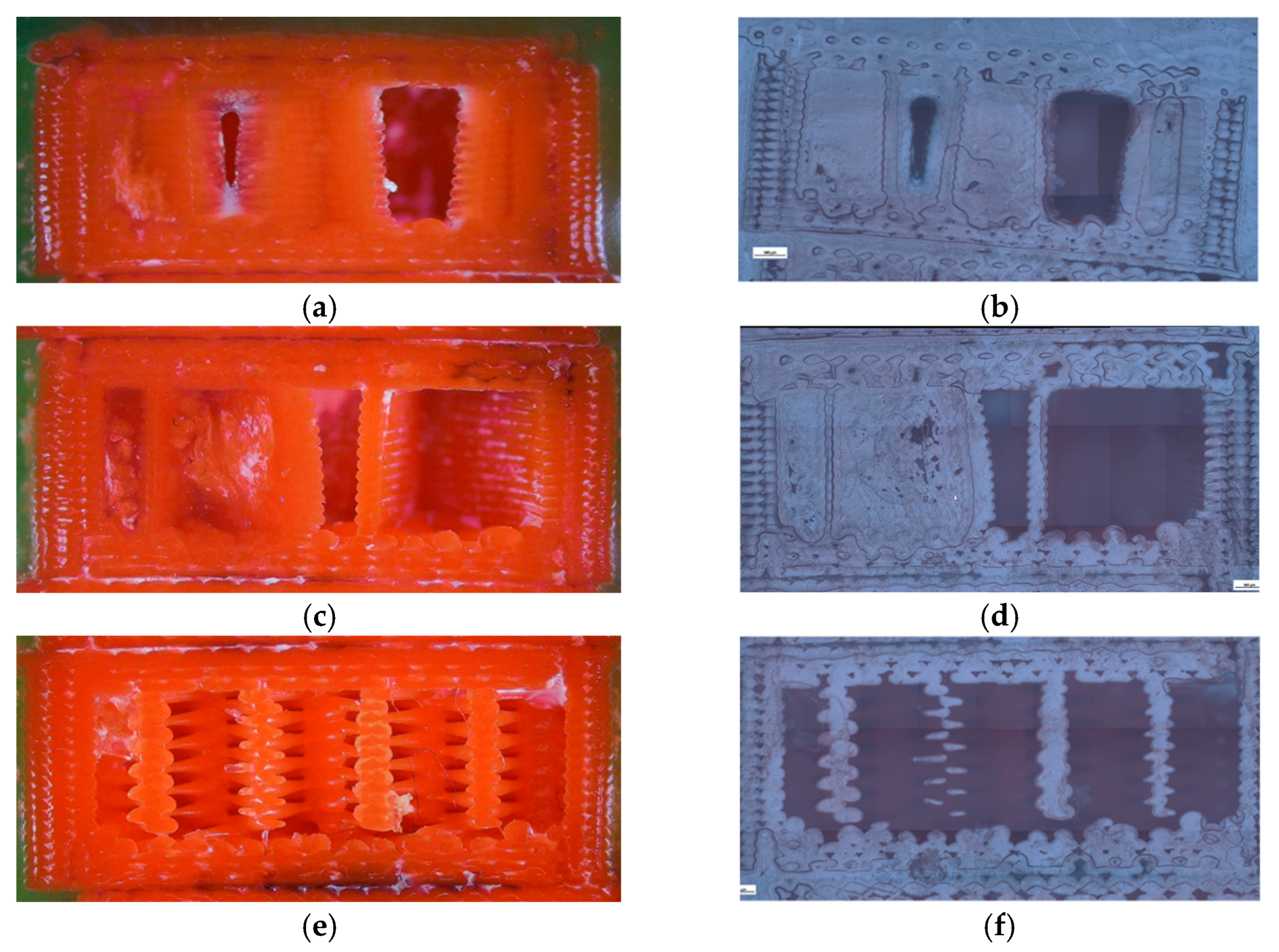

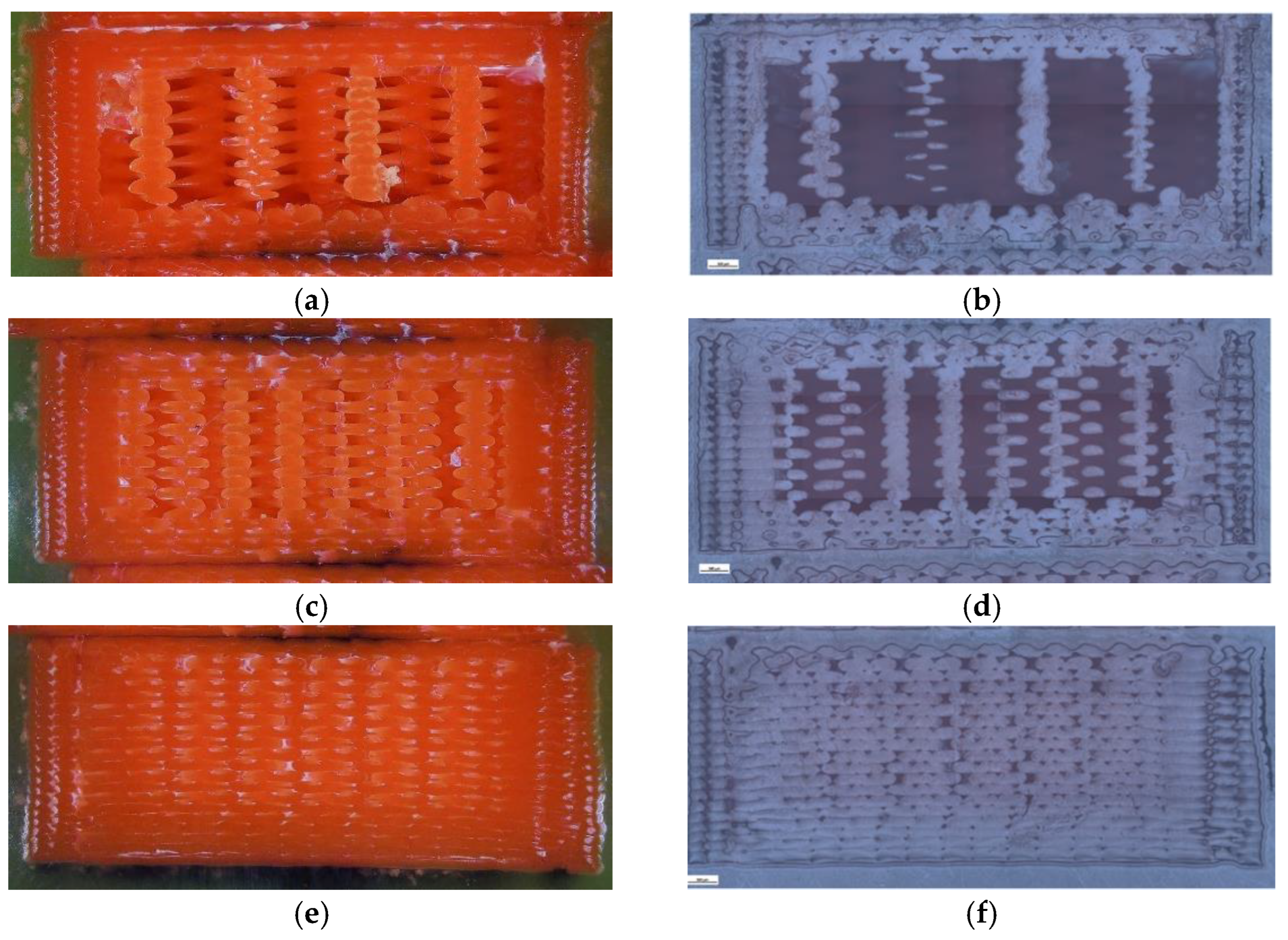

To complement the mechanical findings, unfractured specimens were analyzed using a micro-camera and optical microscopy (

Figure 6) to assess the internal morphology, porosity distribution, and interlayer adhesion quality.

Clear geometry-dependent differences were observed. The hexagonal sample (V1B) contained small voids aligned with the cell geometry, exhibiting stable sidewalls with only minor delamination near the upper layers. The triangular sample (V2B) displayed larger voids concentrated at the vertices, whereas the linear infill (V3B) showed a uniform structure with fewer, smaller voids mainly located near the model edges.

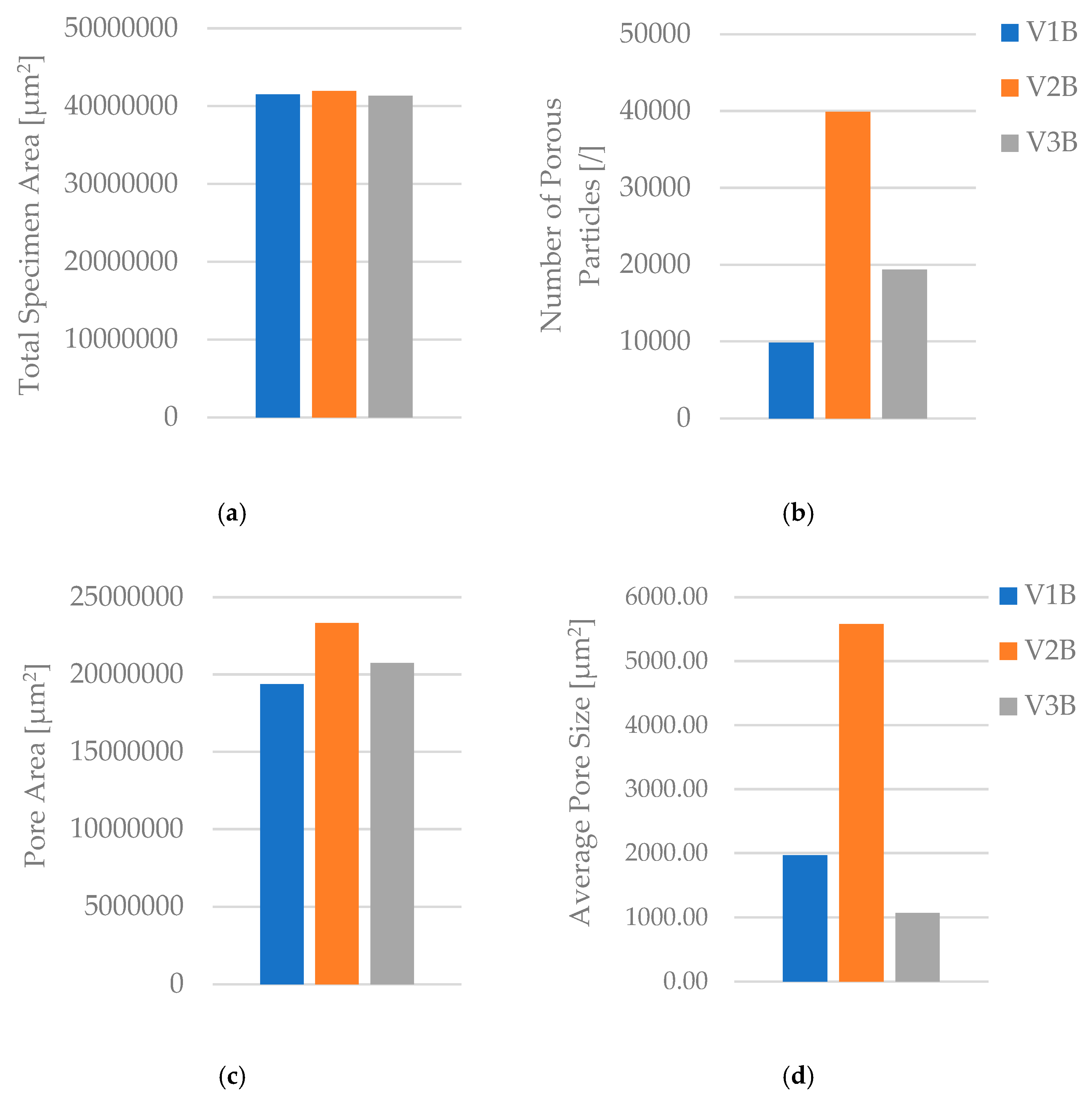

Quantitative microstructural data obtained using Fiji software (

Table 4 and

Figure 7) demonstrated a clear correlation between infill geometry and porosity.

The triangular pattern (V2B) exhibited the highest total pore count and pore area, resulting in the largest average pore size (5 578.05 µm2) and the highest pore area fraction (55.64%). In contrast, the hexagonal structure (V1B) showed fewer and smaller voids, while the linear pattern (V3B) exhibited the lowest overall porosity.

The quantitative microstructural analysis supports the observed mechanical trends. The linear infill (V3A) exhibited the lowest porosity and the most uniform interlayer bonding, which corresponded to its highest tensile strength. Conversely, the triangular structure (V2A), characterized by the largest average pore size and highest pore area fraction, showed the lowest strength and stiffness, indicating that void formation critically impairs stress transfer across adjacent filaments. The hexagonal pattern (V1A) provided an intermediate behavior, where moderate porosity allowed for limited plastic deformation and higher ductility. These results confirm that mechanical performance in FDM-printed PLA is governed by a direct interplay between infill geometry, porosity distribution, and interlayer adhesion.

In summary, these findings highlight the critical influence of infill geometry on the mechanical and microstructural behavior of FDM-printed PLA. Optimizing internal architecture enables effective control over strength, stiffness, and ductility, providing a valuable framework for the design of lightweight, high-performance polymeric components. Such insights are particularly relevant for functional and load-bearing applications in mechanical, aerospace, and biomedical engineering. The correlation between lower porosity and improved tensile performance confirms that enhanced filament fusion and reduced void formation facilitate more efficient stress transfer across layers.

These results form the basis for further correlation analysis between pore morphology and apparent tensile properties, as discussed in

Section 4.

3.1.2. Influence of Infill Density on the Mechanical and Microstructural Behavior of 3D-Printed PLA Specimens

The infill density is one of the most influential parameters determining the mechanical strength, stiffness, and microstructural quality of FDM-printed polymer components. Variations in infill density affect the material continuity, void fraction, and efficiency of stress transfer between adjacent filaments. To evaluate this influence, three groups of PLA specimens with identical geometry (linear infill pattern, V3 series) but different infill densities—30 % (V3A), 60 % (V4A), and 100 % (V5A)—were fabricated under identical printing conditions.

