1. Introduction

With the advancement of the “dual-carbon” goal, the shape of the power system on both the source and the load side changes dramatically [

1]. The application of a high proportion of new energy sources increases the risk of uncertainty in power system operation [

2,

3]. As the hub of energy transmission, the substation is the basis for the power system to realise new energy consumption and maintain the bilateral balance of source and load. Therefore, comprehensively assessing the substation operation risk and risk prevention and control is particularly important.

There is also relevant literature on substation operational risk assessment. In [

4], to effectively detect the external risk of a substation, the article proposes a method for assessing the external risk of a substation based on single and superimposed anomaly risk. In [

5], aiming at the complexity and ambiguity of the risk of substation operation, a risk assessment method of substation operation based on the triangular fuzzy number AHP method and cloud model is presented. In [

6], this paper proposes a new risk assessment methodology for obtaining weaknesses in the main electrical connections. In [

7], an online fault detection and diagnosis (FDD) method for substation sensors based on long and short-term memory networks is proposed. In [

8], this paper proposes a deep neural network-based risk assessment method for intelligent substation subsystems to improve the accuracy of operational status assessment. In [

9], this paper incorporates human factors into integrated substation automation system (ISAS) reliability studies and proposes an ISAS risk assessment technique that considers human reliability. The above research focuses more on the influence of external environment, substation electrical connection mode, and operation condition of secondary equipment on substation operation, and does not consider the influence of the dynamic change of the state of core main equipment, such as transformer, circuit breaker, and disconnector, on the operation of the substation. The core main equipment is the core of substation energy conversion and transmission; once the main equipment state degrades, it will directly or indirectly affect the other equipment operating state, resulting in a chain reaction that exacerbates the risk of substation operation. Therefore, it is necessary to consider the impact of the core main equipment on substation operation risk.

Situational awareness technology refers to the perception, understanding, and predictive presentation of the elements in the environment under certain spatial and temporal conditions [

11]. Currently, situational awareness technology has been used by many experts and scholars to solve problems related to the electric power field. In [

12], based on the theory of situational awareness, this paper proposes a peaking optimisation model for hybrid energy systems with wind power storage units to optimise the peaking strategy. In [

13], this paper proposes a flexible scheduling strategy based on situational awareness technology under extreme weather events, which realises sensing the extreme operation scenarios of the system in advance and formulating a flexible scheduling scheme. In [

14], a situational awareness system based on the new energy power system was established to effectively tap into the operation of the power system. In [

15], situational awareness of line and transformer components in distribution networks is investigated to ensure the reliability and security of the power supply. In [

16], a data-driven power system security situational awareness is proposed, which monitors and assesses the security status of the power system and alerts the organisation when the system encounters a suspected threat. The above literature illustrates that situational awareness techniques can be effective in exploring situational issues such as operational risks associated with the power field. However, at present, there is no in-depth research on the analysis of substation operation risk posture.

To solve the issue, the paper combines the theoretical framework of situational awareness and proposes a situational awareness method for substation operation risk based on the health state of the main equipment. The main contributions of this paper are as follows:

1) In the situational perception layer, the time-varying failure rate of substation main equipment is obtained based on the equipment failure rate model considering the effect of equipment aging.

2) In the situational understanding layer, a risk propagation model considering the health state of main equipment is proposed with reference to the SI virus transmission model to simulate the process of risk propagation among main equipment in a substation.

3) In the situational presentation layer, the set of time sequences of equipment risk propagation paths obtained from the risk propagation model is used to construct a potential equipment risk severity indicator to realise the potential equipment risk presentation.

4) In the situational guidance layer, based on the results of the situational understanding layer and the situational presentation layer, the potential equipment risk indicator of the substation main equipment is optimised to achieve the potential equipment risk presentation.

2. A Method for Substation Operation Risk Situational Awareness Based on the Health State of Main Equipment

The health status of the substation’s main equipment is closely related to the substation’s operation risk. This paper proposes a situational awareness method of substation operation risk based on the health state of main equipment, based on the technical framework of situational awareness, to prevent the change trend of substation operation risk, and to ensure the safe and stable operation of substations.

2.1. Situational Perception

Situational perception is the data basis of the situational awareness technology, and the equipment failure rate, which is the core parameter to quantify the health state of the equipment [

17], can intuitively reflect the degree of aging, potential defects, and the degree of health. Therefore, this paper selects the equipment failure rate to portray the equipment health state, and obtains the time-varying failure rate of the substation main equipment based on the equipment failure rate model considering the effect of equipment deterioration [

18], which provides the data basis for exploring the risk situation of substation operation.

The equipment failure rate model that considers the effect of equipment aging is modelled as follows, with a Weibull model [

19] that characterises the effect of equipment aging on the equipment failure rate, as shown in equation (1).

Time differentiation of the equipment life function yields the equipment life probability density function:

The equipment life failure rate function can be obtained by solving equations (1) and (2), as shown in equation (3).

Where β and γ are the scale parameter and shape parameter of the Weibull distribution, respectively. When γ > 1, the equipment failure rate λ(t) increases with time increment, which also indirectly reflects the aging of the equipment.

The approximate equivalence of equation (3) is performed by characterising the desired computational time period in terms of T, as shown in equation (4).

Substituting equation (4) into equation (3) yields the equipment failure rate considering the effect of equipment aging, as shown in equation (5).

2.2. Situational Understanding

The risk propagation model considering the health state of the main equipment is proposed based on the health state data of the main equipment obtained by the situational perception layer, and the situational understanding layer simulates the risk propagation among the main equipment of the substation by referring to the SI virus transmission model [

20].

