1. Introduction

Stable lubrication is important in bearings, gears, compressors, and other high-speed components. Refrigeration compressors rely on a continuous lubricant film in thrust bearings, scroll elements, and discharge side contacts. These zones operate under high load and speed. Any loss of film strength increases friction and accelerates wear. Polyalkylene glycol oils are used in refrigeration systems because they resist oxidation and maintain viscosity at high temperature [

1]. Even with these advantages, PAG oils can experience higher friction, increased wear, and thermal stress when the contact moves from boundary to mixed or elastohydrodynamic regimes [

2,

3,

4]. Rising traction raises shear heating and increases local oil temperature [

5].

Nanoparticles offer a way to strengthen the lubricant film in refrigeration systems. TiO

2 and SiO

2 are widely studied because they are stable and compatible with common refrigeration oils [

6,

7]. Earlier studies showed that nanoparticles reduce boundary friction, improve wear resistance, and increase thermal conductivity. These improvements help maintain viscosity and support heat transfer during compressor operation. TiO

2 improves anti wear behaviour through tribofilm formation and by filling micro scale surface defects [

8]. SiO

2 can also reduce friction and stabilise sliding contacts, but its improvement is smaller than TiO

2 at similar concentrations [

9,

10]. The performance depends on concentration and dispersion quality. TiO

2 nanocomposites also produce smoother steel surfaces under high stress sliding due to the mending of asperities [

11]. Other studies reported increases in thermal conductivity and viscosity with TiO

2 in refrigeration oils, which contribute to improved film strength [

12,

13]. SiO

2 based nanolubricants also showed temperature stability in static tests [

14].

Many earlier studies used four ball or pin on disk tribometers. These systems mainly produce sliding contacts and cannot reproduce the rolling sliding balance found in compressor bearings and rotor interfaces. They also do not allow independent control of rolling speed, sliding speed, and SRR. Elastohydrodynamic lubrication governs load support in compressor bearings and scroll contacts [

15,

16]. Small changes in SRR influence traction, film thickness, temperature rise, and energy usage. SRR varies continuously in actual compressors during speed and load changes. Controlled SRR tests are therefore needed to understand nanolubricant behaviour. Few studies have tested TiO

2 or SiO

2 nanolubricants under controlled EHL conditions using an MTM. No study has compared both nanoparticle types in the same PAG base oil under identical rolling sliding conditions. The effect of nanoparticle concentration on traction stability, Stribeck behaviour, temperature, wear progression, and shear viscosity across a full SRR range remains unclear. This limits the understanding of how these nanolubricants behave in compressor contacts where film stability and heat control are critical.

This study fills these gaps. It compares TiO2 and SiO2 nanolubricants at 0.01, 0.03, and 0.05 vol percent in the same PAG oil using an MTM under controlled EHL conditions. The work measures traction at various SRR values and fixed SRR, wear progression, thermal stability, and high shear viscosity. The aim is to determine how nanoparticle type and concentration influence friction, load support, temperature behaviour, and wear protection.

2. Materials and Methods

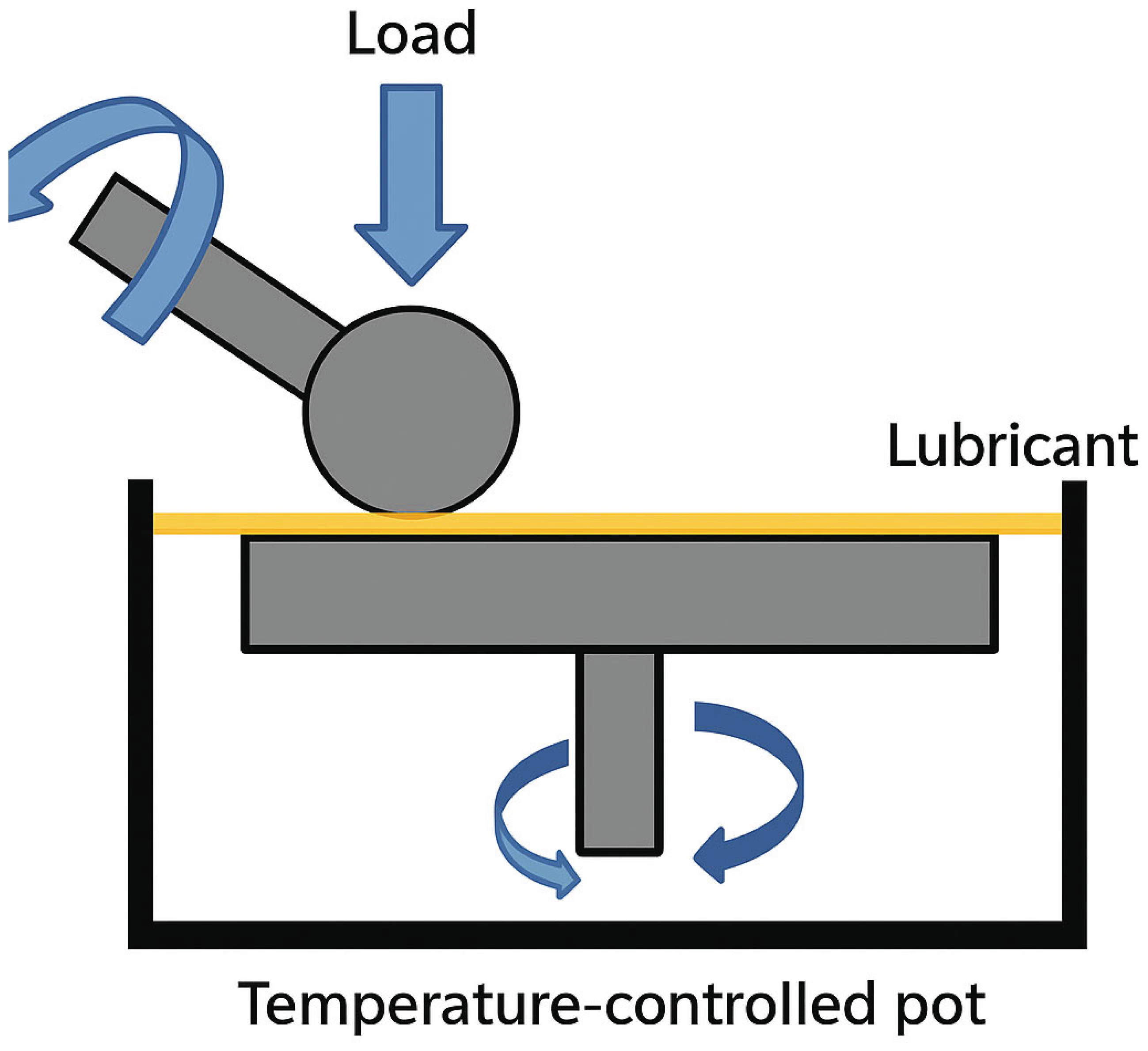

2.1. Ball-on-Disk Rig and Test Parameters

Tribological experiments were performed using a Mini-Traction Machine (MTM, PCS Instruments) in a ball-on-disk configuration (

Figure 1). A steel ball contacted a rotating steel disk under a controlled normal load. Independent motors drove the ball and disk. This allowed direct control of rolling motion and sliding motion. The entrainment speed varied from 10 to 500 mm/s to capture boundary, mixed, and elastohydrodynamic (EHL) lubrication regimes. Each test was repeated three times to ensure reproducibility, and the contact area was fully submerged in a temperature-controlled oil bath maintained at 40 °C. Each component is driven by a separate motor, allowing independent control of both disk and ball speeds to produce a wide range of slide-to-roll ratio (SRR) conditions. The SRR is calculated using the formula [

17]:

Where:

The traction coefficient was calculated using:

Where:

Wear was determined from the vertical displacement of the ball holder. Wear depth was calculated using:

Where:

The specimens were made from AISI 52100 chromium steel, selected for its hardness and wear resistance. Disks were 46 mm in diameter and 6 mm thick, while balls measured 19.05 mm in diameter. All surfaces were polished to Sa = 6 nm and Sq = 20 nm, providing a smooth baseline for evaluating lubricant performance. No surface texturing was applied, ensuring that results reflected only lubricant formulation effects. The MTM recorded temperature using an internal sensor located in the lubricant bath. The traction curve test measured friction, wear, and temperature while SRR changed. SRR was swept from low to high values during each run. The entrainment speed stayed constant. Loads of 20 N and 40 N were tested. The MTM recorded traction force, wear displacement, and temperature throughout the test. This procedure produces traction curves against SRR along with wear and temperature behaviour under the same sliding conditions. The traction curve EHL behavior test measured traction under changing entrainment speed at fixed SRR. SRR was held constant at selected levels. The entrainment speed increased from low to high values. Loads of 20 N and 40 N were used. Only traction force was recorded during this procedure. This allowed identification of changes in lubrication regime without interference from wear accumulation. Wear progression data came from the traction curve tests. Each test ran for 500 seconds after the initial ramp. The vertical displacement data provided wear depth as a function of time. This produced wear curves that reflected the ability of each lubricant to protect the contacting surfaces. Temperature behaviour also came from the traction curve tests. The temperature sensor recorded oil temperature throughout the run. The data showed how each lubricant controlled frictional heat during rolling and sliding contact.

