1. Introduction

Food dehydration is one of the oldest preservation techniques that plays a fundamental role today, especially given the growing global interest in achieving greater energy sustainability and reducing post-harvest losses. Drying processes are not only applied to improve the quality and extend the shelf life of agricultural products, but also to optimize energy consumption, thus responding to environmental challenges. Although significant technological advances have been made in this area, significant gaps persist between traditional methods and new technologies in terms of efficiency, quality control, and sustainability. This situation highlights the importance of developing innovative solutions that incorporate innovative control and monitoring technologies, capable of effectively transforming industrial dehydration processes.

Efficient energy use and precise control are essential for optimizing food dehydration processes, especially in the food industry. These processes aim to preserve nutritional and sensory properties while reducing energy consumption [

1]. Food dehydration and preservation are part of a process whose greatest impact is the removal of moisture content from products, through the implementation of solar and electric food dehydrators. Conventional food drying methods have been widely used, but their energy efficiency can vary considerably, up to 50% or more, depending on the operating conditions and the technical design used [

2].

Current advances in food processing have highlighted the critical role of incorporating intelligent control systems along with real-time monitoring to increase the efficiency of the drying process. Specifically, the biochemical and physicochemical properties of food, dehydration, require continuous monitoring to ensure final product quality [

3,

4].

Factors such as the distribution of drying thermal energy, the speed of the dryer's hot air, and dehydration time are elements that affect both the nutrient retention and microbiological safety of dehydrated foods [

4]. Furthermore, creative modeling methods, such as predictions using machine learning techniques and drying kinetics analysis, have proven to be efficient tools for optimizing industrial dryer parameters, achieving precise control over volume reduction and moisture content [

1,

5].

Solar drying is primarily limited to areas receiving high solar radiation. Several studies have shown that the use of parabolic solar dryers allows for the preservation of fruits such as pitahaya and pineapple, maintaining their sensory properties [

5]. Furthermore, the type of drying method used has been observed to significantly influence the functional properties of fruit powders, as documented in research using guava pulp [

6].

However, the application of heat-free dehydration techniques, combined with vacuum microwave drying, has led to advances in mass transfer and the preservation of sensitive bioactive compounds [

7].

In recent years, the application of physical simulations and Monte Carlo methods to optimize carrot drying processes has gained relevance. This has resulted in significant advances in thermal energy allocation and reduction of dehydration times [

8]. Furthermore, the use of machine learning algorithms, such as decision trees, random forest, and AdaBoost, has made it possible to accurately predict dehydration kinetics and energy consumption in temperature-controlled microwave drying [

9]. In the case of products such as lucuma powder, the application of mathematical modeling and artificial intelligence techniques has facilitated the effective characterization of microstructural properties during the foam dehydration process [

10].

Among the most recent technological advances are new dehydrator models, such as the fountain bed dryer. This equipment, thanks to its predictive systems, optimizes the efficiency of the dehydration process within modern fluidized bed systems [

11]. Furthermore, the addition of thermal energy storage in indirect solar dehydrators has proven to be very effective, especially in the drying of red chili peppers. This allows dehydration to remain continuous and stable, even with changes in sunlight intensity [

12].

In the technological field of indirect solar dehydrators, innovative systems have emerged that use the Internet of Things (IoT) to monitor variables in the moisture removal process in real time. This allows the potato dehydration process to be improved according to the thickness of the slices in the dryer [

13].

Analyzing the performance of solar chambers for dewatering apples, it has been concluded that both chamber design and control of internal conditions are determining factors in increasing drying speed [

14].

The integration of various sensors in dehydration processes that use far-infrared radiation and hot air, as is the case in ginger dehydration, is essential for achieving precise control of crucial variables such as temperature, humidity, and water content in the product [

15]. Optimizing these aspects not only improves food quality but also promotes more efficient energy use. These advances project the current application of digitalization and automation in dehydration processes, highlighting the importance of incorporating technologies to achieve more sustainable and efficient agro-industrial production.

The development of technologies such as IoT has completely transformed the way we optimize agricultural drying processes. With the implementation of real-time monitoring systems, we have been able to improve not only energy efficiency but also the quality of the dehydrated product [

16].

These innovations are very important in the design of solar forced convection dehydration systems, which leverage renewable sources to mitigate the environmental impact of the moisture removal process. Dehydration methods have been shown to be significantly related to the sensory properties of agricultural products such as coffee. This highlights the importance of selecting appropriate methods to preserve quality after harvest [

17]. The relevance of this consideration increases even further when applying control and monitoring technologies to other foods, such as carrots, where maintaining their organoleptic properties is essential.

In control methods for dehydration processes, current studies have proposed the integration of Proportional-Integral (PI) control with fuzzy logic. This combination has improved stability and efficiency in rotary dryers, demonstrating significant advances in the precision of thermal variable control [

18]. Furthermore, the application of sensing systems that incorporate signal conditioning and fuzzy systems in these dryers has enabled optimal data acquisition. This leads to more efficient and adaptive decision-making, both directly and in real time, resulting in higher operational efficiency [

19].

The implementation of artificial neural networks to predict drying process parameters, such as dehydration time, energy consumption, and exergy efficiency, is relevant in the process of removing moisture from corn grains using convective-infrared rotary dryers [

20]. This advancement has a significant impact on predictive modeling of dehydration processes in the field of food preservation.

A key element in the performance of rotary drum dryers is the maintenance and durability of their components, especially the internal sensors. The lifespan of these components can be estimated through experimental data, which facilitates preventive maintenance planning and ensures operational continuity [

21].

The final result of dehydrated agricultural products is directly related to the drying method implemented. For Arara Arabica coffee, different dehydration techniques have been found to affect both the physical properties and sensory characteristics of the product. This highlights the crucial role of accurately instrumenting and controlling conditions during the process [

22]. Furthermore, current studies have proposed approaches to accurately measure the overall heat transfer coefficient in rotary drum dehydrators. These data are essential for thermal energy optimization and the industrial expansion of these devices [

23]. These research advances in thermal modeling are highly relevant for designing more innovative systems.

Research into dehydration methods has evolved toward the implementation of pretreatments such as osmotic impregnation, edible coatings, and the use of reduced pressures. These techniques have shown significant improvements in the physical and functional properties of carrots dehydrated using microwave and vacuum technologies, significantly minimizing structural damage [

24]. These innovations open up new opportunities for adding pretreatments to rotary dryers, tailoring them to specific drying conditions.

Furthermore, the modification of carrot cell walls with pectin, influenced by ultrasound and infrared treatments, has demonstrated new texture formation mechanisms that are crucial for the quality of the dehydrated product. This helps strengthen multivariate control of moisture and temperature parameters in dehydration. This is especially relevant when seeking to optimize both the sensory and structural properties of low-moisture food [

25].

The application of drying conditions at controlled temperatures has been shown to have a significant impact on the drying rate and key parameters of carrot. This highlights the importance of adjusting method conditions to increase the preservation of bioactive compounds [

26]. This research is essential for developing strategies that allow for the sustainable use of agricultural waste through drying processes.

Although significant progress has been made in the implementation of various technologies in drying processes, the implementation of integrated cyber-physical systems with adaptive fuzzy control remains an emerging field. This technology offers significant opportunities for optimizing energy and the quality of dehydrated products.