Complex networks are often used to solve various propagation control problems [

21]. Multiple voltage levels generally exist within a substation, so the overall connectivity of the equipment is more complex. The substation equipment can be set as a point, and the power supply connection lines between the equipment are treated as edges, which equates the substation interior to a specific network. The risk propagation between equipment inside the substation can be regarded as a propagation control problem according to certain rules in a network. When the equipment inside the substation has an operation risk due to its own health state deterioration, the risk will be transmitted to other equipment connected with the equipment with operation risk as the centre, which is consistent with the propagation mechanism of virus infection.

The research on viral transmission in the medical field has been very mature [

22], and many transmission models have been proposed. The interconnection relationship between the equipment’s own health state and the operating state between the equipment is constantly changing at any time and space advancement, and the risk propagation of the equipment inside the substation is consistent with the SI virus contagion model, therefore, this paper will take the complex network as a framework, analogous to the SI virus contagion model to explore the process of the spatio-temporal evolution of the risk of the equipment inside the substation.

2.2.1. SI Virus Transmission Model

The SI viral transmission model is the classic viral transmission model. In the SI virus transmission model, the population can be divided into two states: S (susceptible) and I (infected). The two-state transition process is shown in

Figure 1.

In the SI virus transmission model, the behaviour of the transmission dynamics [

23] can be described by the following set of differential equations, as shown in equation (6).

Where S(t) and I(t) denote the density of the number of susceptible individuals and the number of infected individuals in the total number of people at time t, and α is the probability of infection, respectively.

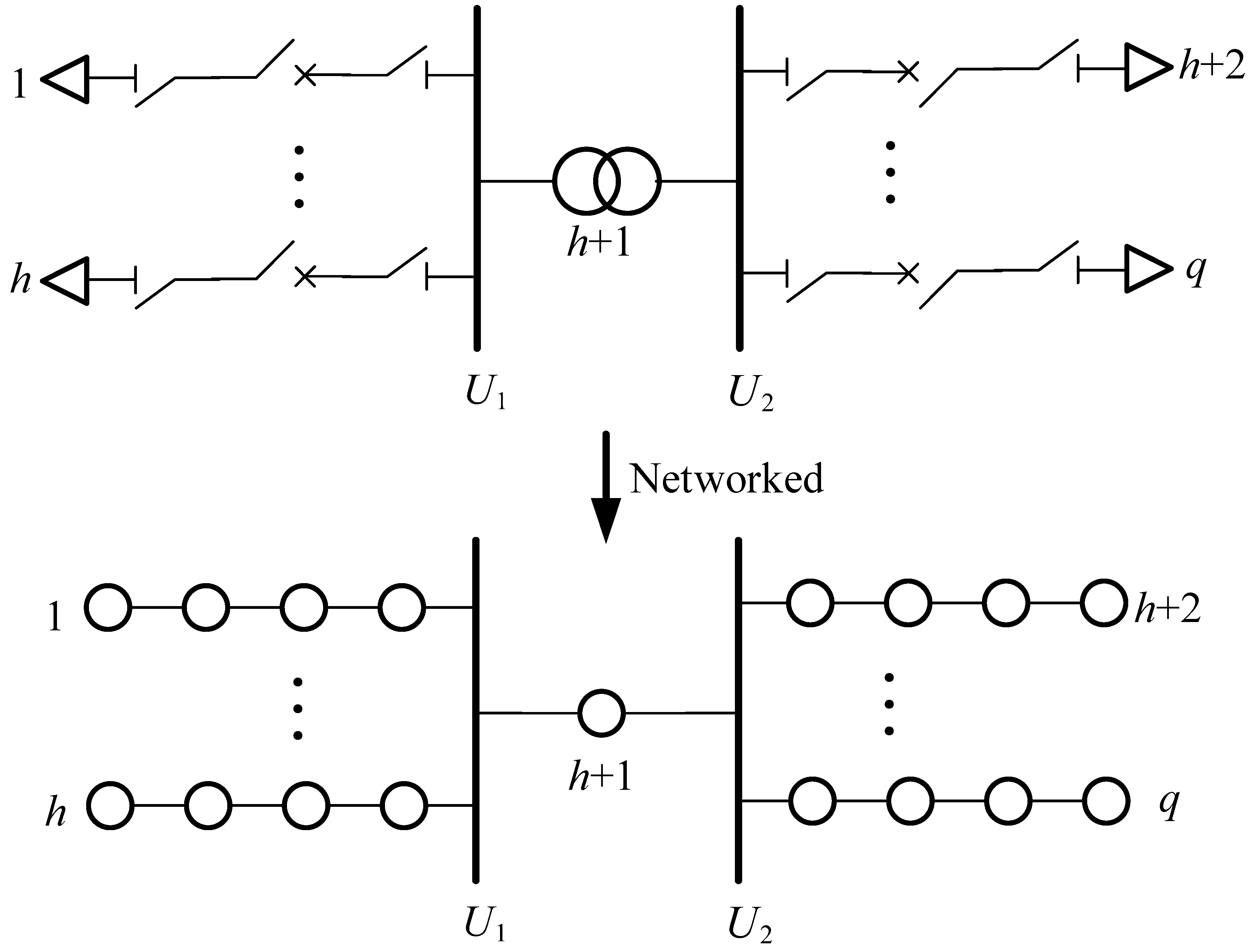

2.2.2. Risk Propagation Modelling Considering the State of Health of the Main Equipment

This paper simulates the risk propagation process between equipment within a substation with reference to the SI virus transmission model, and proposes a risk propagation model for the health state of the main equipment. The main equipment inside the substation is divided into two states, S and I. S represents the main equipment in the normal state, and I represents the main equipment in a deteriorated equipment health state.

The root cause of risk propagation among main equipment within a substation is the strength of equipment vulnerability, and the stronger the vulnerability, the more susceptible the equipment is to risk. This paper portrays the equipment vulnerability from the perspective of the health state of the main equipment, which is used to physically define the propagation probability a for the risk propagation model of the main equipment within the substation.