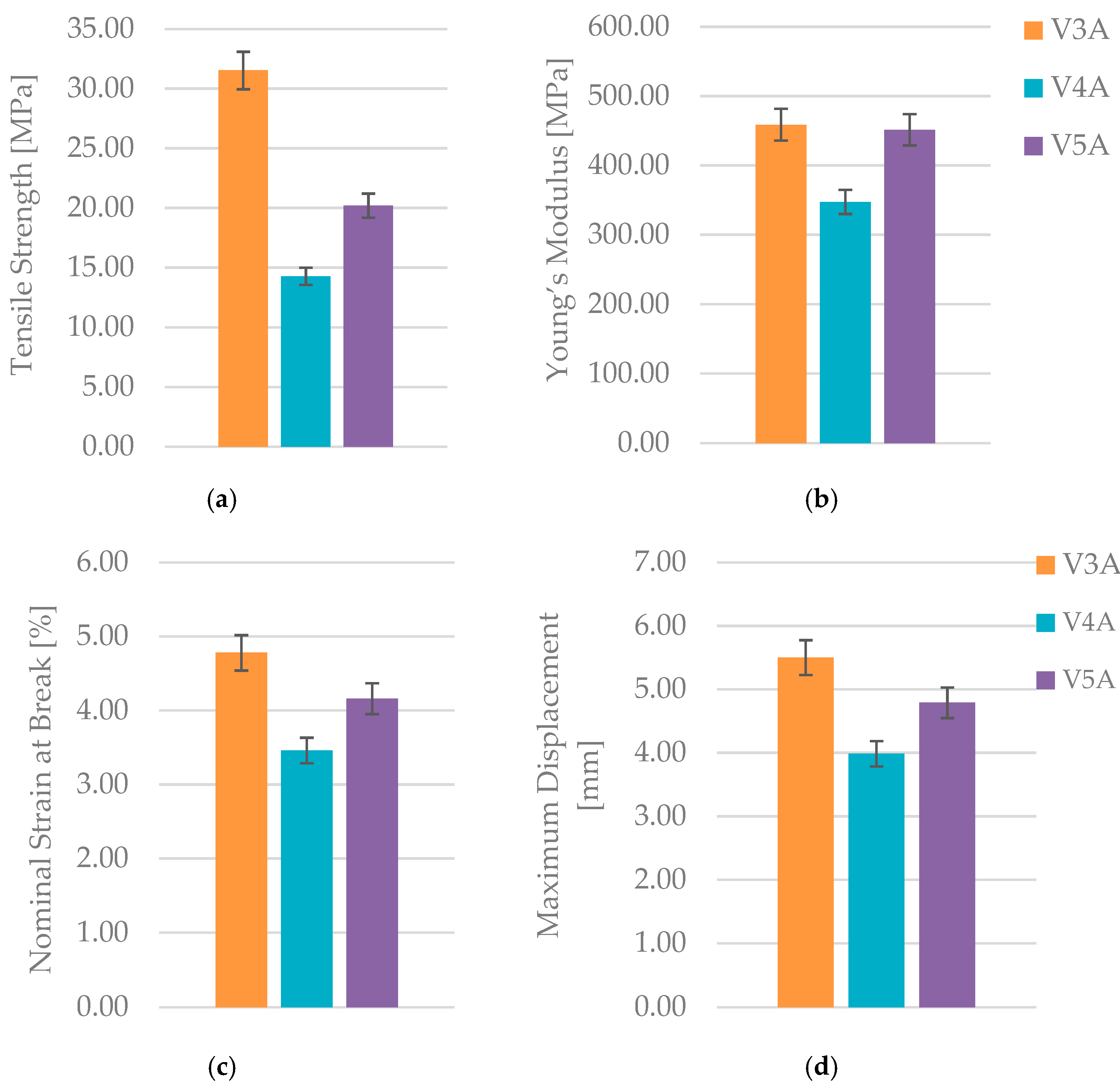

Figure 8 shows the appearance of the specimens after tensile testing, revealing clear differences in fracture morphology between low- and high-density structures.

The corresponding mechanical parameters obtained from the tensile tests are summarized in

Table 5, while

Figure 9 compares the key mechanical indicators—tensile strength (

), Young’s modulus (

), nominal strain at break (

), and maximum displacement (

).

The dependence of tensile performance on infill density is non-monotonic. At 30% (V3A), favorable filament orientation and controlled porosity maximize strength; at 60% (V4A), partially filled cells create irregular load paths and stress localizations; at 100% (V5A), material continuity rises but interfacial constraints and residual stresses can promote premature cracking. The specimen with 30 % infill (V3A) unexpectedly achieved the highest tensile strength (31.53 Mpa) and stiffness ( = 458.76 Mpa), combined with moderate ductility ( = 4.78 %, = 5.50 mm). In contrast, the 60 % infill specimen (V4A) exhibited the lowest mechanical response ( = 14.28 Mpa, = 347.47 Mpa, εₑ = 3.46 %), likely due to stress localization within partially filled void regions and irregular interlayer bonding.

The fully dense specimen (V5A, 100 %) demonstrated an intermediate tensile strength (20.20 MPa) and Young’s modulus ( = 451.46 Mpa), suggesting that although material continuity was maximized, increased internal stress concentration at the fully compacted structure may have initiated premature fracture.

Fractographic analysis provided additional insight into the distinct failure mechanisms observed among the specimens (

Figure 10). The 30 % infill specimen (V3A) exhibited a relatively smooth fracture surface with limited delamination, suggesting effective load redistribution and stable filament fusion despite reduced material content. This behavior can be attributed to the stress redistribution effect associated with partially porous internal structures. At 30% infill, the presence of voids enables localized strain accommodation and delays the onset of brittle fracture, while excessive densification (100% infill) restricts internal stress relaxation and may promote microcrack initiation along the interlayer boundaries. The 60 % infill specimen (V4A) revealed a brittle fracture with sharp edges and visible interlayer gaps, confirming incomplete filament bonding and localized stress accumulation at pore junctions. Conversely, the 100 % infill specimen (V5A) demonstrated compact fracture morphology with strong interlayer adhesion but also exhibited microcracks originating from interfacial defects, indicating local overstressing within the highly compact structure.

Mechanistically, the 60 % layout leaves ligaments and void clusters that act as micro-notches within the infill, concentrating stress at filament junctions. This explains the brittle-like features and the reduced tensile strength () and Young’s modulus () despite higher material usage than 30 %.

To further support these findings, the unfractured specimens were examined using optical microscopy to assess the internal infill morphology, void distribution, and interlayer adhesion quality (

Figure 11). Increasing the infill density visibly reduced the number and size of internal pores, while improving structural uniformity and contact between adjacent filaments.

The 30 % infill specimen (V3B) contained larger but evenly distributed pores, which contributed to partial stress dissipation during tensile loading. The 60 % infill specimen (V4B) exhibited irregularly shaped void clusters that acted as stress concentrators, explaining its inferior mechanical response. The 100 % infill specimen (V5B) displayed minimal visible porosity, although the dense filament packing may have induced microcrack initiation under localized stress accumulation.

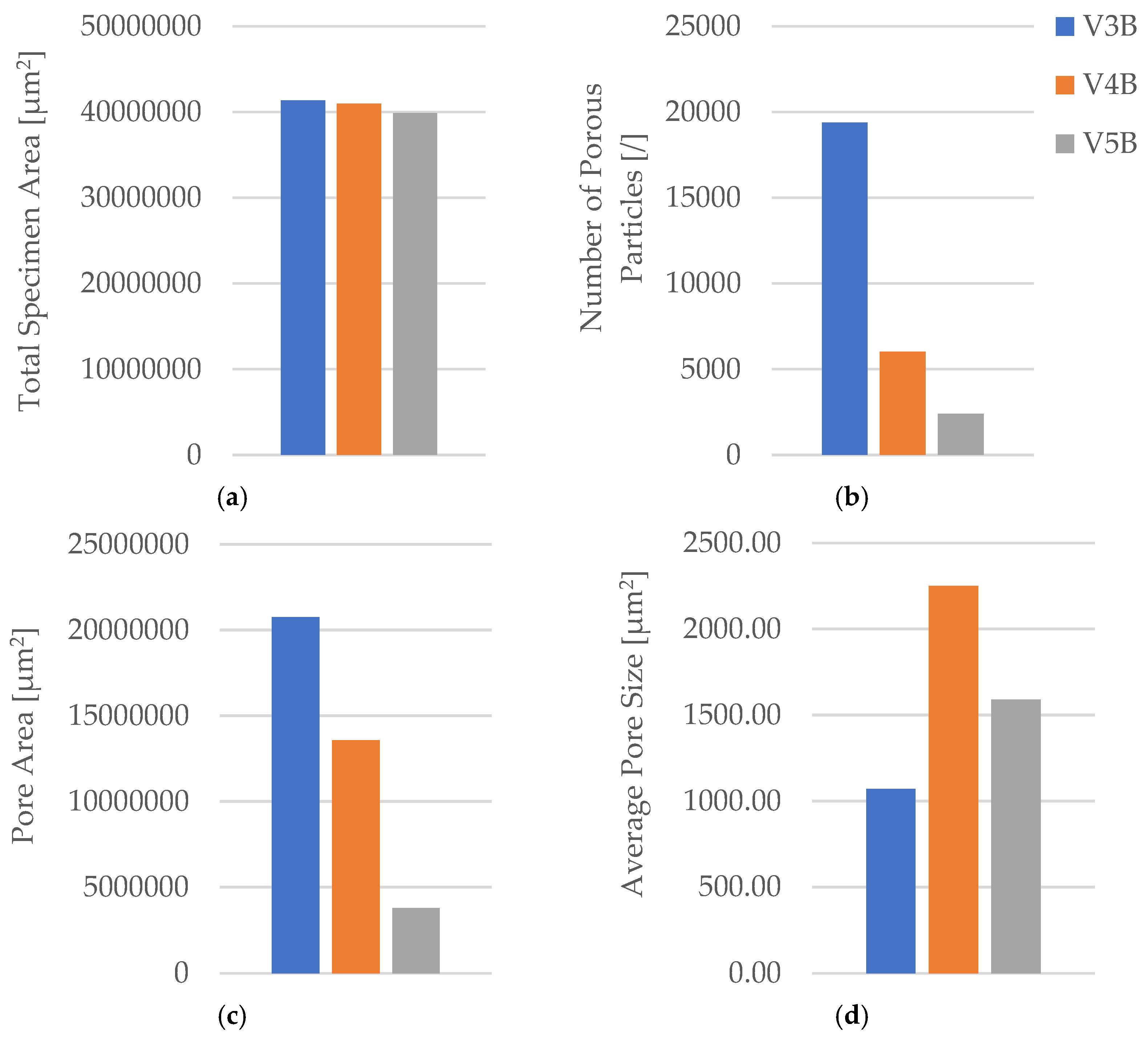

Quantitative analysis of the microstructural features was performed using Fiji software (

Table 6,

Figure 12), confirming the relationship between density, pore distribution, and average pore size.

The pore count and total pore area decrease with increasing infill density, while the average pore size exhibits a non-monotonic trend, reflecting local variations in interlayer fusion and thermal history. This indicates that densification improves compactness overall, but micro-scale processing conditions still govern defect morphology.

The microstructural results are consistent with the mechanical trends. Specimens with higher infill density exhibited a more compact structure, stronger interlayer bonding, and fewer voids, while intermediate-density samples showed irregular pore clusters that weakened local adhesion. The non-monotonic mechanical behavior suggests that excessive densification can lead to stress concentration and early crack initiation, while lower density allows limited energy absorption due to larger, evenly distributed voids.

In summary, increasing infill density from 30 % to 100 % did not result in a simple linear improvement in tensile performance. Instead, the optimal mechanical response was achieved at 30 % infill, where balanced filament orientation and moderate porosity contributed to superior strength and ductility. These findings confirm that mechanical behavior in FDM-printed PLA is controlled not only by infill density but also by the quality of interlayer fusion and pore morphology, consistent with the correlations reported by Guessasma et al. [

62].

Note that tensile strength () and Young’s modulus () are apparent values referenced to the gross cross-section; thus, comparisons are meaningful within the present geometry/density framework. The superior apparent response at 30 % infill is attributed to raster alignment and void topology that enhance axial load transfer despite reduced solid fraction.

3.1.3. Influence of Exposure to Mineral Engine Oil on the Mechanical and Microstructural Behavior of 3D-Printed PLA Specimens

The environmental exposure of FDM-printed polymer components to chemical agents such as mineral oils can significantly alter their mechanical integrity and microstructural morphology. To evaluate this influence, tensile tests were conducted on PLA specimens with hexagonal infill geometry (30 % density) before and after 7 days of immersion in mineral motor oil. Two specimen groups were analyzed: V1A (unexposed) and V6A (7 days oil-exposed).

Figure 13 presents the PLA specimens after tensile testing, showing clear visual differences in the fracture morphology between the unexposed and oil-exposed samples. The corresponding mechanical parameters are summarized in

Table 7, while the comparative analysis of the key mechanical indicators—tensile strength (

), Young’s modulus (

), nominal strain at break (

), and maximum displacement (

)—is illustrated in

Figure 14.

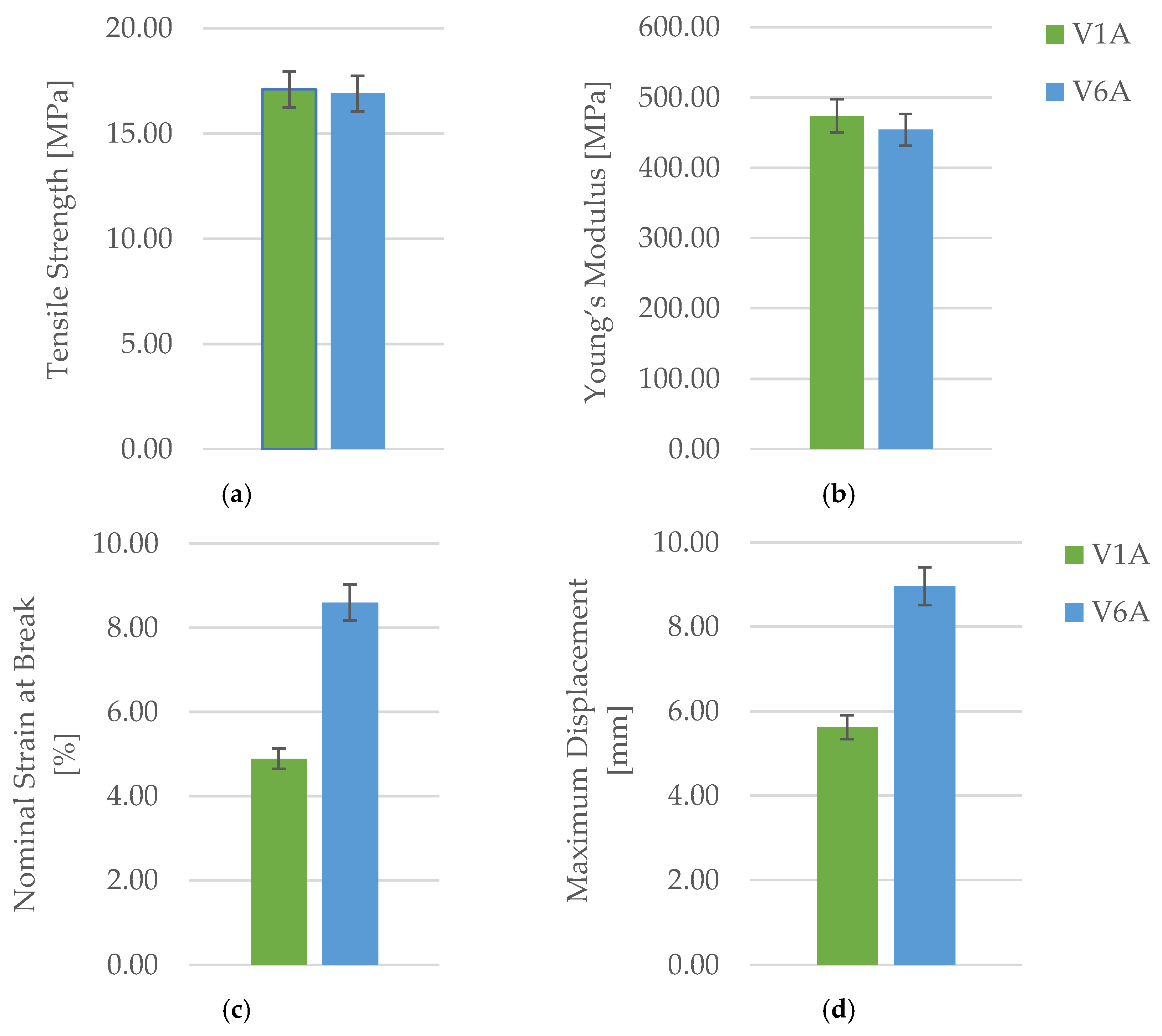

The results summarized in

Table 7 and illustrated in

Figure 14 indicate that exposure to mineral oil slightly affected the mechanical behavior of the PLA specimens.