This study focuses on the development and evaluation of a cyber-physical system that implements adaptive fuzzy control. This system aims to implement direct, real-time multivariate monitoring of temperature, humidity, dryer wind speed, and mass loss during the carrot dehydration process in a rotary dryer. Additionally, it is proposed that the use of sensors integrated into a microcontroller will allow for more precise automatic adjustments, optimizing drying conditions in the face of environmental variations. It is expected to validate that the intelligent control system can reduce the specific energy consumption of the process, improve the thermal stability of the dryer, and maintain the organoleptic properties of dehydrated product. In this way, the goal is to promote drying approaches in the agricultural sector aimed at optimizing resources, developing and implementing dehydration practices based on sustainability, energy efficiency and operational artificial intelligence.

2. Materials and Methods

The experimental trials were carried out at the Agroindustrial Processes Laboratory of the National Institute of Technology of Mexico in Celaya, Guanajuato, from January 2024 to February 2025. Locally sourced carrots (Daucus carota L.) were selected at their optimum state of commercial ripeness and with an initial water content close to 90% on a wet basis. Before each trial, the samples were stored under refrigeration at 4 ± 1 °C to ensure their microbiological stability. They were subsequently dehydrated using a rotary dryer with an adaptive fuzzy control system. This system allows real-time monitoring and regulation of the water removal process, continuously analyzing critical variables such as temperature, relative humidity during the drying process, and sample mass loss. The integration of these parameters into the system design seeks to maximize the energy efficiency of the process while maintaining optimal operating conditions to preserve the quality of the final product [

27].

2.1. Design and operational characteristics of the drying system applied in carrot dehydration.

The dehydration system implemented in this study consists of a cylindrical rotary dryer, 0.35 m long and with an internal diameter of 0.30 m. The drum is coupled to a direct current motor that allows it to rotate at a constant speed of 1.5 revolutions per minute. This uniform rotation promotes even distribution of heat and airflow over the product surface, achieving uniform dehydration on the product surfaces and producing internal laminar flow in the dryer.

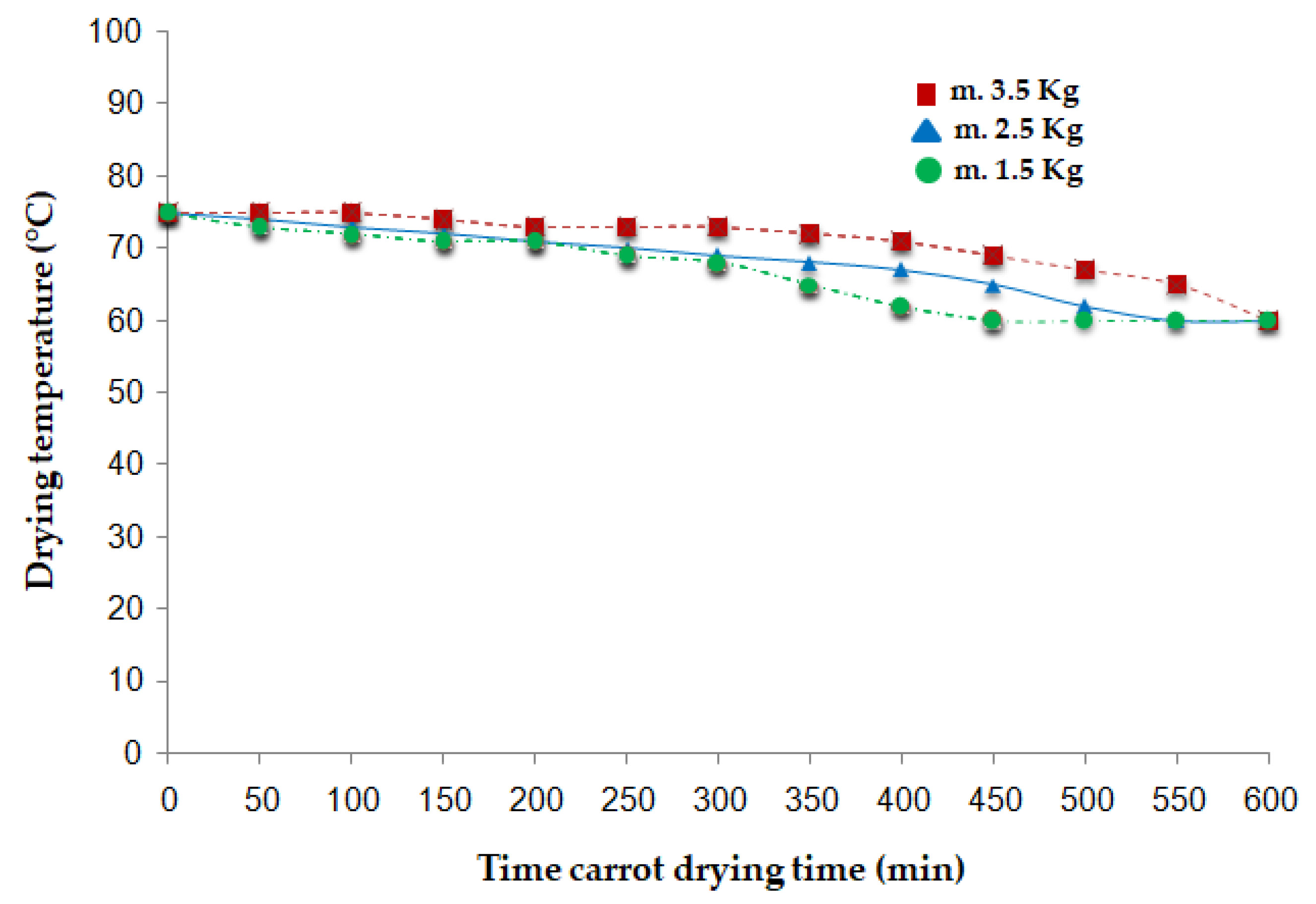

The drying chamber uses a 1 kW electric resistance, located at the bottom of the system, to generate heat by forced convection. The heat intensity is regulated by a pulse-width modulator (PWM), allowing the operating temperature to be controlled within an adjustable range of 50°C to 75°C, depending on the type of food and the specific process conditions. For the generation and circulation of the hot air flow, a 200 W centrifugal fan with variable flow rate, adjustable between 0.5 and 2.0 m/s, is used, which produces efficient heat exchange without generating turbulence.

The design of this moisture removal unit is based on recent studies on rotary dryers applied to agri-food products, which have proven effective in improving the thermal stability of the process and preserving the physicochemical properties of vegetables such as carrots [

28,

29,

30]. The developed system integrates a cyber-physical environment by incorporating distributed sensors, enabling real-time multivariate monitoring. This advanced instrumentation facilitates the implementation of adaptive control based on fuzzy logic, as shown in