The dual-voltage level topology is used as an example to illustrate the risk propagation between multiple voltage levels within a substation. The dual-voltage level topology with networked results is shown in

Figure 2.

1) The health status of the main equipment

The health state of the main equipment is a reflection of how reliable it is to maintain its normal functioning at present and in the future, and the deterioration of the health state of the main equipment will lead to the operational risk of the equipment, and will also have an effect on the operational state of the associated equipment. Therefore, the equipment failure rate model, which takes into account the effect of equipment aging, obtains the equipment failure rate at the moment of risk propagation, and is used to characterise the health state of the main equipment, as shown in equation (7).

Where λi(t) is the equipment failure rate of main equipment i at moment t, and q is the total number of substation equipment.

The risk propagation between main equipment is considered based on the strength of each equipment’s health state; the better the health state, the lower the failure rate and the stronger the risk resistance. Therefore, the risk propagation probability

α is defined based on the health state of the main equipment, and the risk propagation model considering the health state of the main equipment is proposed, as shown in equation (8).

Where k is the total number of equipment affected by the risk, αi is the ith probability of being affected by the risk propagation, Sc(t) is the equipment c with severe deterioration of the health state of the equipment at the moment t that acts as a source of risk propagation, and Ii(t) is the equipment i associated with the source of risk propagation at the moment t.

2.3. Situational Presentation

Situational presentation refers to obtaining the set of operational risk propagation paths between equipment within a substation, based on the risk propagation model of the situational understanding layer, which takes into account the health state of the main equipment after perception and understanding of the elements of the operational risk situation for the equipment within the substation. The equipment risk propagation path time series set is used to construct the equipment potential risk severity index, which presents the real-time and future operational risk situation of the main equipment within the substation.

For the existence of health state degradation equipment, which is an independent risk propagation source that affects the safe operation of the substation, it is assumed that a total of

d health state degradation equipment constitutes the equipment numbering set

F=[

f1, ...,

fd] as an independent risk propagation source. The risk propagation model considering the health state of the main equipment is used to obtain the temporal set

SXJ=[

sxjc], (

c∈

F) of the risk propagation among the main equipment within the substation, as shown in equation (9).

Where G is the set of equipment numbers affected by the risk, b is the total number of equipment affected by the risk, sxjc is the set of risk propagation timings in equipment number c as an independent source of risk, and tc,g1 is the moment corresponding to the moment when equipment number g1 is affected by the risk of equipment number c as an independent source of risk.

The risk propagation paths between equipment within a substation can be intuitively plotted based on the temporal set SXJ=[sxjc], (c∈F), but considering that a substation with a longer operating life may have multiple risk propagation source equipment at the same time, the multiple risk propagation paths may lead to a certain piece of equipment appearing in different temporal states in different risk propagation paths, which does not intuitively present the severity of the operational risk posture of each piece of equipment. The severity of each equipment’s operational risk posture cannot be visualised.

The risk iteration time of the equipment is considered to reflect its risk resistance. When the associated equipment becomes a risk propagation source, until the iteration time of the equipment itself becomes a risk propagation source, which can effectively measure the degree of the potential risk posture of the equipment. Therefore, this paper constructs the equipment potential risk severity index based on the temporal set

SXJ=[

sxjc], (

c∈

F) of risk propagation between equipment within a substation obtained from the posture presentation layer, which intuitively reflects the degree of potential risk posture of the equipment, as shown in equation (10).

2.4. Situational Guidance

Situational guidance refers to the provision of solutions for preventing and controlling the development of operational risk postures in substations based on the results of risk propagation model simulations that consider the health state of the main equipment and the results of the potential risk severity index of the equipment in the situational presentation. Therefore, this paper provides a situational awareness program based on the results obtained from situational understanding and situational presentation as follows.

1) Real-time monitoring of potential operational risks of substation equipment based on a risk propagation model.

Assuming that there are a total of q equipment inside the substation, based on the set of equipment potential risk severity index CX=[cx1, cx2, ..., cxq] obtained from the posture presentation, which is based on the grid scheduling platform of the State Grid, combined with the electrical main wiring diagrams of the substation, the real-time data of the potential risk of the equipment inside the substation is pushed to monitor the potential operational risk of the substation equipment.

2) Optimisation of substation equipment operation and inspection plan programming based on the equipment potential risk severity indicator set CX.

The equipment potential risk severity indicator set CX obtained from the posture presentation is sorted from largest to smallest, and the higher the sorting, the higher the equipment potential risk is, and the opposite is the lower the potential risk. Based on the sorted equipment potential risk severity index set CX, the operation and inspection department can optimise the development of the substation equipment operation and inspection plan. On the one hand, in the operation and maintenance patrol, to enhance the potential high-risk equipment of the various operational status of concern and timely feedback of relevant data, on the other hand, to shorten the potential high-risk equipment corresponding maintenance test cycle, according to the test results promptly to find defects in the equipment for overhaul and maintenance, to ensure that the substation is safe and stable to operate.

