1. Introduction

Temporomandibular joint disorder is defined as a comprehensive term that includes several clinical problems occurring in the temporomandibular joint capsule and tissues within the joint capsule. Temporomandibular joint disorder includes jaw pain during mandibular movement, restriction, and incoordination of mandibular movement. It is accompanied by various symptoms such as joint noise and joint dislocation [

1].

Temporomandibular joint [TMJ] disorder is known to be one of the main causes of tooth pain in the orofacial region, and in severe cases, it is highly likely that it will ultimately have a negative impact on quality of life by reducing the ability to chew, which is a basic human need [

2]. Although the actual prevalence of temporomandibular joint disorder is not low, patients often do not recognize it and just overlook it, so the timing of accurate evaluation and treatment is missed, leading to chronic pain [

3]. Patients with pain in the TMJ area complain the pain and functional limitations in the temporomandibular joint area during chewing and mouth opening. If the pain is severe, the opening of the mouth may be restricted [

4].

The treatment method for temporomandibular joint disorder includes various methods such as physical therapy, psychological therapy, drug therapy, and surgical therapy.

The primary goal of physical therapy in the patients with temporomandibular joint disorder is to relieve the pain of patients. Heat therapy is a method of relieving pain and promoting healing by applying heat to the painful area using a heating device or ultrasound. Heat therapy is divided into ‘Superficial heat therapy’ and ‘Deep heat therapy’. Surface heat therapy includes warm compresses and infrared therapy, but the disadvantages are that it is difficult to maintain heat for a long time and that a specific posture must be maintained. On the other hand, ultrasound, which is commonly used among deep heat therapies, increases the temperature inside the tissue and has a deeper effect than surface heat. While moist heat packs or infrared rays cannot penetrate deeper than 1 cm of the skin surface and only increase the temperature of the superficial layer, ultrasound has the advantage of being able to transfer heat up to 5 cm deep under the skin [

1,

5].

Ultrasound using the piezoelectric phenomenon can control vibration from 1 million to 100 million times per second. The subtle vibration effect can provide a micro-massage effect deep into the human body, and in addition, it promotes the flow of blood and lymph, activating cell activity and activating the immune system. [

6]

In a previous study about the effect on the thermal effect depending on the material of the transducer of an ultrasonic therapy device [

7], there were differences in the surface temperature and core temperature measurements depending on the material of the ultrasonic transducer, and the average temperature rise rate also differed. Therefore, even if an ultrasonic piezoelectric vibrator of the same size is used in the same ultrasonic therapy machine, the actual irradiated output value may differ depending on the transducer material. This suggests that there are various considerations when performing ultrasound treatment.

In general, temporomandibular joint ultrasound therapy device uses ultrasound waves with wavelengths of 1 MHz and 3 MHz to generate the heat inside the tissue, thereby promoting blood circulation and increasing cell regeneration, So, ultrasound therapy method can help to heal temporomandibular joint.

And, for the application of ultrasonic facial massager, their operating frequency can be increased up to 10 MHz to infiltrate into the surface of skin. In order to increase the operating frequency of the ultrasonic transducer device to MHz, the thickness vibration mode of the piezoelectric ceramics must be used. their thickness vibration modes include the 1st, 3rd, and 5th order vibration modes, and the higher order vibration mode can be used to further increase the frequency[

8]. The requirements for an ultrasonic device are that the electromechanical coupling coefficient k

t in the thickness direction must be large, the loss at high frequencies must be small, and the thickness mode mechanical quality coefficient Q

mt must be large to increase selectivity. And also, the requirement for an ultrasonic transducer is that Dynamic Range (D.R) showing a measure of the impedance difference between resonance and anti-resonance must be large to sustain its stable driving condition. A composition with a high anisotropy (kt/kp) of the electromechanical coupling coefficient of piezoelectric materials is advantageous for transformers, filters, and resonators that operate in the thickness direction. Conventional piezoelectric Pb (Zr,Ti)O

3 system ceramics have been widely used as the application devices such as piezoelectric actuators, piezoelectric transformers, ultrasonic transducers for ultrasonic physical therapy machines[

9,

10,

11,

12,

13,

14,

15]. Particularly, ultrasonic transducers for nondestructive testing, and ultrasonic physical therapy machines require higher kp for further increasing an electromechanical conversion efficiency in case of using radial vibration mode. In a typical Pb (Zr,Ti)O

3 composition ceramic, kp and kt are almost the same, so unwanted vibration in the radial vibration mode can be occurred. Therefore, the PbTiO

3 system ceramics with high anisotropy is good for making a thickness vibration mode ultrasonic device [

16,

17,

18,

19,

20,

21,

22,

23,

24]. However, PbTiO

3-based ceramics have a high Curie temperature due to the large anisotropy of the electromechanical coupling coefficient, and the cracks occur when the Curie temperature falls, making it difficult to sinter. To alleviate the anisotropy, the substituent La

3+ and Sm

3+ ions can be substituted for the Pb

2+ site , taking into consideration ion radius [

25].To decrease the sintering temperature of PNN-PMN-PZT, PMW-PNN-PZT and PNN-PZT ceramics, sintering aids such as CuO, CaCO

3, PbO, Sb

2O

5and Li

2CO

3 can be added to the main compositions [

21,

22,

23,

24,

25,

26].

In this study, in order to develop the composition ceramics for the application of thickness vibration mode ultrasonic transducer device with high kt, high Q mt, and high D.R for temporomandibular joint disorder pain relief and facial skin massage, PbTiO3 system ceramics were manufactured using CuO as sintering aids, and their piezoelectric and resonant properties were investigated.. And also, ultrasonic device was designed with different dimensions . Resonant and piezoelectric characteristics were measured by varying the length of one side as 3.5, 4.9,6.3,7.7 and 9.1mm respectively.

2. Experimental

The specimens were manufactured using a conventional mixed oxide process. The compositions used in this study were as follows.

Pb 0.88(La 0.6 Sm 0.4)0.08(Mn 1/3 Sb 2/3)0.02 Ti 0.98 O3

sintering aids( 0.25wt% CuO)

The raw materials such as PbO, La

2O

3, Sm

2O

3, MnO

2, Sb

2O

5, TiO

2 for the given composition were weighted by mole ratio and the powders were ball-milled for 24h. After drying, they were calcined at 850℃ for 2h. Thereafter, CuO was added, ball-milled, and dried again. A polyvinyl alcohol (PVA: 5%) was added to the dried powders. The powders were molded by the pressure of 1,000 kg/cm

2 in a mold which has a diameter of 17mm, burned out at 600℃ for 3h, and then sintered at 1200℃ and 1230℃for 2h. Density was measured using Archimedes method. For measuring the piezoelectric and dielectric characteristics, the specimens were polished to 1mm thickness and then electrodeposited with Ag paste. Poling was carried out at 120℃ in a silicon oil bath by applying DC fields of 40kV/cm for 30min. All samples were aged for 24h prior to measuring the piezoelectric and dielectric properties. The microstructure and crystal structure of specimens were investigated with the aids of a scanning electron microscope (SEM: Model Hitachi, S-2400) and X-ray diffraction (XRD: Rigaku, D/MAX-2500H), respectively. For investigating the dielectric properties, capacitance was measured at 1kHz using an LCR meter (ANDO AG-4034) and dielectric constant was calculated. For investigating the piezoelectric properties, the resonant and anti- resonant frequencies were measured by an Impedance Analyzer (Agilent 4294A) according to IRE standard [

26]and then the electromechanical coupling factor and mechanical quality factor were calculated. Dynamic range (D.R.) was calculated as 20Log (Za/Zr). Here, Zr is the impedance at the anti-resonant frequency and Za is the impedance at the resonant frequency. And also, using the ceramics sintered at 1200℃ for 2h. ultrasonic devices with the fixed thickness as 0.7 mm were manufactured by square type(length ×width, length=width). The ultrasonic devices were fabricated by varying the length of one side as 3.5, 4.9,6.3,7.7 and 9.1mm, respectively. Resonant and piezoelectric characteristics were analyzed.