2.2. High Shear Viscosity

The high shear viscosity test was conducted to support interpretation of traction behaviour. High shear viscosity was measured separately using a PCS Ultra Shear Viscometer. The viscometer used a rotating Couette cell to generate high shear rates. Shear rate increased up to 1000000 per second. Tests were conducted at 40, 60, 80, and 100 °C. Samples rested for five minutes at each temperature before measurement. Three readings were taken and averaged. This procedure produced viscosity curves across temperature and shear rate for each formulation. Viscosity was calculated using:

Where:

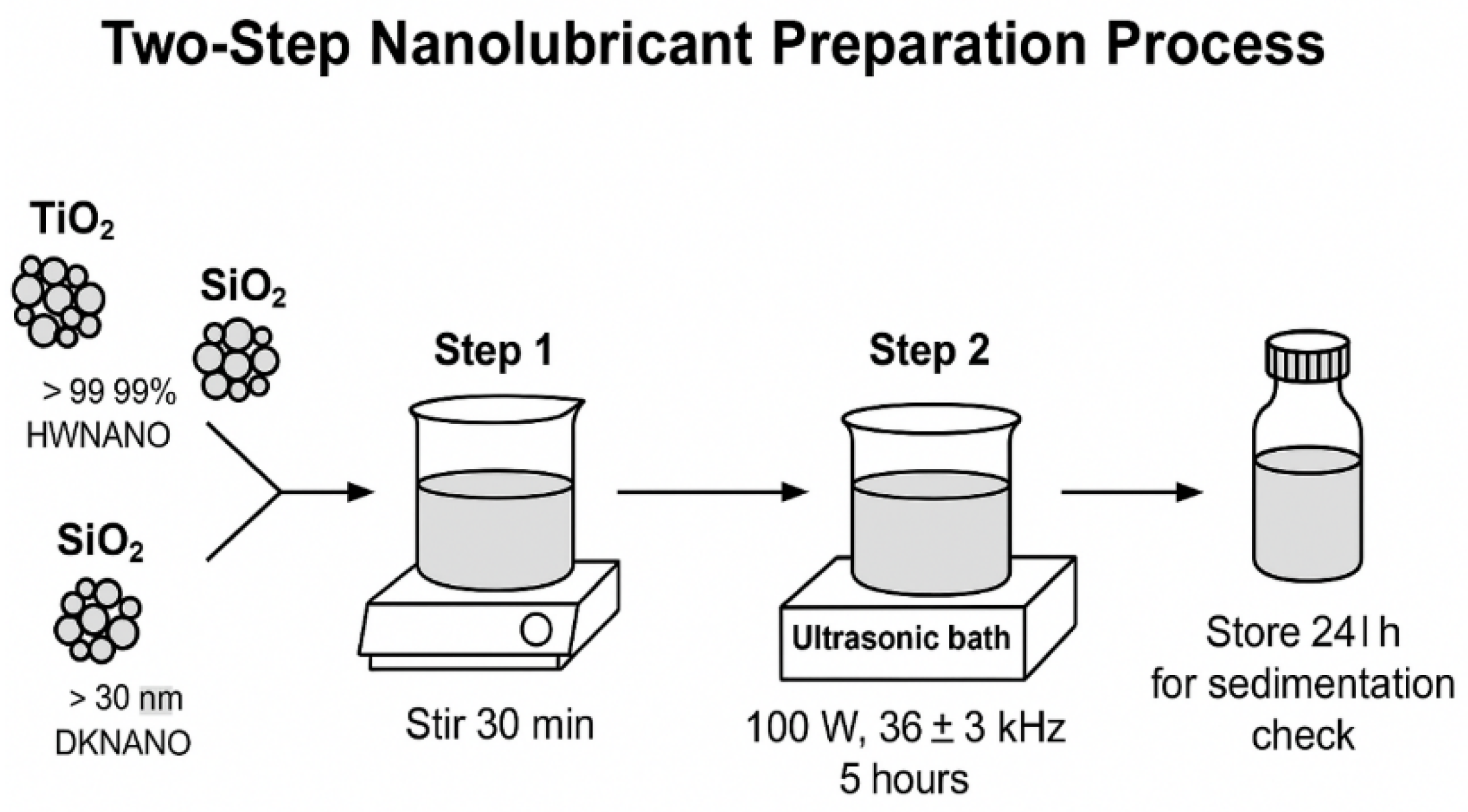

2.3. Nanolubricant Preparation and Stability

The base lubricant was polyalkylene glycol (PAG) oil. TiO

2 and SiO

2 nanoparticles were dispersed into PAG at concentrations of 0.01, 0.03, and 0.05 vol%. Metal oxide nanoparticles, TiO

2 and SiO

2, were used to prepare the PAG-based nanolubricants. The SiO

2 nanoparticles were amorphous, 99.9 percent purity, with an average diameter of 30 nm and spherical morphology. They were supplied by DKNANO (Beijing Deke Daojin Science and Technology Co., Ltd., China). The TiO

2 nanoparticles had 99.9 percent purity with a particle size of 30 to 50 nm and were obtained from HWNANO (Hongwu International Group Ltd., Guangzhou, China). Transmission electron microscopy was used to verify particle size and shape. The key properties of both nanoparticles and base lubricant used are presented in

Table 1. All preparation steps were conducted with proper personal protective equipment. A two-step preparation method was used to disperse TiO

2 and SiO

2 nanoparticles into the PAG lubricant as shown in

Figure 2. This method improves dispersion quality and reduces particle agglomeration. Nanolubricants were prepared at 0.01, 0.03, and 0.05 percent volume concentration based on previous optimization trends reported for metal-oxide nanolubricants in refrigeration oils. The volume concentration was calculated using:

Where:

2.2. Testing Conditions

The stability of nanolubricant were observed using visual observation. Tests were carried out under applied loads of 20 N and 40 N. The MTM was calibrated prior to testing to ensure accuracy. Friction (traction coefficient), wear depth, and oil temperature were continuously recorded over a sliding duration of 500 s. Summary of test condition were summarised in

Table 2.

3. Results

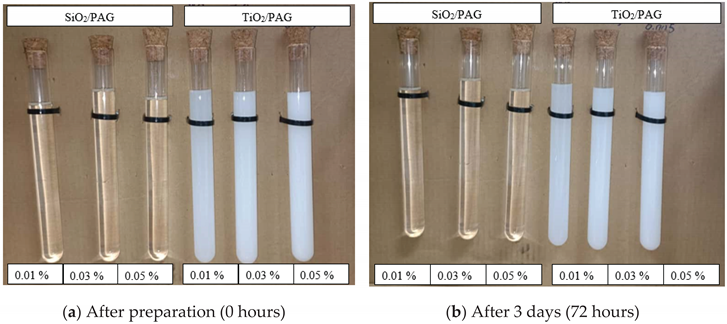

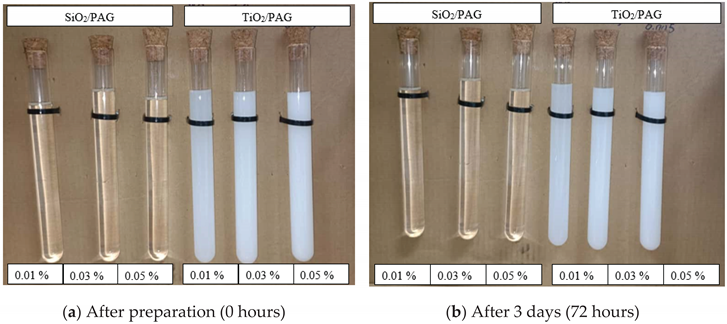

3.1. Visual Stability of Nanolubricant

The ability of the nanolubricants to remain evenly dispersed in the base fluid is important for reliable performance. Visual observation is a common method to detect particle settling in nanolubricants. Each sample was placed in a test tube, and images were taken at specific time intervals to record any change in appearance, as shown in Figure 3. Any aggregation or settling indicates weak stability. In this study, images were taken immediately after preparation and again after three days. The results show that no sedimentation appeared in any sample. The colour and opacity of the TiO2/PAG nanolubricants remained unchanged, and no particle layer formed at the bottom of the tubes. Higher concentrations produced more opaque samples, but the appearance stayed consistent over time. These observations confirm that all nanolubricants maintained good static stability. The absence of settling indicates strong dispersion quality and supports their suitability for refrigeration and compressor applications where long-term suspension is required. The stability recorded here is comparable to, and in some cases better than, the stability reported in earlier studies.