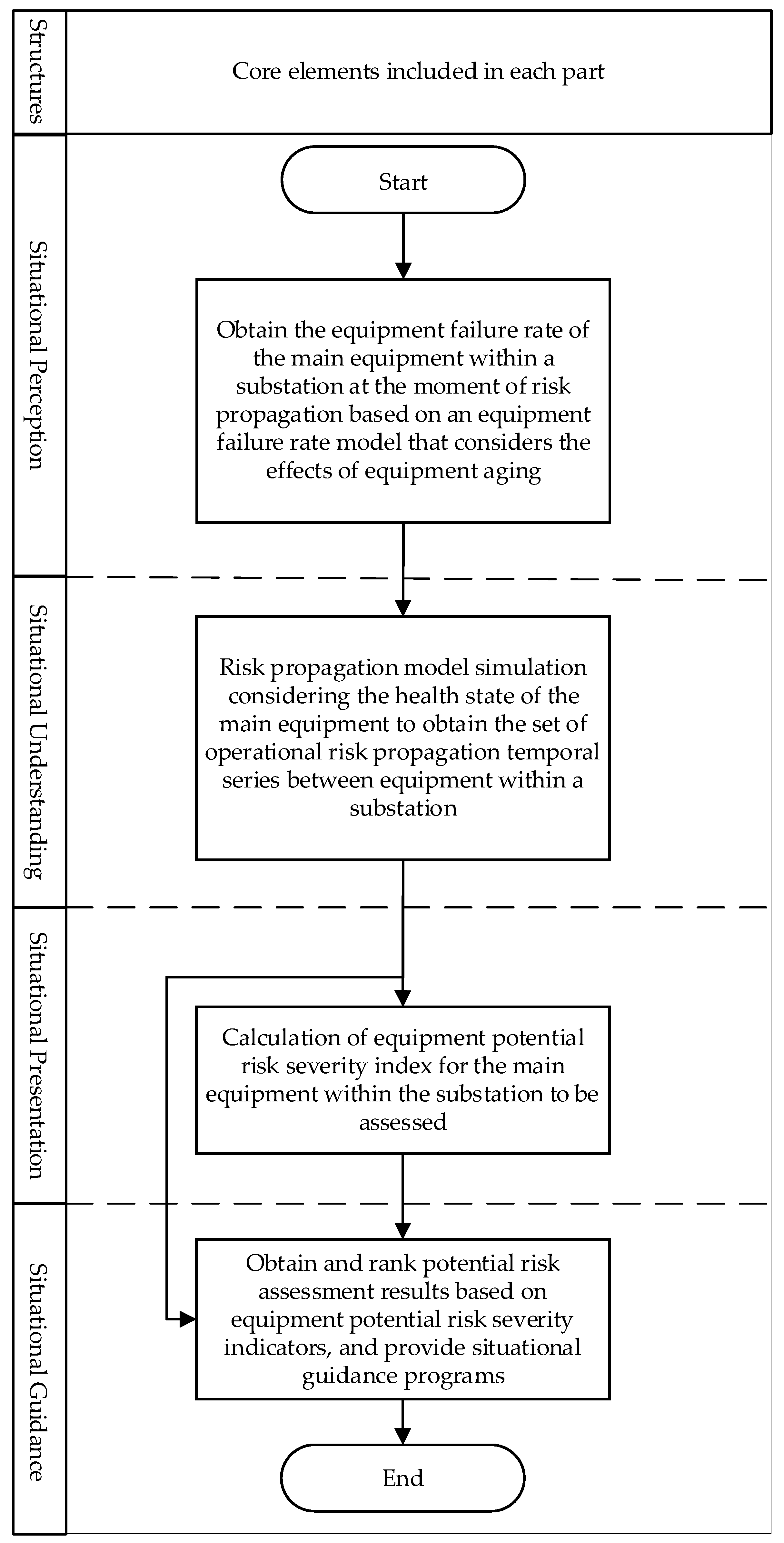

3. Flow of Substation Operation Risk Situational Awareness Method based on the Health State of the Main Equipment

The flow of the substation operation risk situational awareness method based on the health status of the main equipment is specified as follows:

1) Based on the equipment failure rate model considering the effect of equipment aging, the equipment failure rate of the main equipment inside the substation at the moment of risk propagation is obtained and used to portray the health state of the main equipment.

2) Based on the equipment health state data of the main equipment at future moments, the risk propagation model considering the health state of the main equipment is used to simulate the acquisition of the operational risk propagation temporal set SXJ=[sxjc], (c∈F) between the equipment within the substation.

3) The risk posture assessment of the main equipment within the substation is carried out based on the risk propagation temporal set SXJ=[sxjc], (c∈F) between the main equipment within the substation, combined with the potential risk severity index of the equipment.

4) The equipment potential risk assessment results of the main equipment are obtained and ranked based on the equipment potential risk severity index set, which on the one hand assists the scheduling department in real-time monitoring of the potential operational risks of the substation main equipment, and on the other hand, guides the operation and inspection department in the optimization of the main equipment operation and inspection plan of the substation.

The flow of the substation operation risk situational awareness method based on the health status of the main equipment is shown in

Figure 3.