The tensile strength decreased marginally from 17.10 MPa (V1A) to 16.90 Mpa (V6A), while the Young’s modulus dropped from 473.71 Mpa to 454.13 Mpa, indicating a small but measurable reduction in stiffness. Conversely, the nominal strain at break increased significantly from 4.89 % to 8.60 %, and the maximum displacement rose from 5.62 mm to 8.96 mm, confirming a pronounced improvement in ductility and elongation capacity.

These findings suggest that mineral oil acts as a mild plasticizing medium: absorbed molecules penetrate between polymer chains, reducing intermolecular cohesion and enhancing chain mobility. Consequently, the material exhibited slightly lower stiffness and strength but improved flexibility and energy absorption capability.

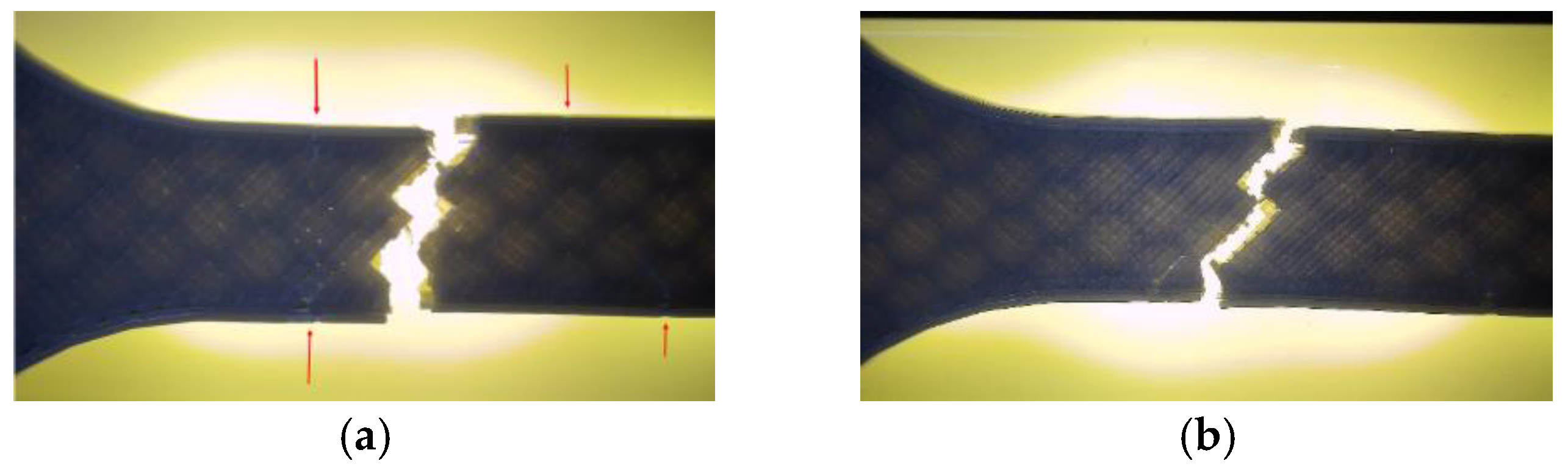

Fractographic examination revealed distinct differences in the failure mechanisms between the unexposed and oil-exposed specimens (

Figure 15).

The unexposed specimen (V1A) fractured at the narrowest cross-section, exhibiting a clean and predominantly brittle fracture with minor tearing along the inner cell walls. Local color variations at the hexagonal junctions indicated stress redistribution prior to failure, while the outer surfaces remained well bonded, confirming strong interlayer adhesion.

In contrast, the oil-exposed specimen (V6A) displayed a rougher fracture surface with visible shear zones, indicating enhanced plastic deformation. The crack propagation followed weakened filament junctions within the hexagonal structure, where localized softening and partial delamination were observed.

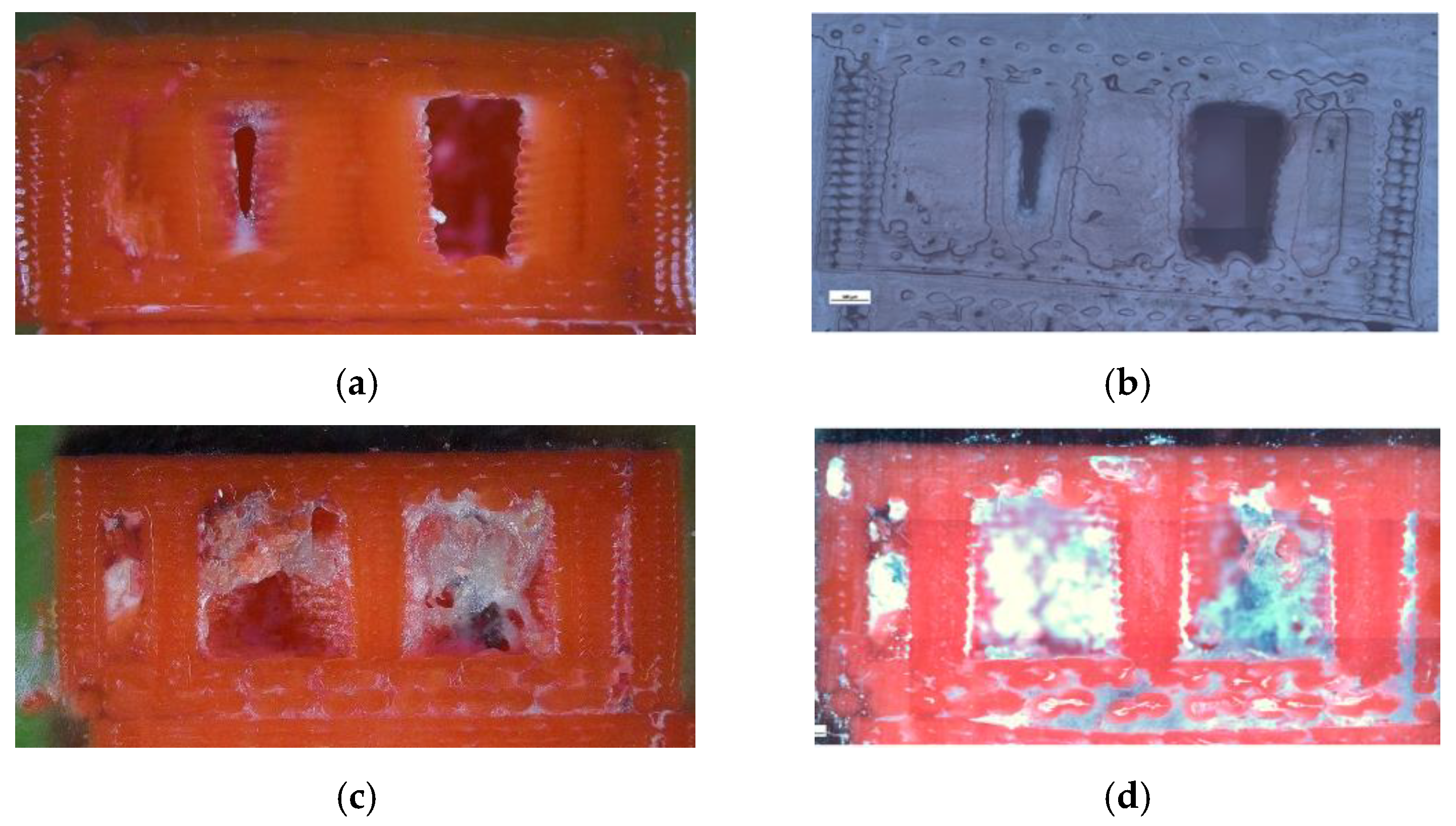

Optical microscopy was used to examine unfractured specimens and assess morphological changes induced by oil exposure (

Figure 16).

The unexposed specimen (V1B) showed small, regularly distributed voids corresponding to the hexagonal infill structure and well-formed interlayer bonding. Only minor delamination was observed near upper layers.

The oil-exposed specimen (V6B) exhibited partially oil-filled pores and mild interlayer separation, particularly near the lower specimen region. These observations confirm that mineral oil infiltrated the voids, weakened interlayer adhesion, and induced local softening, resulting in greater ductility but reduced rigidity.

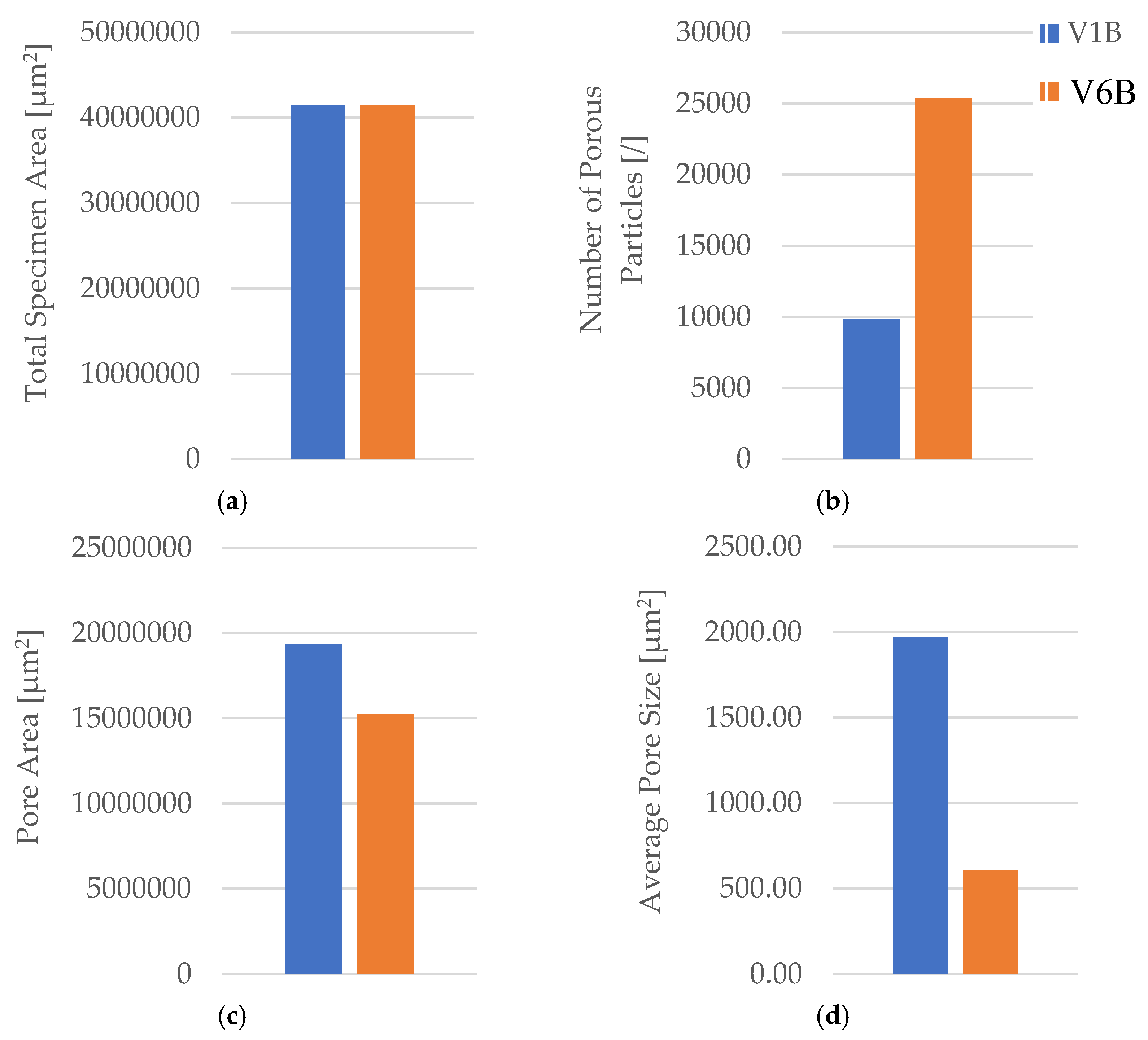

Quantitative image analysis using Fiji software (

Table 8,

Figure 17) confirmed significant microstructural changes after oil exposure.

The total specimen area remained nearly constant, while the number of pores increased from 9 841 (V1B) to 25 338 (V6B)—a 2.6-fold rise. Despite the higher pore count, the total pore area decreased from 19.36×106 µm2 to 15.27×106 µm2, and the average pore size reduced from 1 967.24 µm2 to 602.74 µm2, indicating the formation of finer and more uniformly distributed voids within the matrix.

The combined mechanical and microstructural results demonstrate that exposure to mineral motor oil induces partial softening and microstructural refinement of the PLA matrix. A minor decrease in tensile strength (−1.2 %) and Young’s modulus (−4.1 %) was accompanied by a substantial increase in elongation (+76 %), reflecting plasticization of the polymer network.

The correlation between the increased ductility and refined microstructure indicates that oil absorption reorganized the internal structure, facilitating stress relaxation and energy dissipation during loading.

These findings are consistent with the softening mechanisms reported by Pascual-González et al. [

61] and Guessasma et al. [

62], where exposure to liquid media enhanced polymer flexibility by reducing secondary intermolecular interactions.

Compared to the results in

Section 3.1.1 and 3.1.2, where infill geometry and density primarily affected the mechanical response through structural continuity and void fraction, the present results show that environmental exposure influences the PLA matrix itself, introducing molecular-level softening rather than geometric weakening.