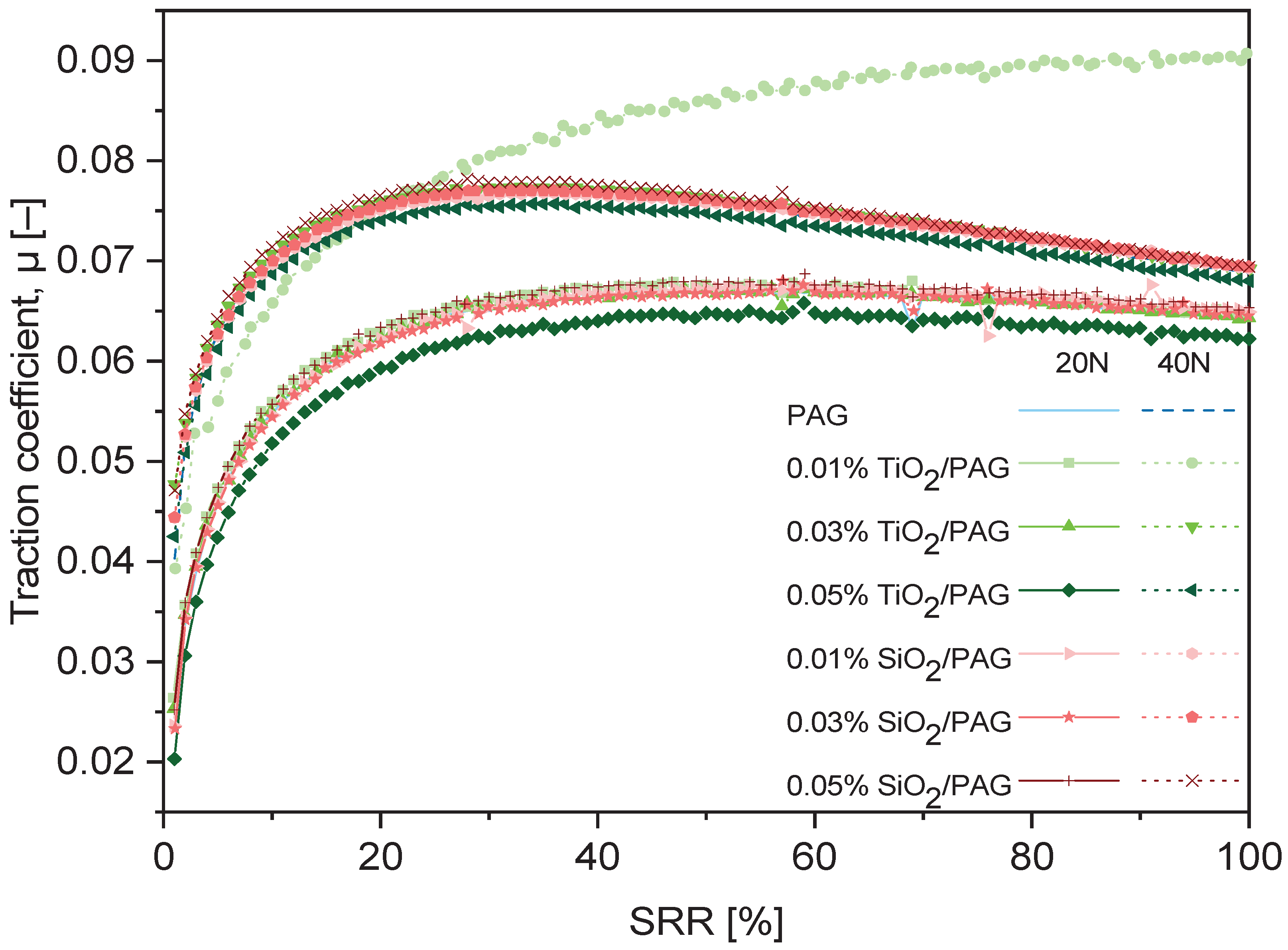

3.2. Traction–SRR Curve

Figure 5 shows the traction behaviour of PAG, SiO

2/PAG, and TiO

2/PAG across the slide to roll ratio (SRR) range under both load levels and at different nanoparticle concentrations. The results show how nanoparticle type, concentration, and load affect traction under elastohydrodynamic lubrication conditions. Traction increased with SRR for all samples, which matches established EHL behaviour. At low SRR the lubricant operated in a full film state, where friction was dominated by viscous shearing within the lubricant film. As SRR increased the amount of sliding between the surfaces rose, which increased shear rate and raised traction. Earlier studies reported the same rising trend up to a plateau region in traction tests using base oils without additives, as documented by Zhang, Tan [

18] and Zhang and Spikes [

19].

At 20 N the traction coefficients for all samples are lower than at 40 N. The lighter load promotes a thicker lubricant film and reduces asperity contact, which matches the observations of Sun, Bai [

20]. Both TiO

2 and SiO

2 nanolubricants record lower traction than PAG, particularly below SRR 20 percent. The 0.05 vol percent TiO

2 and SiO

2 blends give the largest reductions, with about 5 to 7 percent improvement at SRR 5. These results indicate that nanoparticles reduce internal shear and strengthen the film. Reported mechanisms include rolling and mending actions of spherical particles, tribofilm formation, and the filling of micro scale surface defects [

21,

22]. At 40 N the traction values increase for all lubricants because of higher contact stress and thinner film thickness. Even so, the nanolubricants maintain lower traction than PAG, which shows effective load support and film reinforcement. TiO

2 consistently performs better than SiO

2, especially between SRR 20 and 50 percent. The 0.05 vol percent TiO

2 blend remains the most stable and consistent across the SRR range. This matches the findings of Cortés, Sánchez [

9], who reported stronger performance for TiO

2 than SiO

2. TiO

2’s higher hardness, smaller particle size, and higher thermal conductivity contribute to better load carrying ability and heat dissipation. SiO

2 provides smoother interactions but does not achieve the same traction reduction.

The concentration effect follows a clear pattern. At 0.01 percent the particle content is likely too low to influence the rheology or form a meaningful tribofilm. At 0.05 percent the traction reduction is more evident, which indicates good dispersion and active interaction at the contact. Excessive concentration can lead to agglomeration, as reported by Yeap, Lim [

23], which increases local shear resistance and film instability. However, excessive concentrations may lead to particle agglomeration, as observed by Yeap, Lim [

23], which increases local shear resistance and reduces film stability. The 0.03 percent blends show intermediate behaviour, with moderate friction reduction and no signs of instability. Quantitatively, TiO

2 at 0.05 percent produces about 5 to 7 percent traction reduction at 20 N, depending on SRR. At 40 N the reduction narrows to about 1 to 2 percent. These values fall within the range reported in earlier studies, where nanolubricants typically show 5 to 20 percent reduction depending on base oil and test method [

6]. The smaller improvements at higher load suggest that under severe EHL conditions the benefit relies more on dispersion stability and heat dissipation than on concentration alone.

