Submitted:

20 September 2025

Posted:

22 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

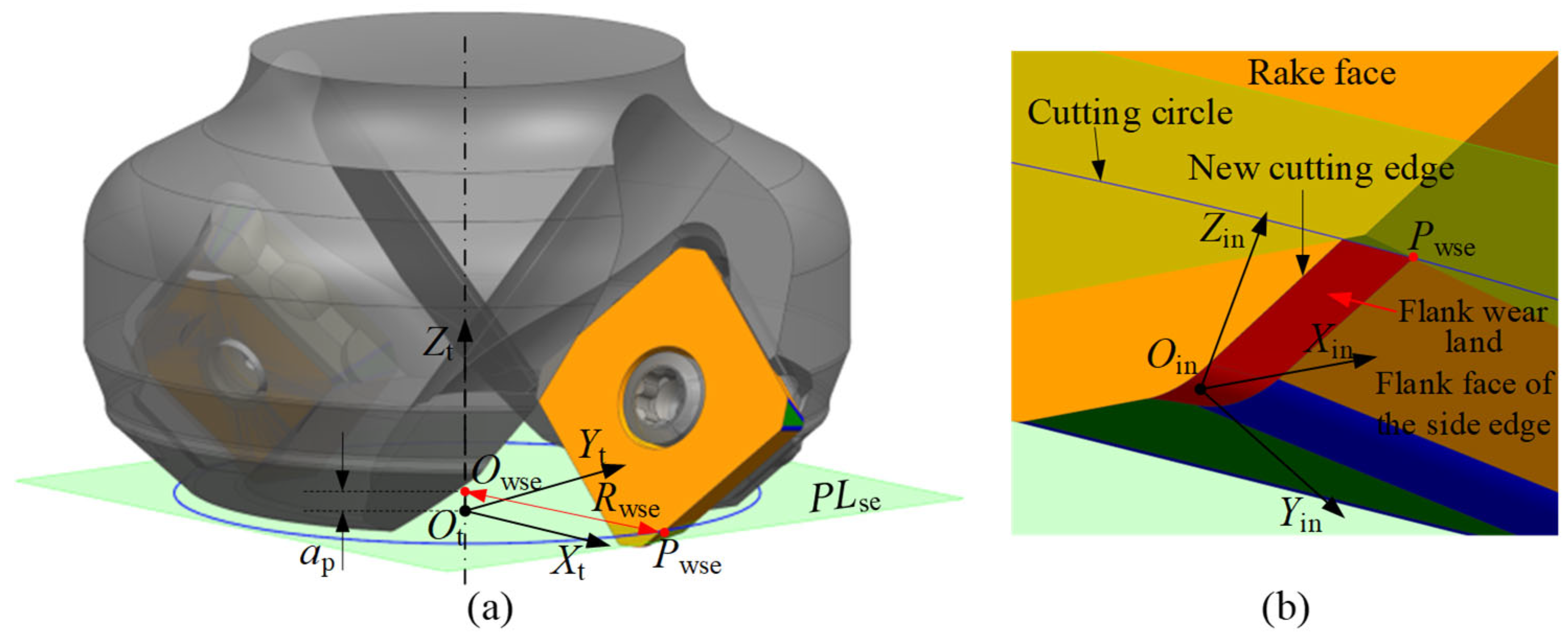

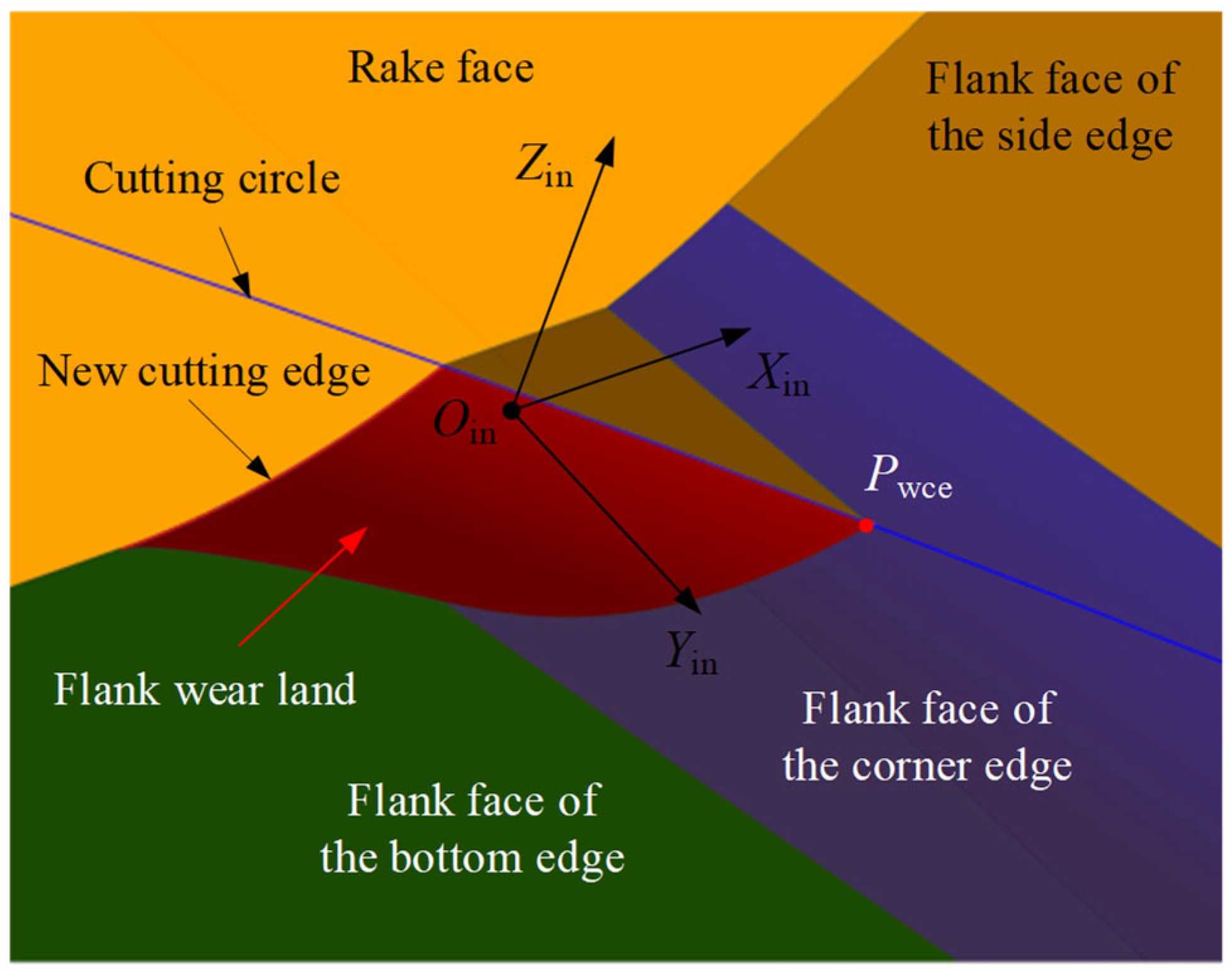

2. Mechanism of Flank Wear Formation in Indexable Face Milling Tools

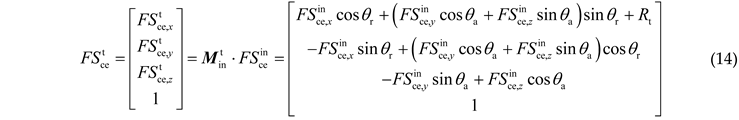

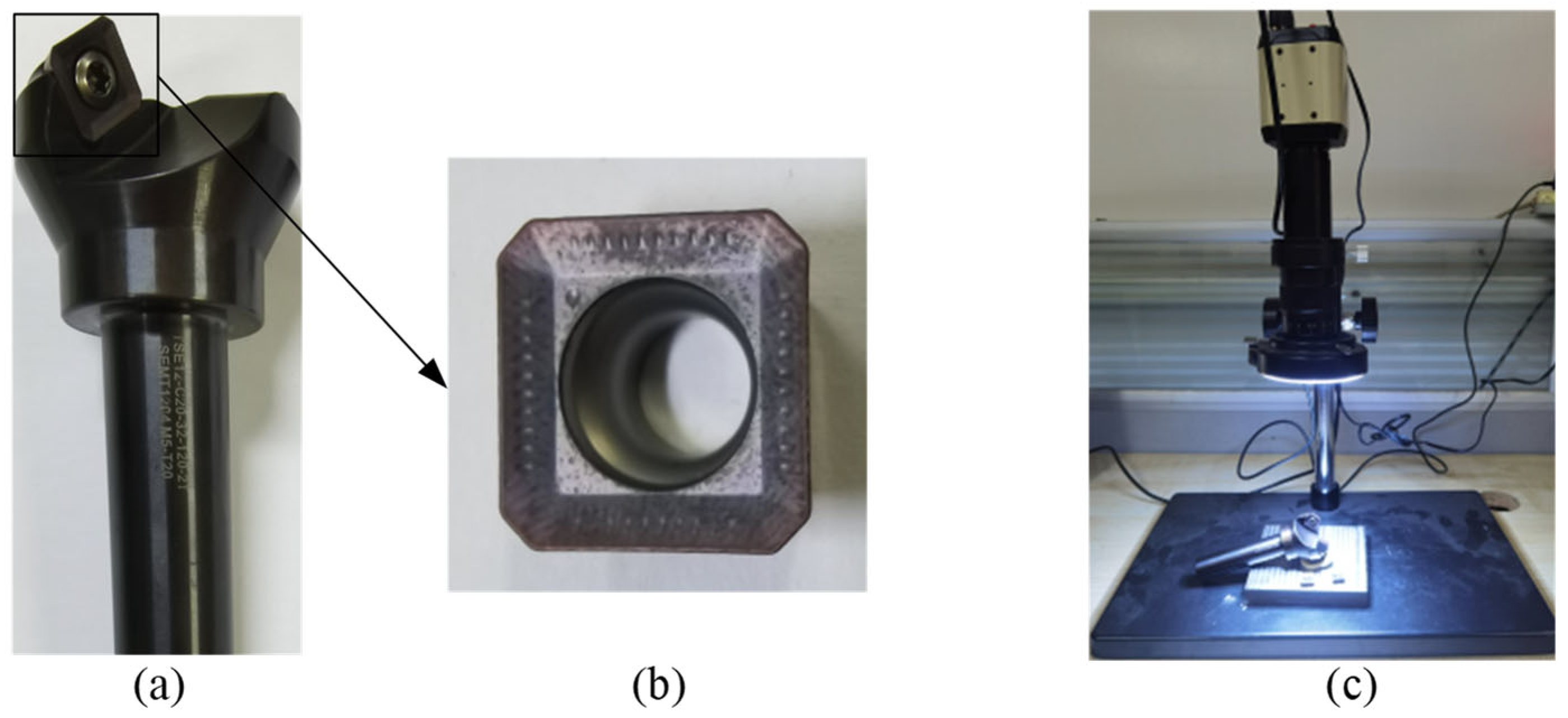

2.1. Overview of Indexable Face Milling Tools

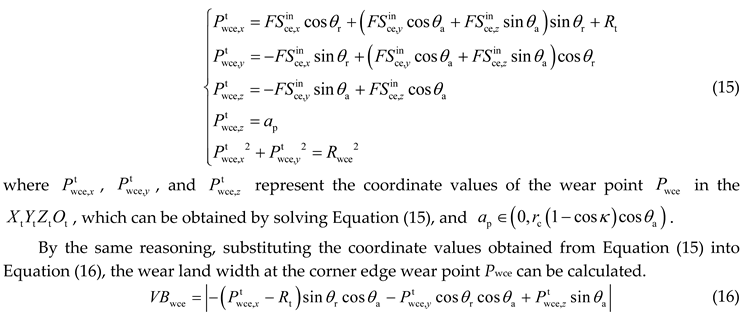

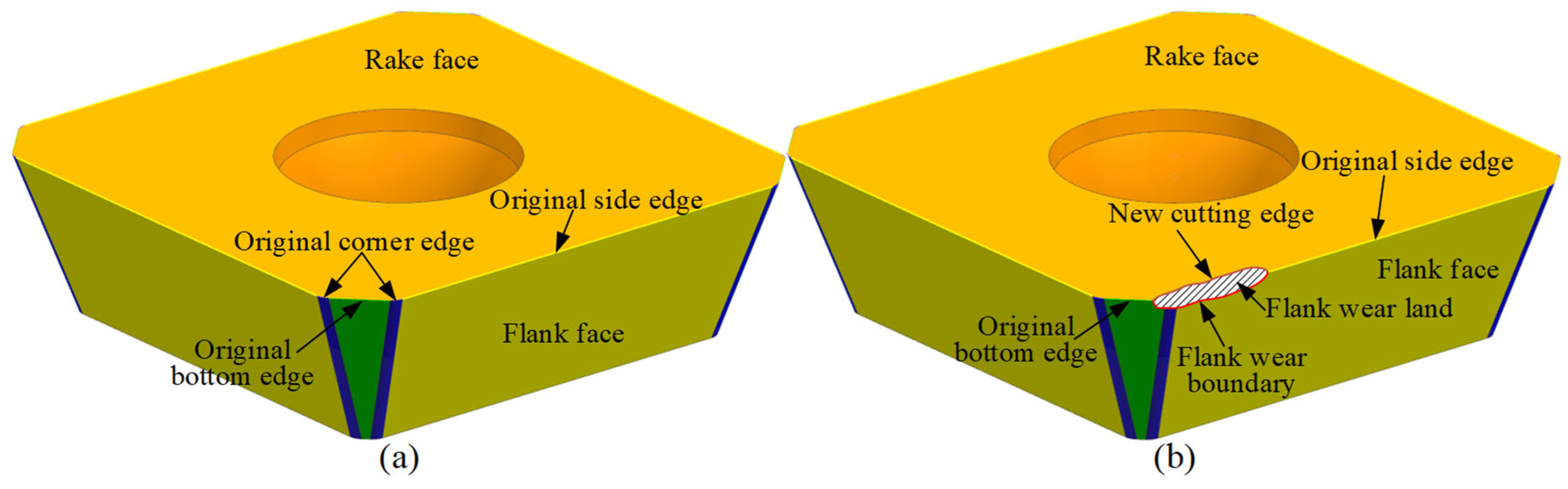

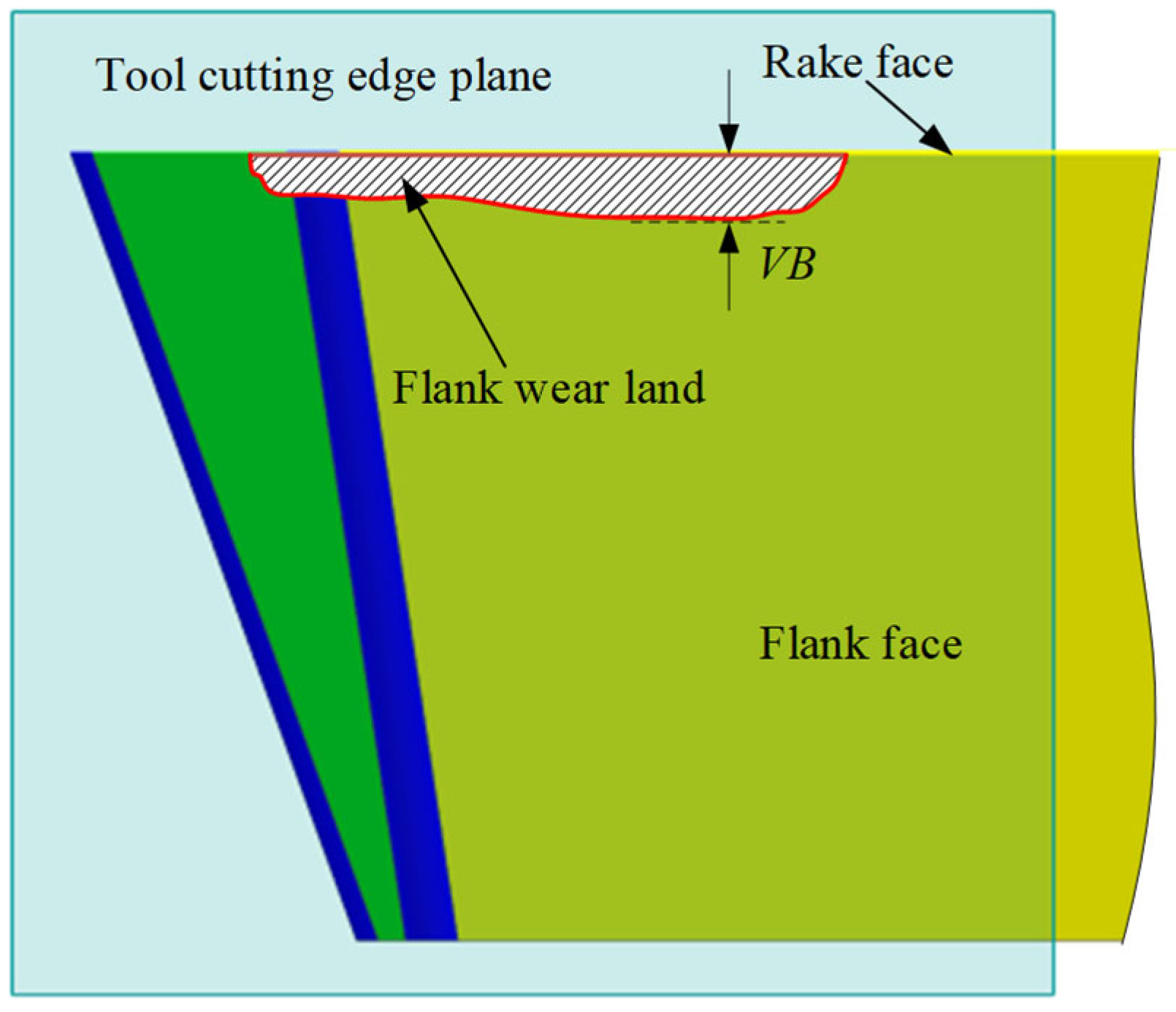

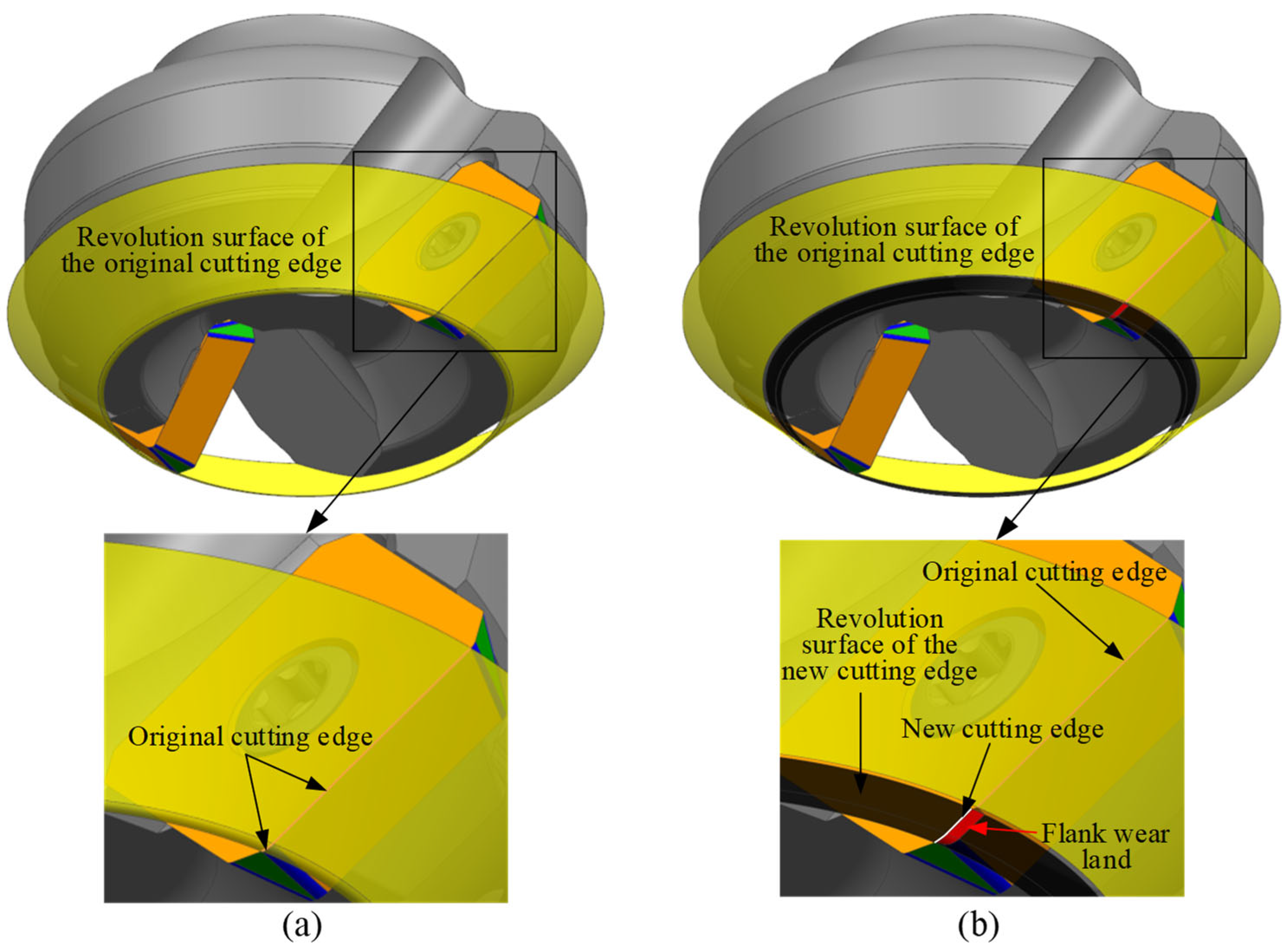

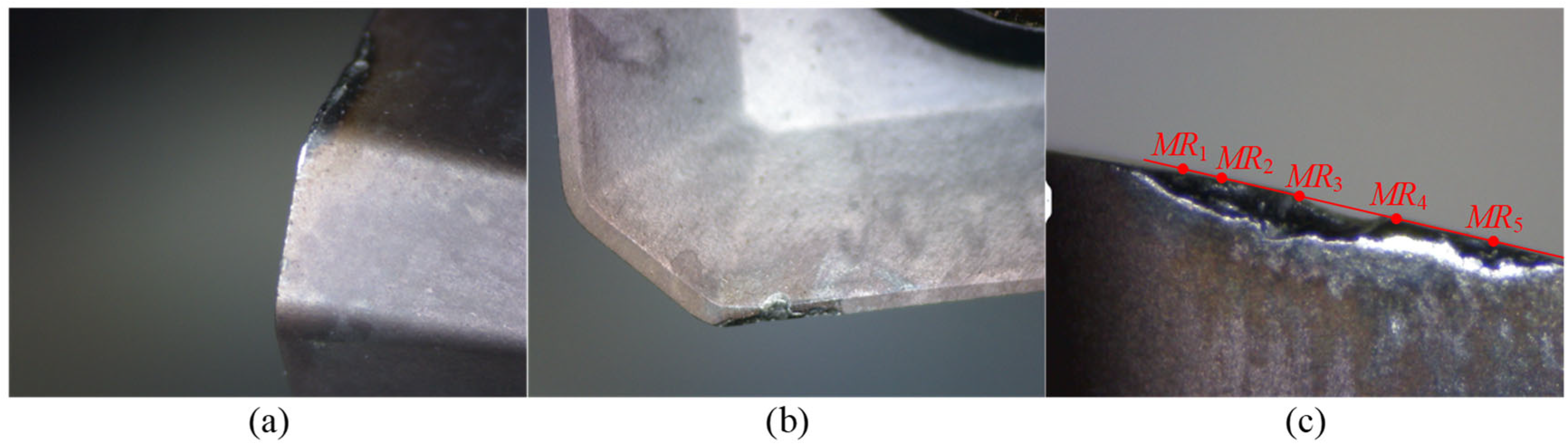

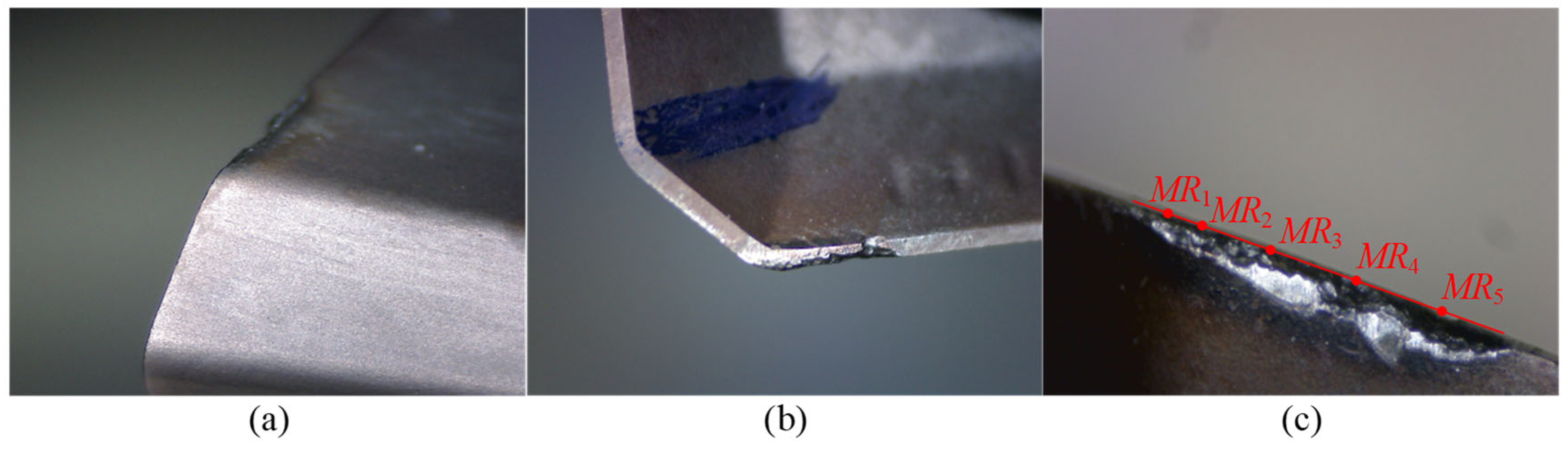

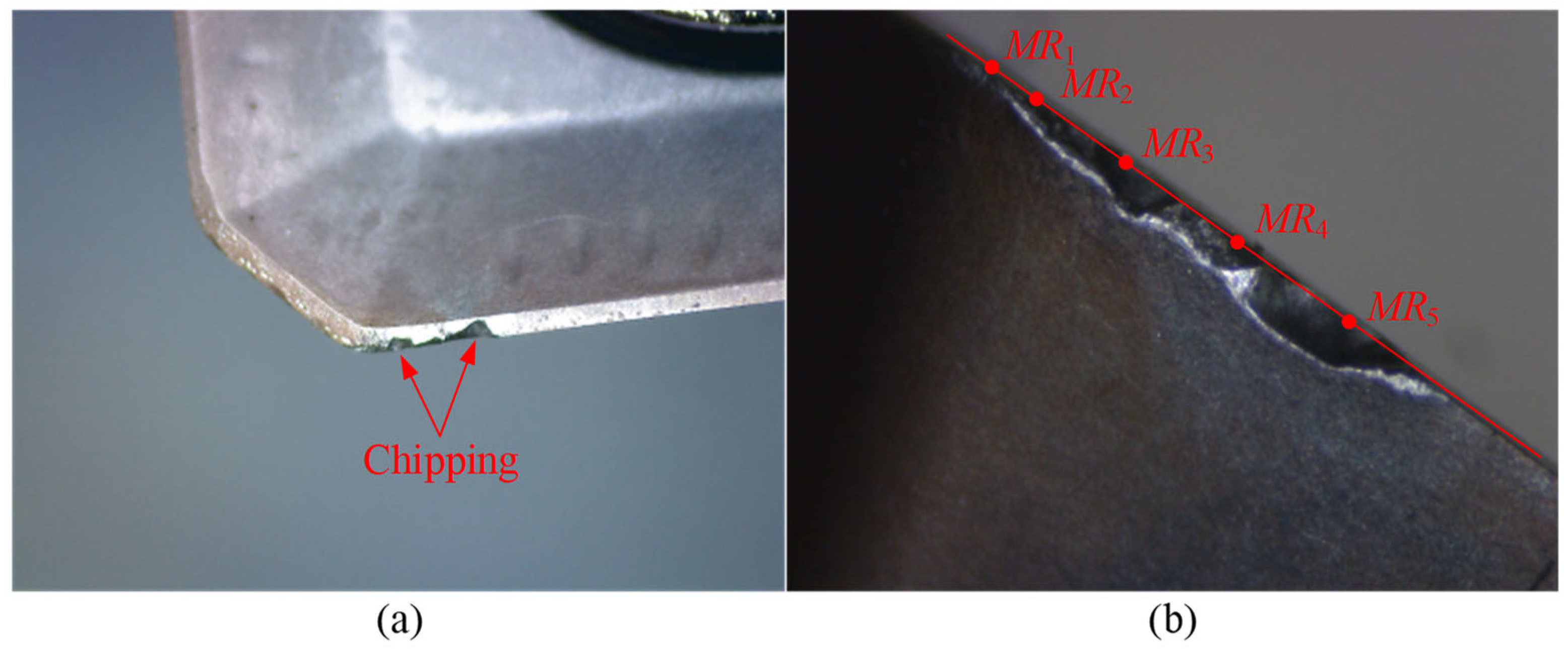

2.2. Formation Process of the Flank Wear Land in Indexable Face Milling Tools

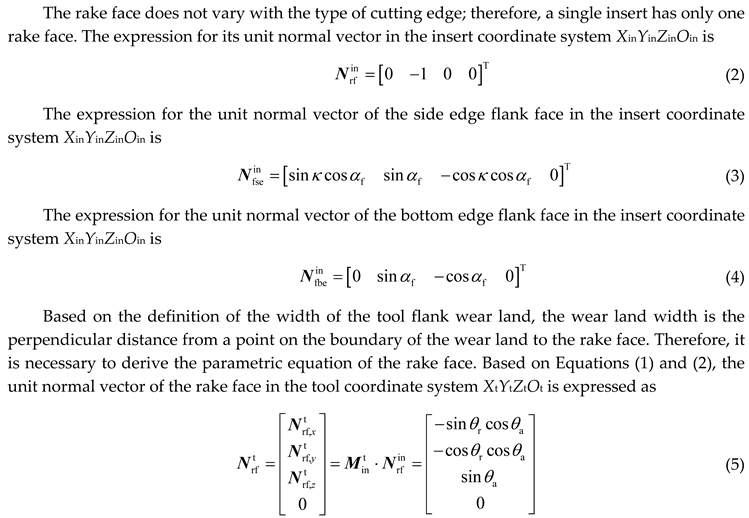

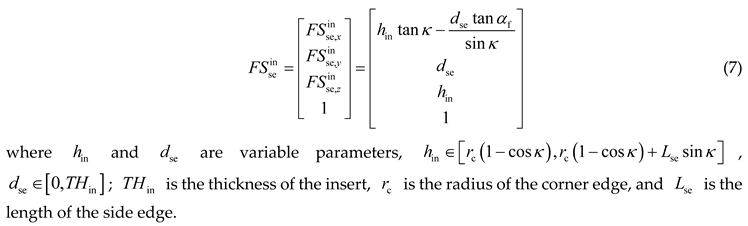

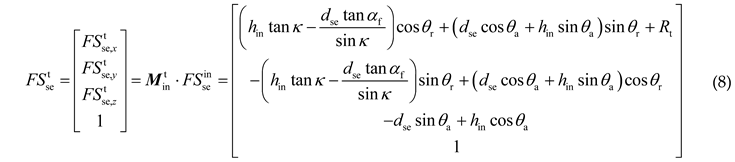

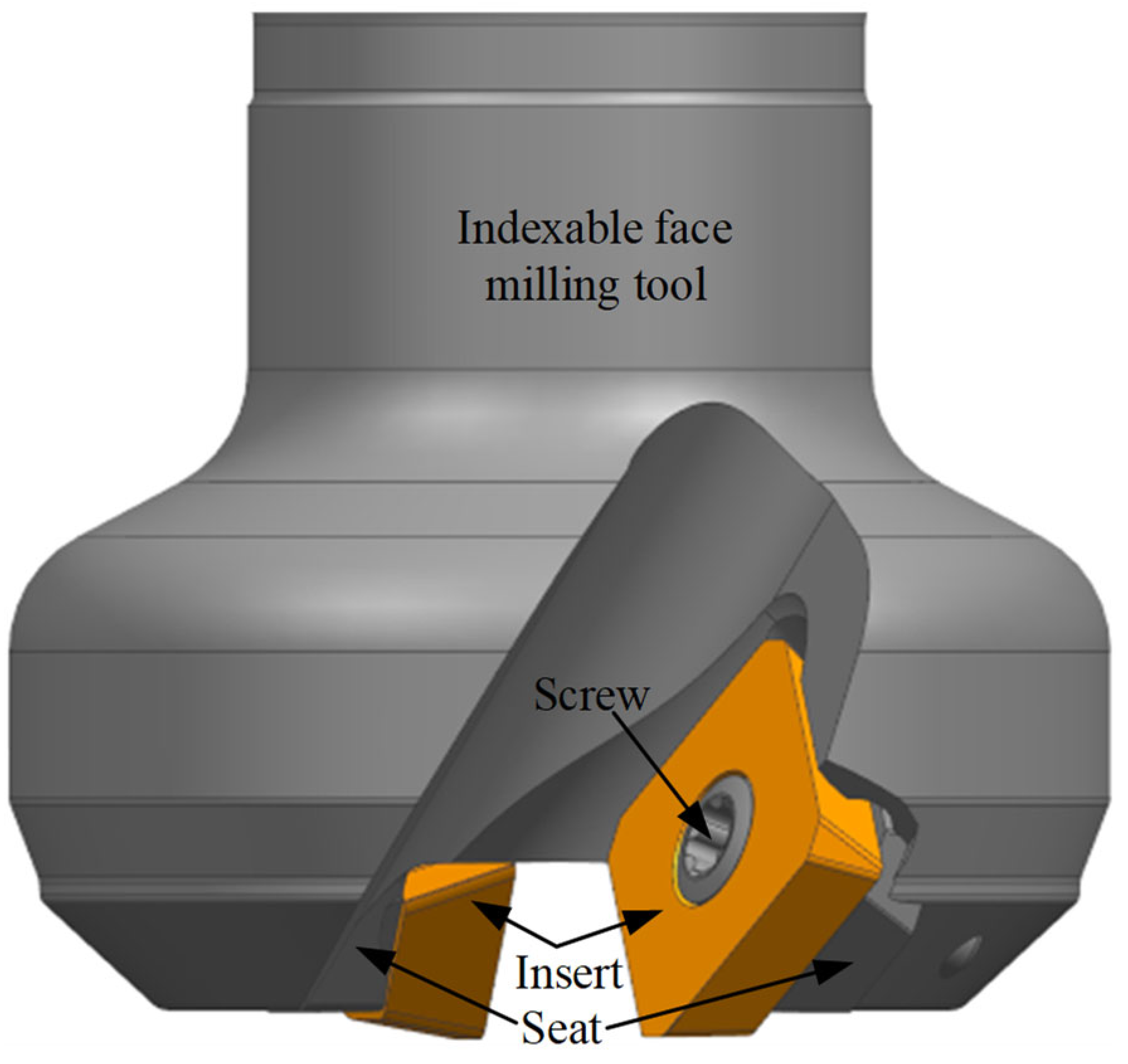