In summary, immersion in mineral motor oil slightly reduces stiffness and strength but significantly enhances ductility, confirming that chemical–environmental exposure can substantially modify the mechanical behavior of FDM-printed PLA through matrix plasticization and microstructural adaptation.

These results highlight the importance of considering lubricant compatibility when designing PLA-based components intended for service in oil-contact or hydrocarbon-rich environments.

Tensile behavior of FDM-PLA is governed by two coupled levers: (i) structural topology (raster orientation, cell junction sharpness, void topology) and (ii) matrix conditioning (oil-induced plasticization). Aligning the raster with the load and avoiding sharp junctions improves , while judicious density selection prevents stress localization (the 30% linear case outperforms 60–100 % in ). Oil exposure introduces molecular-level softening and defect refinement (pore count ↑2.6× with pore size ↓3.3×), trading small losses in for a ~76 % gain in ductility.

Limitations. The present results are specific to the selected PLA grade and printing parameters. Potential confounders include environmental humidity, filament moisture content, and build-plate temperature history. Oil exposure was limited to 7 days; longer conditioning or different lubricants (e.g., synthetic or bio-based oils) may alter the magnitude of plasticization. These aspects warrant future study.

In addition, the use of apparent stress and modulus for < 100 % infill implies geometry-dependent values that are not directly comparable to fully dense, isotropic datasheet properties. Future work should complement apparent metrics with normalization to effective load-bearing area and with larger sample sizes to increase statistical power.

3.2. Mechanical Parameters and Microstructural Response of 3D-Printed PLA+CF Specimens

The mechanical behavior and microstructural response of FDM 3D-printed PLA+CF specimens were systematically evaluated by examining the influence of infill structure geometry (

Section 3.2.1), the infill density of the linear pattern (

Section 3.2.2), and the exposure duration to mineral motor oil in specimens with hexagonal infill structures (

Section 3.2.3).

Across

Section 3.2.1–3.2.3, specimen codes are used as follows: geometry series (30 % infill): V7A/V7B = hexagonal, V8A/V8B = triangular, V9A/V9B = linear. Density series (linear infill): V9A–V11A (tensile) and V9B–V11B (microstructure) correspond to 30 %, 60 %, and 100 %. Oil exposure (hexagonal, 30 %): V7A/V7B = unexposed; V12A/V12B = 7-day exposure. Suffix A = tensile specimens; B = unfractured for microscopy.

3.2.1. Influence of Infill Geometry on the Mechanical and Microstructural Behavior of 3D-Printed PLA+CF Specimens

The geometry of the internal infill structure plays a decisive role in determining the load-bearing capacity, stiffness, and fracture behavior of FDM-printed composite components. For PLA reinforced with short carbon fibers (PLA+CF), the effect of infill geometry is further amplified by the partial alignment of fibers along the extrusion direction, which governs both the mechanical response and the resulting microstructural morphology.

Figure 18 presents the PLA+CF specimens after tensile testing, printed with three distinct infill geometries: hexagonal (V7A), triangular (V8A), and linear (V9A). The corresponding tensile test results are summarized in

Table 9, and the comparative analysis of the principal mechanical parameters—tensile strength (

), Young’s modulus (

), nominal strain at break (

), and maximum displacement (

)—is shown in

Figure 19.

The obtained results clearly demonstrate that the infill geometry exerts a significant influence on the tensile performance of PLA+CF specimens. The triangular infill (V8A) exhibited the highest tensile strength (19.58 MPa), attributed to the efficient load transfer through short, stiff cell junctions that minimize stress concentration. The hexagonal structure (V7A) showed slightly lower strength (18.30 Mpa) but the highest ductility ( = 4.82 %), confirming its ability to absorb deformation energy and delay catastrophic failure. The linear infill (V9A) displayed the lowest mechanical performance ( = 15.72 Mpa, = 228.84 Mpa), likely due to stress accumulation along filament boundaries and weaker interlayer bonding.

The addition of short carbon fibers enhanced the stiffness and dimensional stability compared to pure PLA (

Section 3.1.1), although the magnitude of improvement depended strongly on the geometric arrangement of the internal structure. The triangular and hexagonal patterns provided better stress redistribution and interlayer fusion, whereas the linear pattern—although aligned with the loading axis—showed premature interfacial separation and lower stress tolerance.

The observed differences were further interpreted through a combined mechanical–microstructural correlation analysis.

Fractographic analysis (

Figure 20) revealed distinct failure mechanisms for each geometry. The hexagonal specimen (V7A) fractured through a combination of matrix cracking and fiber pull-out, with smooth fracture regions surrounded by localized shear zones. The triangular specimen (V8A) exhibited brittle-like fracture features at the cell vertices, with visible fiber imprints and microvoids at interlayer junctions. The linear specimen (V9A) showed a more uniform fracture surface dominated by filament splitting and limited fiber bridging, indicating interfacial decohesion between fibers and the PLA matrix.

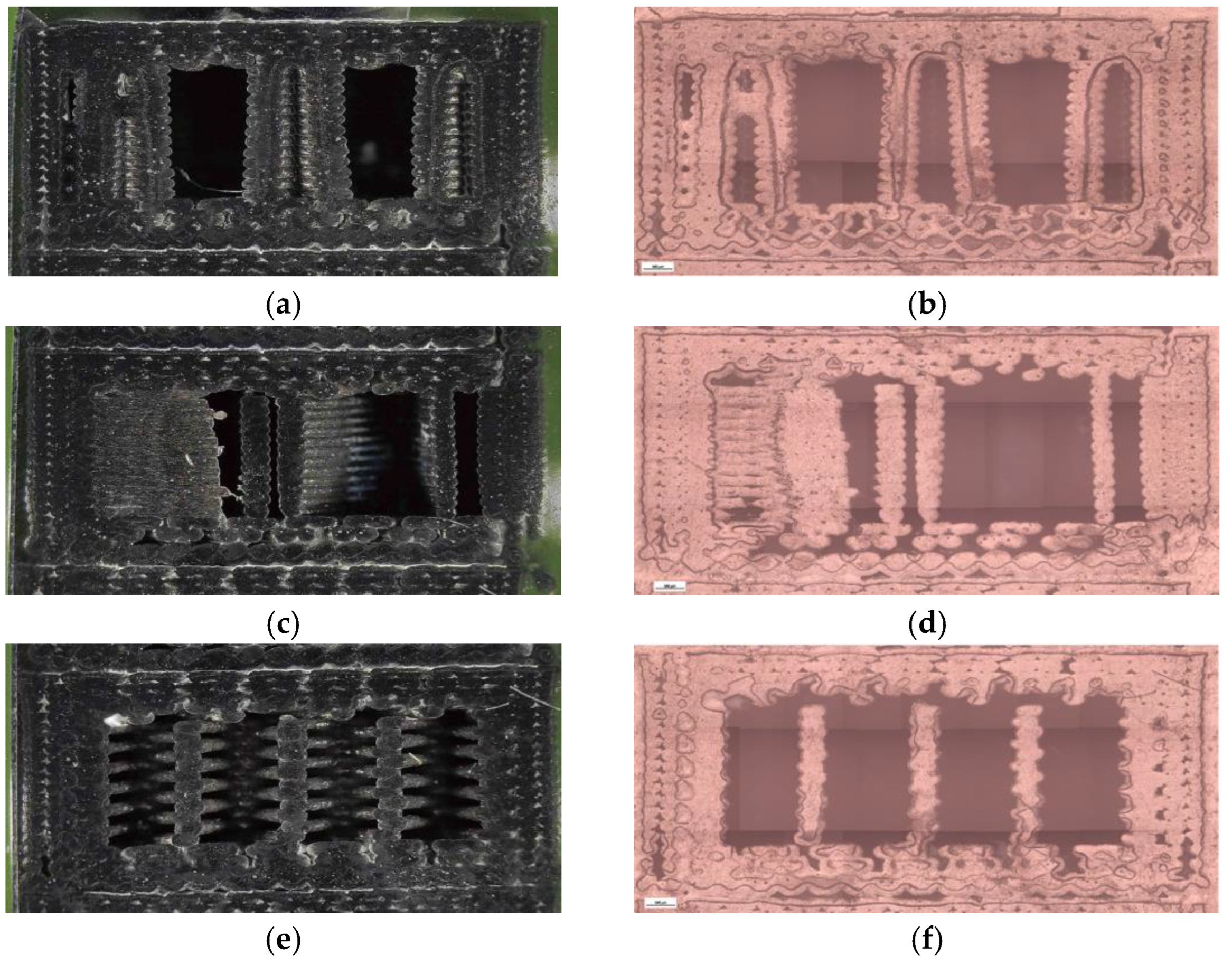

To complement the mechanical results, unfractured specimens were analyzed using optical microscopy to assess internal morphology, porosity distribution, and fiber–matrix interfacial bonding.

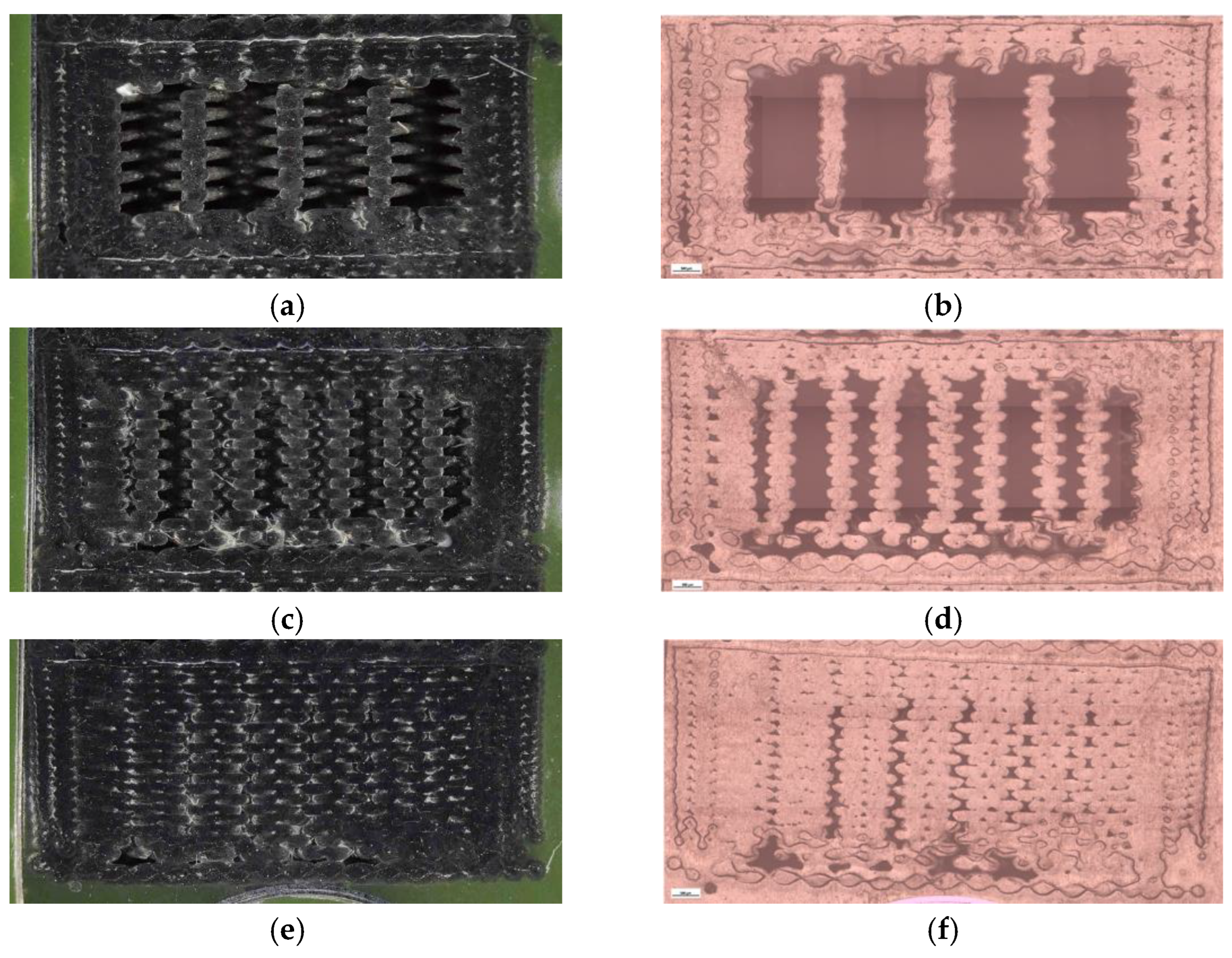

Unfractured specimens were further examined using optical microscopy (

Figure 21) to assess the internal porosity and fiber distribution. The hexagonal structure (V7B) exhibited moderately distributed voids and well-bonded interlayers. The triangular infill (V8B) showed compact regions with minimal porosity, while the linear infill (V9B) revealed elongated voids parallel to the filament orientation, indicating incomplete fusion between adjacent rasters.

The triangular infill (V8B) showed the smallest and most uniformly distributed voids, which correspond to improved filament coalescence and reduced fiber–matrix debonding zones.

Quantitative image analysis using Fiji software provided detailed pore metrics, confirming geometry-dependent variations in porosity and void morphology (

Table 10,

Figure 22).

Quantitative microstructural data obtained using Fiji software (

Table 10,

Figure 22) demonstrated a direct correlation between infill geometry and porosity distribution. The quantitative analysis confirms that the triangular infill (V8B) exhibited the lowest porosity and smallest average pore size, correlating with its highest tensile strength and stiffness. The linear infill (V9B) presented the largest pore area fraction and highest average pore size, explaining its reduced mechanical performance. The hexagonal structure (V7B) provided an intermediate balance between porosity and ductility, indicating that moderate internal voids can enhance energy absorption without severely compromising strength.

In summary, the results demonstrate that infill geometry substantially affects both the mechanical performance and microstructural integrity of PLA+CF composites. The triangular pattern yielded the highest tensile strength due to superior compaction and stress distribution, while the hexagonal pattern offered enhanced ductility and energy absorption capacity. The linear pattern was the least effective configuration, primarily due to its higher porosity and reduced interlayer fusion. These findings highlight the necessity of optimizing internal geometry in carbon-fiber-reinforced FDM structures to achieve a desired balance between stiffness, strength, and ductility. The correlation between reduced porosity and enhanced tensile performance confirms that improved interlayer fusion, controlled fiber dispersion, and optimized filament alignment jointly determine the superior mechanical integrity of PLA+CF composites.

Compared to pure PLA (

Section 3.1.1), the addition of short carbon fibers enhanced overall stiffness and dimensional stability, although the relative influence of infill geometry on ductility became more pronounced due to the reduced polymer chain mobility within the reinforced matrix.