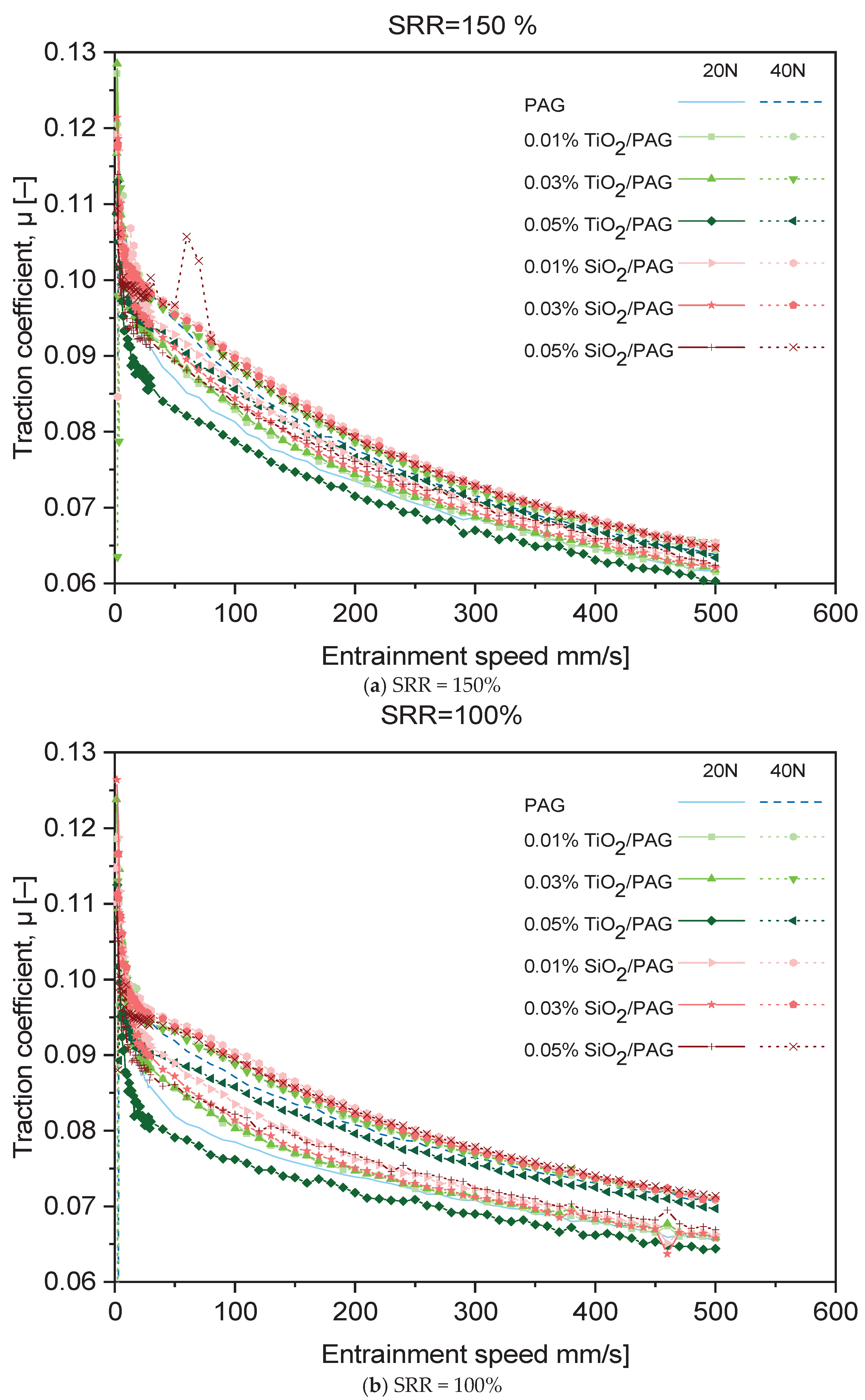

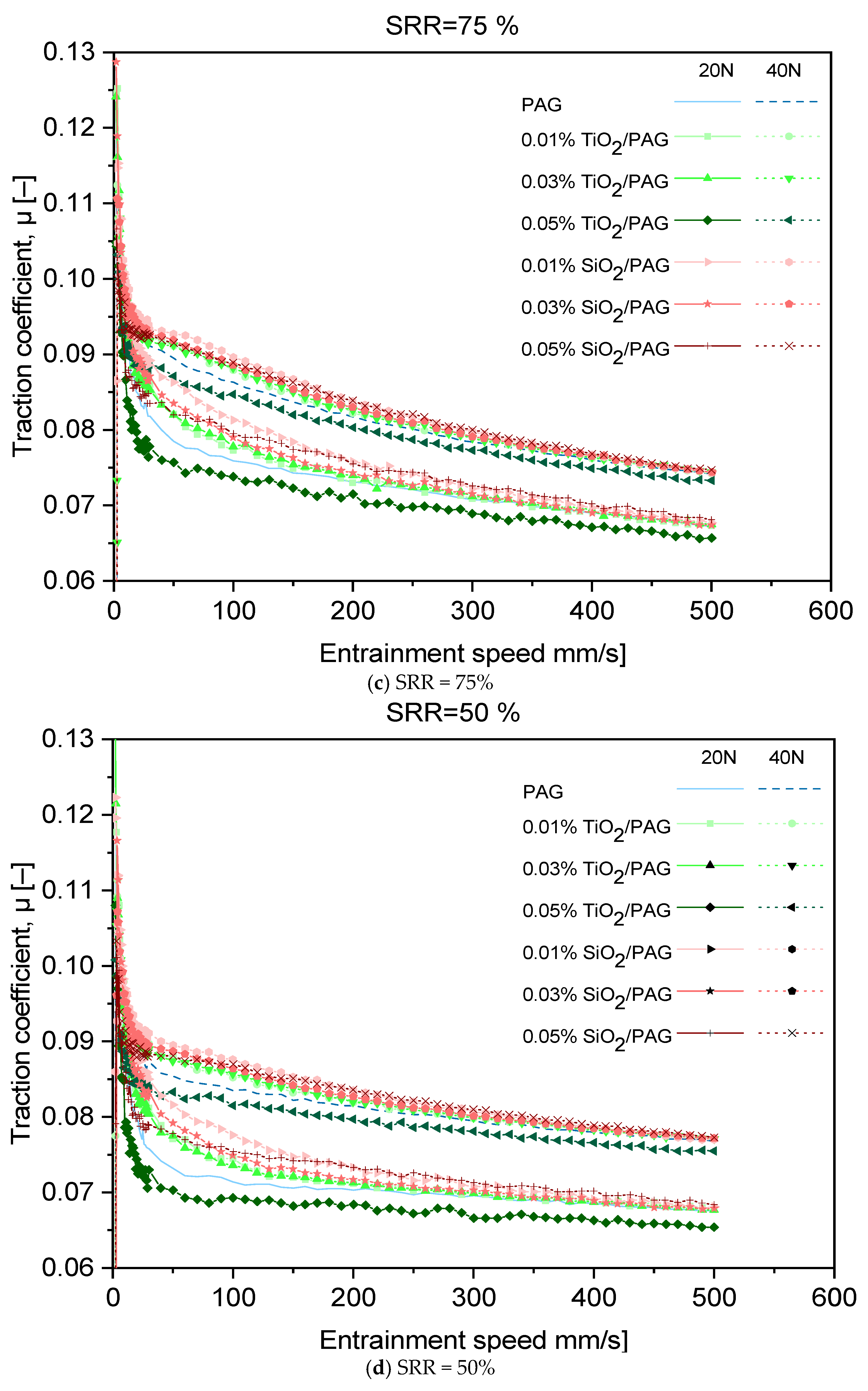

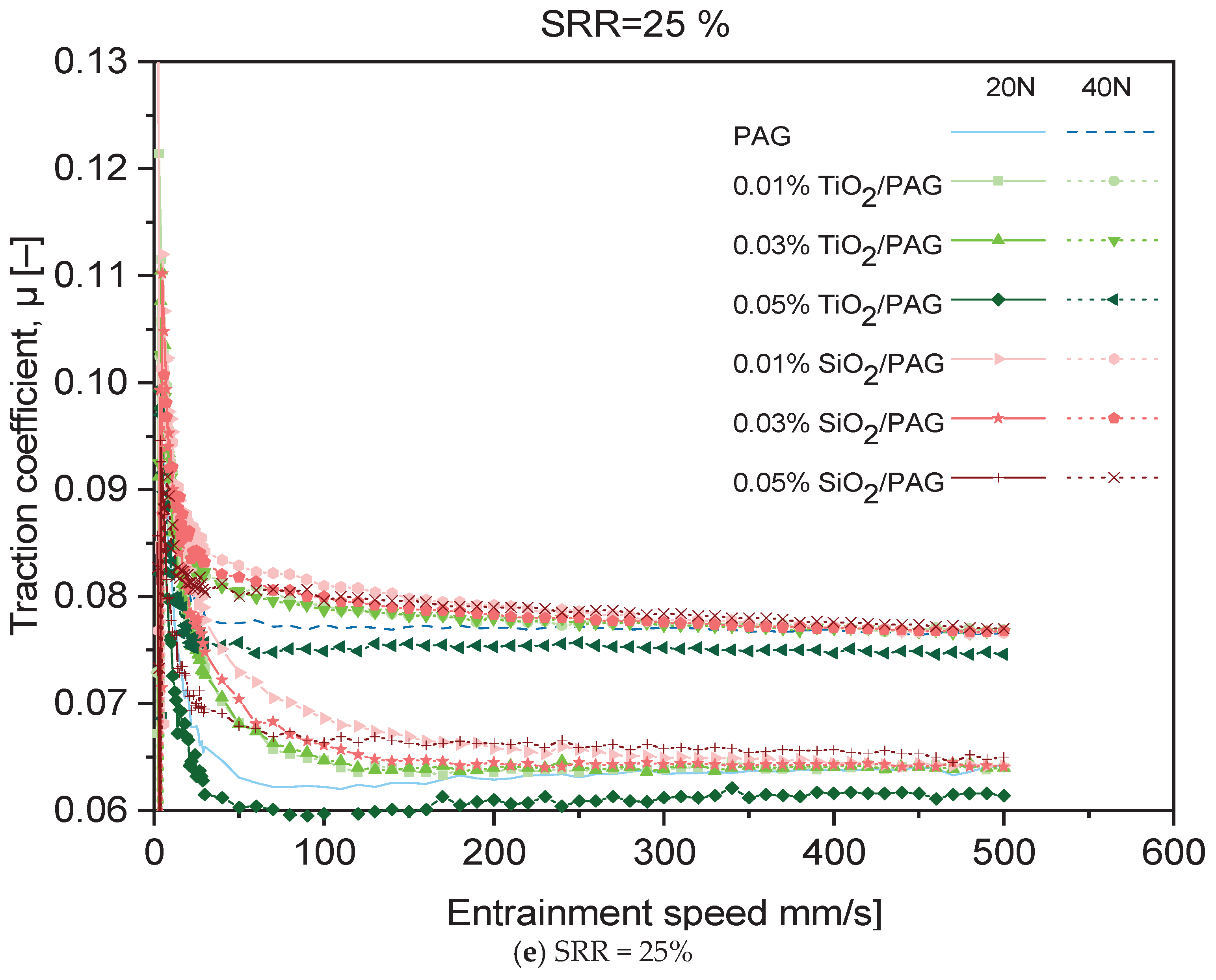

3.3. Elastohydrodynamic Lubrication Behavior at Fixed SRR (150 to 25%)

The traction against entrainment speed curves in

Figure 6 for SRR values of 150, 100, 75, 50, and 25 percent show consistent trends across lubricant type, concentration, and load level. At most SRR values the nanolubricants record higher mean traction than PAG, and only the 0.05 vol percent samples produce lower traction than the baseline. Normalising each sample to PAG shows improvements up to 4.89 percent for TiO

2 at 0.05 vol percent under 20 N and about 2.99 percent under 40 N. All other concentrations show negative improvement because their mean traction remains higher than PAG. When comparing SRR levels, the traction reductions are larger at 25 and 50 percent than at 150 percent. Lower SRR keeps the contact more strongly within the EHL regime, which allows the nanoparticles to influence the film more effectively. Higher SRR increases shear and reduces this effect. With respect to load, the 20 N tests produce larger percent reductions than the 40 N tests for the same formulation. The lower load allows the particle related mechanisms to act with less interference from contact stress and heat generation.

The concentration trend shows that only the 0.05 vol percent samples reduce traction compared with PAG. All lower concentrations increase traction. This means that 0.01 and 0.03 vol percent do not provide any improvement in this dataset. The higher traction at low concentration suggests that the particle content is not enough to support the contact or stabilise the film. The reduction at 0.05 vol percent indicates that a higher particle loading is needed before any benefit appears. TiO2 at 0.05 vol percent gives the strongest reduction under both loads. SiO2 follows the same pattern but with smaller reductions. These results differ from earlier studies that reported improvements at lower concentrations. This shows that the optimum concentration depends on the contact type and the shear conditions. In this study the EHL contact requires a higher particle population before any measurable improvement occurs.

TiO

2 performs better than SiO

2 at the same concentration and load, which matches findings reported in previous research [

9]. This is linked to its higher hardness and stronger stability, which improve load support and film behaviour in EHL conditions. The traction results show that the benefit of nanolubricants appears only at the correct concentration. Low concentrations increase traction. High concentration at 0.05 vol percent reduces traction. This highlights the need to match concentration with operating conditions rather than assume that nanoparticle addition always improves performance.