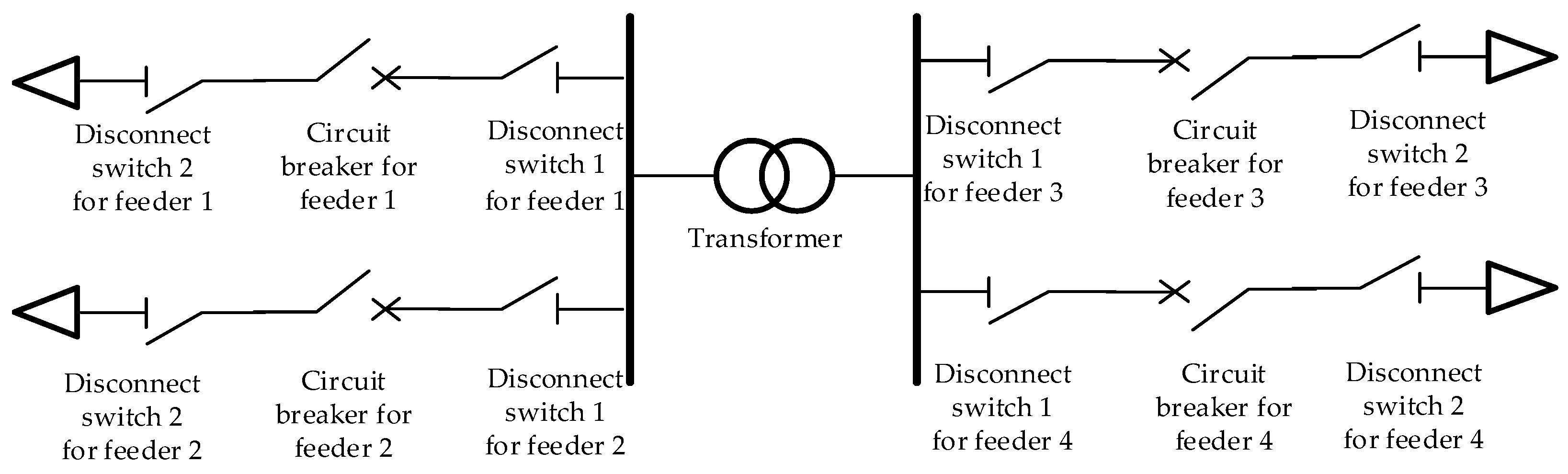

4. Example analysis

This paper takes a substation with dual-voltage level 4 feeders as an example to analyse the substation operation risk posture; the specific topology is shown in

Figure 4.

This paper considers the effect of equipment aging equipment failure rate model parameter settings reference [

24], as shown in

Table 1.

The main equipment inside the dual-voltage level 4 feeder substation is assumed to be of different ages to obtain different failure rates to characterise the health status of the equipment, to simulate the differences in the health status of different equipment and to consider the existence of the substation equipment rotation overhaul situation, as shown in

Table 2.

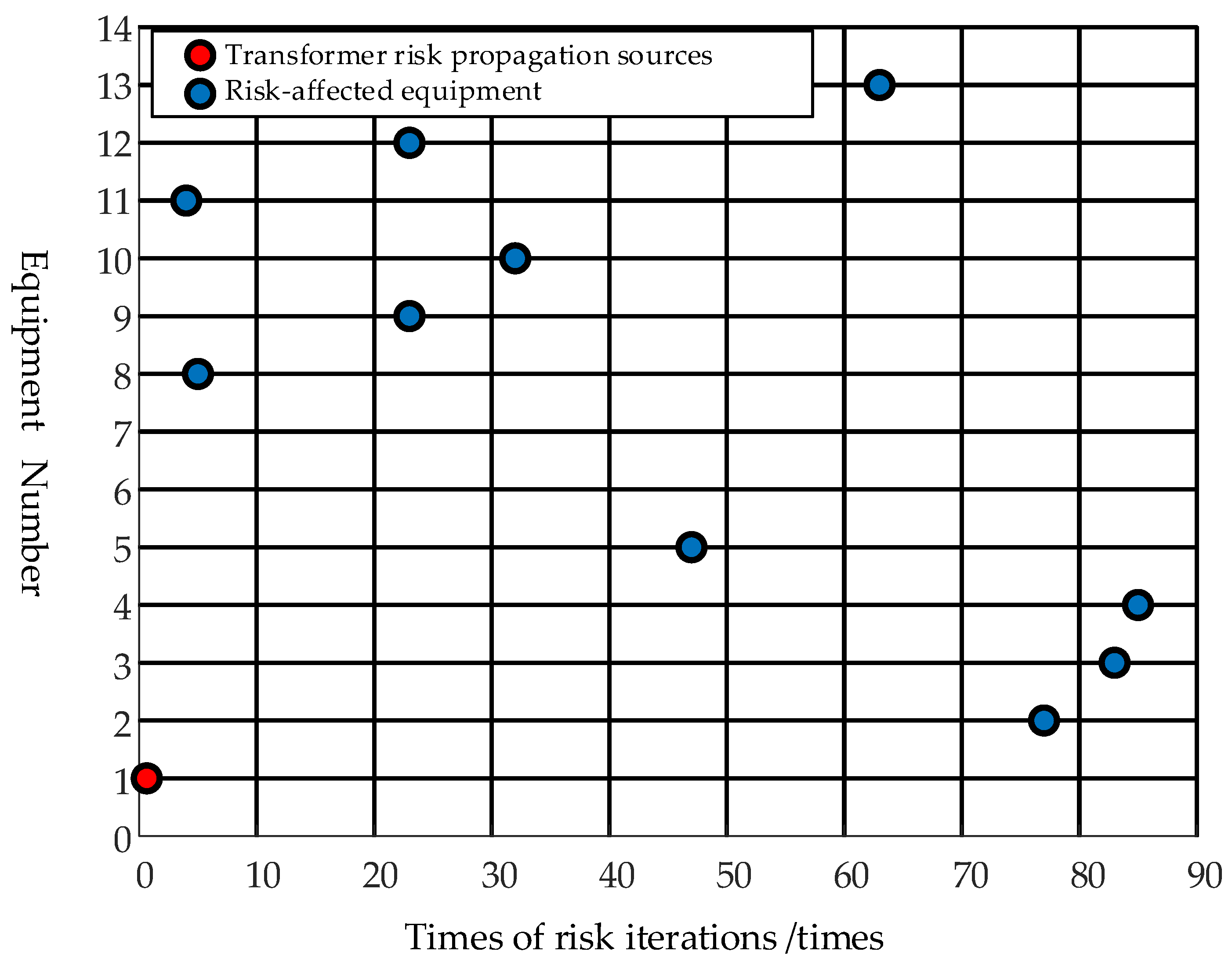

Considering the problem of space, this paper selects the transformer with the highest failure rate as the source of risk propagation for example analysis. Based on the risk propagation simulation model considering the health state of the main equipment, the simulation of the risk propagation process between the main equipment within the substation is carried out by combining the simulation of the health state of the substation equipment in

Table 2, and the results are shown in

Figure 5. The operational risk propagation temporal set

SXJ of the main equipment inside the substation, and the results are shown in

Table 3.