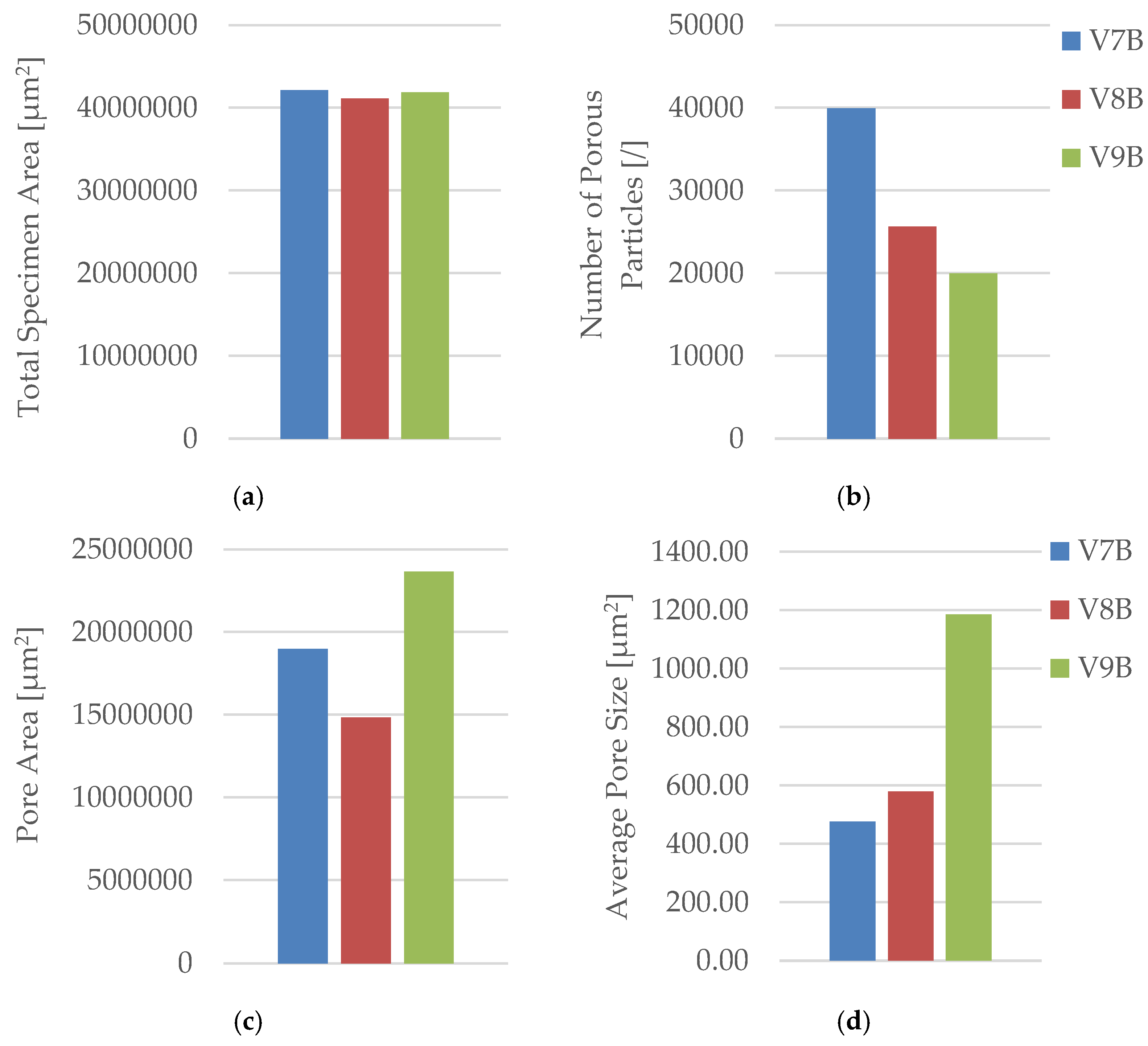

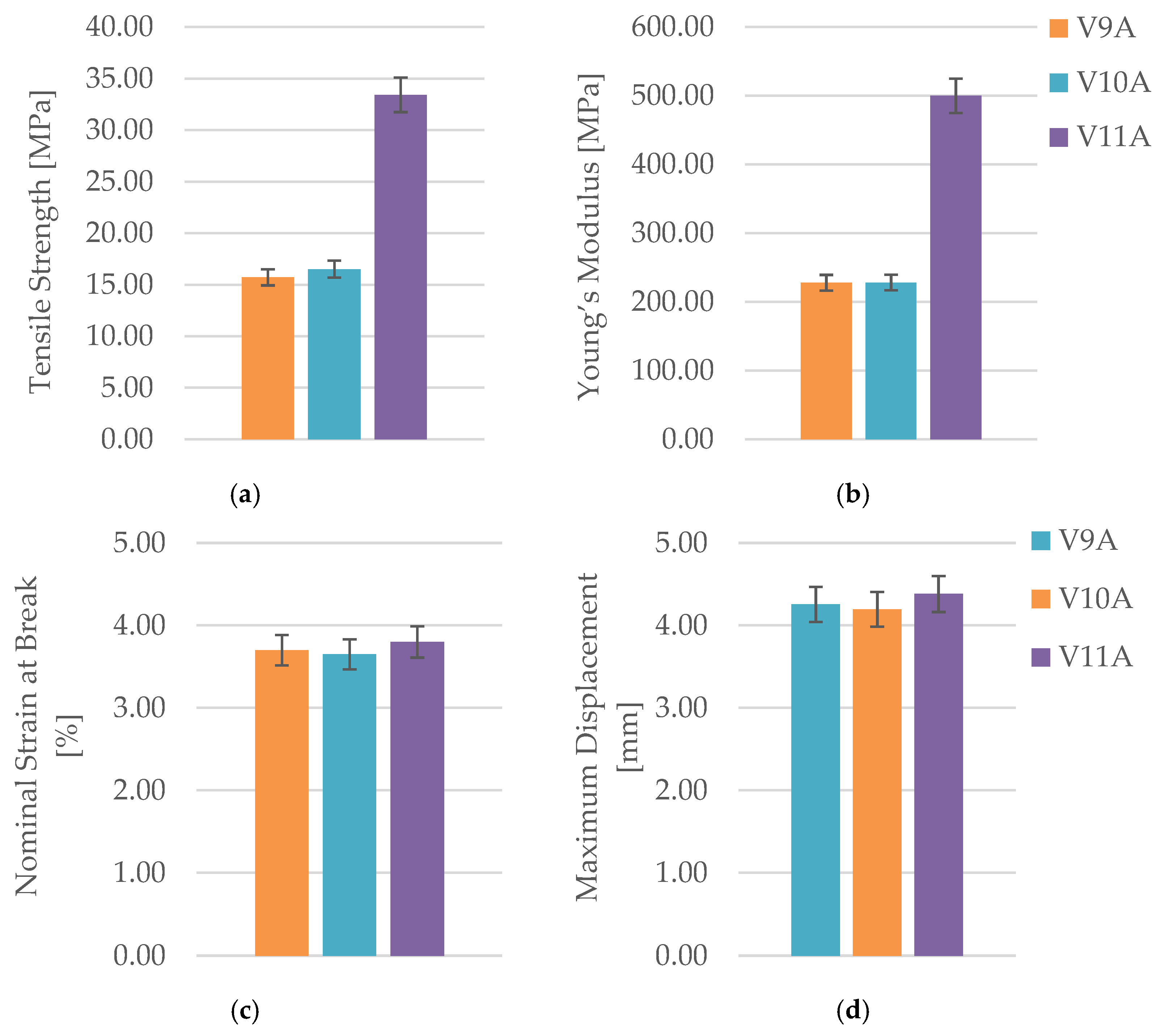

3.2.2. Influence of Infill Density on the Mechanical and Microstructural Behavior of 3D-Printed PLA+CF Specimens

The infill density is a critical factor determining the mechanical strength, stiffness, and internal integrity of FDM-printed composite parts. In the case of PLA reinforced with short carbon fibers (PLA+CF), changes in infill density not only modify the effective load-bearing area but also affect the degree of filament consolidation, porosity distribution, and fiber orientation within the printed matrix. These factors collectively influence stress transfer efficiency and fracture behavior under tensile loading.

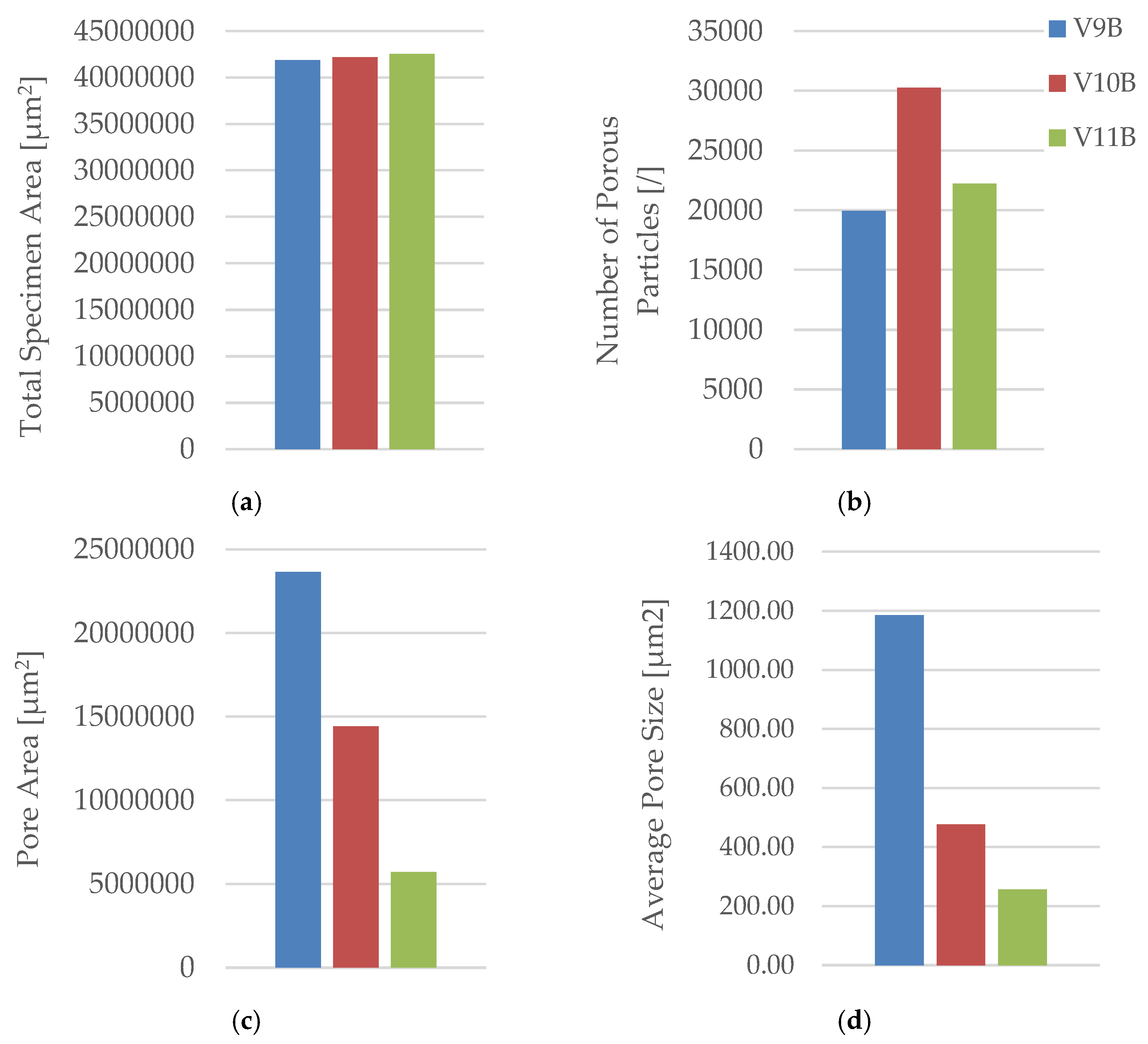

Three groups of PLA+CF specimens with identical geometry (linear infill pattern) but different infill densities—30 % (V9A), 60 % (V10A), and 100 % (V11A)—were fabricated under identical process conditions. The specimens were printed in the same build orientation and raster direction to isolate the effect of density on mechanical and microstructural performance.

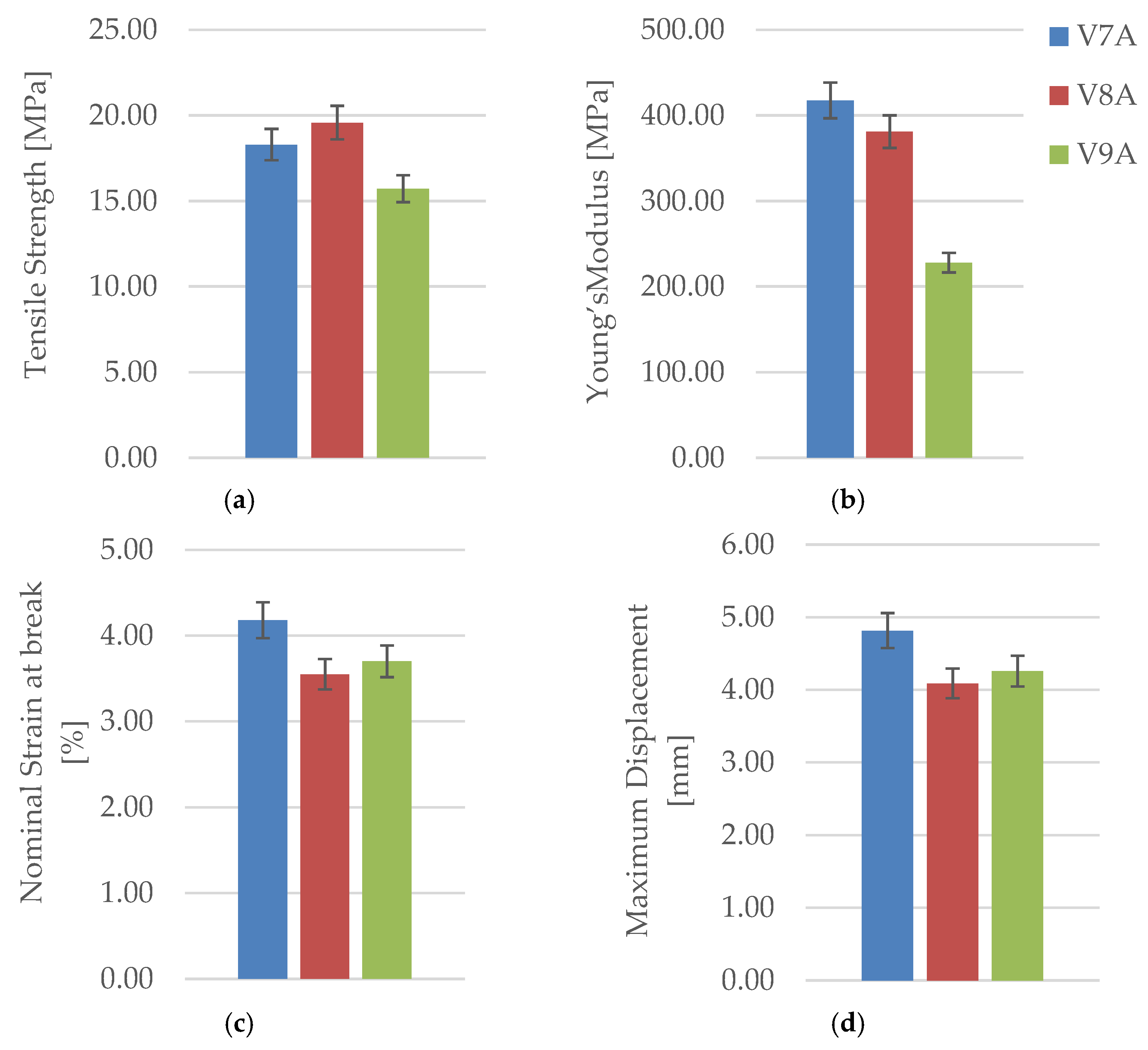

Figure 23 shows the appearance of the specimens after tensile testing.