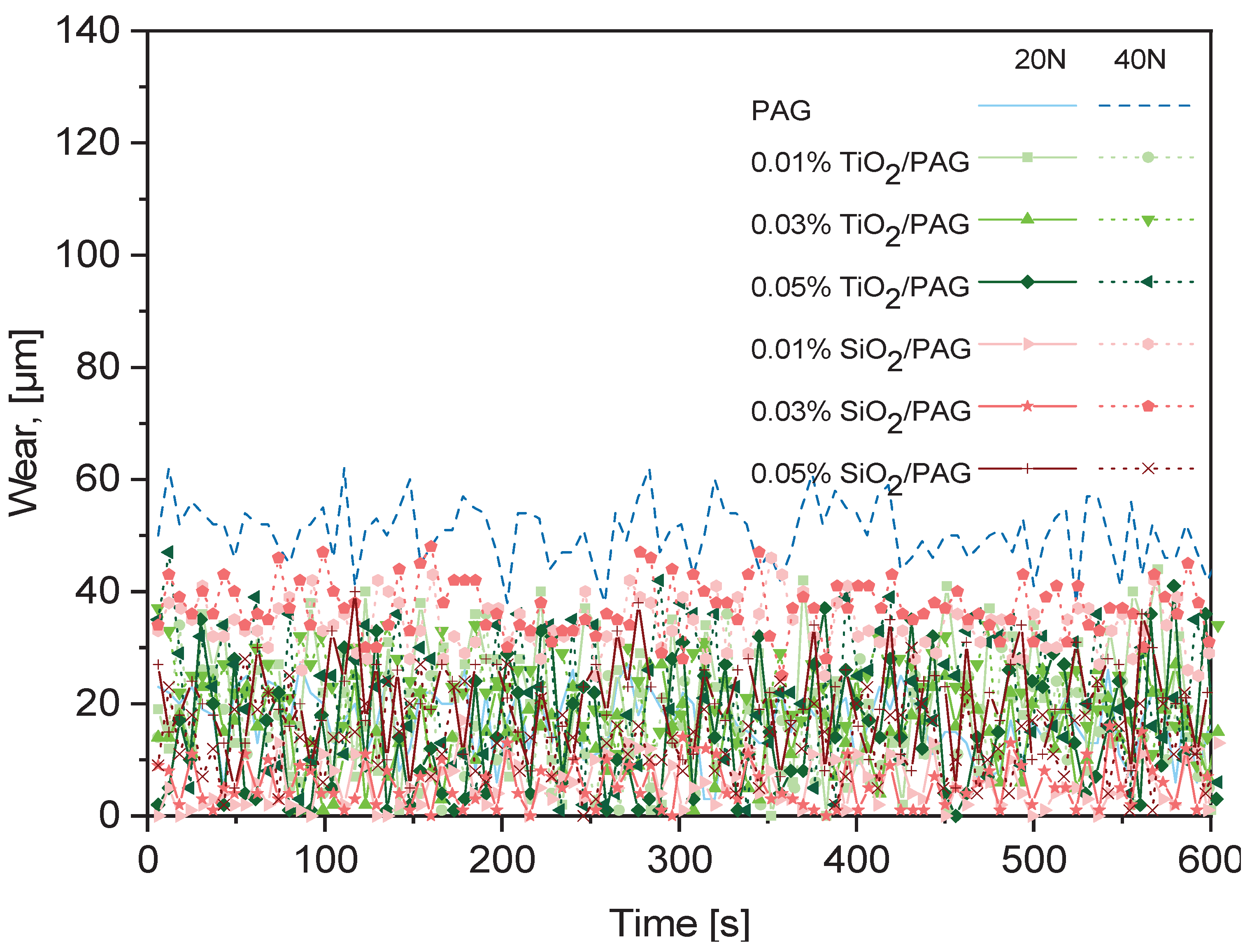

3.4. Wear

Figure 7 shows the wear on the steel ball over the specified test duration for each lubricant. The results clearly show that PAG produces the highest wear at both 20 N and 40 N. The addition of TiO

2 or SiO

2 reduces wear significantly, which indicates stronger film formation and reduced asperity contact. TiO

2-based nanolubricants consistently record lower wear than SiO

2-based ones, showing a stronger protective effect. This agrees with published findings. Zhao, Huang [

24] reported that nanoparticles improve tribofilm formation, micro-bearing effects, and self-repair actions. Birleanu, Pustan [

25] and Corina, Pustan [

26] also found that TiO

2 increases load-carrying capacity and anti-wear behaviour in base oil. At 20 N the nanolubricants already provide improved wear resistance relative to PAG, showing that the nanoparticle film can protect moderately loaded contacts. When the load rises to 40 N, wear increases for all lubricants, but the improvement from nanoparticle addition remains. TiO

2 at 0.03 vol percent records the lowest wear under the higher load, which indicates strong film resilience under elevated contact stress. This behaviour matches earlier work on oxide nanoparticles. Wu, Zhao [

27] reported that surface-modified TiO

2 reduced wear under rough surfaces and oxide scale conditions. The results also show a clear concentration effect. At 0.01 vol percent the improvement is small. At 0.03 vol percent wear reaches the lowest level. At 0.05 vol percent wear begins to increase again, likely due to slight particle agglomeration at higher loading.

Between the two additives, TiO

2 shows stronger anti-wear performance than SiO

2. Comparative work by Cortés, Sánchez [

9] reported that SiO

2 reduced wear volume in sunflower oil by about 74.1 percent, while TiO

2 achieved about 70.1 percent. Although the test medium and conditions differ from the present study, the qualitative ranking (TiO

2 ≥ SiO

2) is consistent. The superior performance of TiO

2 is linked to its higher hardness, stronger adhesion to metal surfaces, and its ability to form more stable protective tribofilms during sliding contact, as supported by recent reviews [

24].

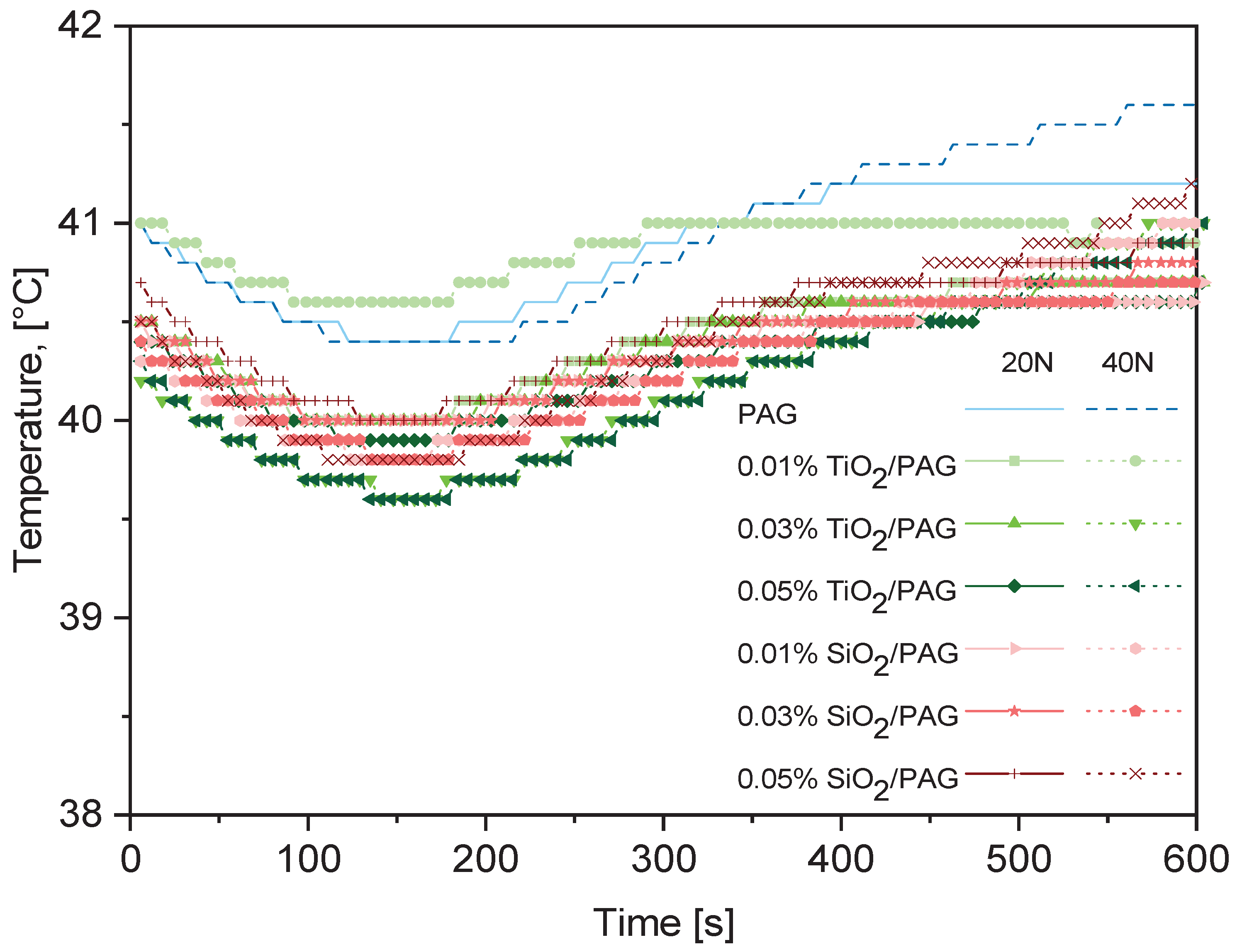

3.5. Temperature Stability

Figure 8 shows the temperature behaviour of PAG and the two nanolubricant types, TiO

2/PAG and SiO

2/PAG, at concentrations of 0.01, 0.03, and 0.05 percent under 20 N and 40 N. The results indicate how load, nanoparticle type, and concentration influence the lubricant’s ability to control heat during operation. The temperature remains stable for all samples across the full test duration. This shows that the lubricant film stayed in thermal balance, where the heat generated by friction was matched by the heat removed from the contact zone. Such stability reflects effective lubrication and consistent temperature regulation, both of which are important indicators of thermal reliability. All nanolubricants record lower temperatures than PAG. This agrees with earlier findings by Kim, Hyun [

28], who reported that nanoparticle-enhanced lubricants maintain stable operating temperatures by improving heat transfer through the lubricant film.