3. Geometric Modeling of Flank Wear Land Width

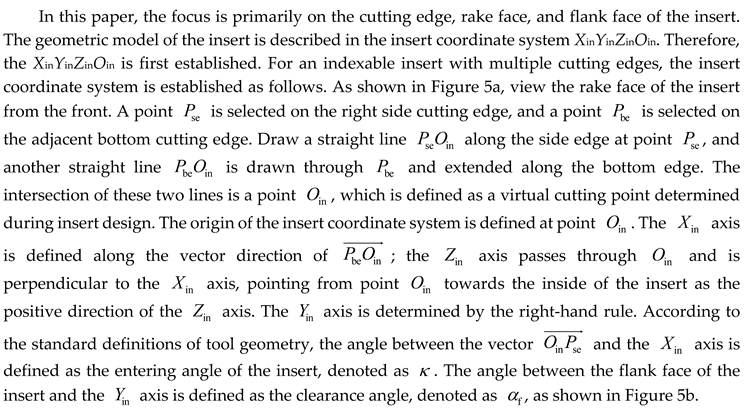

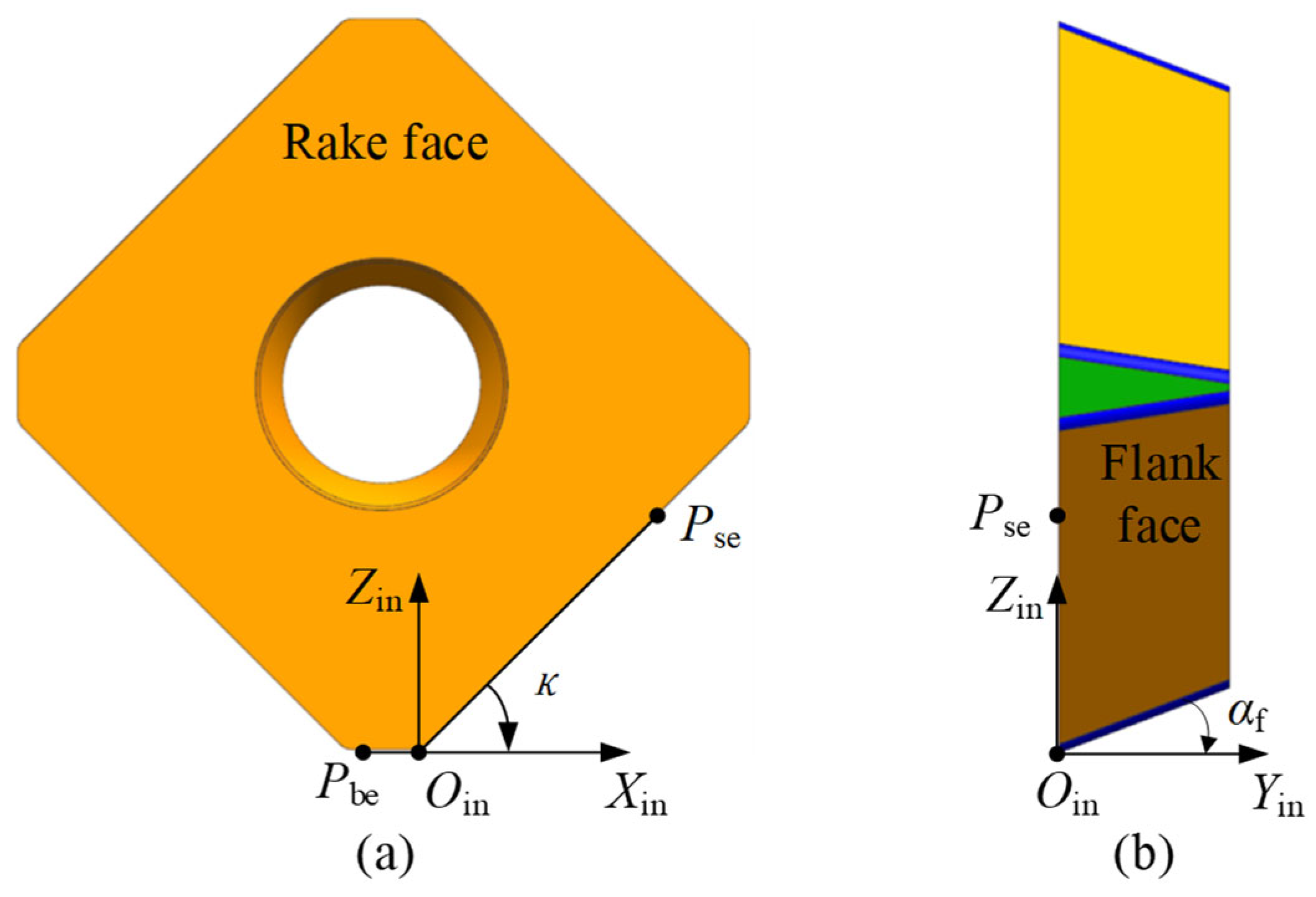

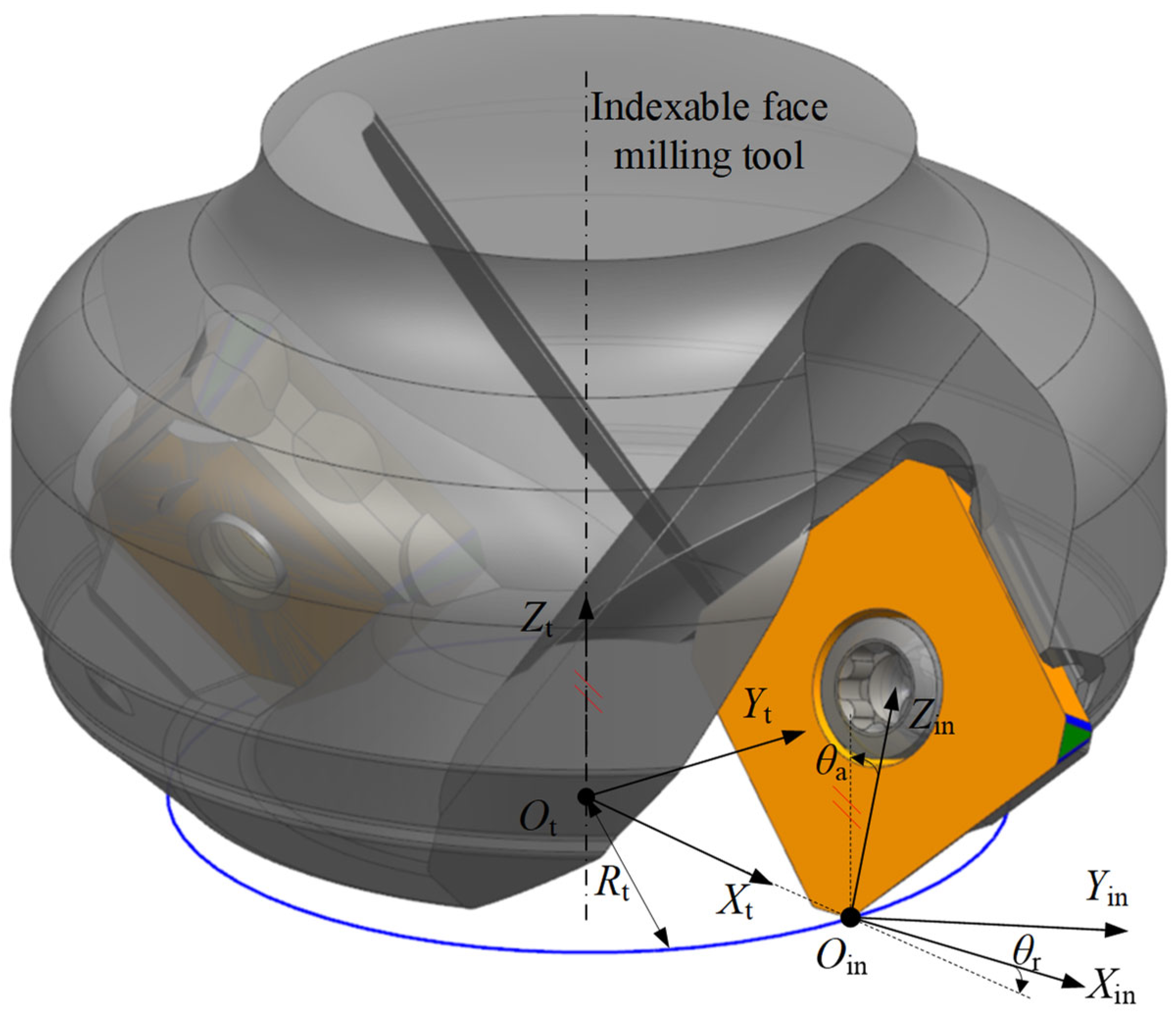

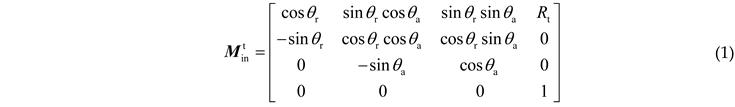

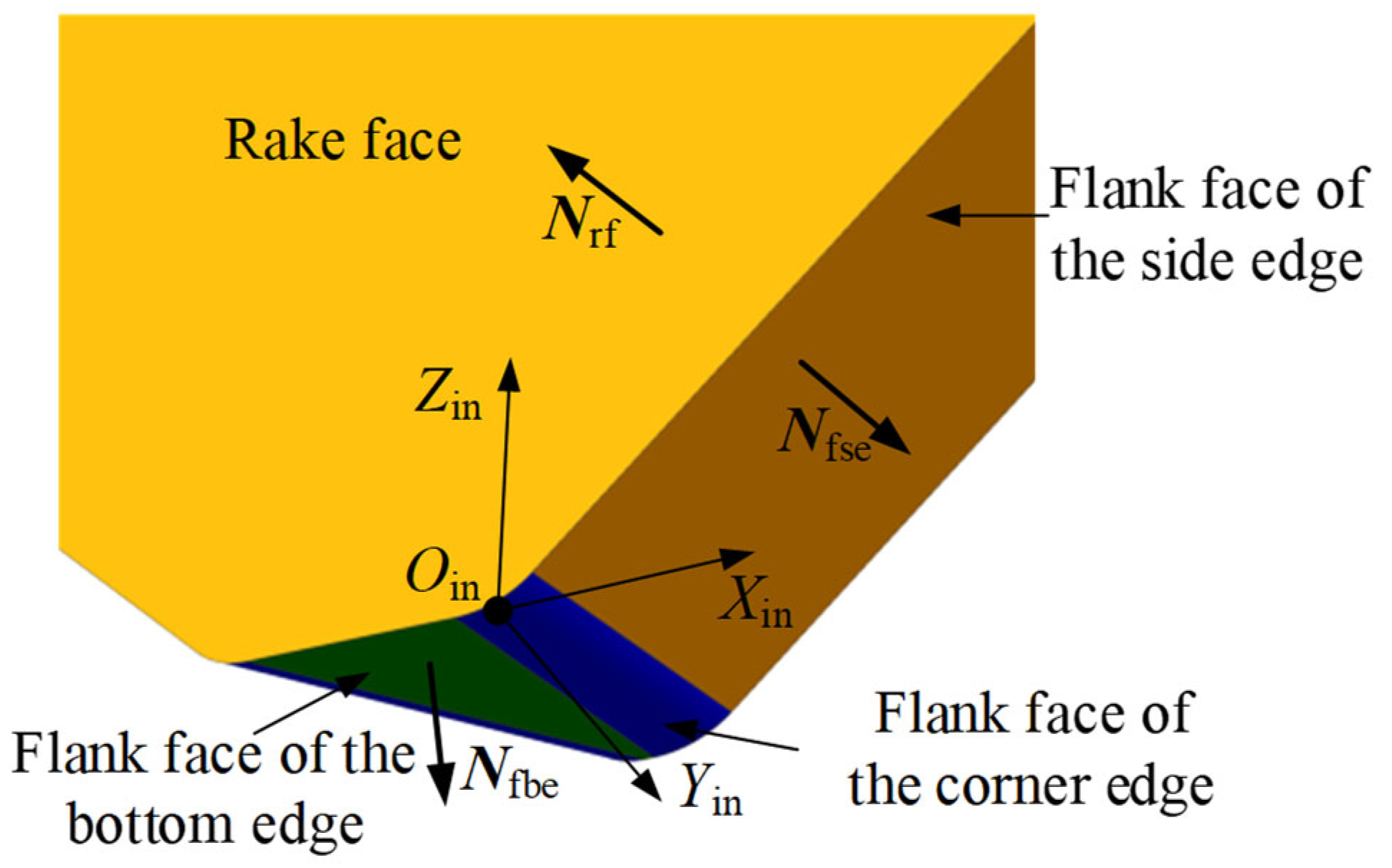

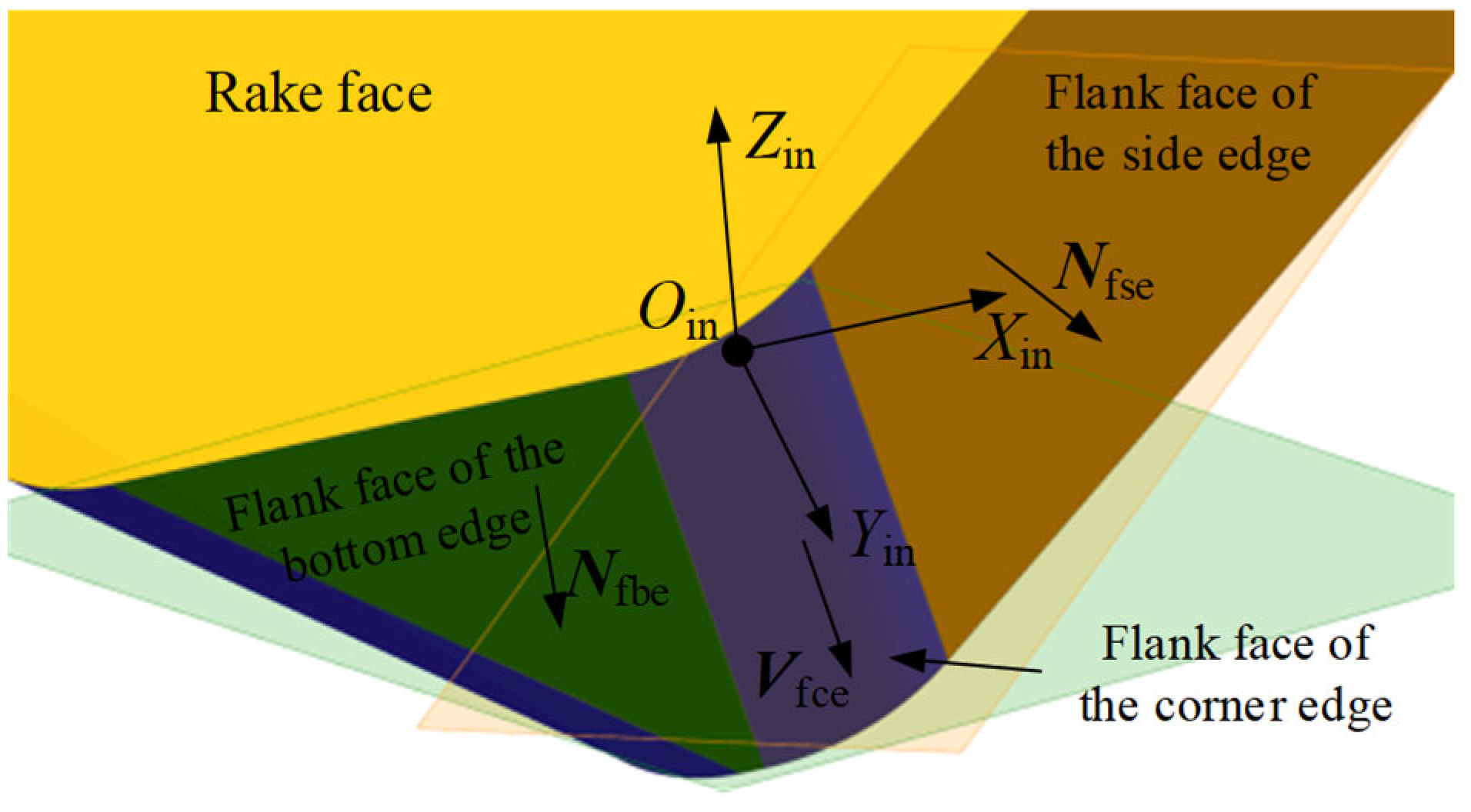

3.1. Establishment of the Insert Coordinate System and Tool Coordinate System

3.2. Geometric Model of the Indexable Face Milling Tool and Flank Wear Land Width

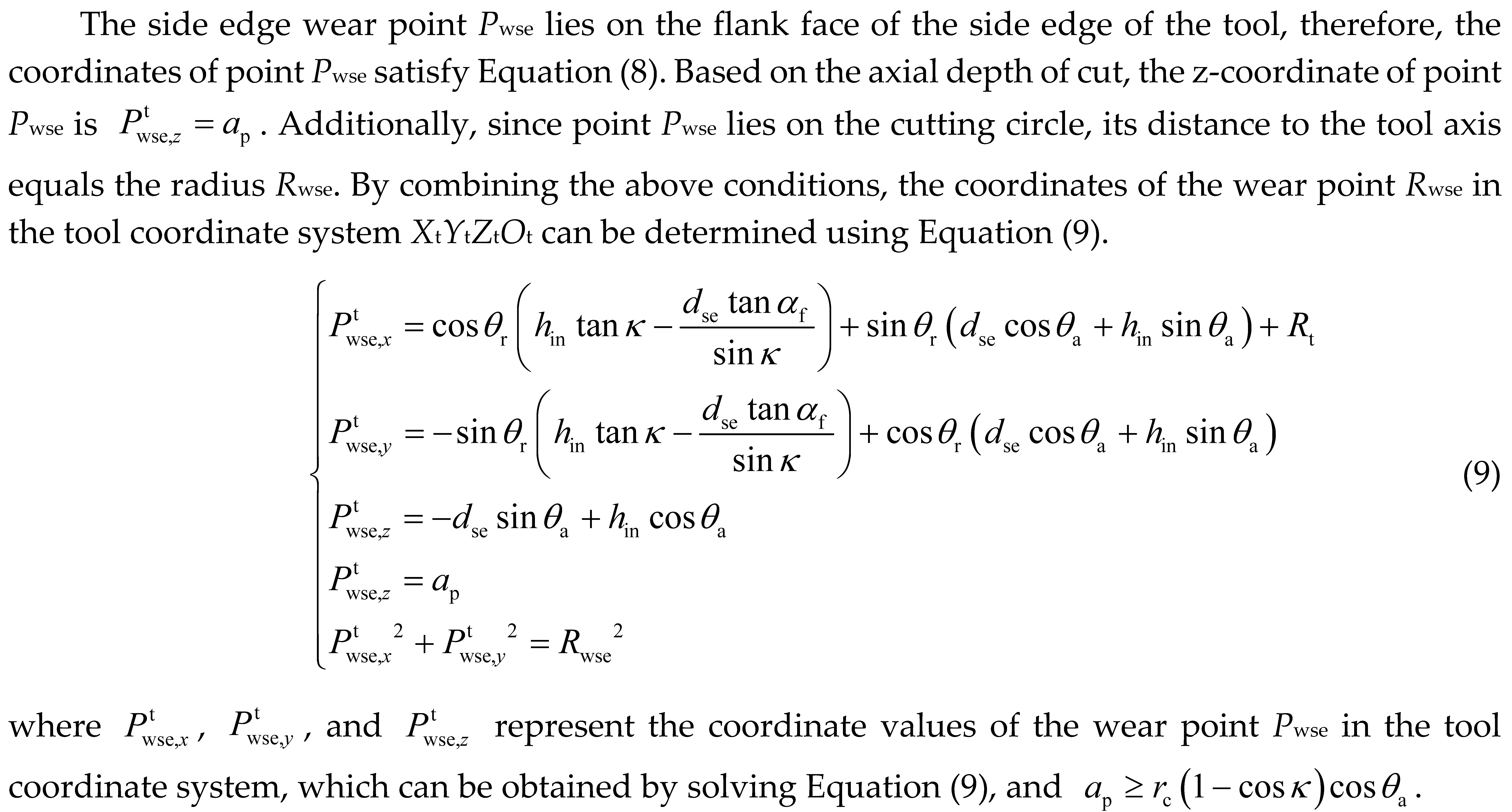

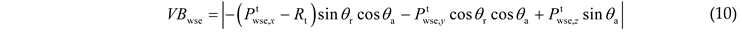

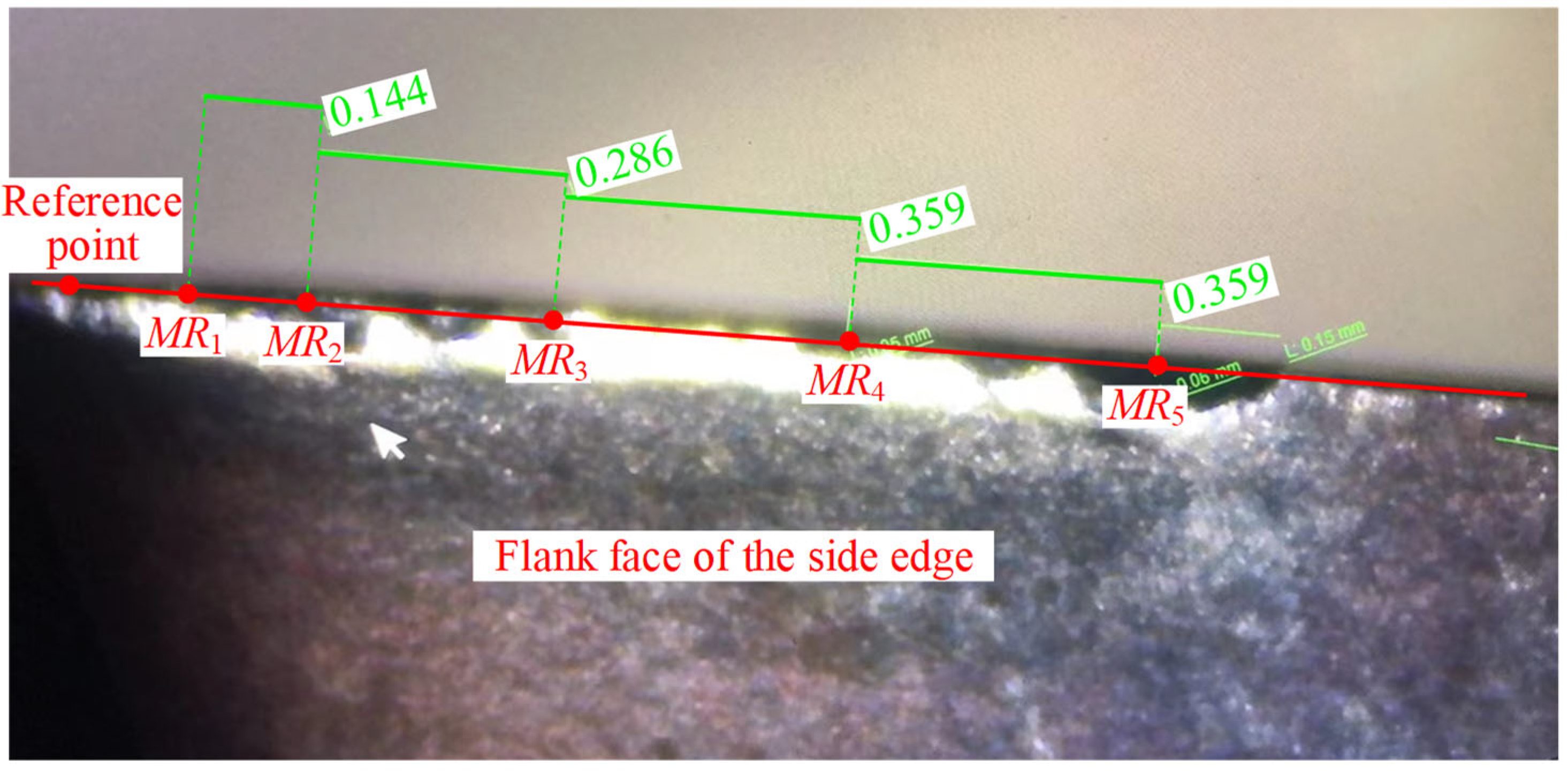

3.2.1. Flank Wear Land Width of the Side Edge

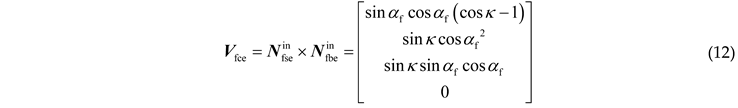

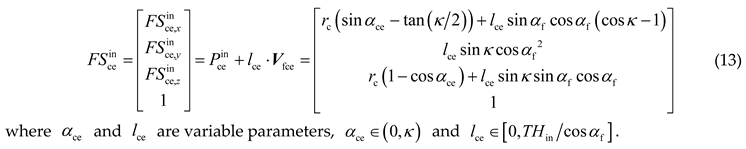

3.2.2. Flank Wear Land Width of the Corner Edge

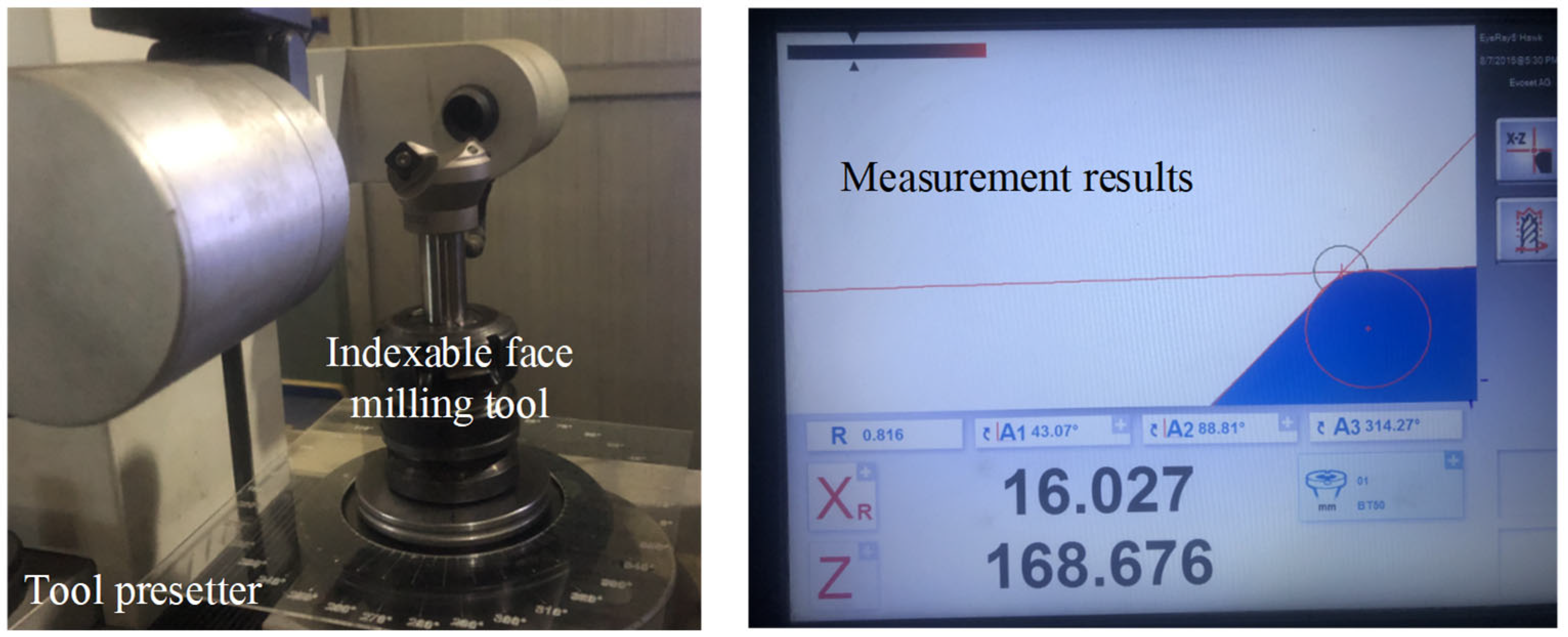

4. Flank Wear Land Width Measurement Method Based on Laser Tool Setters