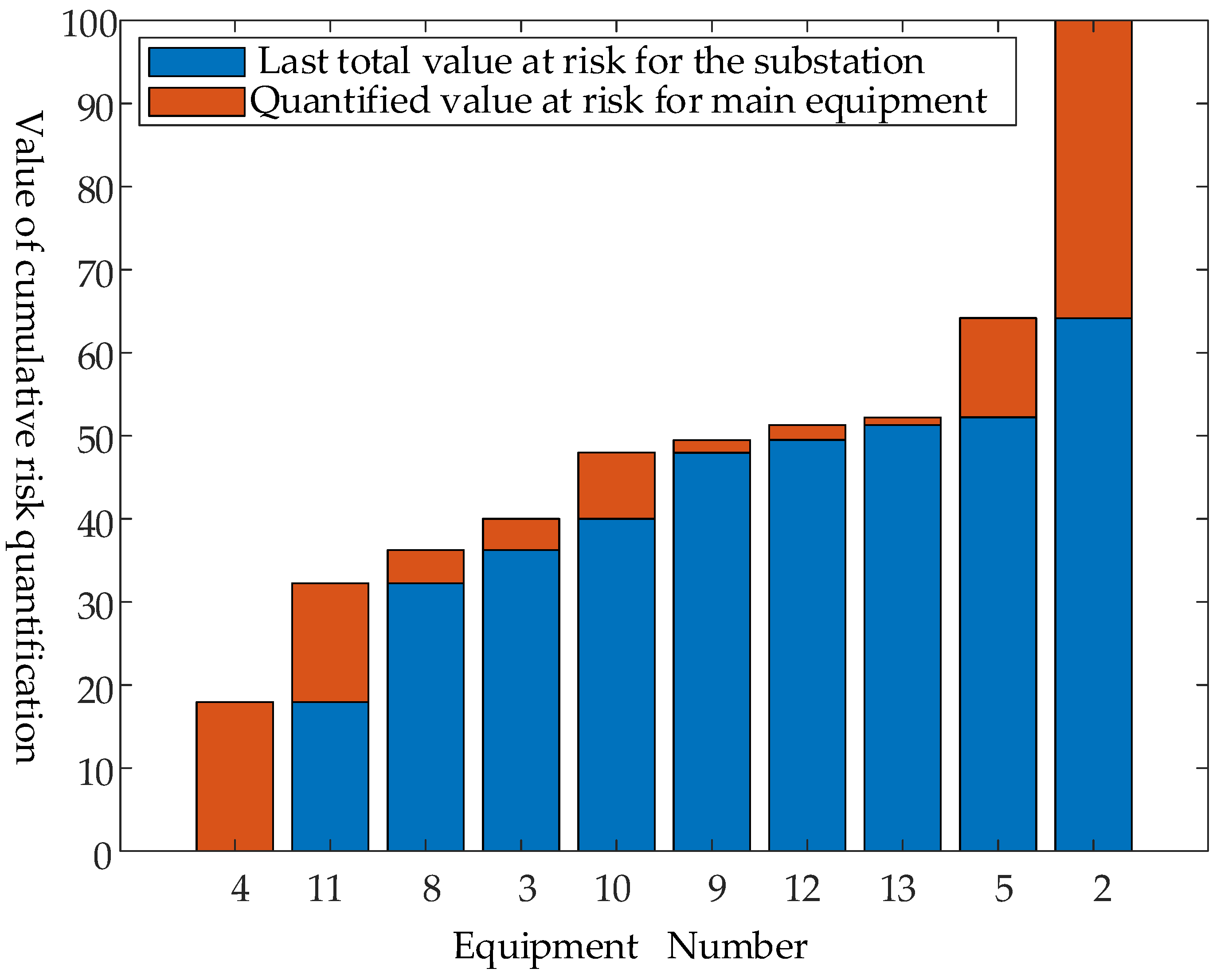

The risk posture of the substation operation is presented by combining the operational risk propagation temporal set

SXJ among the main equipment within the substation and obtaining the equipment potential risk severity indicator set