3. Results and Discussion

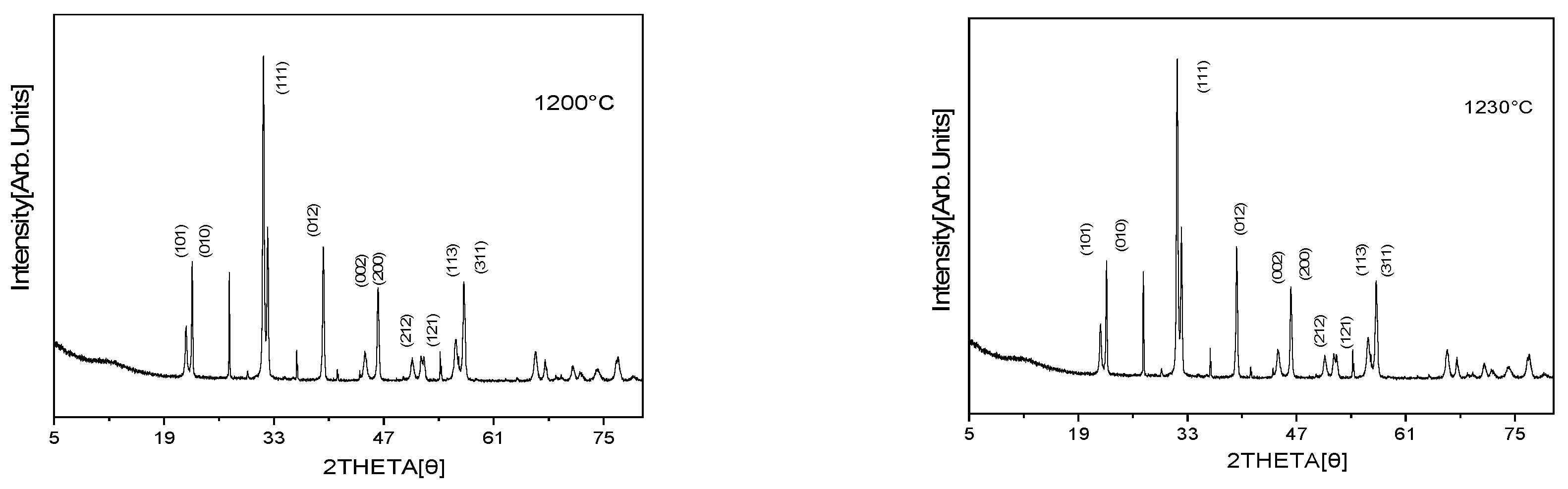

Figure 1 shows X-ray diffraction patterns of Pb

0.88(La

0.6 Sm

0.4)

0.08(Mn

1/3 Sb

2/3)

0.02 Ti

0.98 O

3 ceramics sintered at 1200℃ and 1230℃. The sample exhibited pure perovskite phase, and a little secondary phases are observed in the measurement range of XRD . The ceramic specimens possess a tetragonal phase, which is characterized by a the tetragonal (002) and (200) peak between 40° and 50°.

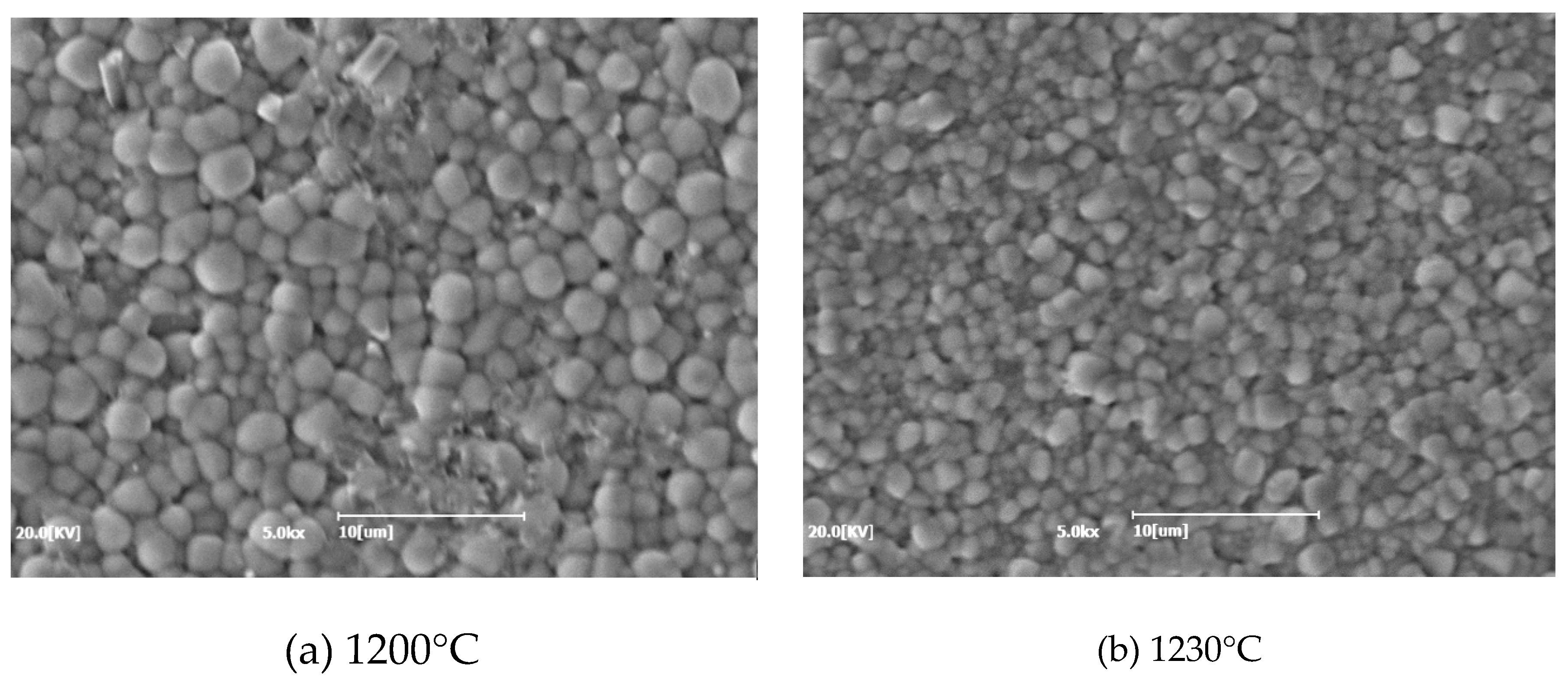

Figure 2 shows the microstructure of PbTiO

3 system ceramics sintered at 1200℃ and 1230℃. As the La

3+ and Sm

3+ ion is substituted for the Pb site, one Pb ion is removed for two La

3+ and Sm

3+ ions, creating a vacancy at the A site in the ABO

3 structure, increasing diffusion flux and promoting the sintering of the ceramics. In addition, the density increases and the mechanical strength increases. As can be seen in