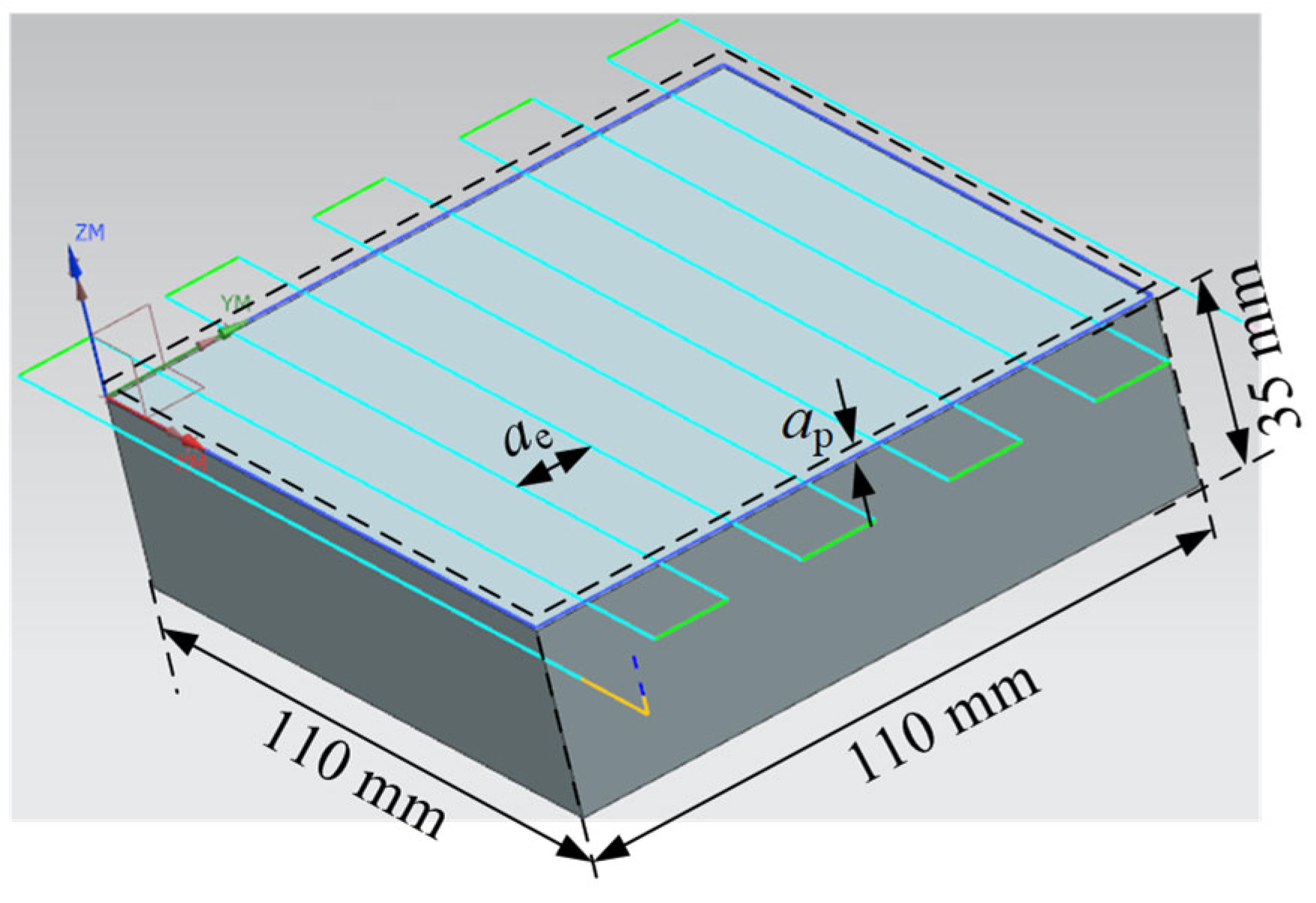

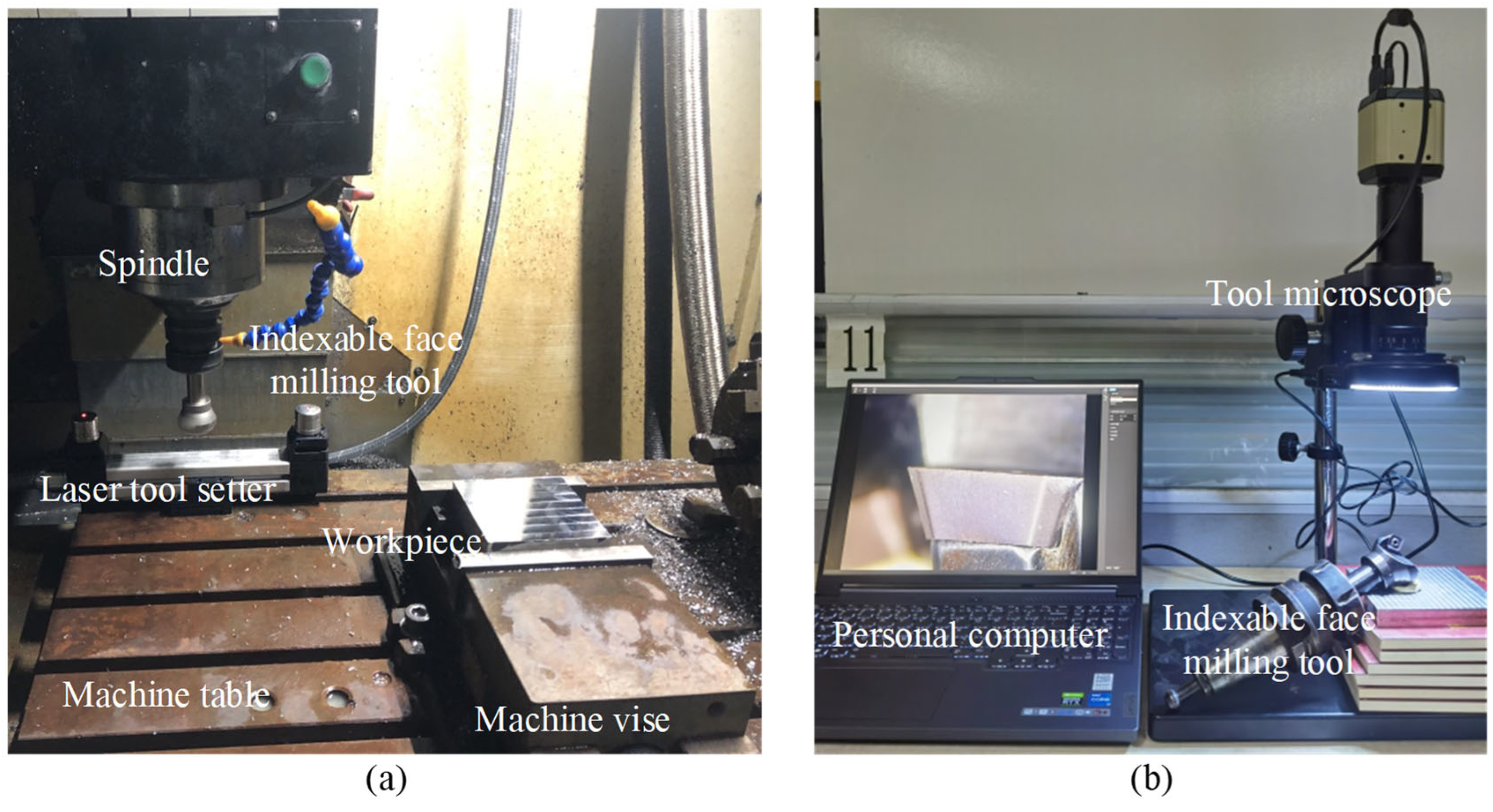

5. Experimental Verification and Application

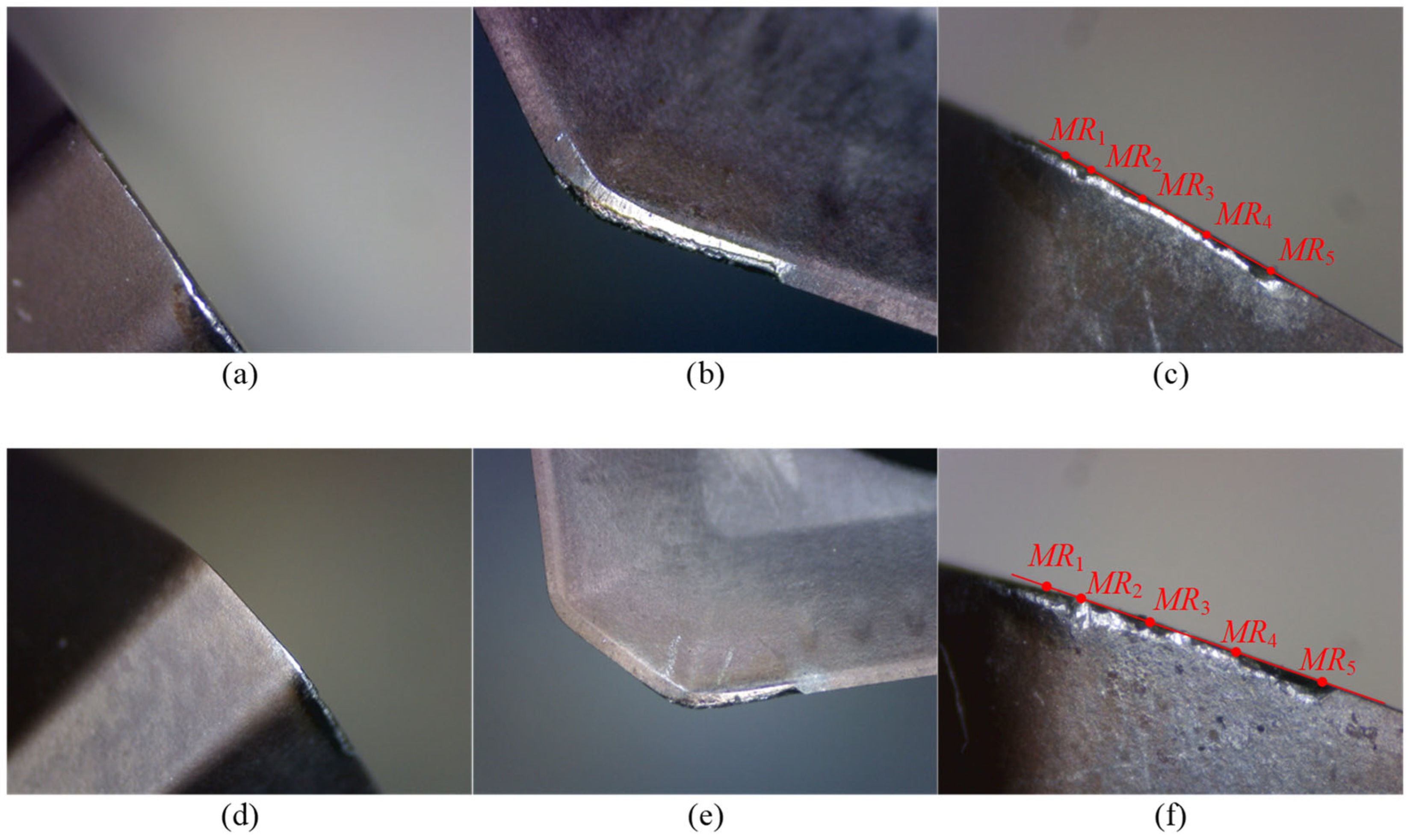

5.1. Experiment I

| Insert number | Number of cutting segments | Tool length, Lt(mm) | Cutting edge radius, Rw(mm) | Flank wear land width, VB(mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ML1 | ML2 | ML3 | ML4 | ML5 | MR1 | MR2 | MR3 | MR4 | MR5 | MR1 | MR2 | MR3 | MR4 | MR5 | ||

| 1 | 0 | 168.653 | 168.653 | 168.652 | 168.651 | 168.652 | 16.087 | 16.196 | 16.403 | 16.642 | 16.862 | 0 | 0 | 0 | 0 | 0 |

| 2 | 168.652 | 168.651 | 168.651 | 168.650 | 168.650 | 16.052 | 16.154 | 16.340 | 16.598 | 16.791 | 0.05 | 0.07 | 0.11 | 0.06 | 0.07 | |

| 2 | 0 | 168.653 | 168.653 | 168.652 | 168.651 | 168.652 | 16.087 | 16.196 | 16.403 | 16.642 | 16.862 | 0 | 0 | 0 | 0 | 0 |

| 2 | 168.652 | 168.651 | 168.651 | 168.650 | 168.650 | 16.052 | 16.154 | 16.340 | 16.598 | 16.791 | 0.04 | 0.05 | 0.08 | 0.11 | 0.10 | |