The corresponding mechanical parameters obtained from the tensile tests are summarized in

Table 11, while

Figure 24 compares the principal mechanical indicators—tensile strength (

), Young’s modulus (

), nominal strain at break (

), and maximum displacement (

).

The obtained results demonstrate a monotonic increase in tensile strength and stiffness with increasing infill density. The 100 % infill specimen (V11A) achieved the highest tensile strength (33.41 MPa) and Young’s modulus (499.89 Mpa), approximately double those of the 30 % infill specimen (V9A). This improvement is attributed to the elimination of large internal voids and the formation of a continuous load path through the fiber-reinforced matrix. The intermediate-density specimen (V10A, 60 %) exhibited moderate mechanical performance ( = 16.51 Mpa, = 228.13 Mpa), indicating partial improvement in interlayer bonding but still containing irregular pores acting as local stress concentrators.

Figure 24b clearly illustrates the sharp rise in stiffness from 60 % to 100 % infill, consistent with the near doubling of the modulus in

Table 11.

Despite the higher material content, the nominal strain at break remained in a narrow range (3.6–3.8 %), reflecting the intrinsic stiffness of the carbon-fiber-reinforced PLA matrix. The modest increase in elongation for the 100 % specimen ( = 4.38 mm) suggests that enhanced interlayer cohesion allows limited plastic deformation prior to fracture, even in the dense composite structure.

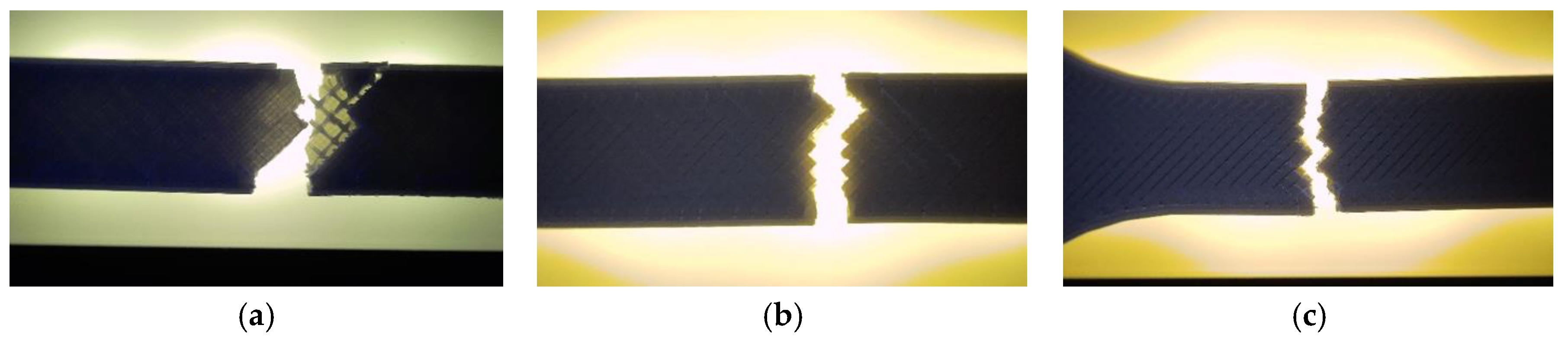

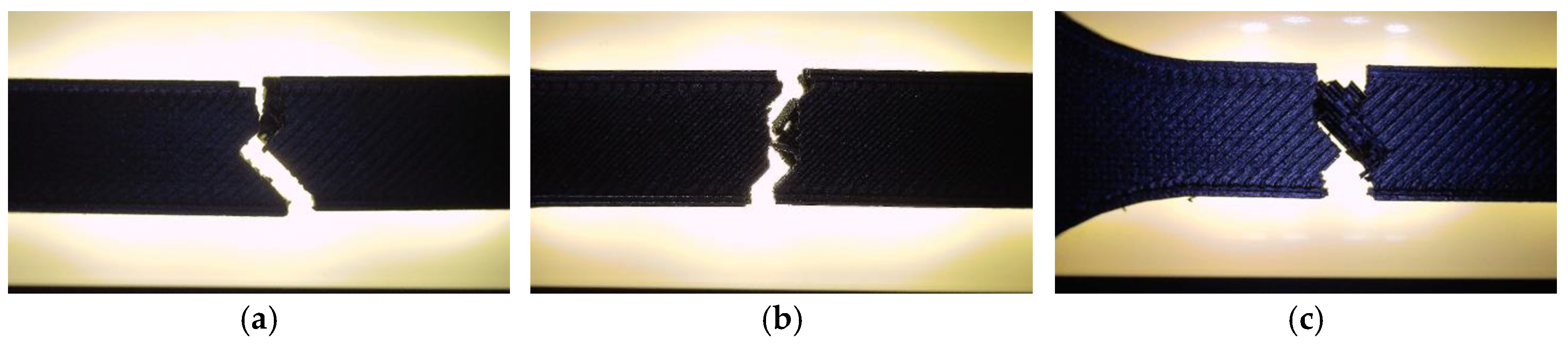

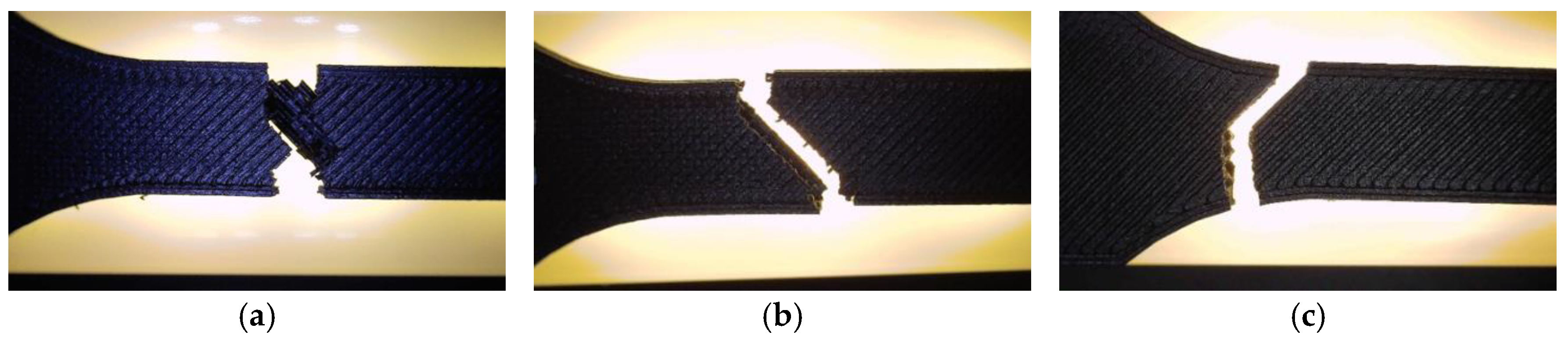

Fractographic analysis (

Figure 25) provided further insight into the failure mechanisms as a function of infill density.

The 30 % infill specimen (V9A) exhibited a rough fracture surface with extensive void regions and partially pulled-out fibers, indicating interlayer decohesion. The 60 % specimen (V10A) displayed a mixed fracture morphology characterized by partially fused filaments and microvoid coalescence at fiber-rich zones. In contrast, the 100 % infill specimen (V11A) showed a compact fracture surface with well-bonded layers, clear fiber pull-out traces, and localized shear bands—features typical of ductile–brittle transitions in stiffened polymer composites.

The visible reduction in interlayer gaps from (a) to (c) correlates with the improved bonding observed in optical microscopy (

Figure 26). To complement the fractographic analysis, unfractured specimens were observed under optical microscopy to evaluate internal structure uniformity and pore distribution.

The 30 % infill specimen (V9B) contained elongated voids oriented along the filament direction, suggesting incomplete fusion. The 60 % specimen (V10B) exhibited irregularly shaped pores clustered near the midplane. The 100 % specimen (V11B) displayed minimal porosity, compact raster alignment, and uniformly distributed short fibers embedded within the PLA matrix.

Quantitative image analysis using Fiji software (

Table 12 and

Figure 27) confirmed a strong inverse correlation between infill density and total pore area.

The pore count increased slightly from 19,955 in V9B (30 %) to 30,242 in V10B (60 %) due to irregular partial fusion, and then decreased to 22,235 in V11B (100 %), where nearly complete interlayer bonding was achieved.

Despite this non-monotonic variation in pore count, the total pore area was reduced by more than 75 % between 30 % and 100 % infill, confirming that higher density leads to a more compact and mechanically stable internal structure.

The steep reduction in total pore area at 100 % infill indicates nearly complete material consolidation.

Compared to pure PLA (

Section 3.1.2), the PLA+CF composite exhibited a more linear and predictable strengthening trend with density. This can be attributed to the stabilizing effect of carbon fibers, which reinforce the interlayer junctions and mitigate the internal stresses that can otherwise lead to premature crack initiation in unreinforced polymers.

In summary, the results demonstrate that increasing the infill density in PLA+CF specimens significantly enhances tensile strength and stiffness while reducing internal porosity. The best overall mechanical performance was achieved at 100 % infill, where improved filament coalescence, reduced void fraction, and uniform fiber distribution resulted in the highest apparent modulus and tensile strength. The correlation between the densification of the internal structure and the improved mechanical response confirms that optimizing the infill density is essential for achieving high-performance FDM-printed composites.

These results are of particular importance for engineering applications where high stiffness and dimensional stability are required, such as in functional or load-bearing FDM components.

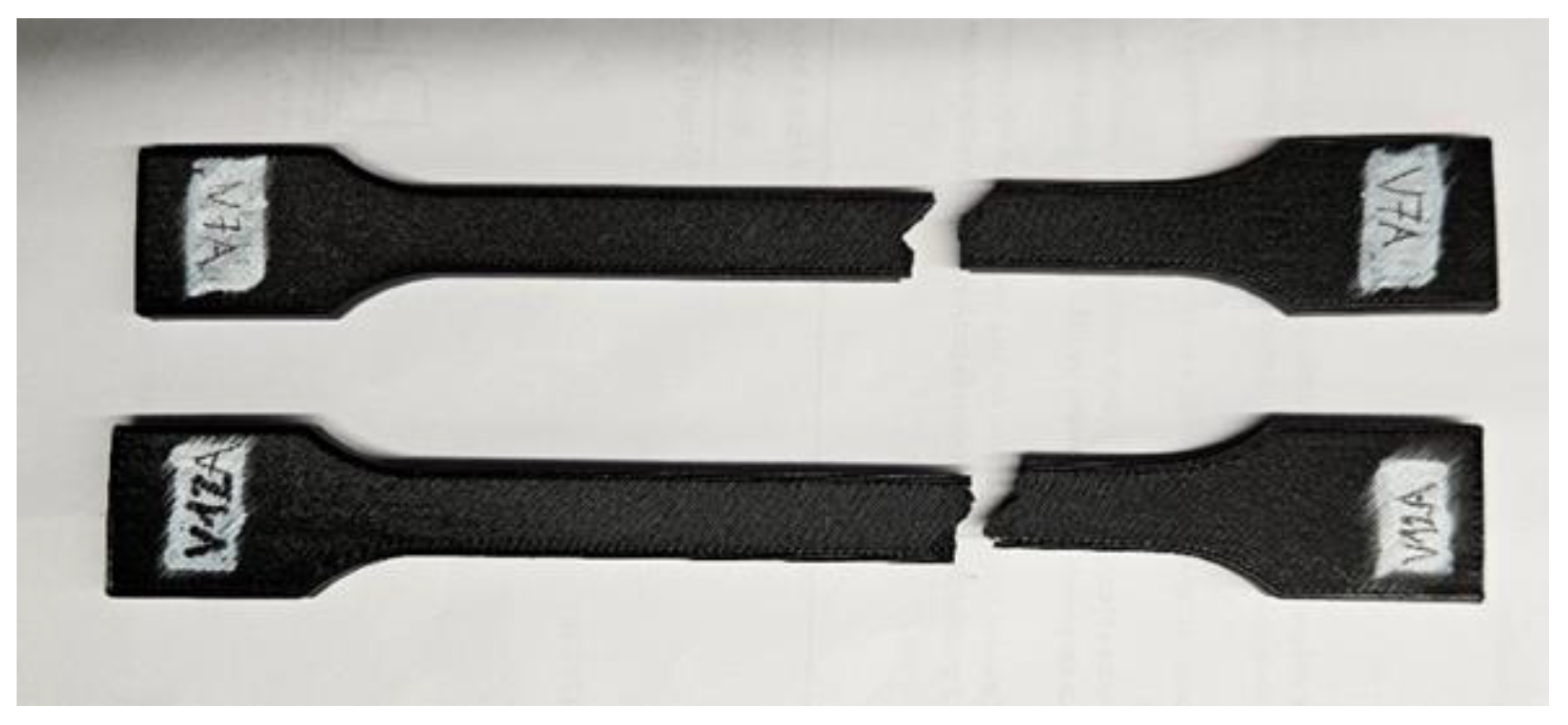

3.2.3. Influence of Exposure to Mineral Engine Oil on the Mechanical and Microstructural Behavior of 3D-Printed PLA+CF Specimens

The environmental exposure of FDM 3D-printed composite materials to lubricating oils or industrial fluids can significantly alter their mechanical integrity and microstructural stability. In the case of PLA reinforced with short carbon fibers (PLA+CF), immersion in mineral motor oil may induce physical swelling, softening of the polymer matrix, and changes in fiber–matrix adhesion, depending on the exposure duration and interfacial compatibility.