Figure 2, the densified grain appeared at the ceramics sintered at 1200℃. In case of the ceramic specimens sintered at 1230℃ , the grain growth was more restrained on account of over firing condition. At the specimens sintered at 1200[℃], the dielectric constant (ε

r) of 202, piezoelectric constant (d

33) of 56[pC/N], first and third overtone electro mechanical coupling factor k

t1 of 0.548, k

t3 of 0.219, and then first and third overtone mechanical quality factor Qmt1 of 345, Qm

t3 of 292 were more suitable than the specimens sintered at 1230[℃ for the device application such as ultrasonic transducer, respectively . At the specimens sintered at 1230[℃], the dielectric constant (ε

r) of 229, first and third overtone electro mechanical coupling factor k

t1 of 0.544, k

t3 of 0.29, and then first and third overtone mechanical quality factor Qm of 94.3, Qm

t3 of 67.8 were also shown . In this study, piezoelectric and resonant properties of the ultrasonic device are important in the first and third vibration modes.

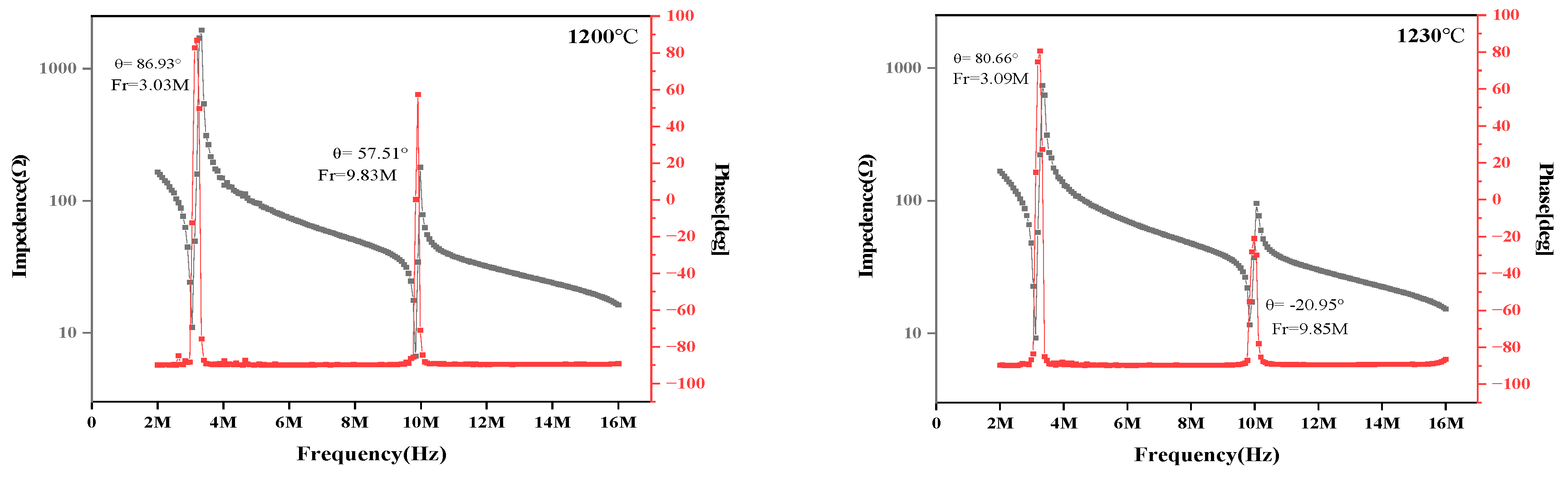

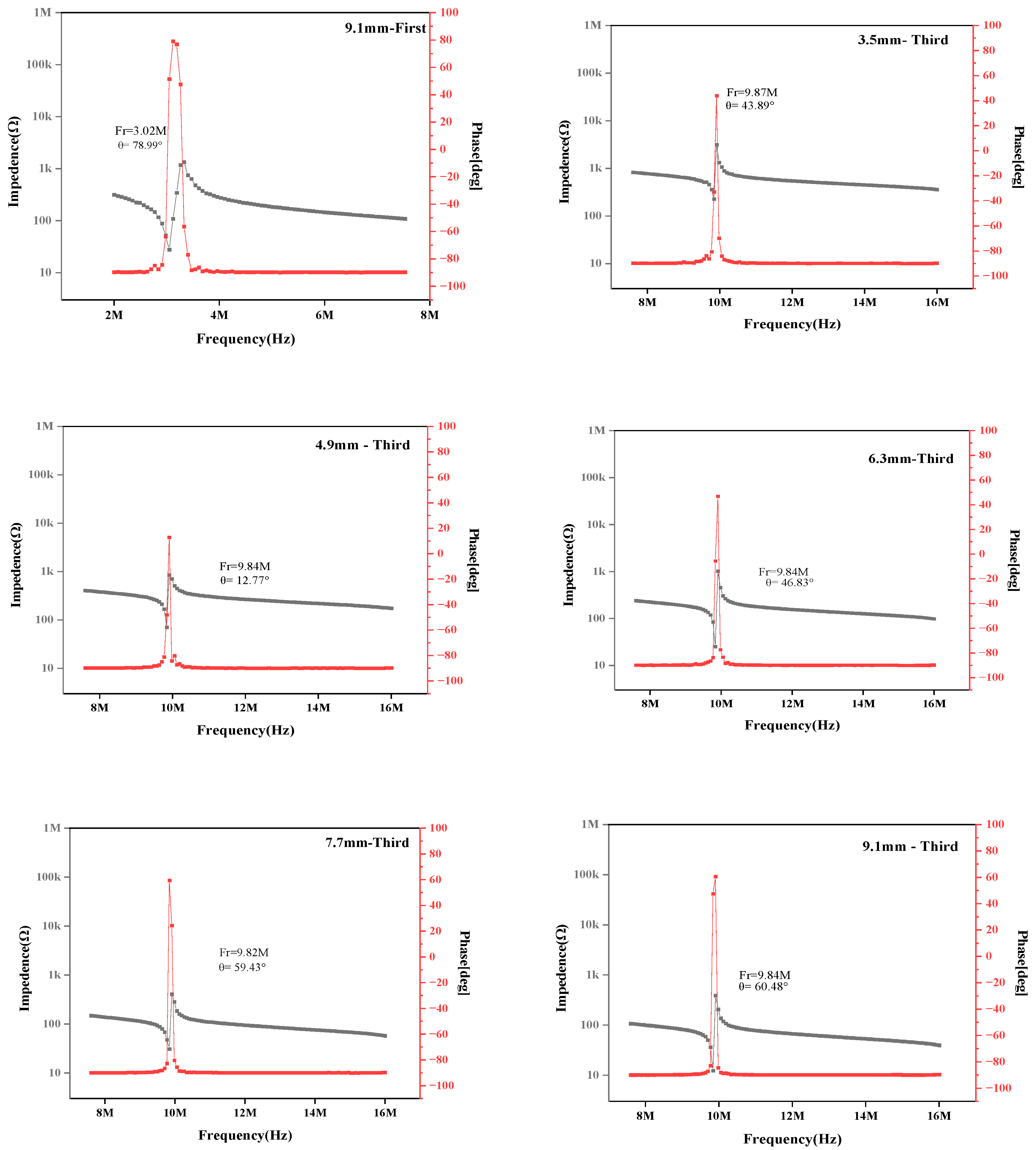

Figure 3 shows the resonant properties with sintering temperature in the ultrasonic device. A vibrator using PbTiO

3-based ceramics generates 1st, 3rd, and 5th order resonance modes in the thickness direction vibration mode, and it is possible to manufacture a resonator using a higher order vibration mode.