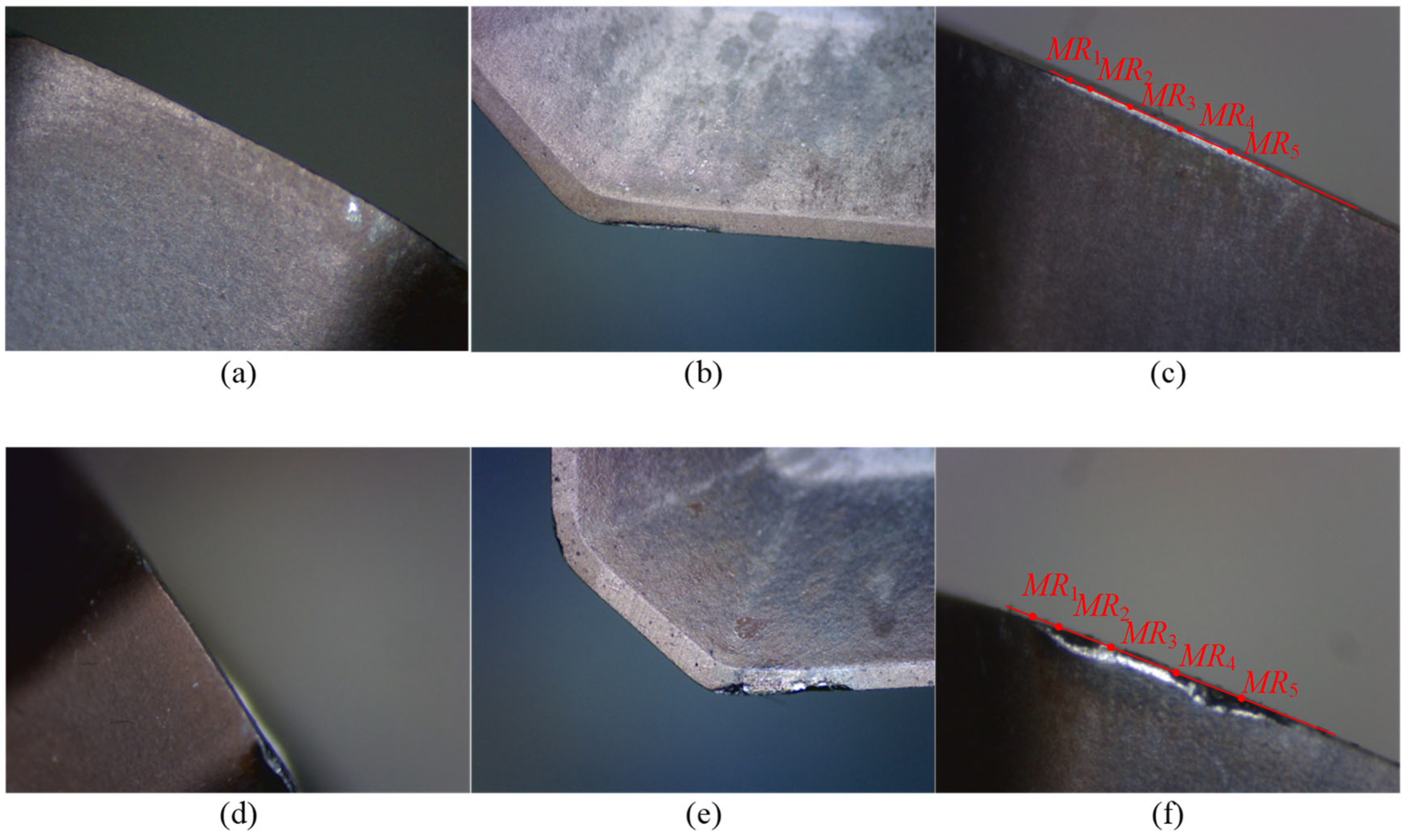

5.2. Experiment II

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, T.Y.; Zhou, J.T.; Luo, X.; Wang, M.W.; Zhang, S.S. A systematic multi-layer cognitive model for intelligent machine tool. J. Intell. Manuf. 2024, 1–25. [Google Scholar] [CrossRef]

- Niu, Q.L.; Chen, M.; Ming, W.W.; An, Q.L. Evaluation of the performance of coated carbide tools in face milling TC6 alloy under dry condition. Int. J. Adv. Manuf. Technol. 2013, 64, 623–631. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Davim, J.P. Tools (Geometry and Material) and Tool Wear. In Machining: Fundamentals and Recent Advances, Davim, J.P., Ed.; Springer London: London, 2008; pp. 29–57. [Google Scholar]

- Naskar, A.; Chattopadhyay, A.K. Investigation on flank wear mechanism of CVD and PVD hard coatings in high speed dry turning of low and high carbon steel. Wear 2018, 396, 98–106. [Google Scholar] [CrossRef]