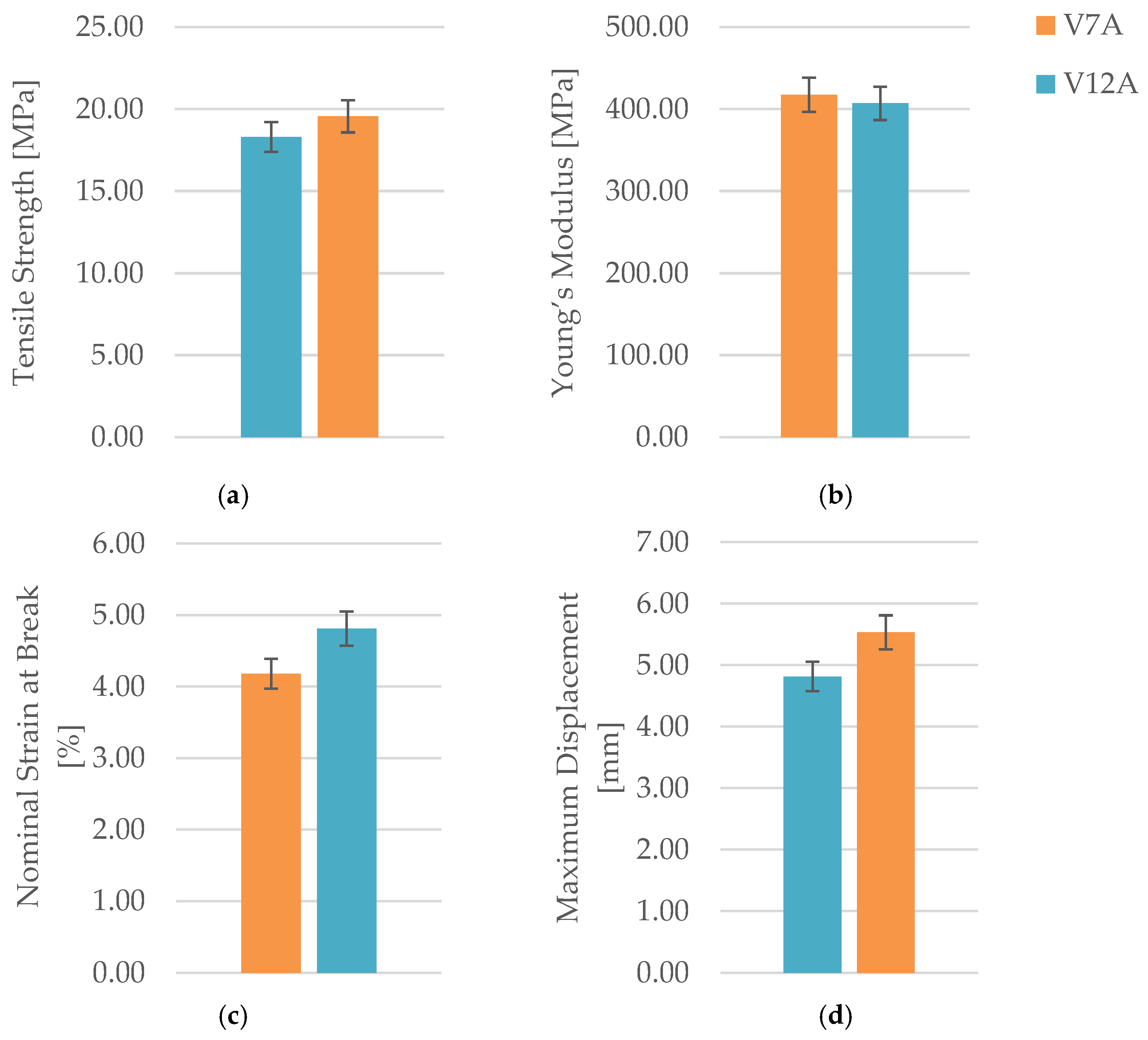

To evaluate these effects, PLA+CF specimens with a hexagonal infill structure (30 % density) were immersed in mineral motor oil for seven days under controlled laboratory conditions. The results were compared with those of unexposed reference specimens to determine the influence of oil exposure on tensile behavior and microstructural integrity.

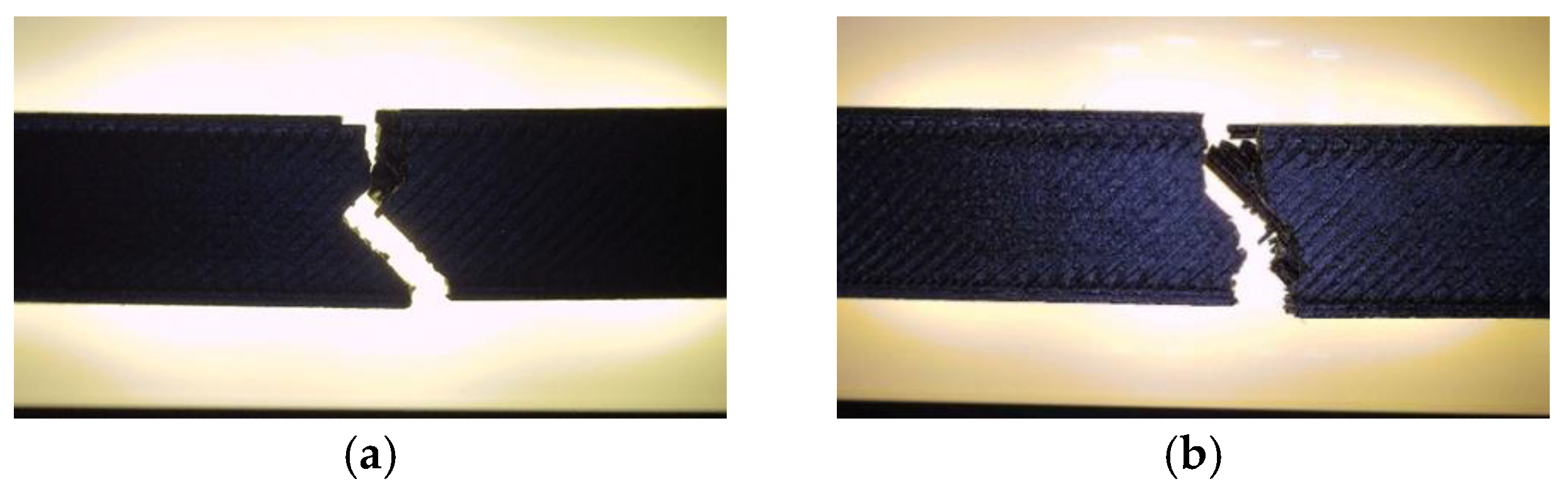

Figure 28 presents the visual comparison between unexposed (V7A) and oil-exposed (V12A) PLA+CF tensile specimens after testing. The oil-exposed samples exhibited a slightly darker surface tone and smoother fracture regions, indicating possible surface plasticization of the matrix.

The tensile test results are summarized in

Table 13, and the comparative variation in key mechanical parameters—tensile strength (

), Young’s modulus (

), nominal strain at break (

), and maximum displacement (

)—is illustrated in

Figure 29.

The results indicate that seven-day exposure to mineral oil did not degrade the mechanical performance of PLA+CF specimens. On the contrary, the tensile strength increased by approximately 6.9 % (from 18.30 MPa to 19.56 MPa), while Young’s modulus showed a minor reduction of about 2.5 %.

The nominal strain at break increased from 4.18 % to 4.81 %, and the maximum displacement rose by nearly 15 %, indicating that oil exposure slightly enhanced ductility and deformation capacity.

These changes suggest that limited oil absorption caused surface plasticization and interfacial stress relaxation, leading to improved filament cohesion and delayed fracture initiation.

From a physicochemical perspective, the observed changes can be attributed to the limited diffusion of low-molecular-weight hydrocarbon chains from the mineral oil into the amorphous PLA regions. This diffusion reduces intermolecular bonding energy and increases local chain mobility, resulting in mild plasticization of the polymer matrix. However, the presence of carbon fibers restricts this diffusion by acting as physical barriers, thereby maintaining overall structural integrity and preventing excessive swelling.

Fracture surfaces of the unexposed and oil-exposed specimens are shown in

Figure 30. The unexposed PLA+CF sample (V7A) exhibited mixed brittle–ductile fracture zones with visible fiber pull-out and localized shear ridges. After oil exposure, specimen V12A showed smoother fracture surfaces with fewer microvoids and shallower fiber imprints, suggesting improved stress redistribution and reduced crack propagation intensity.

Similar findings were reported by Pascual-González et al. [

61] and Guessasma et al. [

62], who observed that short-term exposure of FDM composites to non-polar fluids can induce localized chain relaxation without significant degradation. In contrast, prolonged immersion tends to increase interfacial debonding and porosity. The present results confirm that the duration of exposure is a key factor governing the transition between reversible plasticization and irreversible deterioration in PLA-based composites.

These observations support the mechanical results, indicating that moderate oil absorption improved local ductility without causing significant degradation of the fiber–matrix interface.

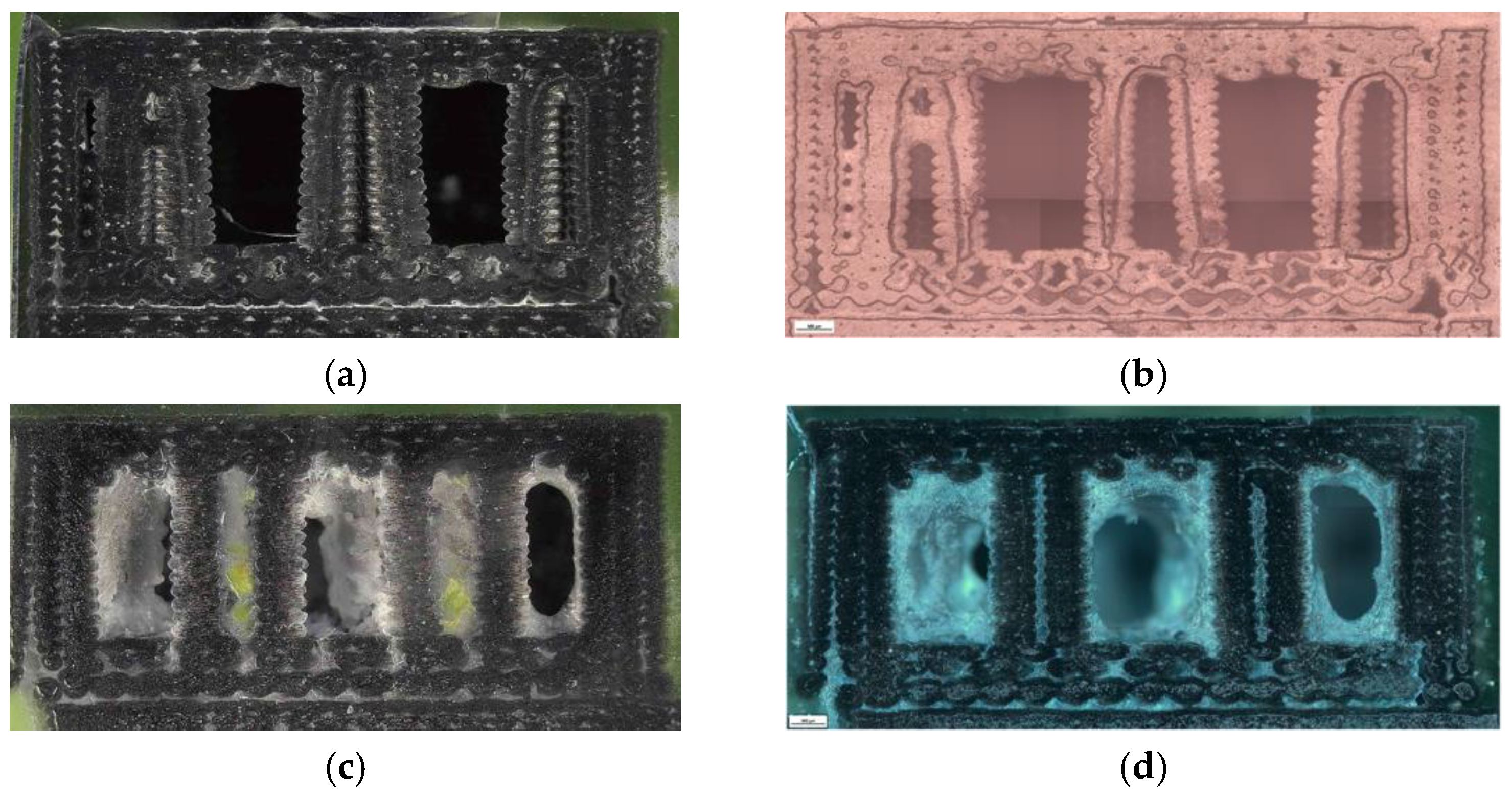

Unfractured specimens were examined under optical microscopy to assess internal porosity and filament cohesion (

Figure 31).

The unexposed specimen (V7B) displayed compact filament alignment and moderately distributed pores.

After oil exposure, the PLA+CF specimen (V12B) exhibited a finer pore structure, with a higher number of smaller voids distributed more uniformly across the matrix.

This transformation indicates a reorganization of interfacial regions due to minor swelling and plasticization of the polymer phase.