At the specimens sintered at 1200[℃], the excellent resonant properties appeared because of high Qmt1 of 345 and high D.R of 74.1 dB in the first vibration mode around 3 MHz. and high Qmt3 of 292 and high D.R of 38.11 dB in the third vibration mode around 9.8 MHz, respectively.

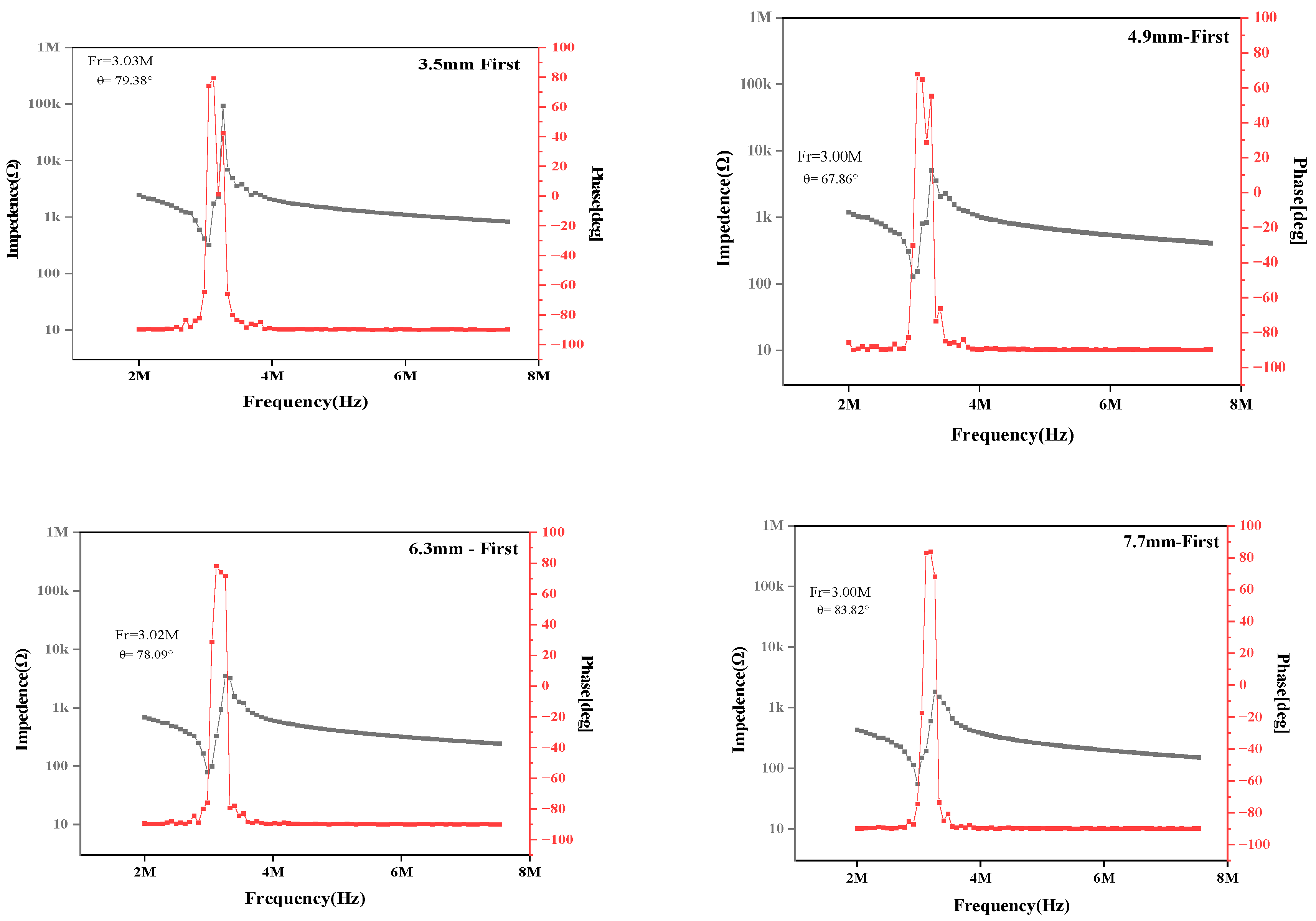

Figure 4 shows resonant properties with the length of one side in the ultrasonic device. The ultrasonic energy is very effective in enhancing micro-circulation and improving the metabolism by increasing the tissue temperature through the generation of its thermal energy. And ultrasonic energy can be delivered to the subcutaneous fat cells to break down the fat’s cells, and this means that the amount of subcutaneous fats will be reduced through the excretion of people [

26]. Accordingly, various kinds of ultrasonic transducers can be used as the piezoelectric device mounted with ultrasonic physical therapy machine and facial massage. The requirement for an ultrasonic transducer is that Dynamic Range (D.R), which is a measure of the impedance difference between resonance and anti-resonance, must be large [

16]. Then, the mechanical quality factor (Q

mt) at thickness vibration mode is high and the impedance at resonance frequency is low, which is advantageous when driven at low voltage. For the treatment of temporomandibular joint disorders, 3 MHz can be utilized for the deep penetration of tissue. Because 10 MHz has a high frequency, so it can be used for facial skin massage with slightly less penetration of tissue. As can be seen in the

Figure 4, the resonance peak was large at around 3 MHz, which is the first resonance, and the phase value showing the efficiency of polarization was also over 67°, presenting excellent characteristics. At the length of one side was 7.7mm, the highest phase of 83.82° appeared.