- Szczotkarz, N.; Mrugalski, R.; Maruda, R.W.; Królczyk, G.M.; Legutko, S.; Leksycki, K.; Debowski, D.; Pruncu, C.I. Cutting tool wear in turning 316L stainless steel in the conditions of minimized lubrication. Tribol. Int. 2021, 156, 106813. [Google Scholar] [CrossRef]

- Gao, S.S.; Duan, X.Y.; Zhu, K.P.; Zhang, Y. Investigation of the tool flank wear influence on cutter-workpiece engagement and cutting force in micro milling processes. Mech. Syst. Sig. Process. 2024, 209, 111104. [Google Scholar] [CrossRef]

- Ding, P.F.; Huang, X.Z.; Zhao, C.Y.; Liu, H.Z.; Zhang, X.W. Online monitoring model of micro-milling force incorporating tool wear prediction process. Expert Syst. Appl. 2023, 223, 119886. [Google Scholar] [CrossRef]

- Wang, C.X.; Li, Y.; Gao, F.; Wu, K.J.; Yin, K.; He, P.; Xu, Y.J. Milling-force prediction model for 304 stainless steel considering tool wear. Machines 2025, 13, 72. [Google Scholar] [CrossRef]

- Song, C.S.; Xiang, D.H.; Yuan, Z.J.; Zhang, Z.Q.; Yang, S.K.; Gao, G.F.; Tong, J.L.; Wang, X.B.; Cui, X.B. Two-dimensional ultrasonic-assisted variable cutting depth scratch force model considering tool wear and experimental verification. Tribol. Int. 2025, 204, 110510. [Google Scholar] [CrossRef]

- Saha, S.; Ansary, S.I.; Deb, S.; Bandyopadhyay, P.P. Influence of tool wear on chip-like burr formation during micro-milling, and image processing based measurement of inwardly-deflected burrs. Wear 2023, 530, 205024. [Google Scholar] [CrossRef]

- Plodzien, M.; Zylka, L.; Sulkowicz, P.; Zak, K.; Wojciechowski, S. High-performance face milling of 42CrMo4 steel: influence of entering angle on the measured surface roughness, cutting force and vibration amplitude. Mater. (Basel) 2021, 14, 2196. [Google Scholar] [CrossRef]

- Prisco, U.; Astarita, A. Prediction of specific energy consumption during face milling of steel. Mater. Manuf. Processes 2024, 39, 711–719. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Krajewska-Spiewak, J.; Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wieczorowski, M.; Gawlik, J. Study on ploughing phenomena in tool flank face-workpiece interface including tool wear effect during ball-end milling. Tribol. Int. 2023, 181, 108313. [Google Scholar] [CrossRef]

- Zhao, P.Y.; Song, Y.F.; Jiang, B.; Wang, B. Distribution and prediction of incremental cutter flank wear in high-efficiency milling. Appl. Sci.-Basel 2023, 13, 4749. [Google Scholar] [CrossRef]

- Pozzato, N.; Bertolini, R.; Moro, L.; Ghiotti, A.; Bruschi, S.; Tagarelli, L. On the wear mechanisms of ceramic round inserts in high-speed turning of Inconel 718. Wear 2025, 571, 205866. [Google Scholar] [CrossRef]