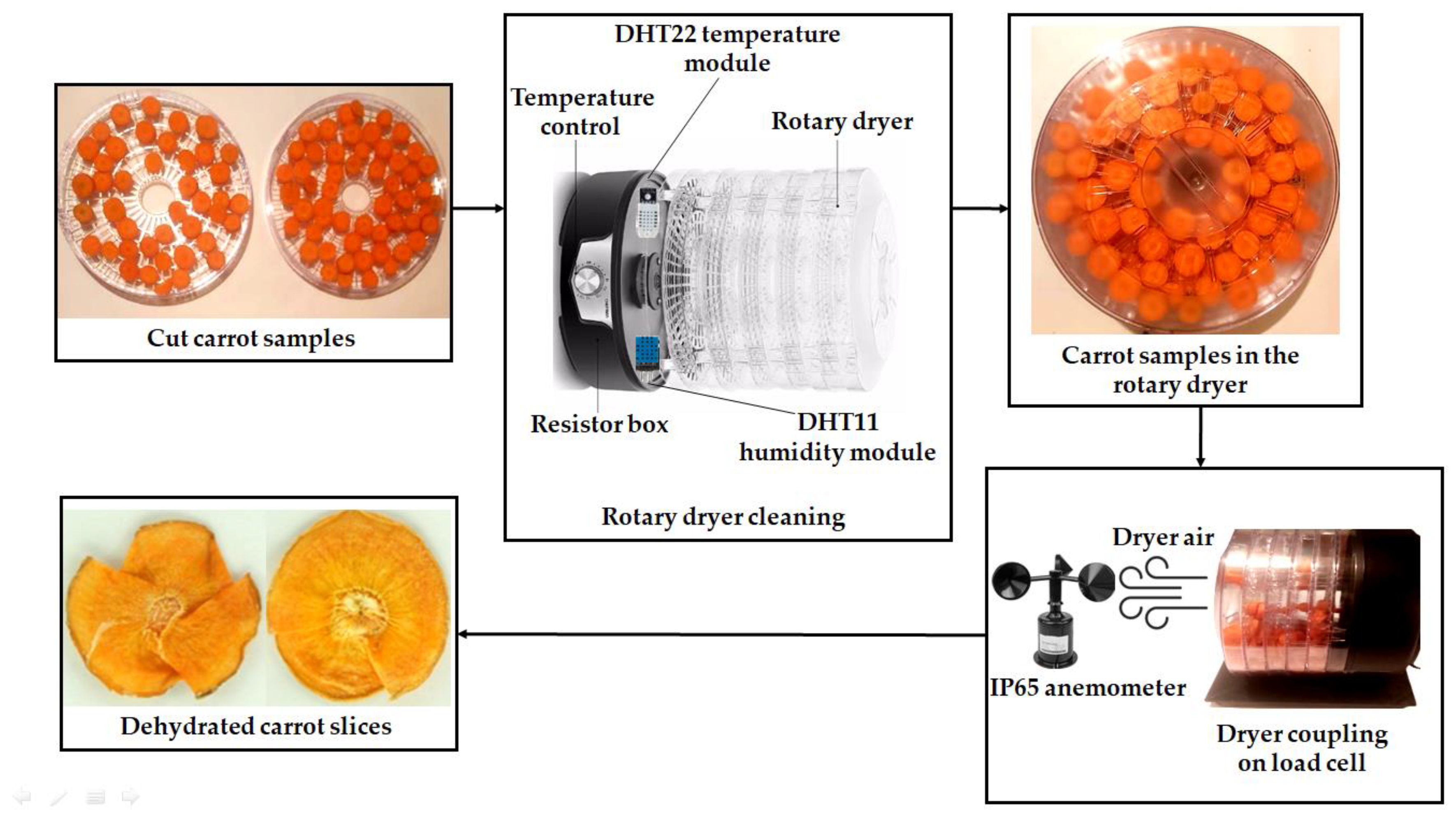

Figure 1.