When comparing loads, the temperature at 40 N is slightly higher than at 20 N. This increase is expected because higher load produces greater contact pressure and more frictional heating. The rise is smaller for the nanolubricants than for PAG. This indicates that TiO

2 and SiO

2 help conduct heat away from the contact zone more efficiently. By keeping the temperature lower under heavy load, the nanolubricants help prevent thermal degradation, oxidation, and viscosity loss. These effects support longer lubricant life and stable performance. With respect to concentration, all nanolubricants perform better than PAG, with the strongest effect at 0.03 percent. At this concentration the particles are well dispersed and create effective heat conduction paths. At 0.01 percent the particle content is too low to influence heat transfer significantly. At 0.05 percent slight agglomeration may occur, which can reduce fluid uniformity and limit efficiency. These results show that concentration optimisation is important to achieve consistent thermal performance without affecting stability. When comparing nanoparticle types, TiO

2-based lubricants consistently record slightly lower temperatures than SiO

2-based ones across both loads and all concentrations. This is linked to the higher thermal conductivity of TiO

2, about 8.4 W m

−1 K

−1, compared with SiO

2, about 1.4 W m

−1 K

−1. TiO

2 also shows better dispersion stability in polar oils such as PAG, which supports the formation of continuous conductive structures in the fluid. These trends match the findings of Madyira and Babarinde [

7] and who reported that TiO

2 nanolubricants provide better heat dissipation and improved energy efficiency in compressor systems. The present results confirm that TiO

2 is more suitable for applications that require rapid heat transfer and stable temperature control.

Compared with PAG, both TiO

2/PAG and SiO

2/PAG show better thermal stability and lower operating temperature. The lower values indicate reduced frictional heat generation and more effective heat removal, which help limit oxidation and maintain viscosity. Luo, Yu [

11] also noted that nanoparticles enhance interfacial heat conduction by forming micro scale bridges within the film. This mechanism appears to be active here, as shown by the steady and lower temperature curves for the nanolubricants.