- Zhao, M.B.; Cai, Y.L.; Wang, H.T.; Mei, J.W. Non-uniform flank wear prediction and tool orientation optimization for ball-end tool 5-axis machining based on real cutting length calculation. Int. J. Adv. Manuf. Technol. 2024, 134, 3251–3265. [Google Scholar] [CrossRef]

- Jin, F.; Bao, Y.; Li, B.H.; Jin, X.L. Tool wear prediction in edge trimming of carbon fiber reinforced polymer using machine learning with instantaneous parameters. J. Manuf. Process. 2022, 82, 277–295. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhu, W.H. Development of a fiber optical occlusion based non-contact automatic tool setter for a micro-milling machine. Rob. Comput. Integr. Manuf. 2017, 43, 12–17. [Google Scholar] [CrossRef]

- Khajornrungruang, P.; Kimura, K.; Suzuki, K.; Inoue, T. Micro tool diameter monitoring by means of laser diffraction for on-machine measurement. Int. J. Autom. Technol. 2017, 11, 736–741. [Google Scholar] [CrossRef]

- Fang, T.; Fang, Z.X.; Chen, Z.Z.; Chang, Z.Y. A methodology for laser tool setters calibration and its precise mathematical model. Chin. J. Aeronaut. 2024, 37, 564–581. [Google Scholar] [CrossRef]

- Vieira Júnior, M.; Pereira, F.H.; Lucato, W.C.; da Costa, F.S. Influence of feed rate and spindle speed on referencing laser tool-setters. J. Braz. Soc. Mech. Sci. Eng. 2014, 37, 1015–1028. [Google Scholar] [CrossRef]

- Wang, W.Q.; Liu, W.; Zhang, Y.; Liu, Y.; Zhang, P.D.; Jia, Z.Y. Precise measurement of geometric and physical quantities in cutting tools inspection and condition monitoring: A review. Chin. J. Aeronaut. 2024, 37, 23–53. [Google Scholar] [CrossRef]

- Zhou, J.Q.; Yue, C.X.; Liu, X.L.; Xia, W.; Wei, X.D.; Qu, J.X.; Liang, S.Y.; Wang, L.H. Classification of tool wear state based on dual attention mechanism network. Rob. Comput. Integr. Manuf. 2023, 83, 102575. [Google Scholar] [CrossRef]

- Zhu, K.P.; Yu, X.L. The monitoring of micro milling tool wear conditions by wear area estimation. Mech. Syst. Sig. Process. 2017, 93, 80–91. [Google Scholar] [CrossRef]

- Boing, D.; Castro, F.L.; Schroeter, R.B. Prediction of PCBN tool life in hard turning process based on the three-dimensional tool wear parameter. Int. J. Adv. Manuf. Technol. 2019, 106, 779–790. [Google Scholar] [CrossRef]

- Iliyas Ahmad, M.; Yusof, Y.; Daud, M.E.; Latiff, K.; Abdul Kadir, A.Z.; Saif, Y. Machine monitoring system: a decade in review. Int. J. Adv. Manuf. Technol. 2020, 108, 3645–3659. [Google Scholar] [CrossRef]

- Saha, S.; Deb, S.; Bandyopadhyay, P.P. Precise measurement of worn-out tool diameter using cutting edge features during progressive wear analysis in micro-milling. Wear 2022, 488, 204169. [Google Scholar] [CrossRef]

- Li, X.B.; Liu, X.L.; Yue, C.X.; Liang, S.Y.; Wang, L.H. Systematic review on tool breakage monitoring techniques in machining operations. Int. J. Mach. Tools Manuf. 2022, 176, 103882. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Wang, W.Q.; Wang, K.; Zhang, Y. Adaptive lighting for complex cutting tools in precise vision measurement. IEEE Trans. Instrum. Meas. 2024, 73, 1–14. [Google Scholar] [CrossRef]

- Zhu, K.P.; Guo, H.; Li, S.; Lin, X. Online tool wear monitoring by super-resolution based machine vision. Comput. Ind. 2023, 144, 103782. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, S.S.; Duan, X.Y.; Zhu, K.P. A visual analytical method for evaluating tool flank wear volumes of micro-milling cutters with AKAZE features matching: A preliminary study. Wear 2025, 564, 205739. [Google Scholar] [CrossRef]

- Wang, C.D.; Bao, Z.K.; Zhang, P.Q.; Ming, W.W.; Chen, M. Tool wear evaluation under minimum quantity lubrication by clustering energy of acoustic emission burst signals. Measurement 2019, 138, 256–265. [Google Scholar] [CrossRef]

- Akhtar, W.; Rahman, H.U.; Lazoglu, I. Machining process monitoring using an infrared sensor. J. Manuf. Process. 2024, 131, 2400–2410. [Google Scholar] [CrossRef]

- Cheng, M.H.; Jiao, L.; Yan, P.; Jiang, H.S.; Wang, R.B.; Qiu, T.Y.; Wang, X.B. Intelligent tool wear monitoring and multi-step prediction based on deep learning model. J. Manuf. Syst. 2022, 62, 286–300. [Google Scholar] [CrossRef]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool condition monitoring techniques in milling process - a review. J. Mater. Res. Technol. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

- He, Z.P.; Shi, T.L.; Xuan, J.P. Milling tool wear prediction using multi-sensor feature fusion based on stacked sparse autoencoders. Measurement 2022, 190, 110719. [Google Scholar] [CrossRef]

- Sun, M.J.; Wang, X.D.; Guo, K.; Huang, X.M.; Sun, J.; Li, D.; Huang, T. Tool wear monitoring based on physics-informed Gaussian process regression. J. Manuf. Syst. 2024, 77, 40–61. [Google Scholar] [CrossRef]

- Liu, D.L.; Liu, Z.Q.; Zhao, J.F.; Song, Q.H.; Ren, X.P.; Ma, H.F. Tool wear monitoring through online measured cutting force and cutting temperature during face milling Inconel 718. Int. J. Adv. Manuf. Technol. 2022, 122, 729–740. [Google Scholar] [CrossRef]

- Zhang, P.F.; Gao, D.; Hong, D.B.; Lu, Y.; Wang, Z.H.; Liao, Z.R. Intelligent tool wear monitoring based on multi-channel hybrid information and deep transfer learning. J. Manuf. Syst. 2023, 69, 31–47. [Google Scholar] [CrossRef]

- Kang, N.S.; Ma, H.W.; Feng, F.; Wu, Q.H.; Wang, J.J.; Zhou, K.; Wu, C.M.; Feng, P.F. A multi-sensor tool wear monitoring method based on mechanism-data fusion for industrial scenario. Mech. Syst. Sig. Process. 2025, 234, 112834. [Google Scholar] [CrossRef]

- Thorenz, B.; Oßwald, F.; Schötz, S.; Westermann, H.H.; Döpper, F. Applying and producing indexable end mills: A comparative market dtudy in context of resource efficiency. Procedia Manuf. 2020, 43, 167–174. [Google Scholar] [CrossRef]

| Number of inserts, Nt | Tool radius, Rt(mm) | Axial rake angle, θa(°) | Radial rake angle, θr(°) | ||||

|---|---|---|---|---|---|---|---|

| 2 | 16 | 10 | −15 | ||||

| Entering angle, κ(°) | Clearance angle, αf(°) | Insert thickness, THin(mm) | Corner edge radius, rc(mm) | Side edge length, Lse(mm) | |||

| 45 | 20 | 4.76 | 1.5 | 9 | |||

| Spindle speed, ns(r/min) | Feed rate, f(mm/min) | Axial depth of cut, ap(mm) | Radial width of cut, ae(mm) |

|---|---|---|---|

| 1800 | 288 | 1 | 14 |

| Insert number | Number of cutting segments | Tool length, Lt(mm) | Cutting edge radius, Rw(mm) | Flank wear land width, VB(mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ML1 | ML2 | ML3 | ML4 | ML5 | MR1 | MR2 | MR3 | MR4 | MR5 | MR1 | MR2 | MR3 | MR4 | MR5 | ||

| 1 | 0 | 168.636 | 168.636 | 168.637 | 168.637 | 168.636 | 16.127 | 16.243 | 16.448 | 16.674 | 16.915 | 0 | 0 | 0 | 0 | 0 |

| 2 | 168.634 | 168.633 | 168.635 | 168.634 | 168.634 | 16.096 | 16.198 | 16.406 | 16.635 | 16.865 | 0.04 | 0.07 | 0.08 | 0.07 | 0.09 | |

| 4 | 168.633 | 168.632 | 168.632 | 168.632 | 168.631 | 16.089 | 16.192 | 16.398 | 16.627 | 16.849 | 0.05 | 0.08 | 0.09 | 0.08 | 0.11 | |

| 2 | 0 | 168.636 | 168.636 | 168.637 | 168.637 | 168.636 | 16.127 | 16.243 | 16.448 | 16.674 | 16.915 | 0 | 0 | 0 | 0 | 0 |

| 2 | 168.632 | 168.633 | 168.635 | 168.634 | 168.634 | 16.096 | 16.198 | 16.406 | 16.635 | 16.865 | 0.01 | 0.01 | 0.03 | 0.03 | 0.03 | |

| 4 | 168.631 | 168.633 | 168.634 | 168.632 | 168.632 | 16.089 | 16.192 | 16.398 | 16.627 | 16.849 | 0.02 | 0.04 | 0.08 | 0.08 | 0.10 | |

| Measurement points | MR1 | MR2 | MR3 | MR4 | MR5 | |

|---|---|---|---|---|---|---|

| Number of cutting segments |

||||||

| 0 | Initial Cutting Edge Radius, Rw(mm) | 16.087 | 16.207 | 16.402 | 16.633 | 16.870 |

| 1 | Cutting Edge Radius, Rw(mm) | 16.067 | 16.183 | 16.377 | 16.618 | 16.850 |

| Calculated wear, VB(mm) | 0.028 | 0.041 | 0.043 | 0.026 | 0.035 | |

| Measured wear, VB(mm) | 0.03 | 0.04 | 0.05 | 0.03 | 0.04 | |

| Error percentage, (%) | 6.67 | 2.50 | 14.00 | 13.33 | 12.50 | |

| 2 | Cutting Edge Radius, Rw(mm) | 16.057 | 16.172 | 16.362 | 16.603 | 16.837 |

| Calculated wear, VB(mm) | 0.042 | 0.059 | 0.069 | 0.052 | 0.058 | |

| Measured wear, VB(mm) | 00.04 | 0.06 | 0.07 | 0.05 | 0.06 | |

| Error percentage, (%) | 5.00 | 1.67 | 1.43 | 4.00 | 3.33 | |

| 3 | Cutting Edge Radius, Rw(mm) | 16.047 | 16.162 | 16.352 | 16.587 | 16.827 |

| Calculated wear, VB(mm) | 0.056 | 0.076 | 0.087 | 0.080 | 0.076 | |

| Measured wear, VB(mm) | 0.06 | 0.07 | 0.09 | 0.08 | 0.08 | |

| Error percentage, (%) | 6.67 | 8.57 | 3.33 | 0.00 | 5.00 | |

| 4 | Cutting Edge Radius, Rw(mm) | 16.037 | 16.152 | 16.349 | 16.582 | 16.811 |

| Calculated wear, VB(mm) | 0.070 | 0.093 | 0.092 | 0.089 | 0.104 | |

| Measured wear, VB(mm) | 0.07 | 0.09 | 0.09 | 0.09 | Chipping | |

| Error percentage, (%) | 0.00 | 3.33 | 2.22 | 1.11 | — | |

| Number of cutting segments | 0 | 2 | 4 | |||

|---|---|---|---|---|---|---|

| Measurement points | MR3 | MR5 | MR3 | MR5 | MR3 | MR5 |

| Cutting Edge Radius, Rw(mm) | 16.410 | 16.881 | 16.355 | 16.830 | 16.336 | 16.811 |

| Calculated wear, VB(mm) | 0 | 0 | 0.069 | 0.076 | 0.102 | 0.110 |

| Tool conditions | Valid | Valid | Valid | Valid | Invalid | Invalid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).