2.2. Preparation of carrot samples and experimental drying conditions.

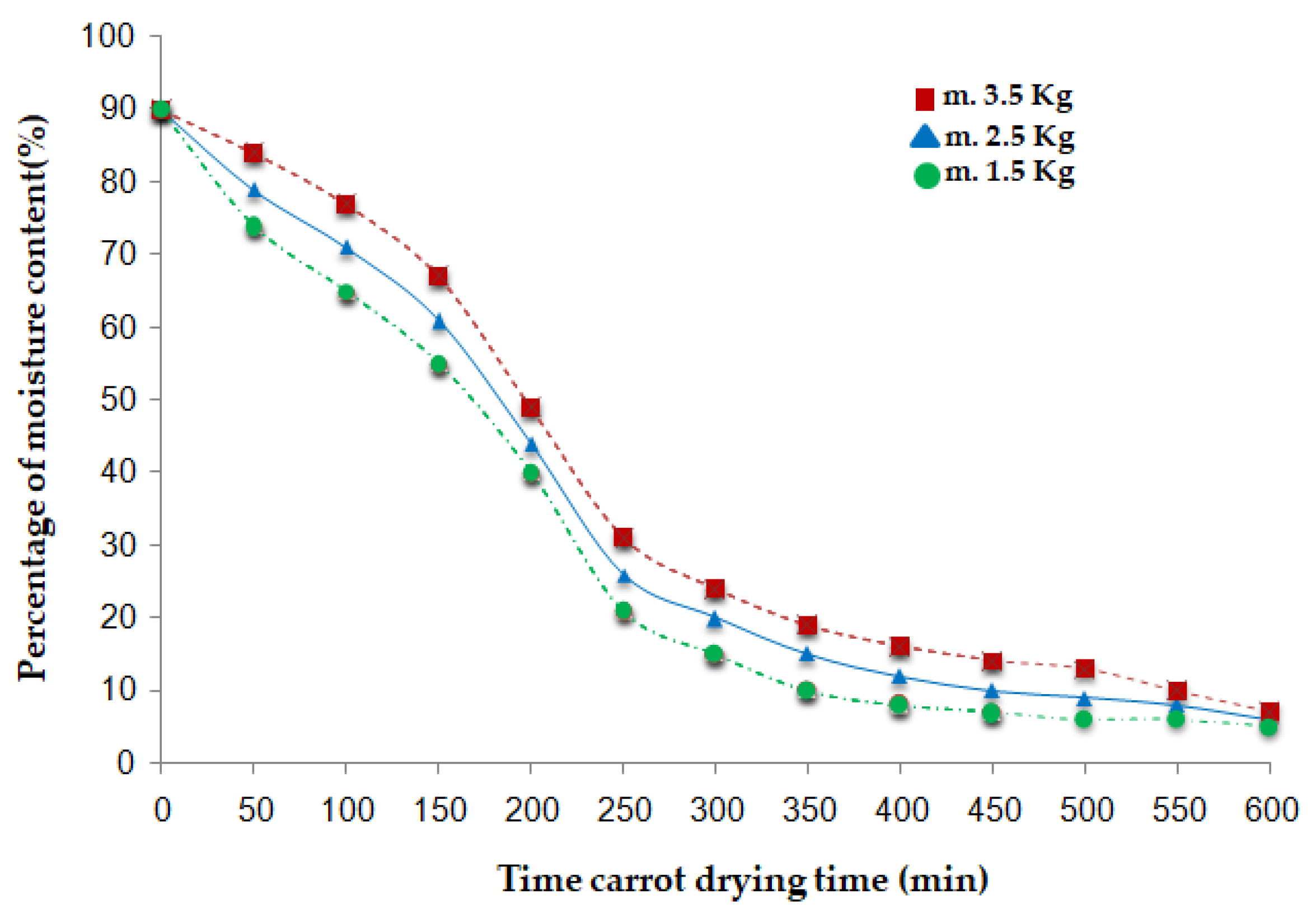

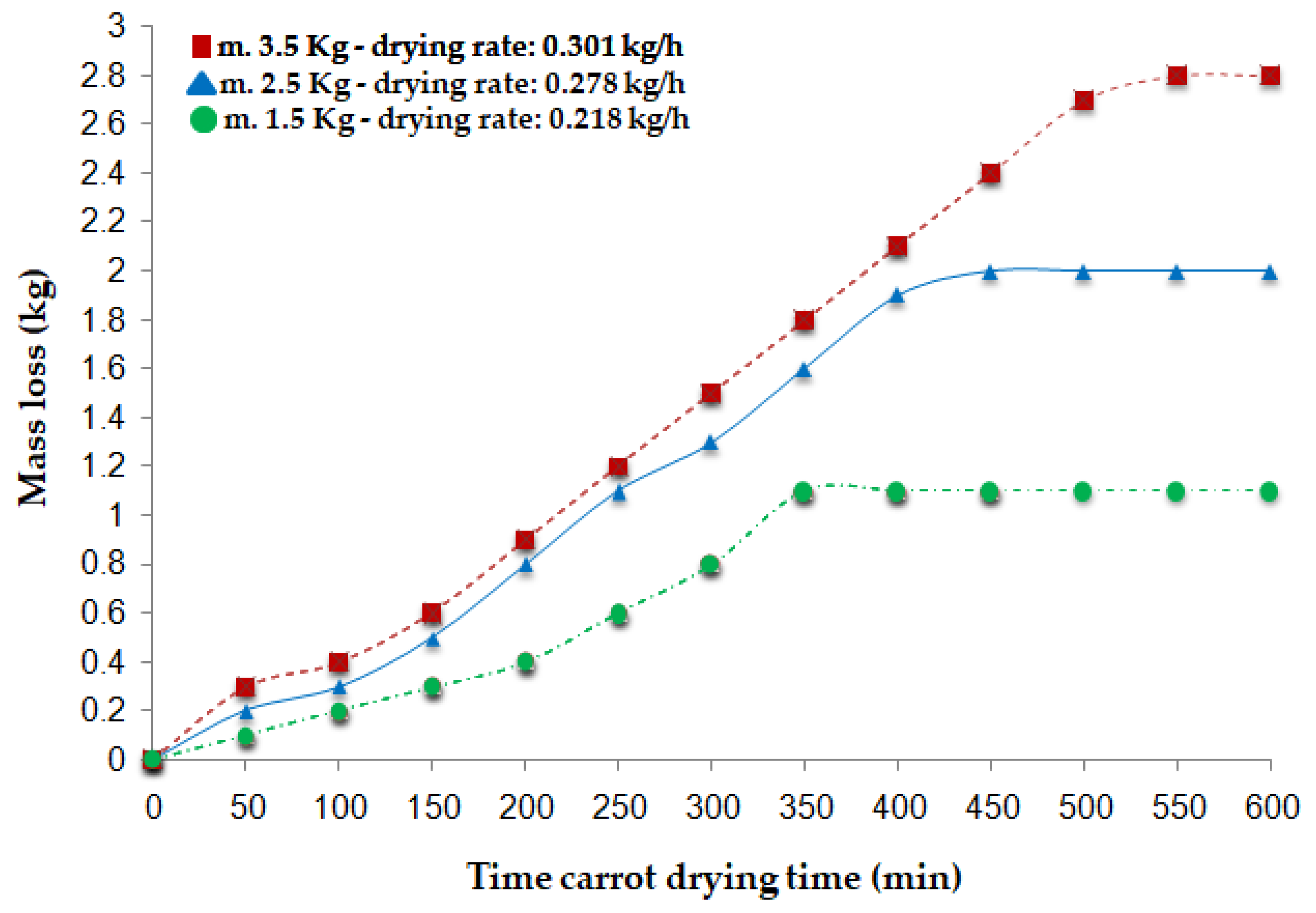

In the development of the experimental phase of the study, fresh carrots with high water content, selected for their uniformity in size, were used. The roots were washed with potable water to remove residues and impurities. Subsequently, the carrots were peeled and cut into uniform slices with a thickness of 5 ± 0.2 mm, obtaining samples with an average major diameter of 3.7 cm and a minor diameter of 2.2 cm. The samples were weighed before each experiment and distributed in the drum of the rotary dryer. Three working loads (1.5 kg, 2.5 kg and 3.5 kg) were evaluated, maintaining average operating conditions: drying temperature of 75 ° C and average air flow velocity of 1.5 m / s, applying optimal parameters described in the literature for this type of process [

31,

32].