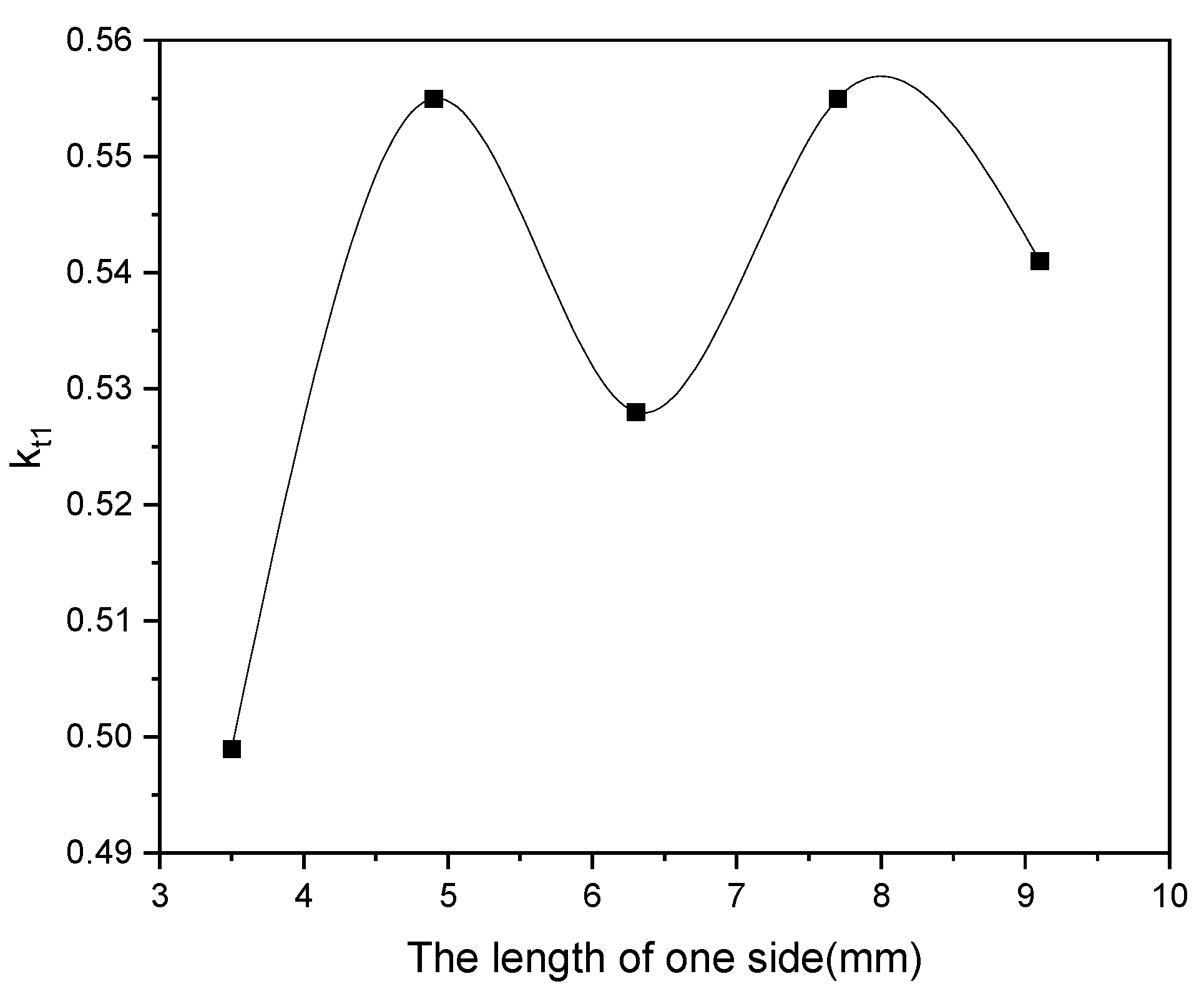

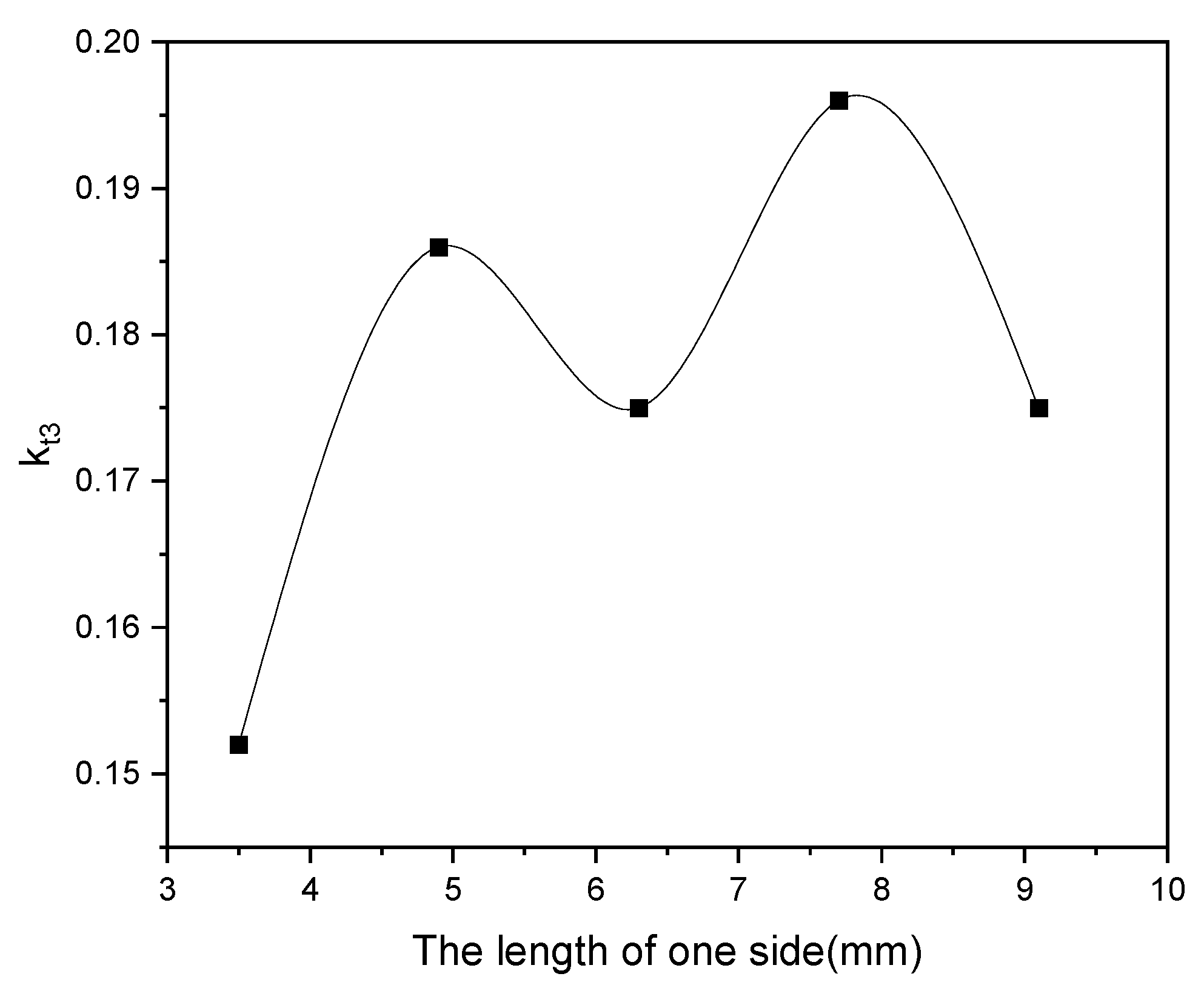

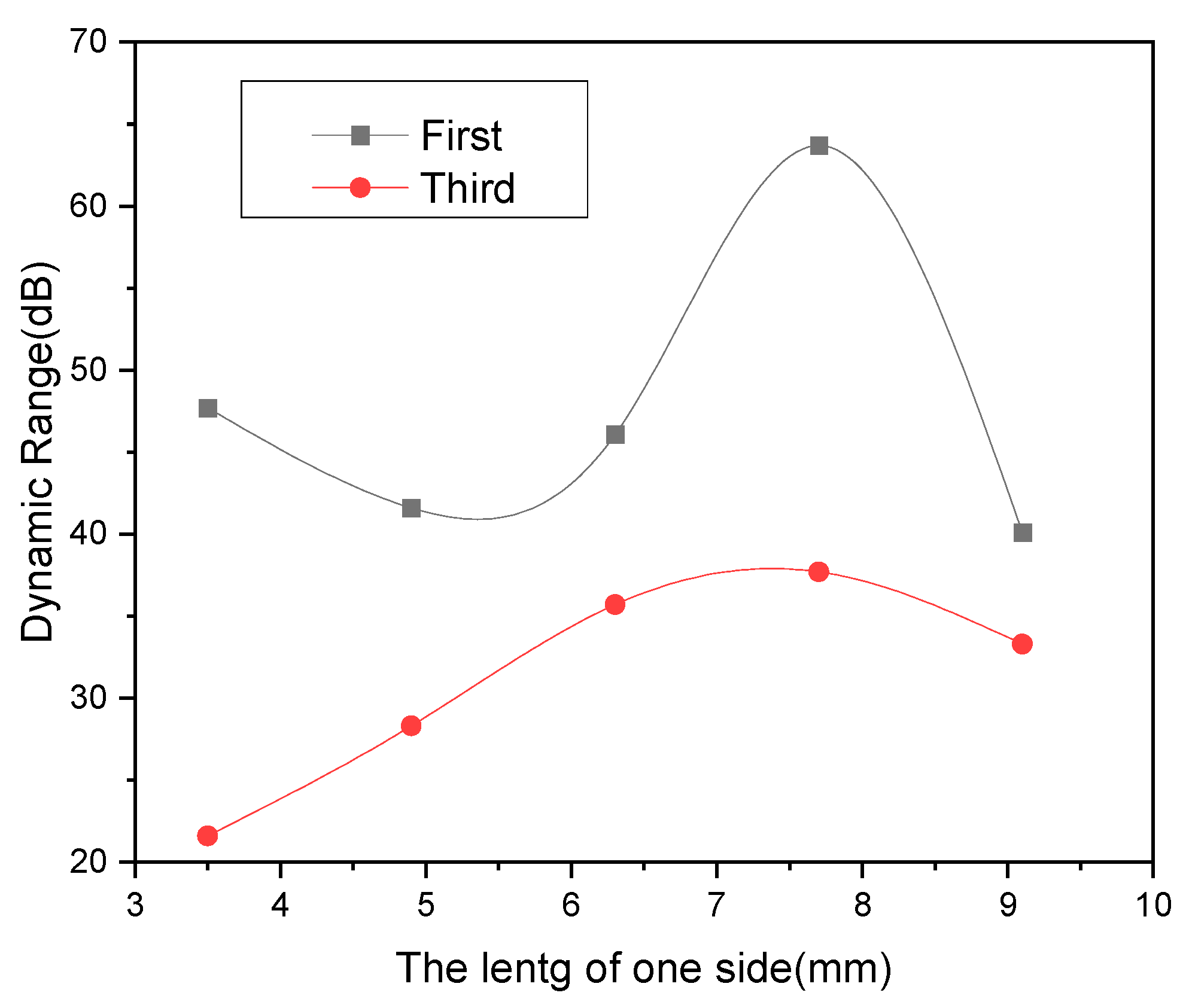

Figure 5 and

Figure 6 show electromechanical coupling factor k

t1 and k

t3 with the length of one side in the ultrasonic device, respectively. The maximum electromechanical coupling factor k

t1 and k

t3 was increased up to 0.555 and, 0.1967 when the length of one side was 7.7mm and then decreased. These phenomena are because the optimal condition was found at L/T (Length/Thickness) = 11, which is like the thickness vibration mode, which corresponds to a thickness-to-diameter ratio of about 10 in the IRE standard.