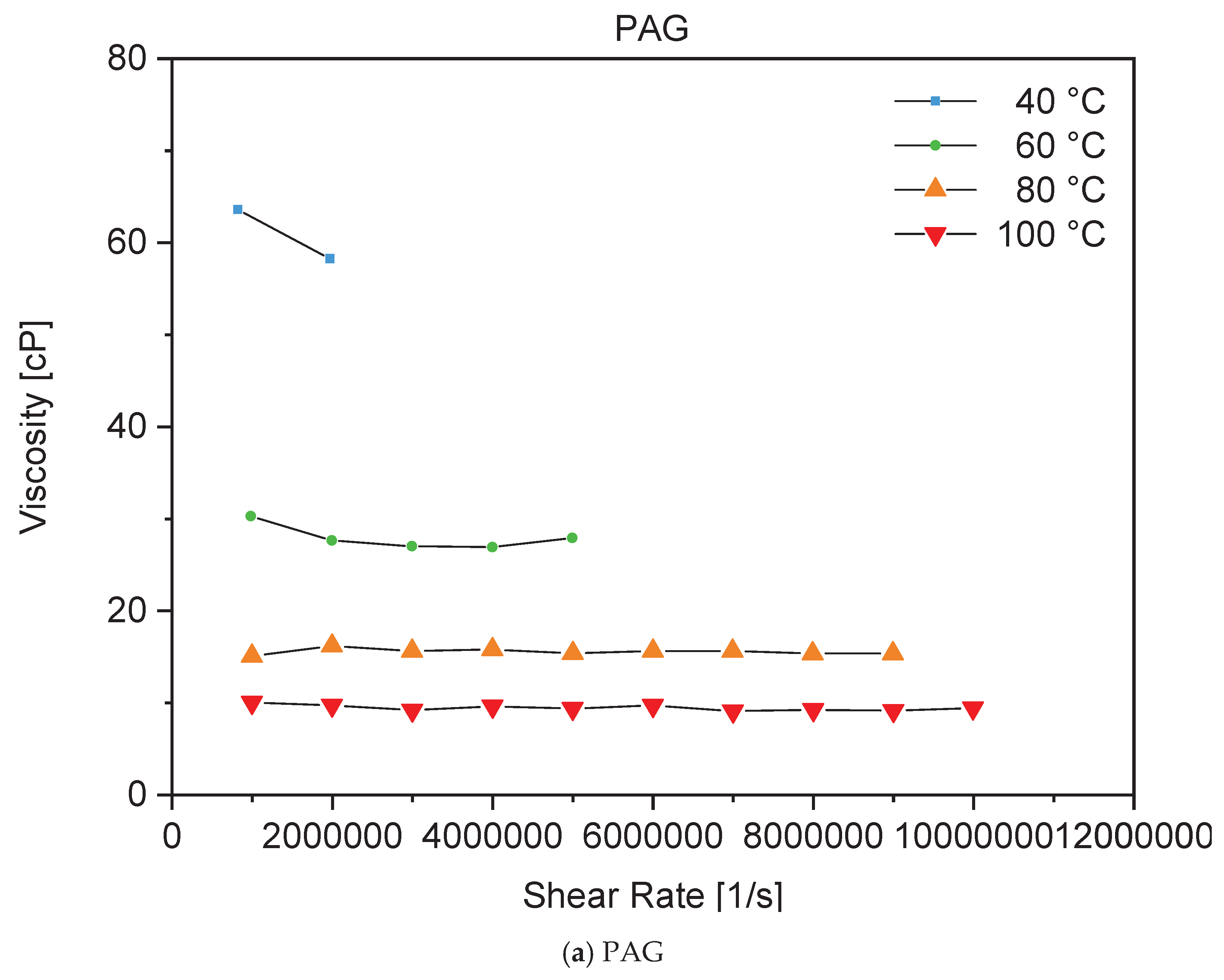

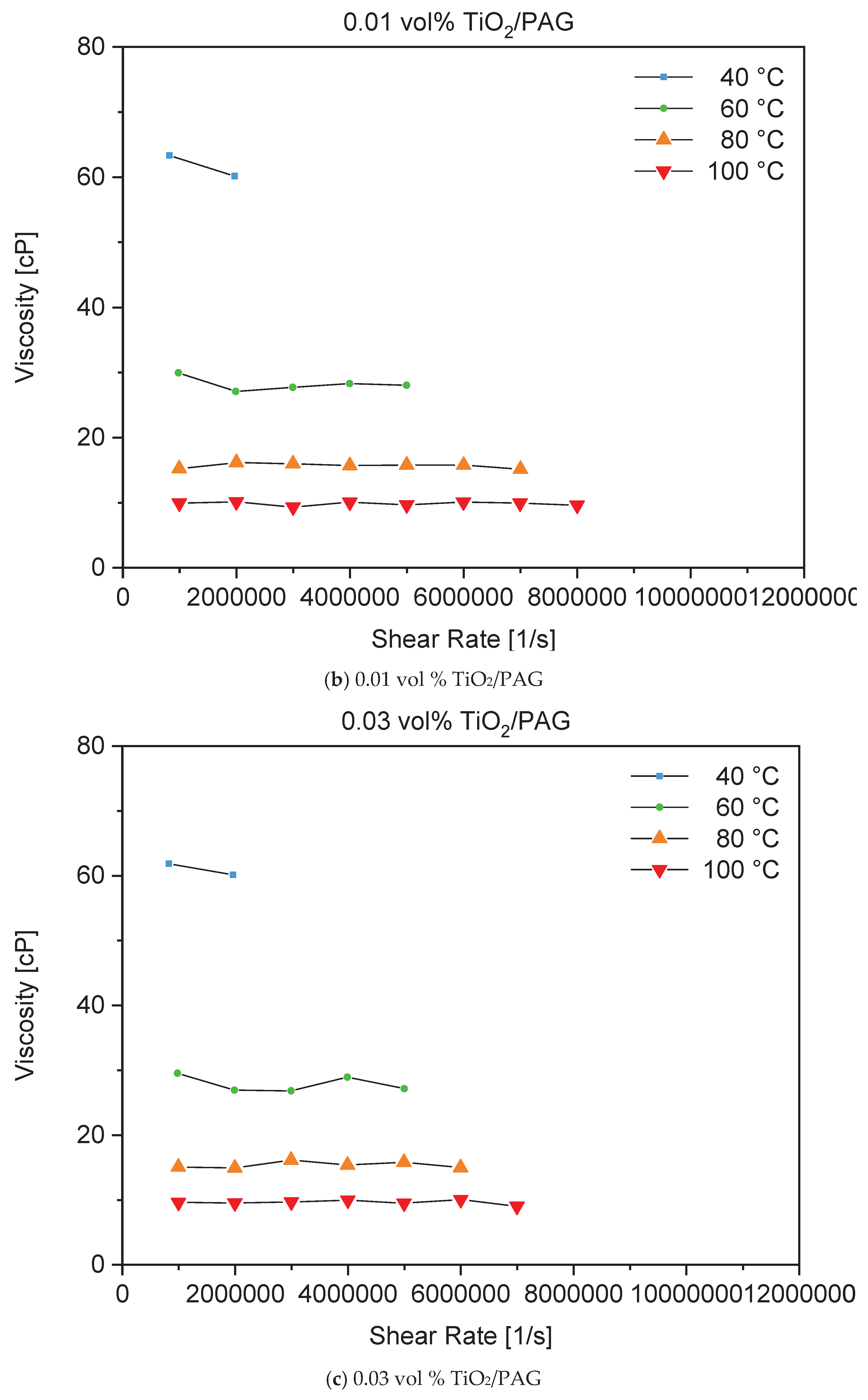

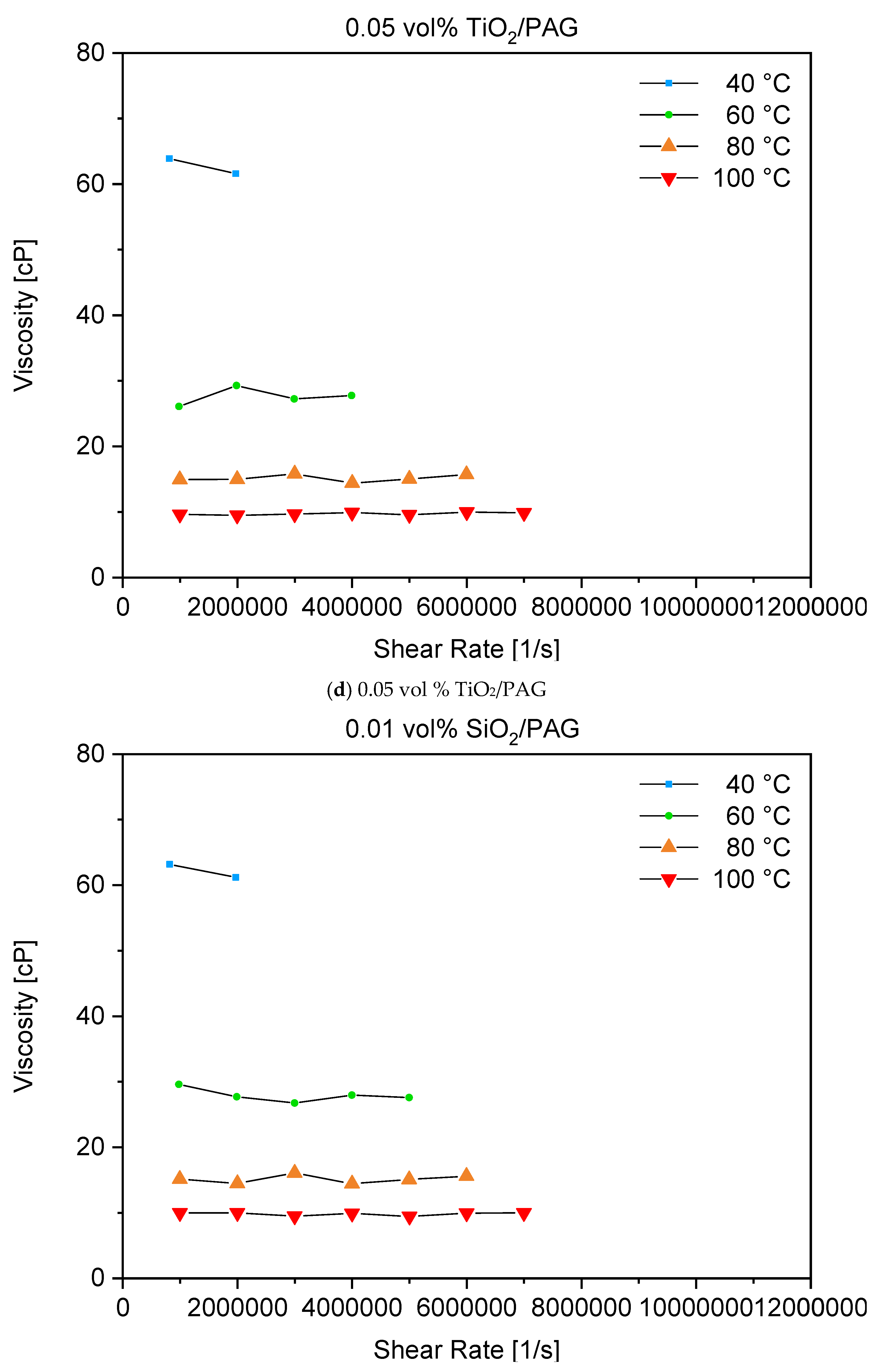

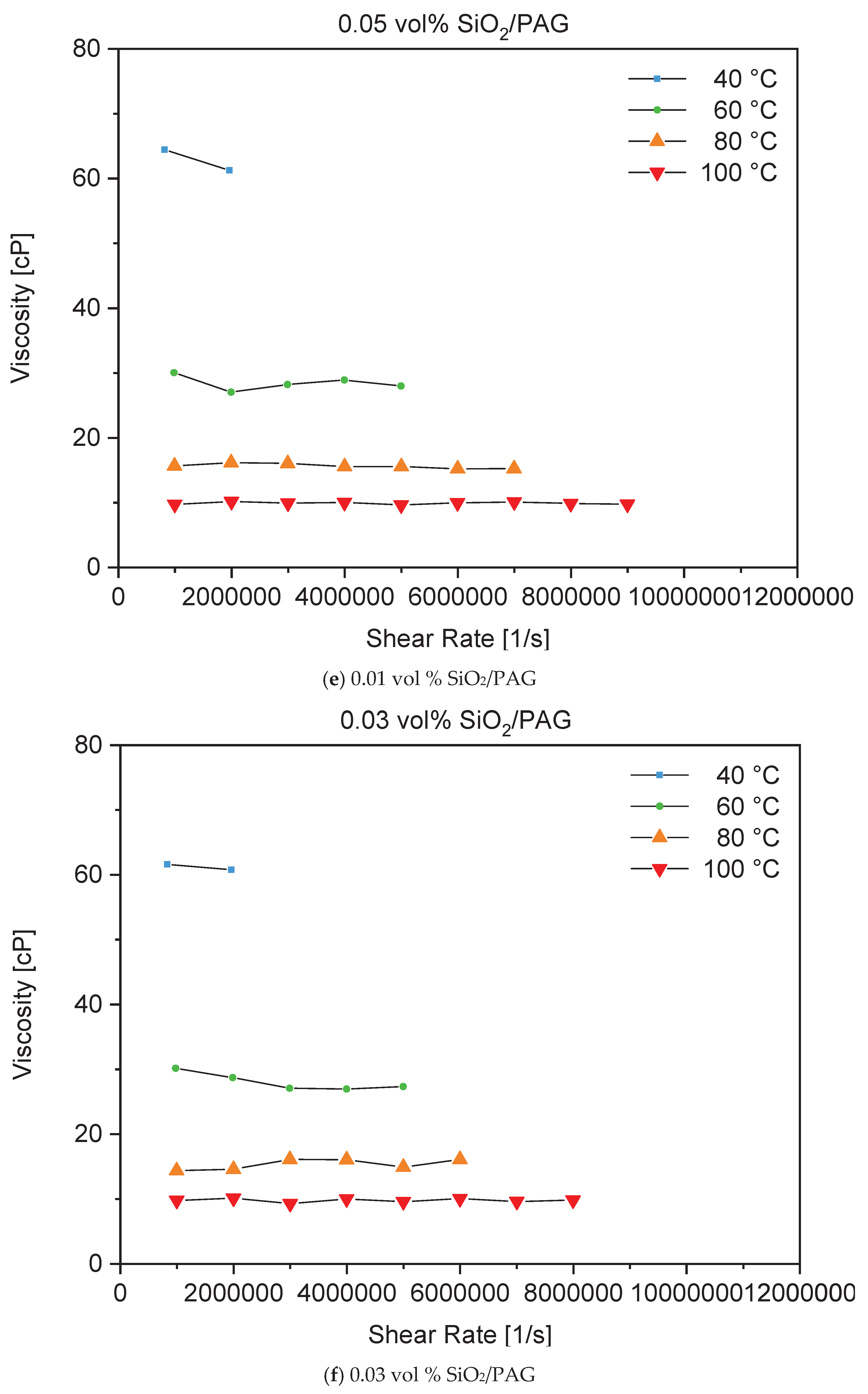

3.6. High Shear Rate Viscosity

The viscosity curves in

Figure 8 show consistent shear thinning for all formulations at 40, 60, 80, and 100 °C. Viscosity decreases as shear rate increases. This non Newtonian behaviour matches previous reports on PAG based nanolubricants, where higher shear rate accelerates structural breakdown in the fluid. Sanukrishna and Jose Prakash [

12] reported the same trend for TiO

2 dispersed in PAG for compressor lubrication and noted that the particle networks weaken under high shear and high temperature. Similar behaviour appears in studies on SiO

2 based nanolubricants, where viscosity drops with shear due to particle alignment effects [

29].

The viscosity of all lubricants decreases as temperature increases. The decline is strongest at high shear rate, which indicates that thermal softening accelerates structural breakdown in the fluid. This matches the results reported by Sanukrishna and Jose Prakash [

12] and Sandy Prayogo, Mamat [

29], who showed that SiO

2 and TiO

2 nanolubricants lose viscosity more rapidly at high temperature when the base oil has limited thermal stability. The high temperature trend in the present data follows the same mechanism. Load also affects viscosity, although the influence is moderate. Higher load produces a small reduction in viscosity, likely due to higher local temperature in the shear zone. While the load dependent changes are not large, the trend aligns with EHL film collapse models where increased contact pressure reduces film thickness at elevated temperature. Nanoparticle concentration influences the viscosity response. At 0.01 percent both SiO

2 and TiO

2 remain close to the PAG baseline. At 0.03 and 0.05 percent the differences become clearer. SiO

2 shows smoother thinning, while TiO

2 provides slightly higher viscosity retention at high shear rate. This agrees with published findings, where TiO

2 forms stronger load bearing structures than SiO

2, which improves viscosity retention and stability at high temperature [

26]. SiO

2 effects are milder and produce smaller viscosity changes relative to base oil at the same concentrations.

Figure 9.

High shear viscosity of PAG, TiO2/PAG and SiO2/PAG nanolubricants (0.01–0.05 vol%) across a wide shear rate range at 40, 60, 80, and 100 °C.

Figure 9.

High shear viscosity of PAG, TiO2/PAG and SiO2/PAG nanolubricants (0.01–0.05 vol%) across a wide shear rate range at 40, 60, 80, and 100 °C.

Comparison with the percent change dataset supports these observations. Across the full shear rate range, TiO2 at 0.05 percent shows the highest positive deviation from PAG, especially at 40 and 60 °C. At 80 and 100 °C the improvement decreases but remains higher than SiO2. SiO2 produces smaller viscosity increases and, in some conditions, slight reductions. This agrees with its weaker structural reinforcement behaviour. These viscosity trends have direct implications for refrigeration systems. Better viscosity retention at high shear improves film strength in compressor contacts, reduces wear, and increases efficiency in boundary dominated regimes. TiO2 nanolubricants are more suitable when high temperature stability is required. SiO2 may be preferable when only small viscosity changes are needed to avoid high pumping losses. The data also show that viscosity enhancement decreases at high temperature, so formulation choices must consider the operating thermal range.