2.3. Cyber-physical monitoring and control system applied to carrot dehydration

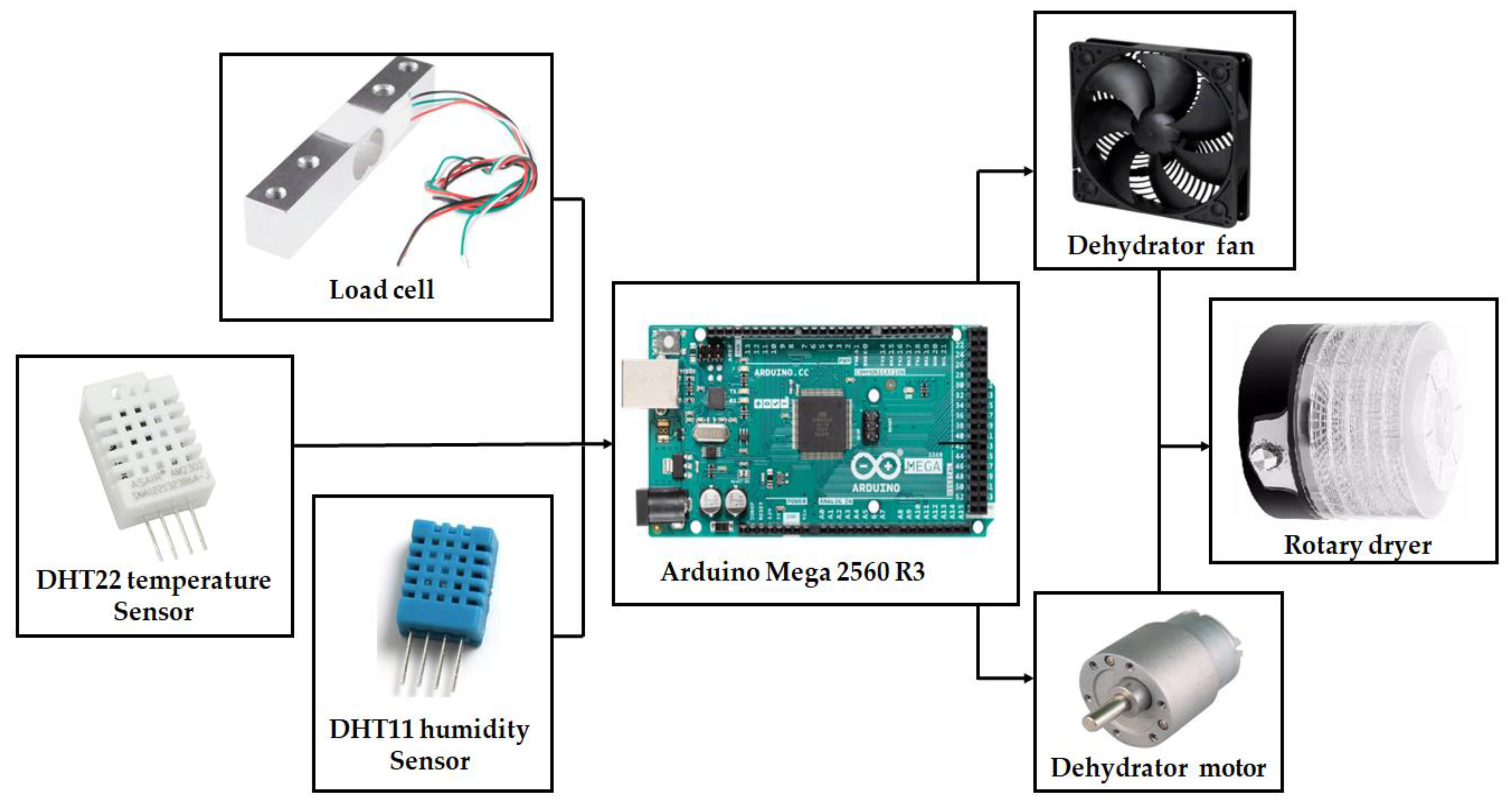

The cyber-physical system was designed to monitor the main variables of the dehydration process in real time using high-precision sensors. DHT22 and DHT11 transducers were used to monitor drying temperature and relative humidity, respectively. Air flow velocity was recorded using an IP65 anemometer, while sample mass loss was measured using load cells connected to the data acquisition card. The analog signals from the sensors were conditioned and digitized using an Arduino Mega 2560 R3 unit, which eliminated electrical noise and improved the stability of the readings, ensuring reliable data for subsequent thermal efficiency analyses and process modeling.

The control system architecture utilized the Arduino Mega 2560 R3 open hardware platform, selected for its compatibility with multiple sensors and its processing capacity for real-time applications. Drying control was managed by an integrated fuzzy logic algorithm programmed in C++, utilizing the specialized artificial intelligence library. This automation scheme allowed for dynamic regulation of process conditions based on monitored variables, following a continuous decision-making logic. The controller structure was designed to respond to temperature fluctuations, changes in air velocity, and variations in product mass, replicating strategies employed in intelligent dehydration systems reported in recent literature [

33,

34,

35].

The experimental trials were carried out with three different carrot loads (1.5, 2.5, and 3.5 kg), with three replicates for each condition. The previously prepared samples were placed in the drum of the rotary dryer, and the heating element and ventilation system. From that point, continuous recording of temperature, relative humidity, air velocity, and product mass began, continuing until a moisture content of ≤10% on a wet basis was reached. Once the process was complete and the drum had cooled, the final mass of the samples and the specific energy consumption were determined, following a process used in previous studies with products with similar characteristics, as shown in

Figure 2.

2.4. Dryer Design and implementation of adaptive fuzzy control in Arduino.

To optimize the dehydration process through the application of intelligent control, an adaptive fuzzy control system was developed using Mamdani logic and programmed on an Arduino Mega 2560 R3 open hardware platform. This controller was designed to integrate real-time data from temperature, humidity, and airflow velocity sensors to dynamically regulate the heating system's resistance power. The adaptive control architecture enabled an efficient response to varying conditions, ensuring uniform product drying, as shown in

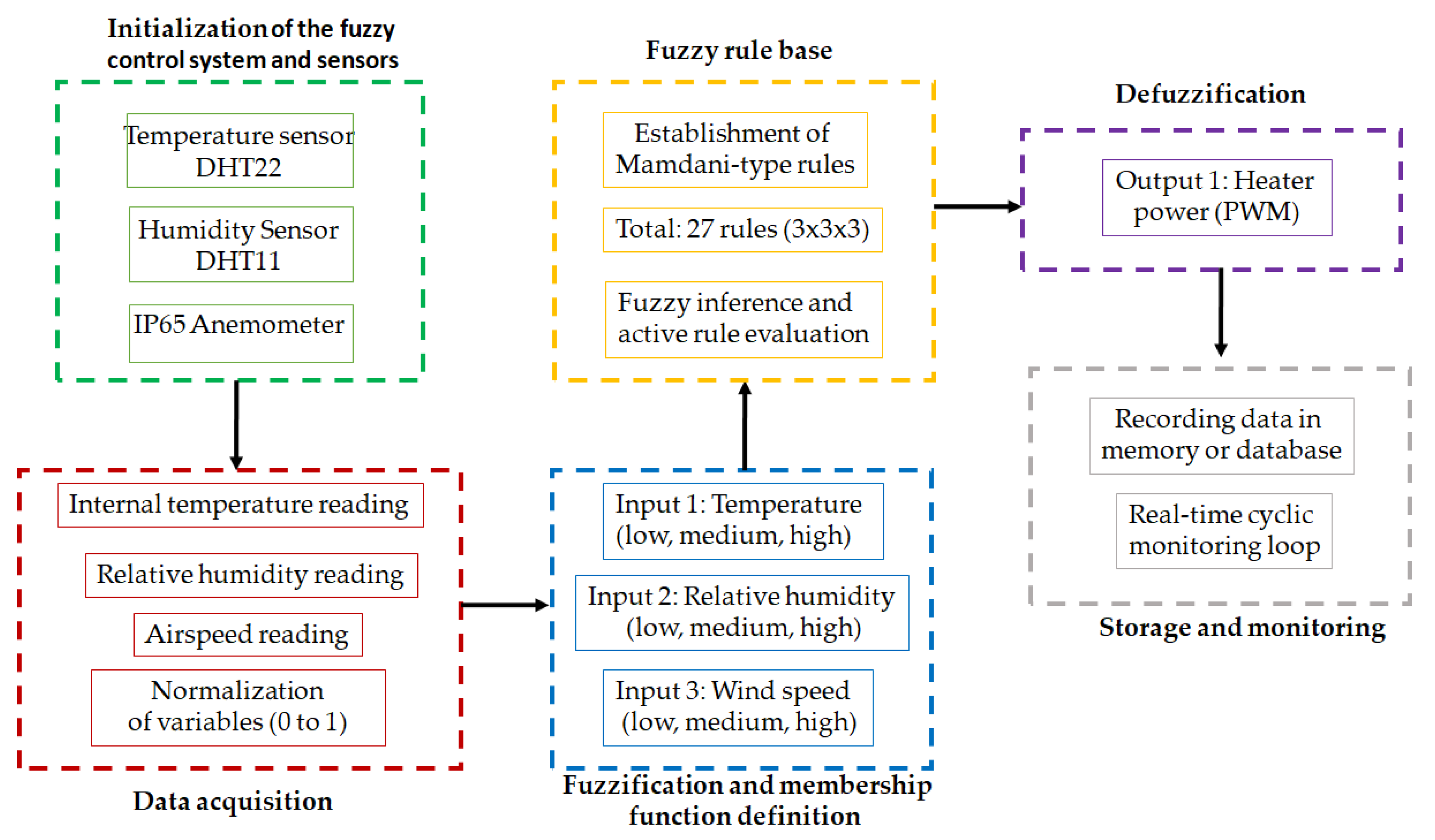

Figure 3 [

36].

2.4.1. Mamdani-type fuzzy logic model.

The Mamdani model was selected for its wide acceptance in industrial applications and its high capacity to represent expert knowledge through "If-Then" rules. This approach facilitates the implementation of control systems in environments with high uncertainty or nonlinearities, such as thermal processes in food dehydration. The model is structured in four phases: (1) fuzzification, which converts crisp values (temperature, humidity and wind speed) into degrees of membership in linguistic sets; (2) rule evaluation, where logical inferences based on minimum and maximum operators are applied; (3) aggregation of results from all activated rules; and (4) defuzzification, which translates the fuzzy results into a concrete numerical output using the centroid method, thus generating the PWM value that regulates the thermal power applied to the dryer resistance [

37,

38].