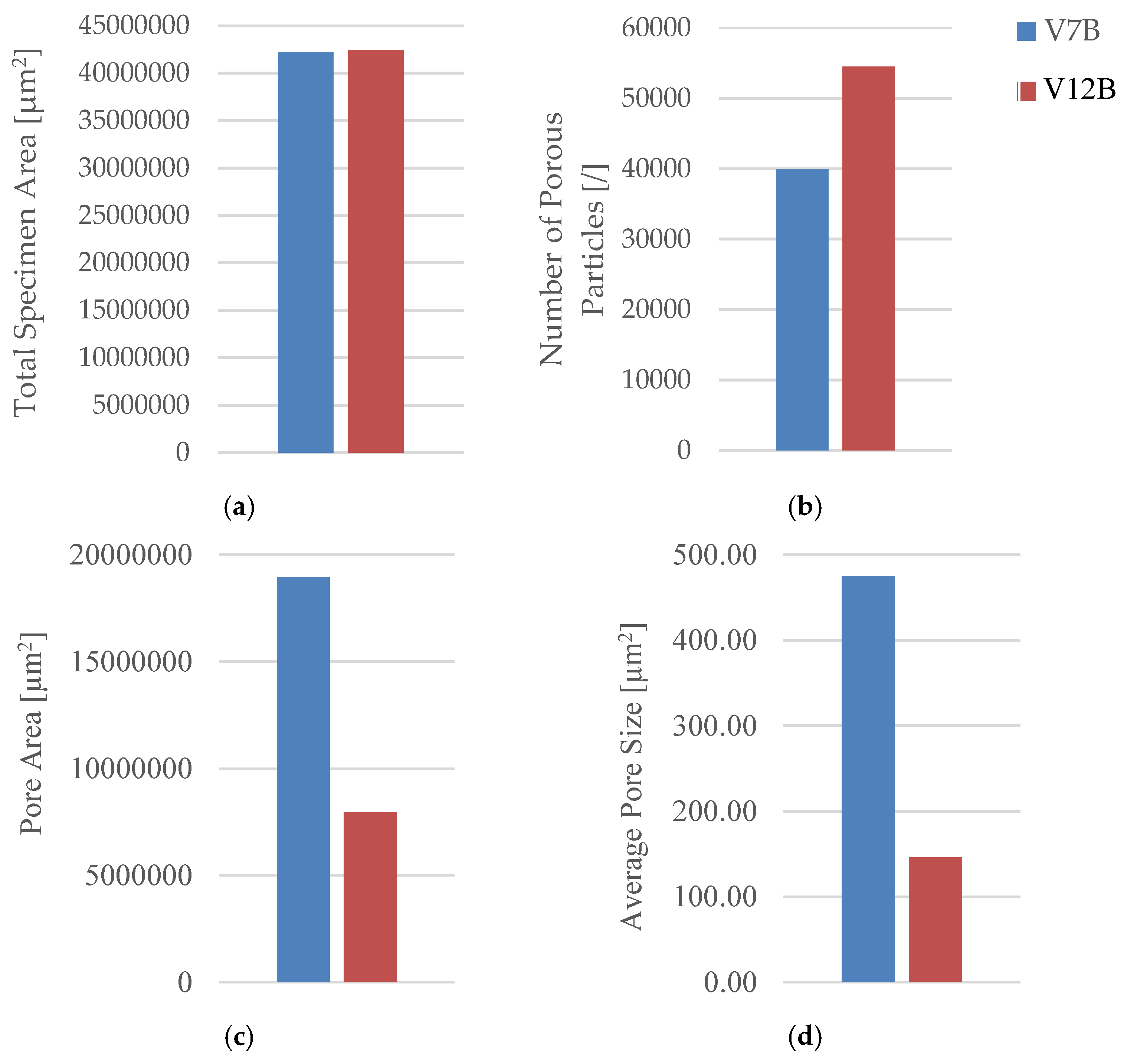

Quantitative image analysis (

Table 14,

Figure 32) confirmed that oil exposure increased the number of detected pores from 39 922 to 54 461, while the total pore area decreased from 18.97 × 10

6 µm

2 to 7.95 × 10

6 µm

2.

This indicates that smaller voids became more numerous but collectively occupied a smaller area—consistent with pore fragmentation and matrix densification following mild oil-induced swelling.

The quantitative data confirm that short-term oil exposure does not damage the PLA+CF internal structure; instead, it induces redistribution and refinement of pores, improving uniformity and cohesion.

The simultaneous increase in pore count and reduction in total pore area suggests a redistribution of internal stresses at the filament interfaces. This process can be described as a micro-mechanical stabilization mechanism, where smaller, evenly distributed voids act as energy-dissipating zones, delaying crack propagation. The presence of carbon fibers further contributes to this stabilization by constraining local deformation and maintaining load transfer continuity across layers.

The reduction in average pore size from 475 µm2 to 146 µm2 indicates enhanced filament packing and matrix compactness due to local surface diffusion of polymer chains.

In summary, the seven-day exposure of PLA+CF specimens with hexagonal infill (30 %) to mineral oil led to slight strengthening and softening effects occurring simultaneously—a modest increase in tensile strength and ductility, coupled with a small reduction in stiffness.

Microstructural and quantitative analyses confirmed that these changes resulted from fine-scale reorganization of the pore network and partial interfacial plasticization rather than material degradation.

Compared to pure PLA (

Section 3.1.3), the PLA+CF composite exhibited higher dimensional and mechanical stability, reflecting the stabilizing effect of carbon fibers, which limit swelling and maintain load transfer capability.

From a thermodynamic standpoint, the diffusion behavior observed can be described by a Fickian-type mechanism limited to the near-surface amorphous zones. The low polarity and high viscosity of mineral oil hinder deep penetration, which explains why plasticization remained localized and reversible. The embedded carbon fibers acted as diffusion barriers, contributing to structural stabilization and maintaining load-bearing continuity throughout the specimen.

These findings are particularly relevant for additive manufacturing of composite components designed for operation in tribological or lubricated environments, such as sealing elements, gear housings, and structural supports in mechanical assemblies. The demonstrated oil resistance of PLA+CF composites highlights their potential as lightweight, dimensionally stable alternatives to conventional thermoplastics in semi-lubricated or maintenance-limited systems. Future investigations should extend to long-term and cyclic exposure tests to establish degradation kinetics and validate performance under dynamic conditions.

Figure 1.

SolidWorks-generated model of standardized tensile specimen geometry (ISO 527-2: 2012) [

72,

73].

Figure 1.

SolidWorks-generated model of standardized tensile specimen geometry (ISO 527-2: 2012) [

72,

73].

Figure 2.

Sample preparation and surface finishing: (a) preparation and sectioning of specimens prior to embedding, (b) progressive surface grinding and polishing of mounted samples.

Figure 2.

Sample preparation and surface finishing: (a) preparation and sectioning of specimens prior to embedding, (b) progressive surface grinding and polishing of mounted samples.

Figure 3.

PLA tensile specimens printed with different infill geometries: hexagonal (V1A), triangular (V2A), and linear (V3A), all with 30 % infill density. Macroscopic differences in fracture appearance reflect the effect of internal geometry on load-bearing behavior.

Figure 3.

PLA tensile specimens printed with different infill geometries: hexagonal (V1A), triangular (V2A), and linear (V3A), all with 30 % infill density. Macroscopic differences in fracture appearance reflect the effect of internal geometry on load-bearing behavior.

Figure 4.

Comparison of tensile properties of PLA specimens with different infill geometries: (a) tensile strength, (b) Young’s modulus, (c) nominal strain at break, and (d) maximum displacement. The linear pattern (V3A) shows the highest tensile strength, while the hexagonal pattern (V1A) demonstrates superior ductility.

Figure 4.

Comparison of tensile properties of PLA specimens with different infill geometries: (a) tensile strength, (b) Young’s modulus, (c) nominal strain at break, and (d) maximum displacement. The linear pattern (V3A) shows the highest tensile strength, while the hexagonal pattern (V1A) demonstrates superior ductility.

Figure 5.

Fracture surfaces of PLA specimens after tensile testing: (a) V1A—hexagonal structure, (b) V2A—triangular structure, (c) V3A—linear structure. Visible stress concentration zones and crack propagation paths indicate distinct fracture mechanisms for each geometry.

Figure 5.

Fracture surfaces of PLA specimens after tensile testing: (a) V1A—hexagonal structure, (b) V2A—triangular structure, (c) V3A—linear structure. Visible stress concentration zones and crack propagation paths indicate distinct fracture mechanisms for each geometry.

Figure 6.

Optical micrographs of unfractured PLA specimens showing internal infill morphology: (a, b) hexagonal (V1B), (c, d) triangular (V2B), and (e, f) linear (V3B) structures. The hexagonal pattern shows minimal voids and good interlayer adhesion, whereas the triangular pattern exhibits larger pores near cell vertices.

Figure 6.

Optical micrographs of unfractured PLA specimens showing internal infill morphology: (a, b) hexagonal (V1B), (c, d) triangular (V2B), and (e, f) linear (V3B) structures. The hexagonal pattern shows minimal voids and good interlayer adhesion, whereas the triangular pattern exhibits larger pores near cell vertices.

Figure 7.

Quantitative microstructural analysis of PLA specimens with different infill geometries obtained using Fiji software: (a) total specimen area, (b) number of porous particles, (c) pore area, and (d) average pore size.

Figure 7.

Quantitative microstructural analysis of PLA specimens with different infill geometries obtained using Fiji software: (a) total specimen area, (b) number of porous particles, (c) pore area, and (d) average pore size.

Figure 8.

PLA tensile specimens printed with different infill densities: (a) 30 %, (b) 60 %, and (c) 100 %. Increasing infill density reduces the internal void fraction and produces a more compact structure.

Figure 8.

PLA tensile specimens printed with different infill densities: (a) 30 %, (b) 60 %, and (c) 100 %. Increasing infill density reduces the internal void fraction and produces a more compact structure.

Figure 9.

Comparison of tensile properties of PLA specimens with different infill densities: (a) tensile strength, (b) Young’s modulus, (c)nominal strain at break, and (d) maximum displacement. The 30 % infill specimen (V3A) achieved the highest tensile strength, while the 60 % infill (V4A) exhibited the weakest mechanical response.

Figure 9.

Comparison of tensile properties of PLA specimens with different infill densities: (a) tensile strength, (b) Young’s modulus, (c)nominal strain at break, and (d) maximum displacement. The 30 % infill specimen (V3A) achieved the highest tensile strength, while the 60 % infill (V4A) exhibited the weakest mechanical response.

Figure 10.

Fracture surfaces of PLA specimens after tensile testing: (a) 30 % (V3A), (b) 60 % (V4A), and (c) 100 % (V5A). The intermediate-density specimen (V4A) shows brittle fracture features and poor interlayer bonding.

Figure 10.

Fracture surfaces of PLA specimens after tensile testing: (a) 30 % (V3A), (b) 60 % (V4A), and (c) 100 % (V5A). The intermediate-density specimen (V4A) shows brittle fracture features and poor interlayer bonding.

Figure 11.

Optical micrographs of PLA specimens with different infill densities: (a, b) 30 % (V3B), (c, d) 60 % (V4B), and (e, f) 100 % (V5B). The 100 % infill specimen (V5B) exhibits the highest compactness and uniformity, while the 60 % infill specimen (V4B) displays irregular void clusters.

Figure 11.

Optical micrographs of PLA specimens with different infill densities: (a, b) 30 % (V3B), (c, d) 60 % (V4B), and (e, f) 100 % (V5B). The 100 % infill specimen (V5B) exhibits the highest compactness and uniformity, while the 60 % infill specimen (V4B) displays irregular void clusters.

Figure 12.

Quantitative microstructural analysis of PLA specimens with different infill densities obtained using Fiji software: (a) total specimen area, (b) number of porous particles, (c) pore area, and (d) average pore size.

Figure 12.

Quantitative microstructural analysis of PLA specimens with different infill densities obtained using Fiji software: (a) total specimen area, (b) number of porous particles, (c) pore area, and (d) average pore size.

Figure 13.

PLA tensile specimens printed with hexagonal infill (30 % density) after tensile testing: (a) unexposed sample (V1A), (b) sample after 7 days of exposure to mineral motor oil (V6A).

Figure 13.

PLA tensile specimens printed with hexagonal infill (30 % density) after tensile testing: (a) unexposed sample (V1A), (b) sample after 7 days of exposure to mineral motor oil (V6A).

Figure 14.

Comparison of tensile properties of PLA specimens before and after 7-day exposure to mineral motor oil: (a) tensile strength, (b) Young’s modulus, (c) nominal strain at break, and (d) maximum displacement. Oil exposure increased ductility while slightly reducing stiffness and tensile strength.

Figure 14.

Comparison of tensile properties of PLA specimens before and after 7-day exposure to mineral motor oil: (a) tensile strength, (b) Young’s modulus, (c) nominal strain at break, and (d) maximum displacement. Oil exposure increased ductility while slightly reducing stiffness and tensile strength.

Figure 15.

Fracture surfaces of PLA specimens after tensile testing: (a) V1A—unexposed, brittle fracture with clean separation; (b) V6A—after 7 days in mineral oil, showing ductile failure and localized plastic deformation.

Figure 15.

Fracture surfaces of PLA specimens after tensile testing: (a) V1A—unexposed, brittle fracture with clean separation; (b) V6A—after 7 days in mineral oil, showing ductile failure and localized plastic deformation.

Figure 16.

Optical micrographs of unfractured PLA specimens with hexagonal infill (30%): (a, b) unexposed (V1B); (c, d) after 7 days of mineral oil exposure (V6B). Oil absorption caused pore filling and slight delamination between layers.

Figure 16.

Optical micrographs of unfractured PLA specimens with hexagonal infill (30%): (a, b) unexposed (V1B); (c, d) after 7 days of mineral oil exposure (V6B). Oil absorption caused pore filling and slight delamination between layers.

Figure 17.

Quantitative microstructural analysis of PLA specimens before and after mineral oil exposure: (a) total specimen area, (b) number of porous particles, (c) pore area, and (d) average pore size. Oil exposure increased pore count but reduced pore size and total pore area, leading to a finer and more uniform void distribution.

Figure 17.

Quantitative microstructural analysis of PLA specimens before and after mineral oil exposure: (a) total specimen area, (b) number of porous particles, (c) pore area, and (d) average pore size. Oil exposure increased pore count but reduced pore size and total pore area, leading to a finer and more uniform void distribution.

Figure 18.

PLA+CF tensile specimens printed with different infill geometries: hexagonal (V7A), triangular (V8A), and linear (V9A), all with 30 % infill density. The fracture surfaces reveal geometry-dependent differences in filament failure and fiber–matrix interaction.

Figure 18.

PLA+CF tensile specimens printed with different infill geometries: hexagonal (V7A), triangular (V8A), and linear (V9A), all with 30 % infill density. The fracture surfaces reveal geometry-dependent differences in filament failure and fiber–matrix interaction.

Figure 19.

Comparison of tensile properties of PLA+CF specimens with different infill geometries: (a) tensile strength, (b) Young’s modulus, (c) nominal strain at break, and (d) maximum displacement. The triangular pattern (V8A) exhibits the highest tensile strength, while the hexagonal pattern (V7A) demonstrates the best combination of stiffness and ductility.

Figure 19.

Comparison of tensile properties of PLA+CF specimens with different infill geometries: (a) tensile strength, (b) Young’s modulus, (c) nominal strain at break, and (d) maximum displacement. The triangular pattern (V8A) exhibits the highest tensile strength, while the hexagonal pattern (V7A) demonstrates the best combination of stiffness and ductility.

Figure 20.

Fracture surfaces of PLA+CF specimens after tensile testing: (a) V7A—hexagonal structure, (b) V8A—triangular structure, (c) V9A—linear structure. The fracture morphology reflects the interplay between infill topology and fiber–matrix adhesion.

Figure 20.

Fracture surfaces of PLA+CF specimens after tensile testing: (a) V7A—hexagonal structure, (b) V8A—triangular structure, (c) V9A—linear structure. The fracture morphology reflects the interplay between infill topology and fiber–matrix adhesion.

Figure 21.

Optical micrographs of unfractured PLA+CF specimens showing internal infill morphology: (a, b) hexagonal (V7B), (c, d) triangular (V8B), and (e, f) linear (V9B) structures. The triangular infill exhibits the most compact structure with reduced void fraction.

Figure 21.

Optical micrographs of unfractured PLA+CF specimens showing internal infill morphology: (a, b) hexagonal (V7B), (c, d) triangular (V8B), and (e, f) linear (V9B) structures. The triangular infill exhibits the most compact structure with reduced void fraction.

Figure 22.