CX, and the results are shown in

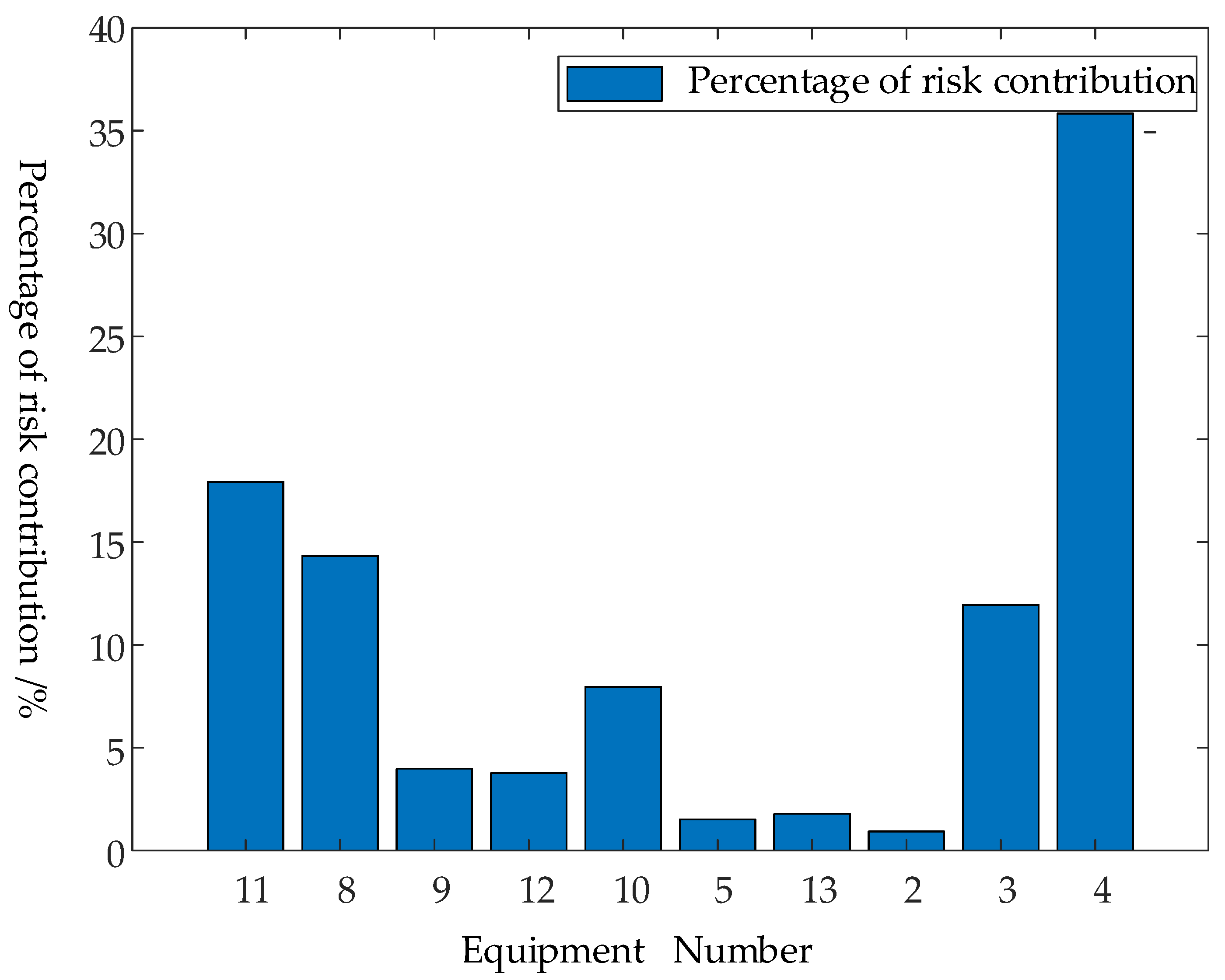

Figure 6, and the risk contribution share of each main equipment is shown in

Figure 7.

Figure 6 and

Figure 7 show that the transformer is used as the source of risk propagation, and with the iteration of the risk model, the risk propagation is carried out among the main equipment, and the overall operational risk of the substation increases cumulatively, and the quantitative value of the risk of each main equipment is also different. Among them, disconnect switch 2 for feeder 1 has the largest risk contribution percentage, and disconnect switch 2 for feeder 3 has the smallest risk contribution percentage. The larger the risk contribution, the higher the risk of the main equipment itself, and the higher the possibility of affecting the operation of the substation. Based on the risk contribution of each main equipment, the results are shown in

Table 4.

According to the results in

Table 4, the grid scheduling platform of the State Grid is utilised to push the potential risk data of the main equipment inside the substation in real time to monitor the potential operational risks of the main equipment. On the one hand, based on the results of the risk contribution ranking of each main equipment in the substation, the operation and inspection department focuses on the operation status of the main equipment with the highest risk contribution ranking during operation and maintenance inspections of the substation, and continuously monitors the status and risk change trends. On the other hand, the maintenance program should also shorten the corresponding test cycle, so as to timely discover the defects of the main equipment for maintenance, and enhance the safe and stable operation of the substation.

5. Conclusions

This paper proposes a substation operation risk situational awareness method based on the health state of main equipment according to the theoretical framework of situational awareness, and the conclusions are as follows:

1) Analogous to the SI virus transmission model, the equipment vulnerability is comprehensively portrayed from the health state and perspective of the main equipment and the risk propagation probability is given physical significance, and a risk propagation model is constructed considering the health state of the main equipment to realize the simulation of risk propagation among the equipment within the substation, and the equipment potential risk severity indicator set CX of the main equipment is obtained to monitor the potential operation risk of the substation equipment.

2) The operation and inspection department can monitor the potential risks of the main equipment in real time based on the equipment potential risk severity index set CX of the main equipment after the sorting process and optimize the development of the operation and inspection plan for the main equipment of the substation, and discover the defects of the main equipment in time for maintenance according to the results of the operation and inspection of the main equipment to ensure the safe and stable operation of the substation.

Author Contributions

Conceptualization, Z.C. and Y.X.; methodology, Z.C.; software, Z.C.; validation, Z.C. and Y.X.; formal analysis, Y.X.; investigation, Y.X.; resources, Z.C.; data curation, Y.X.; writing—original draft preparation, Z.C.; writing—review and editing, Z.C.; visualization, Y.X.; supervision, Y.X.; project administration, Y.X.; funding acquisition, Z.C. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors want to thank all the partners of the project for their important support, which was essential for the completion of this paper.

Conflicts of Interest

Author Zonghan Chen was employed by State Grid Quanzhou Electric Power Supply Company. Author Yonghai Xu was employed by School of Electrical and Electronic Engineering, North China Electric Power University. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- HUANG, H., LI, Y. G., LIU, H. Z., et al. Source-Network-Load-Storage Cooperative Scheduling Based on Nash-Q Algorithm; proceedings of the 5th Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, PEOPLES R CHINA, 2023.