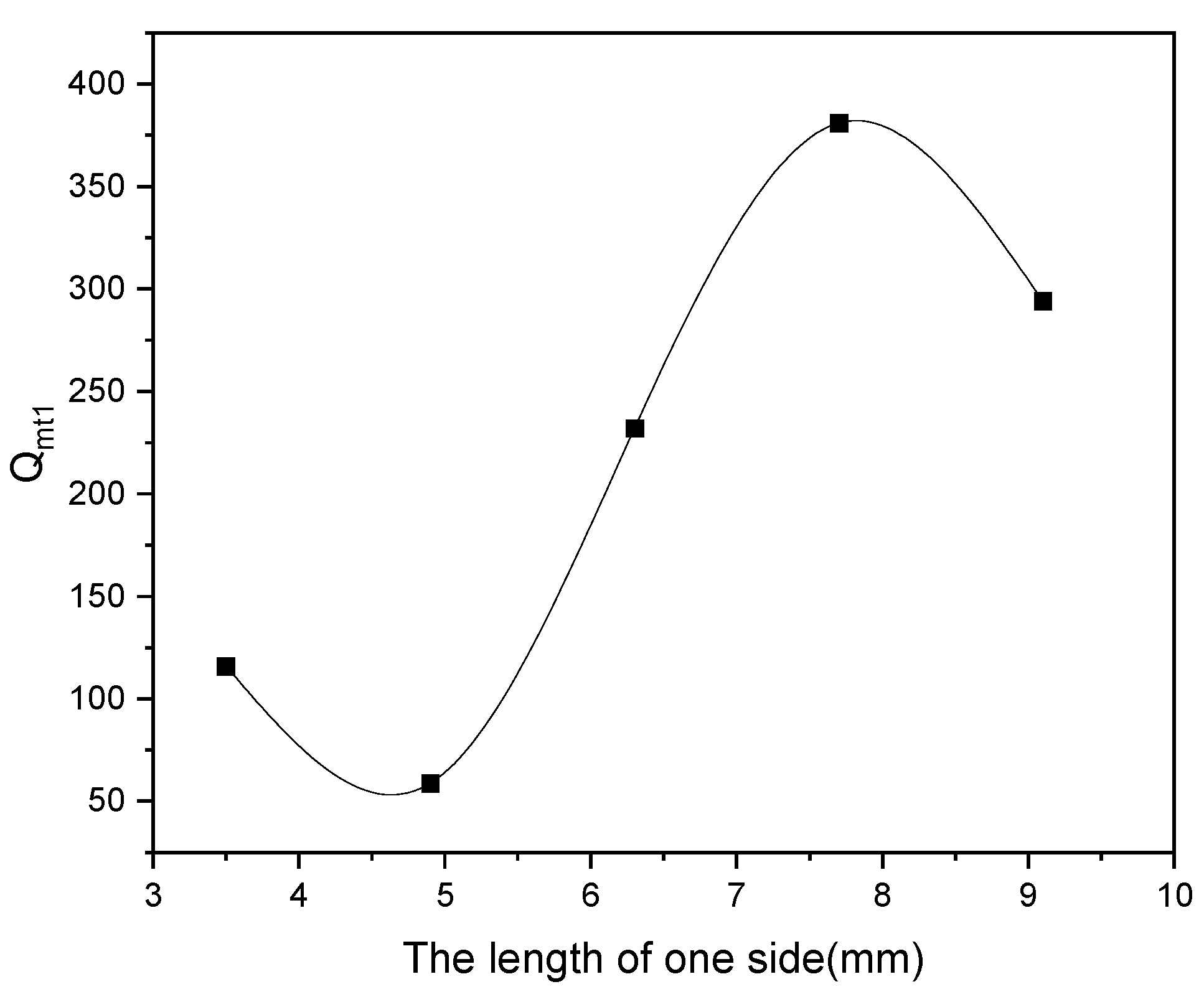

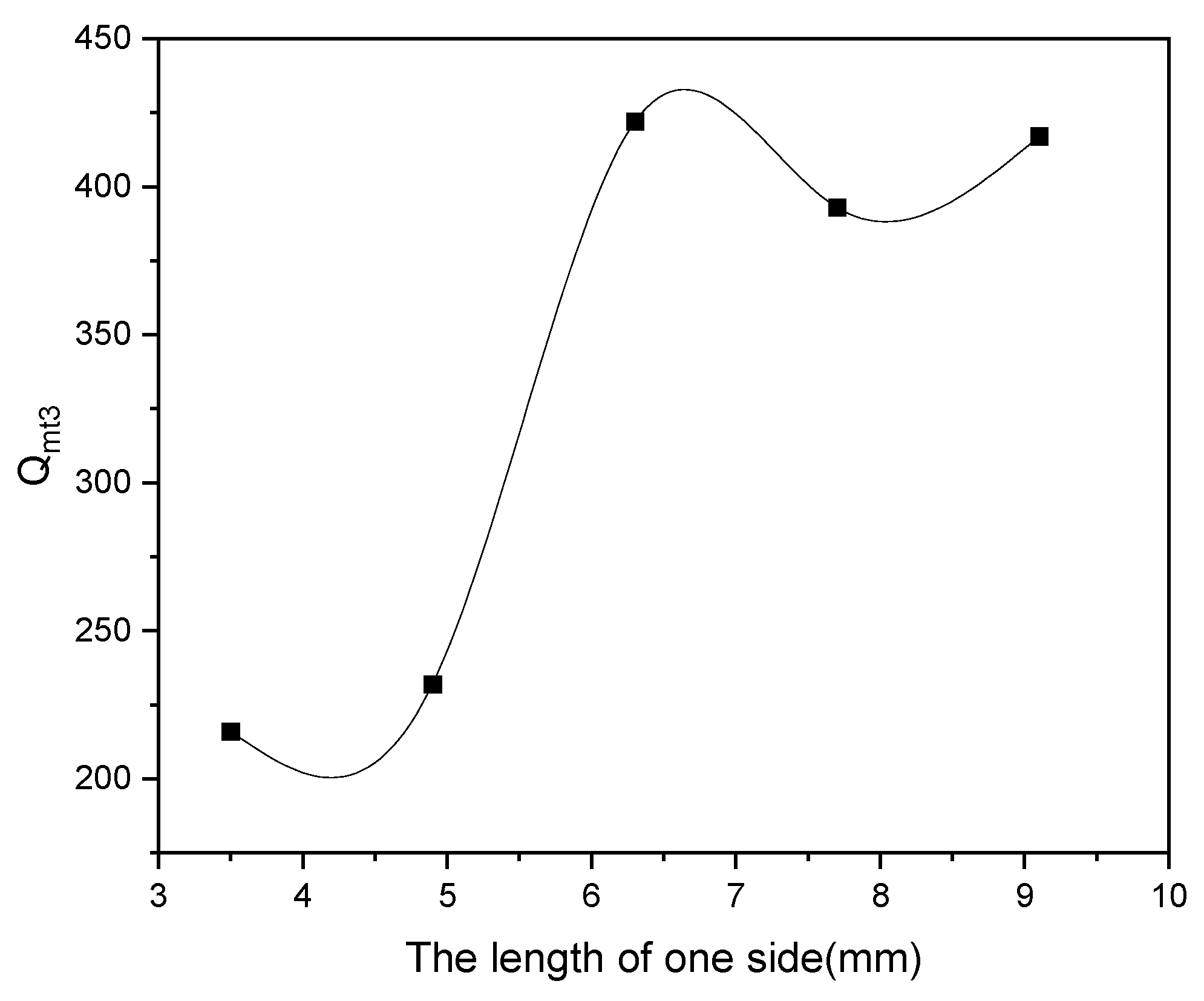

Figure 7 and

Figure 8 show mechanical quality factor Qm

t1 and Qm

t3 with the length of one side in the ultrasonic device, respectively. when the length of one side was 7.7mm(L/T=11), the excellent properties relatively appeared. As the size of the ceramic substrate increases, its electrode area expands, which reduces resonance resistance at the resonant frequency and can increase the mechanical quality factor Q

mt.

Figure 9 shows the change in Dynamic Range (D.R) in the first and third vibration modes according to changing the length of one side. Their highest values were 63.7 and 37.7 dB at 7.7 mm in the 1st and 3rd vibration modes, respectively when the length of one side was 7.7mm(L/T=11). These results are also because the optimal condition in thickness vibration mode is a thickness-to-diameter ratio of about 10.

And it can be illustrated as the fact that the high-order mode of the area vibration mode disappeared, and unnecessary noise was removed.

Finally, when the length of one side was 7.7 mm, first and third overtone electromechanical coupling factor kt of 0.555, kt3 of, 0.196, and then first ,third overtone mechanical quality factor Qmt1 of 381, Qmt3 of 3938 , and the first dynamic ratio(D.R) and third overtone dynamic ratio(D.R) of 63.7(dB),and 37.7(dB) were suitable for the device application such as ultrasonic transducer ,respectively.

Table 1 and

Table 2 show the physical properties of PbTiO

3 system ceramics and with the variation of the length of one side.

4. Conclusions

In this experiment, in order to develop the composition ceramics for the application of thickness vibration mode ultrasonic transducer device with high kt, high Q mt, and high D.R for temporomandibular joint disorder pain relief and facial skin massage, Pb 0.88(La 0.6 Sm 0.4)0.08(Mn 1/3 Sb 2/3)0.02 Ti 0.98 O3 ceramics were manufactured using CuO as sintering aids, and their piezoelectric ,and resonant properties were investigated.

1.The specimen sintered at 1200[℃] exhibited pure perovskite phase, and little secondary phases are observed.

2.At the specimens sintered at 1200[℃], the dielectric constant (εr) of 202, piezoelectric constant (d33) of 56[pC/N], first and third overtone electro mechanical coupling factor kt 1of 0.548, kt3 of 0.219, and then first and third overtone mechanical quality factor Qmt1 of 345, Qmt3 of 292 were suitable for the device application such as ultrasonic transducer , respectively .

3. When the length of one side was 7.7 mm, first and third overtone electromechanical coupling factor kt of 0.555, kt3 of, 0.196, and then first ,third overtone mechanical quality factor Qm of 381, Qmt3 of 393 , and the first dynamic ratio(D.R) and third overtone dynamic ratio(D.R) of 63.7(dB),and 37.7(dB) were suitable for the device application such as ultrasonic transducer for temporomandibular joint disorder pain relief and facial skin massage, respectively.