2.4.2. Definition of linguistic variables and fuzzy sets.

Three input variables were established: air temperature (20–85°C), indoor relative humidity (10–90%), and airflow velocity (0–3 m/s). The output variable was the heating power expressed as a percentage of pulse-width modulation within an operating range of 0–100%. Each variable was defined using three fuzzy sets (low, medium, and high), modeled with triangular membership functions. This formulation allowed for a more accurate representation of the uncertainty associated with sensor measurements and ensured smooth transitions between language levels.

Temperature was categorized as low (20–40°C), medium (35–65°C), and high (60–85°C). Relative humidity was classified into similar ranges: low (10–30%), medium (25–60%), and high (55–90%). Wind speed was segmented into low (0.0–0.8 m/s), medium (0.6–1.8 m/s), and high (1.6–3.0 m/s). Finally, PWM output power was defined with low (0–40%), medium (35–70%), and high (65–100%) settings [

39].

2.4.3. Implementing the control system in Arduino with eFLL.

The fuzzy control algorithm was programmed on an Arduino Mega 2560 R3 using the eFLL (Embedded Fuzzy Logic Library), optimized for embedded systems. This library facilitates the definition of inputs, outputs, membership functions, and inference rules in a structured manner. The system was configured with three fuzzy inputs (temperature, humidity, and wind speed) and one fuzzy output (PWM power), using a total of 27 rules designed based on experimental knowledge of the rotary drying process [

40].

The controller logic was structured through rule combinations using AND logical operators. These rules represented all possible scenarios among the three input variables (3 × 3 × 3), allowing the system to respond accurately to any condition in the drying process. For example, one rule was: "IF the temperature is high AND the humidity is low AND the wind speed is low, THEN the output power is high, as shown in

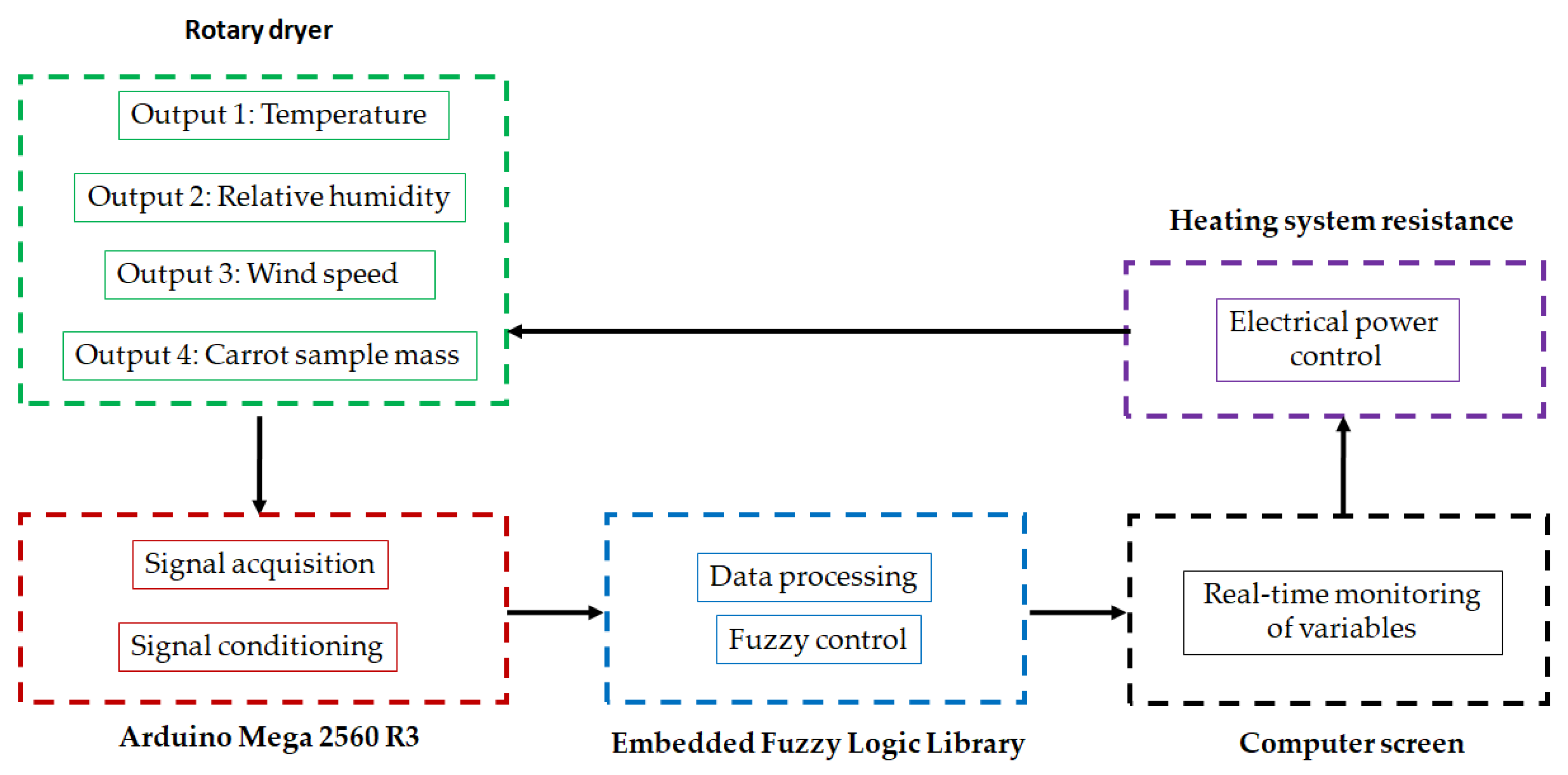

Figure 4.

2.4.4. Fuzzy system rule base

The set of 27 rules was coded directly in Arduino using structures from the eFLL library. A representative example of these rules is shown below: when temperature and humidity are low, and the air speed is also low, the power is adjusted to a medium level (R1); conversely, if humidity is high and the wind speed is low, the power is increased to a high level (R7). This logic seeks to maximize heat transfer in conditions where moisture evaporation is slower, thus ensuring efficient dehydration. The rules were experimentally validated by observing the thermal behavior and response of the system [

41].

2.4.5. Real-time control cycle: inference and defuzzification

After evaluating the rules using Arduino's Mamdani-type fuzzy inference system, the system proceeds to the aggregation phase, in which all the partial outputs generated by the rules are combined. This aggregation is performed using the maximum union operation (max), allowing the conditions of multiple rules to be applied to a single output membership function. The result is a composite fuzzy function that represents the cumulative degree of membership for each possible level of the variable, in this case, the heating power. The defuzzification phase is then applied, the objective of which is to transform the fuzzy representation into a crisp value that can be interpreted and executed by the physical system [

42,

43]. To do this, the centroid method (center of area) is used, due to its efficiency between computational precision and dynamic stability. This method, implemented by the fuzzy library application in Arduino, produces a single numerical value that represents the optimal performance level of the system. This value is converted into a PWM signal, precisely regulating the power supplied to the rotary dryer's electrical resistance. This continuous and adaptive control mechanism allows for maintaining stable thermal conditions, as shown in

Figure 5.