4. Conclusions

This study evaluated TiO2 and SiO2 PAG nanolubricants under controlled elastohydrodynamic conditions using a Mini Traction Machine. The results show that nanoparticle addition can improve film behaviour, reduce wear, and stabilise temperature when the concentration and operating conditions are matched correctly. TiO2 provided the strongest improvements across all measured responses.

For traction, only the 0.05 percent formulations reduced friction relative to PAG under fixed SRR. Lower concentrations increased traction. The data show that EHL contacts require a sufficient particle population before any reduction appears. TiO2 produced the largest reductions, consistent with its higher hardness and better thermal conductivity. The wear tests show clear improvement for both nanoparticle types, with TiO2 providing the lowest wear at both loads. The 0.03 percent TiO2 blend showed the best protection under 40 N, indicating strong film resilience at higher stress. These results agree with reported mechanisms such as tribofilm formation, micro scale filling, and the rolling supports provided by spherical particles. The temperature results show that nanolubricants maintain lower operating temperatures than PAG. TiO2 provides slightly stronger reduction than SiO2. The most consistent performance appears at 0.03 percent, where dispersion is strongest and heat conduction pathways are most effective. The viscosity tests confirm shear thinning across all formulations. TiO2 at 0.05 percent shows the highest viscosity retention at high shear rates, especially at 40 and 60 °C. This supports better film stability in compressor contacts. SiO2 shows milder effects with smaller viscosity changes.

Overall, TiO2/PAG nanolubricants provide better traction stability, stronger wear reduction, and improved thermal and rheological behaviour than SiO2/PAG. The results indicate that concentration control is essential. Low concentrations provide little benefit, while high concentrations at 0.05 percent can reduce traction and improve viscosity retention. For refrigeration and compressor applications, the 0.03 percent TiO2 formulation offers the most balanced performance across all metrics.

Author Contributions

Conceptualization, Sharif Mohd Zaki and Mohd Syafiq Abd Aziz. Methodology, Sharif Mohd Zaki. Software, Sharif Mohd Zaki. Validation, Sharif Mohd Zaki, Mohd Syafiq Abd Aziz, and Ismail Mohd Farid. Formal analysis, Sharif Mohd Zaki. Investigation, Sharif Mohd Zaki. Resources, Ismail Mohd Farid. Data curation, Sharif Mohd Zaki. Writing original draft preparation, Sharif Mohd Zaki. Writing review and editing, Mohd Syafiq Abd Aziz, Abdollah Mohd Fadzli, and Abdul Aziz Mohamad Redhwan. Visualization, Sharif Mohd Zaki. Supervision, Abdollah Mohd Fadzli. Project administration, Ngatiman Nor Azazi. Funding acquisition, Sharif Mohd Zaki and Mohd Syafiq Abd Aziz. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the usage of the facilities of Universiti Teknikal Malaysia Melaka. This research is funded by a grant from the Universiti Teknikal Malaysia Melaka (Grant number: PJP/2024/FTKM/PERINTIS/S01989).

Data Availability Statement

Data supporting the findings of this study are available from the corresponding author upon reasonable request. No publicly archived datasets were generated or analyzed. Data cannot be shared openly due to confidentiality requirements related to experimental facilities and proprietary materials used in the study.

Acknowledgments

The authors acknowledge the technical and administrative support provided by Universiti Teknikal Malaysia Melaka and Imperial College London. The authors also thank the laboratory staff for assistance with equipment setup, sample preparation, and testing activities. This research is funded by a grant from Universiti Teknikal Malaysia Melaka, Grant number PJP/2024/FTKM/PERINTIS/S01989. During the preparation of this manuscript, the authors used ChatGPT, version GPT 5.1, to support language refinement and document formatting. The authors reviewed and edited all generated output and took full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| SRR |

Slide to roll ratio |

| PAG |

Polyalkylene glycol |

| TiO2 |

Titanium dioxide |

| SiO2 |

Silicon dioxide |

| EHL |

Elastohydrodynamic lubrication |

| USV |

Ultra Shear Viscometer |

References

- Zaki, S.M., et al., Critical Properties of Refrigeration Lubricants in Modern Refrigeration System: A Review. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 2025. 131(1). [CrossRef]

- Gangopadhyay, A. and J. Cuthbert Opportunities and Challenges with Polyalkylene Glycol for Engine Oil Application. Lubricants, 2018. 6. [CrossRef]

- Hofmann, S., T. Lohner, and K. Stahl, Influence of water content on elastohydrodynamic friction and film thickness of water-containing polyalkylene glycols. Frontiers in Mechanical Engineering, 2023. Volume 9 - 2023. [CrossRef]

- Sanukrishna, S.S., S. Vishnu, and M. Jose Prakash, Experimental investigation on thermal and rheological behaviour of PAG lubricant modified with SiO2 nanoparticles. Journal of Molecular Liquids, 2018. 261: p. 411-422. [CrossRef]

- Ali, M.K.A., et al., Effect of Lubricant Contaminants on Tribological Characteristics During Boundary Lubrication Reciprocating Sliding. arXiv: Applied Physics, 2017.

- Hamisa, A.H., et al., Tribology Performance of Polyol-Ester Based TiO2, SiO2, and Their Hybrid Nanolubricants. Lubricants, 2023. 11(1).

- Madyira, D. and T. Babarinde, TiO2, CNTs, and SiO2 nanolubricant: An approach to improving the efficiency of a domestic refrigerator. Journal of Physics: Conference Series, 2024. 2748.

- Zeng, K., et al. Synthesis, Stability, and Tribological Performance of TiO2 Nanomaterials for Advanced Applications. Lubricants, 2025. 13. [CrossRef]

- Cortés, V., et al., The Performance of SiO2 and TiO2 Nanoparticles as Lubricant Additives in Sunflower Oil. Lubricants, 2020.

- Xie, H., et al. Synergistic Effect of MoS2 and SiO2 Nanoparticles as Lubricant Additives for Magnesium Alloy–Steel Contacts. Nanomaterials, 2017. 7. [CrossRef]

- Luo, Z., et al., Surface characterization of steel/steel contact lubricated by PAO6 with novel black phosphorus nanocomposites. Friction, 2020. 9: p. 723-733. [CrossRef]

- Sanukrishna, S.S. and M. Jose Prakash, Experimental studies on thermal and rheological behaviour of TiO2-PAG nanolubricant for refrigeration system. International Journal of Refrigeration, 2018. 86: p. 356-372. [CrossRef]

- Ismail, M.F. and W.A. Wan Hamzah. Tribological Performance Effect of SiO2 and TiO2 Nanoparticles as Lubricating Oil Additives. in Lecture Notes in Mechanical Engineering. 2023.

- Sharif, M.Z., et al. Viscosity and Friction Reduction of Double-End-Capped Polyalkylene Glycol Nanolubricants for Eco-Friendly Refrigerant. Lubricants, 2023. 11. [CrossRef]

- Ishii, N., et al. Elasto-Hydrodynamic Lubrication Effect in ThrustSlide Bearings of Scroll Compressors. in International Compressor Engineering Conference. 2012. Purdue University. [CrossRef]

- Wei, C., et al., Mixed Lubrication Analysis of Scrolls Lubricated With CO2/Oil Mixture Based on a Homogeneous Model. Journal of Tribology, 2023. 145(11). [CrossRef]

- Boidi, G., et al., Effect of laser surface texturing on friction behaviour in elastohydrodynamically lubricated point contacts under different sliding-rolling conditions. Tribology International, 2020. 149: p. 105613. [CrossRef]

- Zhang, J., A. Tan, and H. Spikes, Effect of Base Oil Structure on Elastohydrodynamic Friction. Tribology Letters, 2017. 65: p. 1-24. [CrossRef]

- Zhang, J. and H. Spikes, Measurement of EHD Friction at Very High Contact Pressures. Tribology Letters, 2020. 68: p. 1-12. [CrossRef]

- Sun, J., et al., Experimental Study on the Effect of Micro-Texture on EHL Point-Contact Film Thickness Subject to Sliding Conditions. Materials, 2022. 15. [CrossRef]

- Morshed, A., et al., A Study of Water-Based Nanolubricants Using Hexagonal Boron Nitride (hBN)-Based Nanocomposites as Lubricant Additives. Lubricants, 2024. [CrossRef]

- Wang, C., et al., Friction-induced motion evolution of reduced graphene oxide-Al2O3 at contact interface to achieve superior lubrication performance. Applied Surface Science, 2022. 604: p. 154479. [CrossRef]

- Yeap, S.P., et al., Agglomeration, colloidal stability, and magnetic separation of magnetic nanoparticles: collective influences on environmental engineering applications. Journal of Nanoparticle Research, 2017. 19(11): p. 368. [CrossRef]

- Zhao, J., et al., Nanolubricant additives: A review. Friction, 2021. 9(5): p. 891-917.

- Birleanu, C., et al., Effect of TiO2 nanoparticles on the tribological properties of lubricating oil: an experimental investigation. Scientific Reports, 2022. 12(1): p. 5201. [CrossRef]

- Corina, B., et al., Effect of TiO2 nanoparticles on the tribological properties of lubricating oil: an experimental investigation. Scientific Reports, 2022. 12: p. 5201.

- Wu, H., et al., Friction and wear characteristics of TiO2 nano-additive water-based lubricant on ferritic stainless steel. Tribology International, 2018. 117: p. 24-38. [CrossRef]

- Kim, B., et al., Effect of Boundary Layer Modification and Enhanced Thermal Characteristics on Tribological Performance of Alumina Nanofluids Dispersed in Lubricant Oil. Experimental Techniques, 2022. 47: p. 737-746. [CrossRef]

- Sandy Prayogo, G., et al., A Bibliometric Review of the Research Progress and Trends in Nanolubricants for Refrigeration Systems (2003-2025). International Journal of Automotive Science And Technology, 2025. 9(3): p. 353-373. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).