Acknowledgments

This paper was supported by the Semyung University Research Grant of 2023.

References

- Kim, C. Conservative treatment modalities for patients with temporomandibular joint (TMJ) disorders. The Journal of the Korean Dental Association 2013, 51, 74–83. [Google Scholar]

- Lee, Y.S.; Byun, Y.S.; Choi, J.H.; et al. Evaluation of masticatory efficiency and oral health related quality of life in temporomandibular disorder patients. J Oral Med Pain. 2010, 35, 135–147. [Google Scholar]

- Kim, D.K.; Lim, H.D.; Lee, Y.M. Evaluation of quality of life according to temporomandibular disorder symptoms in dental hospital worker. J Oral Med Pain. 2012, 37, 61–72. [Google Scholar] [CrossRef]

- Shim, Y.J. Diagnosis and treatment of acute temporomandibular disorders. The Journal of Korean Dental Association 2020, 58, 354–363. [Google Scholar]

- Ba, S.; Zhou, P.; Yu, M. Ultrasound is Effective to Treat Temporomandibular Joint Disorder. Journal of Pain Research 2021, 14, 1667. [Google Scholar] [CrossRef] [PubMed]

- Shanks, P.; Curran, M.; Fletcher, P.; et al. The effectiveness of therapeutic ultrasound for musculoskeletal conditions of the lower limb: A literature review. Foot (Edinb). 2010, 20, 133–139. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.H.; Choi, W.J.; Lee, S.W. A Study on the Actual Output and Thermal Effect in Tissue Mimicking Phantom by the Material of the Ultrasonic Transducer. Journal of the korean society of physical medicine 2015, 10, 91–97. [Google Scholar] [CrossRef]

- Juhyun, Y.; Dongon, O. Electrical and resonant characteristics of modified PbTiO3 ceramics for SMD-type high frequency resonators using 3rd over thickness vibration mode. Sensors and Actuators A 2003, 105, 55. [Google Scholar]

- Hyun-Jin, K.; Myung-Hoon, K. The Effects of Kettlebell Exercise and Ultrasound Treatment on Body Mass Index and Percent Body Fat in 20’s Adults. J. Korean Phys. Ther. Sci. 2018, 25, 1. [Google Scholar]

- Qiao, L.; Li, G.; Tao, H. Full characterization for material constants of a promising KNN-based lead-free piezoelectric ceramic. Ceram. Int. 2020, 46, 5641. [Google Scholar] [CrossRef]

- Jia, H.; Mi, J.; Li, Z.; Wang, L. Imprved dielectric and piezoelectric properties of Sm-doped PMN-PZN-PT ternary. Ceram. Int. 2022, 48, 14761. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, J.; Yao, W.; Liu, D.; He, G. Remarkably strong piezoelectricity, rhombohedral-orthorhombic-tetragonal phase coexistence and domain structure of (K,Na)(Nb,Sb)O3–(Bi,Na)ZrO3–BaZrO3 ceramics. J. Alloys Compd. 2020, 820, 153411. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, J.; Cheng, X.; Wang, X.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. Giant Piezoelectricity in Potassium–Sodium Niobate Lead-Free Ceramics. ACS Appl. Mater. Interfaces. 2013, 5, 7718. [Google Scholar] [CrossRef]

- Dong, Y.; Yue, Q.; Cheng, D.; Zhou, Z.; Liang, R.; Dong, X. Ultrasonic transducer with BiScO3-PbTiO3-based ceramics of operating temperature over 400°C IRE standards on piezoelectric crystals: Measurement of piezoelectric ceramics. Sens. Actuators. 2022, 49, 1161. [Google Scholar]

- Park, J.; Je, Y.; Lee, H.; Moon, W. Design of an ultrasonic sensor for measuring distance and detecting obstacles. Ultrasonics 2010, 50, 340–346. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.; et al. Electrical properties of (Pb,La,Nd)(Mn,Sb,Ti)O3 ceramics for 20 MHz resonators Jpn. J. Appl. Phys. 2002, 41, 701. [Google Scholar] [CrossRef]

- Seiji, I.; Ichiro, U.; Takahashi, N. Electromechanical properties of PbTiO3 Ceramics containing La and Ma. Journal of the Acoustical Society of America 1971, 50, 1060. [Google Scholar]

- Lee, S.-H.; Yoo, J.-H.; Yoon, H.S. Thickness vibration mode piezoelectric transformer for power converter, Trans. Electr. Electron. Mater. 2000, 1, 1–5. [Google Scholar]

- Juhyun, Y. High Dielectric and Piezoelectric Properties of Low-Temperature Sintering PNN-PMN-PZT Ceramics for Low-Loss Piezoelectric Actuator Application. Trans. Electr. Electron. Mater. 2018, 19, 249. [Google Scholar]

- Yeongho, J.; Kyungjin, Y.; Juhyun, Y. Piezoelectric and dielectric characteristics of low-temperature-sintering Pb(Mg1/2W1/2)O3–Pb(Ni1/3Nb2/3)O3–Pb(Zr,Ti)O3 ceramics according to the amount of PNN substitution. J. Electro Ceram 2009, 23, 387. [Google Scholar]

- Lee, K.S.; Lee, I.H.; Yoo, J.H.; Ryu, S.L. Piezoelectric and Dielectric Properties of PZW-PMN-PZT Piezoelectric Ceramic according to Sintering Aid Li2CO3 Addition. Journal of the Korean Institute of Electrical and Electronic Material Engineers 2007, 20, 1034. [Google Scholar]

- Juhyun, Y.; Jonghyeon, L. The Effects of MnO2 Addition on the Physical Properties of Pb(Ni 1/3 Nb 2/3)O3-Pb(Zr,Ti)O3-Pb(Mg 1/2 W1/2)O3-BiFeO3 Ceramics. Crystal 2021, 11, 29. [Google Scholar]

- Juhyun, Y.; Jonghyeon, L.; Sujin, K.; Minju, E.; Suho, L.; Seonghoon, K. Microstructure and Piezoelectric Properties of Pb(Ni1/3Nb2/3)O3-Pb(Zr,Ti)O3 System Ceramics doped with Sb2O5 for Ultrasonic Nondestructive Testing Transducer. Trans. Electr. Electron. Mater. 2021, 22, 913. [Google Scholar]

- Iula, A.; Parenti, L.; Fabrizi, F.; Pappalardo, M. A high displacement ultrasonic actuator based on a flexural mechanical amplifier. Sensors and Actuators A 2006, 125, 118–123. [Google Scholar] [CrossRef]

- Jaffe, B.; Cook, W.R.; Jaffe, H. Piezoelectric ceramics; Academic Press 1971. 154-159,121-123.

- Kang, S.; Lee, J.; Yoo, J.; Whang, S.A.; Lee, S.; Kee, S.; Im, I.; Oh, C. High-Performance Piezoelectric Characteristics of Sm Substituted Pb(Ni,Nb)O3-Pb(Zr,Ti)O3-Pb(Mg,W)O3 System Ceramics for Ultrasonic Transducer Application. Crystals 2022, 12, 738. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).