2.4.6. Advantages of the Mamdani approach in dehydration processes

The Mamdani-type fuzzy control approach implemented in this work offers multiple advantages for dehydration processes: it offers high flexibility in the face of thermal and environmental variability; it is robust to the noise inherent in low-cost sensors; and it allows for empirical adjustments based on operator experience without the need for complex mathematical models. Furthermore, its scalable structure facilitates the future integration of new variables such as drying time and mass loss, consolidating its applicability in real-world production environments [

44,

45,

46]

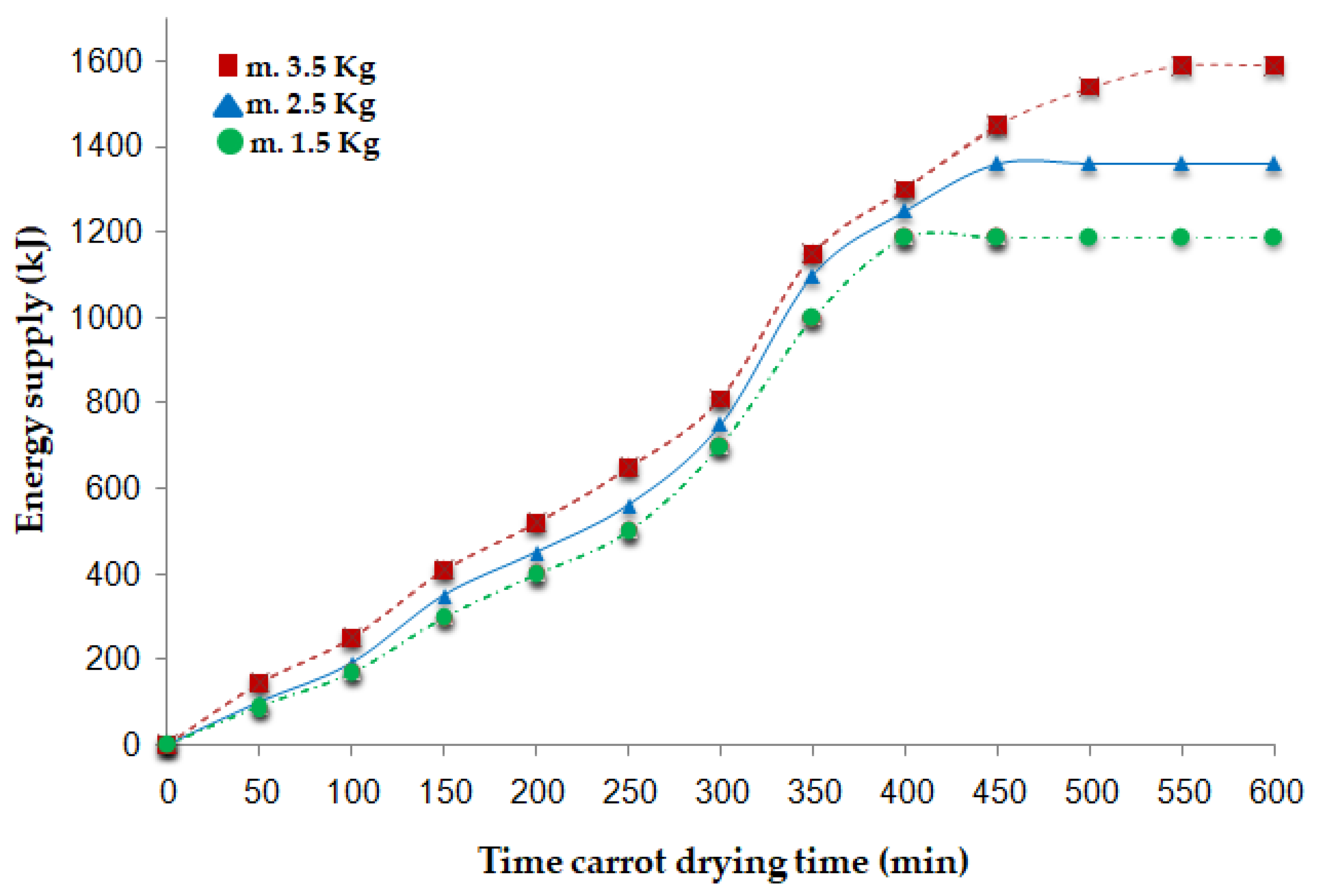

2.5. Evaluation of dehydration kinetics

During the experimental development, variables in the rotary dryer were monitored, with the objective of characterizing the drying kinetics in the dehydration process. The monitored parameters included the thermal energy distribution of the system, the total drying operation time, as well as the mass of the carrot samples in their dehydration process. From these data, energy and mass balance mathematical models were applied to calculate fundamental parameters such as the energy required for moisture removal, heat transfer between the hot air flow and the product surface, dehydration rate, and the efficiency of the drying process. This kinetic evaluation provides a solid basis for validating the proposed cyber-physical system and its applicability in the dehydration of vegetable products [

43,

47].

The energy consumed during the moisture removal process, H

D (kJ), is calculated using equation (1).

The variable

(kJ) represents the amount of energy required to increase the temperature of the water contained in the carrot until it reaches its boiling point.

(kJ) corresponds to the latent heat required to induce the phase change from liquid water to vapor. The total value of thermal energy transferred in the process, represented as QT (kJ), integrates the two components mentioned above and constitutes a key magnitude for the analysis of the efficiency of the drying process [

48].

In the energy analysis of the dehydration process, several thermodynamic properties of the system are considered. The parameter (kJ/kg°C) represents the specific heat of the carrot, while (°C) and (°C) correspond to the temperature of the product and the surrounding environment, respectively. The term (kJ/kg) refers to the latent heat of vaporization of water. The variables and (kg) indicate, respectively, the initial mass of the carrot, and the mass of evaporated water.

Based on these parameters, the total amount of thermal energy supplied by the hot air flow to the product during the drying process is calculated using equation (4) [

49].

In the evaluation of system performance, air density (kg/m³) represents a fundamental variable, since it directly influences the air's capacity to transfer heat to the product. The parameter (kJ/kg°C) corresponds to the specific heat of air, the amount of energy required to increase its temperature by one unit per kilogram. The temperatures and (°C) indicate, respectively, the air temperatures at the inlet and outlet of the dryer, essential parameters for estimating the thermal gradient in heat transfer.

The total air volume implemented in the drying process, denoted as

(m³), is determined by equation (5).

(m/s) represents the air flow velocity generated by the fan,

(m²) is the cross-sectional area of the ventilation system, and

(s) corresponds to the total operating time of the process. This relationship allows calculating the efficient air volume in the transfer of energy to the material, a key parameter to estimate the thermal performance of the rotary dryer [

43,

50,

51].

The moisture content of carrots is determined by continuously heating the samples until a constant mass is reached. The absence of variation in the product weight indicates the complete elimination of water. The moisture content

(% wet basis) was calculated from the ratio of the initial mass of the product to its final dry mass

(kg) [

52].

The dehydration rate, represented as

(kg/h), is calculated as the ratio between the mass of water evaporated during the process

(kg) and the total drying time

(h). This parameter is an indicator to evaluate the performance of the drying process, since it quantifies the amount of water removed per unit of time in the carrot. Throughout the process, this rate tends to progressively decrease as the moisture content approaches equilibrium, which directly influences the drying kinetics and the thermal efficiency of the system. The accurate measurement of this variable is important to establish control strategies that allow optimizing the operating conditions of the dryer [

53].