- CHEN, Z. P.; HU, Y.; TAI, N. L.; et al. Transmission Grid Expansion Planning of a High Proportion Renewable Energy Power System Based on Flexibility and Economy. Electronics 2020, 9(6). [Google Scholar] [CrossRef]

- SHI, J.; QIN, J. R.; LI, H. B.; et al. Probabilistic Power and Energy Balance Risk Scheduling Method Based on Distributed Robust Optimization. Energies 2024, 17(19). [Google Scholar] [CrossRef]

- FENG, J. J.; ZHU, H. J.; WANG, Q.; et al. External Risk Assessment for Substations Based on Single and Superimposed Anomaly Risks[J]. IEEE Access 2024, 12, 159202–159213. [Google Scholar] [CrossRef]

- ZHANG, F. Y.; CHEN, B. Y. Risk assessment for substation operation based on triangular fuzzy number AHP and cloud model. proceedings of the IEEE/PES Transmission and Distribution Conference and Exposition (T and D), Denver, CO, F Apr 16-19, 2018; IEEE. [Google Scholar]

- YANG, H. Y.; ZHANG, K. J.; TANG, A. H. Risk Assessment of Main Electrical Connection in Substation With Regional Grid Safety Constraints. Ieee Access 2022, 10, 27750–8. [Google Scholar] [CrossRef]

- XUE, P. N.; SHI, L. Y.; ZHOU, Z. G.; et al. An online fault detection and diagnosis method of sensors in district heating substations based on long short-term memory network and adaptive threshold selection algorithm. Energy and Buildings 2024, 308. [Google Scholar] [CrossRef]

- ZENG, Z. A.; YAO, S. Y.; ZHANG, T. B. Risk Assessment Method for Smart Substation Secondary System Based on Deep Neural Network. proceedings of the 4th International Forum on Smart Grid Protection and Control (Purple Mountain Forum), Nanjing, PEOPLES R CHINA, F Aug 17-18, 2020. [Google Scholar]

- LIN, C.; XU, Q. F. Risk Assessment of Substation Integrated Anti-Misoperation System Considering Human Reliability. Ieee Transactions on Power Delivery 2023, 38(3), 2022–33. [Google Scholar] [CrossRef]

- LIANG, Z. L.; PARLIKAD, A. K. A Condition-Based Maintenance Model for Assets With Accelerated Deterioration Due to Fault Propagation. Ieee Transactions on Reliability 2015, 64(3), 972–82. [Google Scholar] [CrossRef]

- ENDSLEY, M. R. Toward a Theory of Situation Awareness in Dynamic Systems. In Human Factors: The Journal of the Human Factors and Ergonomics Society; 1995. [Google Scholar]

- LIU, Y. C.; PENG, M. F. Research on peak load shifting for hybrid energy system with wind power and energy storage based on situation awareness[J]. Journal of Energy Storage 2024, 82. [Google Scholar] [CrossRef]

- LIANG, S. H.; LOU, S. H.; YAO, X.; et al. Flexible Scheduling Strategy Based on Situation Awareness Technology under Extreme Weather Events [C]. proceedings of the 7th International Conference on Energy, Electrical and Power Engineering (CEEPE), Yangzhou Univ, Yangzhou, PEOPLES R CHINA, 2024; F, pp. 26–28. [Google Scholar]

- MENG, Q. Y.; WU, J. H.; WANG, H. Y. Research on New Energy Power System Stability Situation Awareness Based on Index Screening and Dynamic Evaluation[J]. Processes 2023, 11(5). [Google Scholar] [CrossRef]

- LUO, Y. H.; CHENG, Q.; YAN, S. J.; et al. Situation awareness method of the distribution network based on EMD-SVD and Elman neural network. Energy Reports 2022, 8, 632–9. [Google Scholar] [CrossRef]

- DING, J.; LU, C.; LI, B. A Data-Driven Based Security Situational Awareness Framework for Power Systems. Journal of Signal Processing Systems 2022, 94(11), 1159–68. [Google Scholar] [CrossRef]

- SHI, C. K.; NING, X.; SUN, Z. T.; et al. Quantitative Risk Assessment of Distribution Networks Based on Real-time Equipment Health Index. High Voltage Technology 2018, 44(02), 534–540. [Google Scholar]

- WANG, Q.; TANG, J. Y. LI Fengjun, et al. Reliability evaluation of active distribution network considering multi equipment aging effect [J]. Advanced Technology of Electrical Engineering and Energy 2024, 43(07), 102–112. [Google Scholar]

- GóMEZ, Y. M.; GALLARDO, D. I.; MARCHANT, C.; et al. An In-Depth Review of the Weibull Model with a Focus on Various Parameterizations[J]. Mathematics 2024, 12(1). [Google Scholar] [CrossRef]

- LEVY, J. W.; COWLING, B. J.; SIMMERMAN, J. M.; et al. The Serial Intervals of Seasonal and Pandemic Influenza Viruses in Households in Bangkok, Thailand. American Journal of Epidemiology 2013, 177(12), 1443–51. [Google Scholar] [CrossRef] [PubMed]

- PAN, D. W.; ZHANG, Y. X. Analysis of information propagation and control of a layered SITR model in complex networks. Frontiers in Physics 2022, 10. [Google Scholar] [CrossRef]

- KHALID, M.; AMIN, O.; AHMED, S. : Modeling of Viral Aerosol Transmission and Detection. Ieee Transactions on Communications 2020, 68(8), 4859–73. [Google Scholar] [CrossRef]

- HAN, X. Dynamic Society’s Information Networks Based on the Complex Network Theory and the Dynamics of Infectious Disease: Part1. Model Theory; proceedings of the 2nd International Conference on Materials Science, Machinery and Energy Engineering (MSMEE), Dalian, PEOPLES R CHINA, F May 13-14, 2017; 2017. [Google Scholar]

- GUO, S.; TONG, X. Y.; WANG, H. B. Reliability evaluation method of intelligent substation protection system considering equipment aging and scheduled maintenance [J]. power system protection and control 2019, 47(09), 97–104. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).