The thermal efficiency of the dehydration process,

(%), is determined from the ratio of the energy actually used to remove moisture from the product

(kJ) to the total energy supplied to the system through the hot air flow

(kJ). This indicator reflects the system's ability to transform the supplied energy into useful evaporation work, thus evaluating the degree of heat utilization in the system. Higher efficiency results in a higher proportion of the energy transferred directly to water removal, which minimizes thermal losses and improves operating efficiency. Variables such as air temperature, air velocity, product drying time, as well as the specific thermal properties of the food influence this parameter. Optimizing efficiency not only reduces the energy consumption of the process, but also favors the preservation of the nutritional and sensory characteristics of the final product, contributing to a more sustainable and efficient dehydration process [

53,

54].

4. Conclusions

This study validates the implementation of a cyber-physical system based on adaptive fuzzy control for the optimization of the carrot dehydration process in a rotary dryer. By implementing a system with multivariate sensors (temperature, relative humidity, air velocity, and mass loss), real-time signal acquisition and conditioning were achieved, allowing for dynamic control of operating conditions, achieving uniform and efficient dehydration.

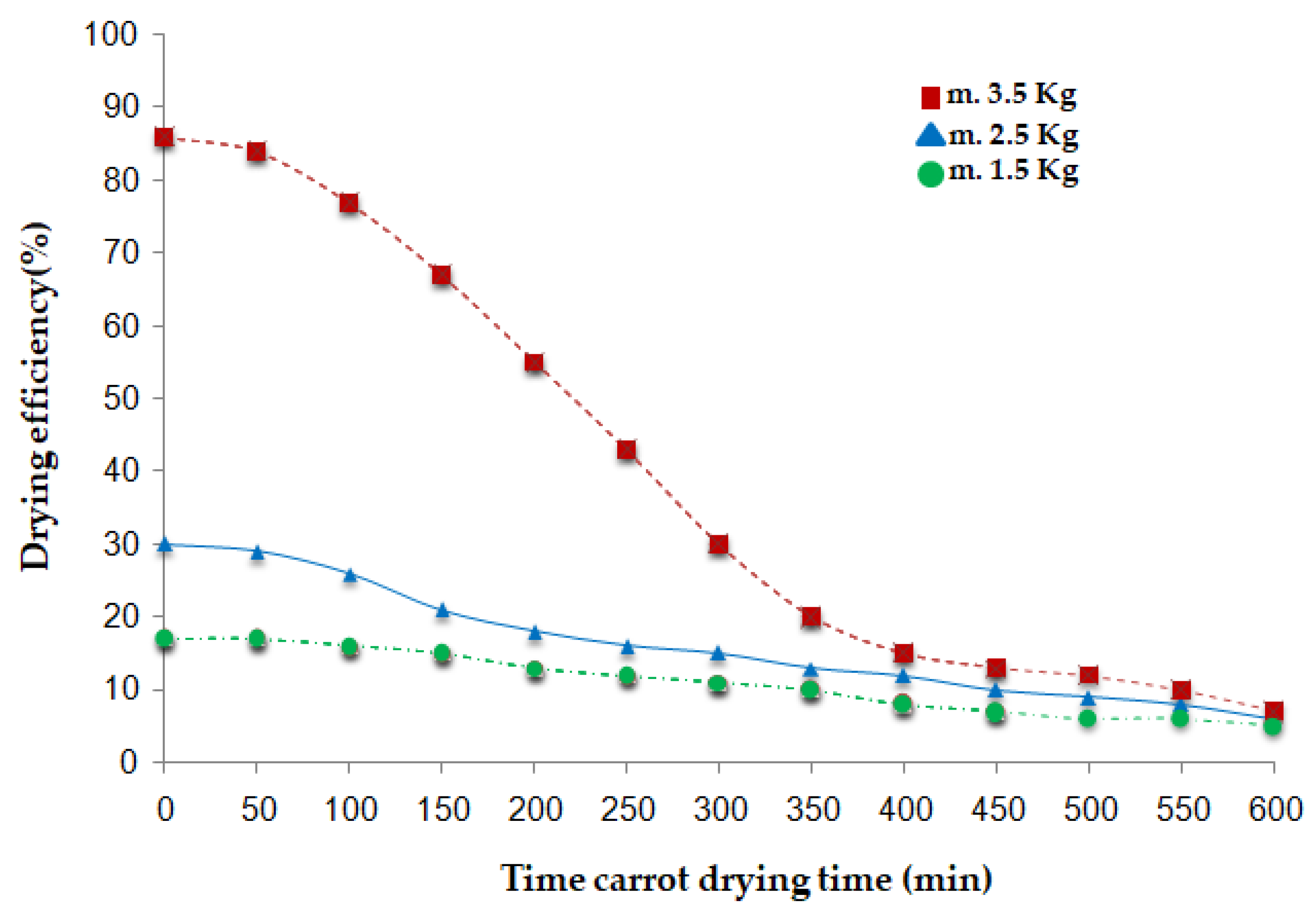

Experimental analysis showed that the energy efficiency of the process depends significantly on the initial product mass, with the largest initial mass (3.5 kg) achieving the highest efficiency of 86%, followed by smaller loads with lower efficiencies. This relationship is attributed to the fact that greater mass implies greater thermal inertia, which favors the absorption and retention of applied heat, as well as to the thermal distribution within the rotary dryer, which favors more effective mass and energy transfer during drying [

19,

26]. In addition, the average air velocity remained stable at around 1.5 m/s, promoting uniform heat distribution and precise humidity control in the drying chamber.

The use of fuzzy control demonstrates a significant advantage over traditional methods such as PID or neural networks. Fuzzy logic facilitated the management of uncertainties and dynamic variations in the drying process, such as fluctuations in initial product moisture content or environmental variations, without requiring constant manual adjustment or large volumes of data for pre-training, as is the case with neural networks [

27,

29,

38]. This enabled more flexible and robust adaptive control, optimizing temperature based on the actual conditions detected by the sensors.

The implementation of a low-cost hardware-based cyber-physical system, using the Arduino Mega 2560 R3 microcontroller, together with the programming of a fuzzy control system, proved to be highly efficient for food dehydration applications [

37,

39]. Among the main advantages identified, the system's ability to optimize operating parameters based on actual drying conditions stands out. This resulted in a notable improvement in energy efficiency and reduction in operating times [

29,

40]. Furthermore, as it is an open and widely documented development platform, the use of Arduino Mega allows the replicability of the system in different drying applications, thus promoting its technological transfer and potential adoption in communities or small agro-industries with limited resources [

34,

41,

46]. A possible restriction was identified regarding the sensitivity of some of the sensors used, especially in larger industrial scale applications or in highly demanding environments; these limitations do not compromise performance in small or medium scale scenarios, where the balance between cost, ease of programming and operational efficiency is essential [

36,

47].

The applied methodology, which includes signal conditioning, noise removal, and real-time fuzzy inference, contributed to improved measurement reliability and process performance, reflected in a significant reduction in dehydration time and a final product moisture content of 10%. For future research, the incorporation of microcontrollers with greater processing capacity is recommended to improve response speed and complex data handling, as well as the integration of machine learning techniques for online process prediction and optimization [

16,

40]. Furthermore, expanding the instrumentation to include additional physical variables and implementing cloud storage systems will enhance the system's applicability within smart agriculture.

Finally, this research demonstrates the technical and operational feasibility of a rotary dryer with adaptive fuzzy control for efficient carrot dehydration, highlighting the importance of signal conditioning and the flexibility of fuzzy control to optimize energy efficiency and final product quality in drying processes.